Research of Dynamic Characteristics in Milling of Thin-walled Parts Under Moving Boundary Constraint

-

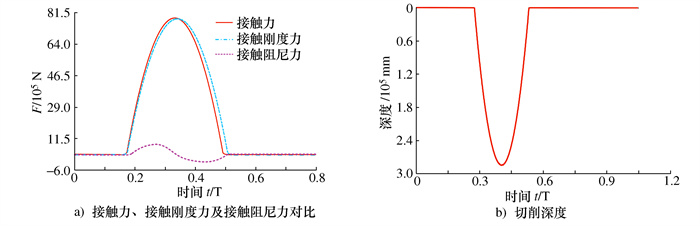

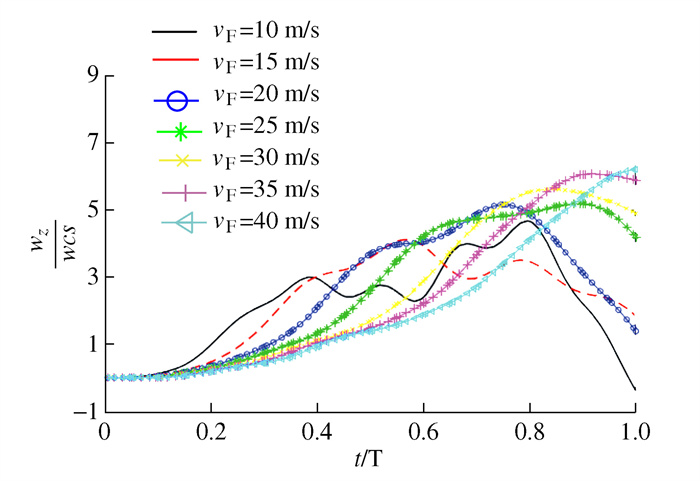

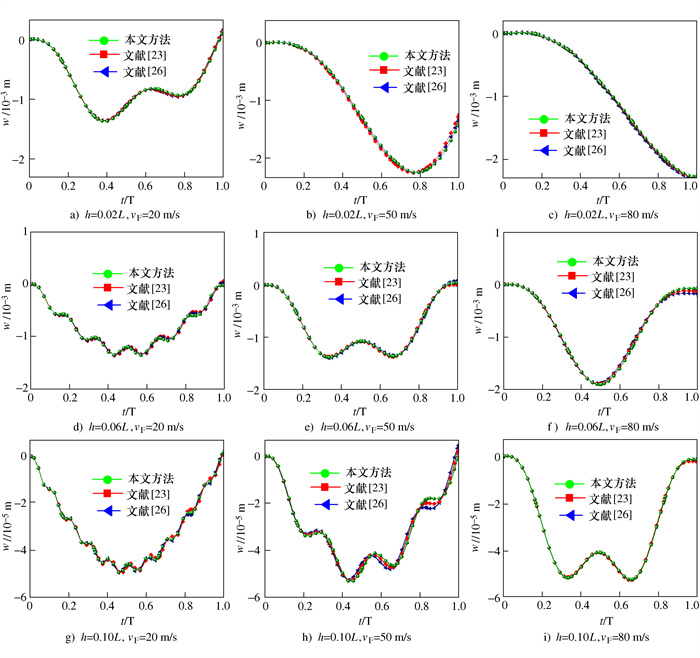

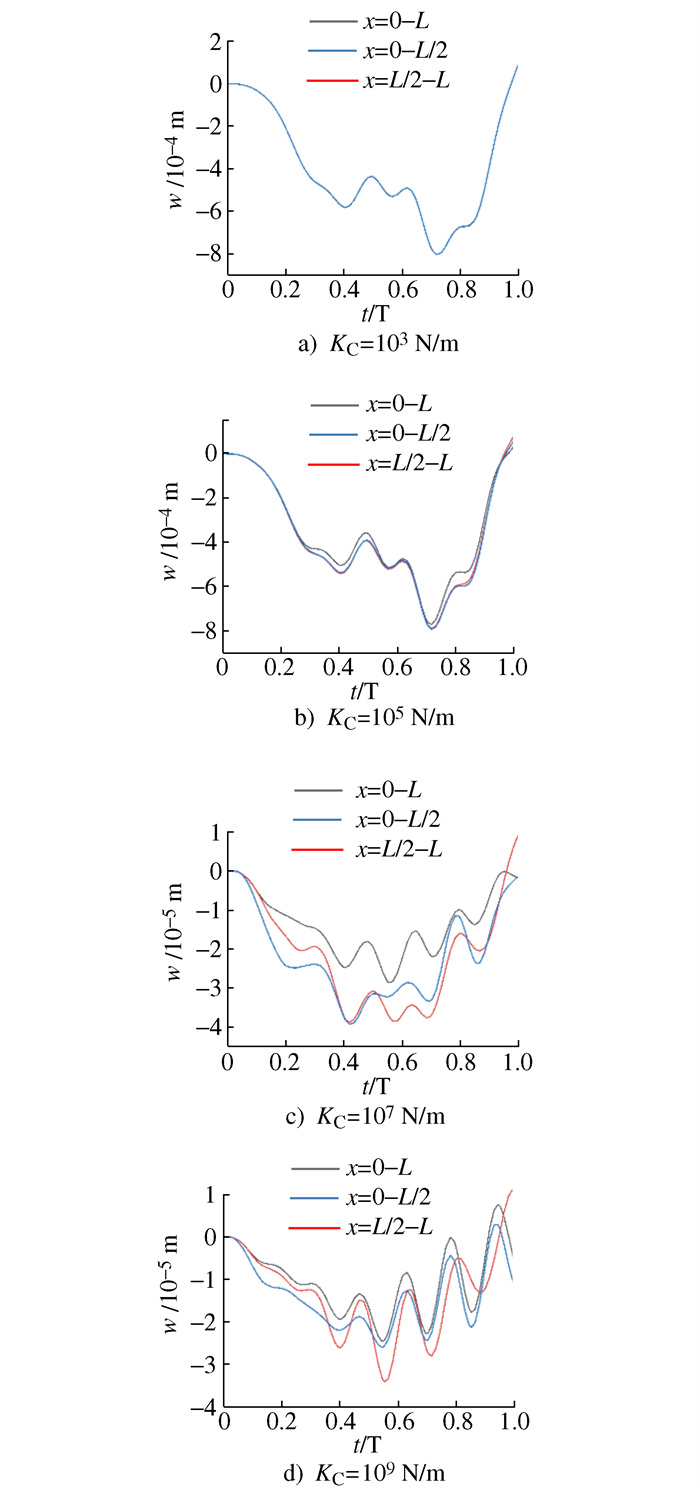

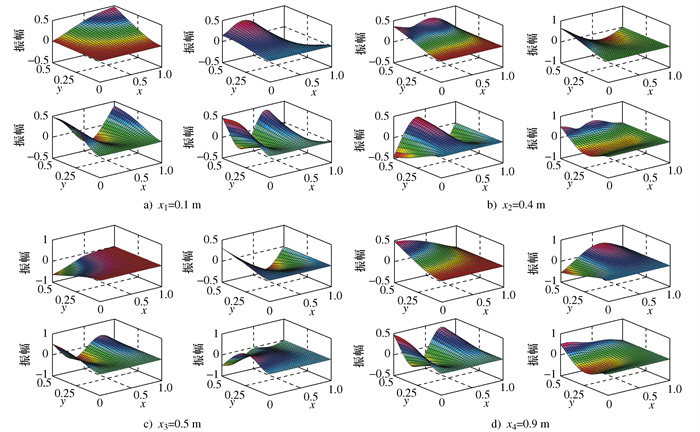

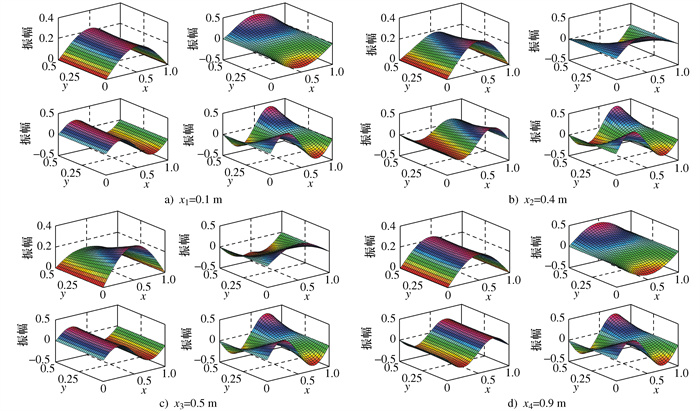

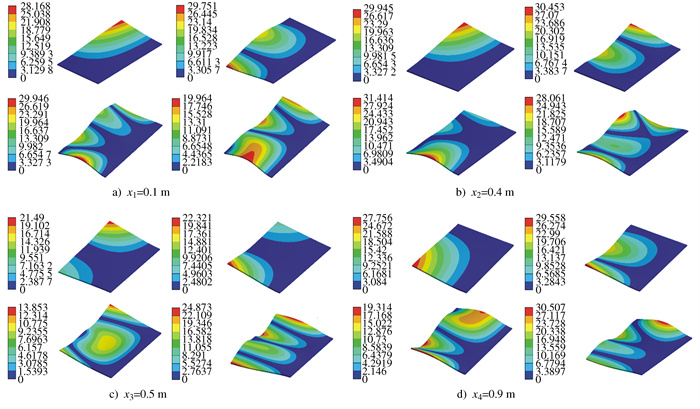

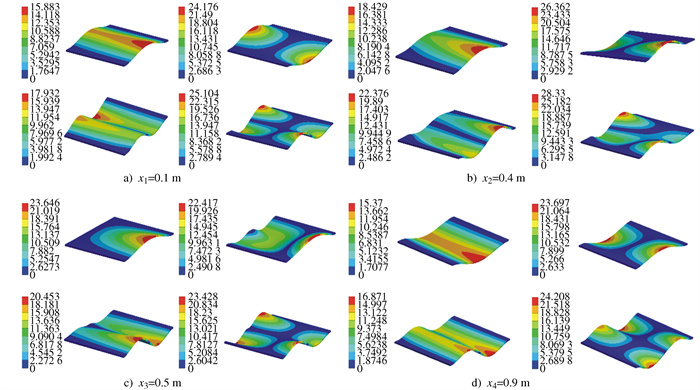

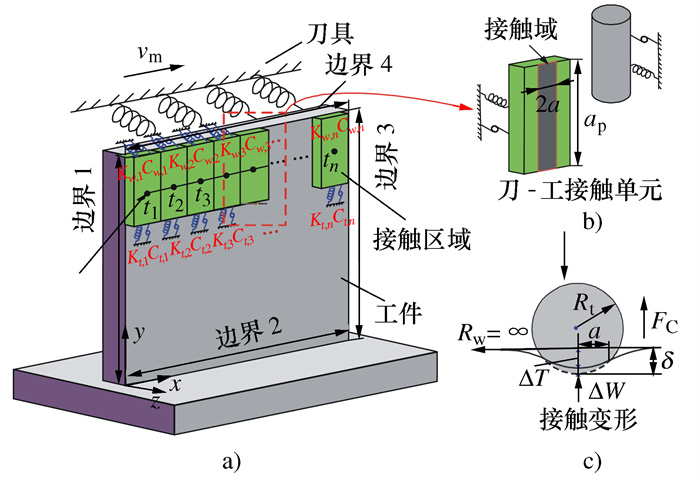

摘要: 针对薄壁件铣削过程工件约束边界复杂及动特性难预测等问题, 创新性的提出了接触移动边界约束的概念, 深入研究了接触移动边界约束对系统动特性的影响规律。首先, 建立了考虑刀-工接触移动边界约束作用的薄板切削过程动力学模型, 提取刀-工接触区域, 分析了接触刚度力和阻尼力与接触参数的复杂影响关系。其次, 预测了任意接触移动边界约束作用的薄板动态响应, 形成了更为全面地任意边界约束选择方案, 包括接触移动边界条件和经典边界条件。基于薄板理论建立系统运动学方程, 综合考虑包括移动边界约束产生的能量项、常规任意边界约束产生的能量项以及薄板变形产生的能量项的组合。最后, 通过不同案例以及有限元法, 与现有文献中的数值、解析和实验等方法获得的结果作了大量对比, 证明了本文提出方法的准确性。结果表明, 接触移动约束效应对系统动态特性的影响不可忽视。Abstract: In view of the complexity of the workpiece constraint boundary and the difficulty of predicting the dynamic characteristics in the milling of thin-walled parts, the moving contact boundary constraint (MCC) was proposed, and the influence of MCC on the dynamic characteristics of the system was studied in detail. Firstly, a dynamic model for thin plate cutting was established considering the constraint of tool-worker contact moving boundary, and the tool-worker contact region was extracted, and the complex relationship between the contact stiffness and damping force and the contact parameters was analyzed. Secondly, the dynamic response of the thin plate under arbitrary MCC is predicted, and a more comprehensive selection scheme for arbitrary boundary constraints is formed, including contact moving boundary conditions and classical boundary conditions. The kinematic equation of the system is established based on the thin plate theory, and the combination of the energy term generated by MCC, conventional arbitrary boundary constraint and thin plate deformation is considered comprehensively. Finally, a large number of results via numerical, analytical and experimental methods in existing literature are compared with that under different cases and via finite element method to prove the accuracy of the present method. The results show that the effect of the contact movement constraint on the dynamic characteristics of the system cannot be ignored.

-

表 1 不同边界约束的弹簧系数组合

Table 1. Combination of spring coefficients with different boundary constraints

约束方式 边界1 边界2 边界3 边界4 Mv kct

kcrkct

kcrkct

kcrkct

kcrkct

kcrF kt

kr0

00

00

00

0S kt

kr∞

0∞

0∞

0∞

0C kt

kr∞

∞∞

∞∞

∞∞

∞G kt

kr0

∞0

∞0

∞0

∞表 2 梁-板的几何及物理参数

Table 2. Geometric and physical parameters of beam-plate

参数 数值 参数 数值 长度L/m 0.103 60 密度ρ/(kg·m-3) 10 686.9 宽度W/m 0.006 35 弹性模量E/GPa 206.8 厚度h/m 0.006 35 泊松比υ 0.29 表 3 不同移动速度下的动态放大系数的对比

Table 3. Comparison of dynamic amplitude factor with different moving velocity

表 4 不同接触刚度的局部约束边界条件

Table 4. Boundary conditions of local constraints for different contact stiffness

案例 a b c d 接触刚度KC/(N·m-1) 103 105 107 109 局部约束边界(y=W) x=0-L, x=0-L/2, x=L/2-L 表 5 方形板的几何及物理参数

Table 5. Geometric and physical parameters of square plate

长度L/m 宽度W/m 厚度h/m 密度ρ/(kg·m-3) 弹性模量E/GPa 泊松比υ 1 1 0.065 5 7 850 200 0.3 表 6 薄板前10阶固有频率

Table 6. First ten natural frequencies of thin plate

Hz 本文方法 有限元法 不考虑刀工接触约束 阶数 x1 x2 x3 x4 x1 x2 x3 x4 1 253.48 436.57 337.70 254.05 250.48 433.57 337.70 254.05 147.87 2 482.47 498.76 601.10 502.67 478.47 495.76 601.10 502.67 427.04 3 779.13 1 038.96 1 006.73 1 001.28 773.13 1 036.96 1 006.73 1 001.28 597.94 4 1 223.58 1 566.24 1 453.80 1 395.21 1 220.58 1 563.24 1 453.80 1 395.21 1 000.45 5 1 390.86 1 742.55 1 806.74 1 720.70 1 386.86 1 742.55 1 806.74 1 720.70 1 352.74 6 1 696.17 1 829.70 1 884.31 1 840.73 1 692.17 1 829.70 1 881.31 1 840.73 1 631.89 7 2 022.87 2 396.55 2 385.69 2 358.17 2 019.87 2 396.55 2 381.29 2 358.17 1 808.63 8 2 177.60 2 917.42 2 919.46 2 933.91 2 173.60 2 917.42 2 916.46 2 933.91 2 267.03 10 2 695.69 3 241.95 3 221.78 3 209.80 2 691.69 3 241.95 3 221.78 3 209.80 2 410.25 -

[1] GARG A, BELARBI M O, CHALAK H D, et al. A review of the analysis of sandwich FGM structures[J]. Composite Structures, 2021, 258: 113427. doi: 10.1016/j.compstruct.2020.113427 [2] KARAMANLI A. Transient vibration analysis of strain gradient multi-directional functionally graded microplates under a moving concentrated load[J]. Composite Structures, 2023, 308: 116678. doi: 10.1016/j.compstruct.2023.116678 [3] ABAD F, ROUZEGAR J, LOTFIAN S. Application of the exact spectral element method in the analysis of the smart functionally graded plate[J]. Steel and Composite Structures, 2023, 47(2): 297-313. [4] KIM T, LEE U. Vibration analysis of thin plate structures subjected to a moving force using frequency-domain spectral element method[J]. Shock and Vibration, 2018, 2018: 1908508. [5] GHAZVINI T, NIKKHOO A, ALLAHYARI H, et al. Dynamic response analysis of a thin rectangular plate of varying thickness to a traveling inertial load[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2016, 38(2): 403-411. doi: 10.1007/s40430-015-0409-2 [6] MONTERRUBIO L E, ILANKO S. Proof of convergence for a set of admissible functions for the Rayleigh-Ritz analysis of beams and plates and shells of rectangular planform[J]. Computers & Structures, 2015, 147: 236-243. [7] SONG Q H, SHI J H, LIU Z Q. Vibration analysis of functionally graded plate with a moving mass[J]. Applied Mathematical Modelling, 2017, 46: 141-160. doi: 10.1016/j.apm.2017.01.073 [8] SONG Q H, LIU Z Q, SHI J H, et al. Parametric study of dynamic response of sandwich plate under moving loads[J]. Thin-Walled Structures, 2018, 123: 82-99. doi: 10.1016/j.tws.2017.11.012 [9] NGUYEN V X, LIEU Q X, LE T A, et al. A novel coupled finite element method for hydroelastic analysis of FG-CNTRC floating plates under moving loads[J]. Steel and Composite Structures, 2022, 42(2): 243-256. [10] KARAMANLI A, ELTAHER M A, THAI S, et al. Transient dynamics of 2D-FG porous microplates under moving loads using higher order finite element model[J]. Engineering Structures, 2023, 278: 115566. doi: 10.1016/j.engstruct.2022.115566 [11] ESEN I. A new finite element for transverse vibration of rectangular thin plates under a moving mass[J]. Finite Elements in Analysis and Design, 2013, 66: 26-35. doi: 10.1016/j.finel.2012.11.005 [12] MALEKZADEH P, MONAJJEMZADEH S M. Nonlinear response of functionally graded plates under moving load[J]. Thin-Walled Structures, 2015, 96: 120-129. doi: 10.1016/j.tws.2015.07.017 [13] LIU Z H, NIU J C, JIA R H. Dynamic analysis of arbitrarily restrained stiffened plate under moving loads[J]. International Journal of Mechanical Sciences, 2021, 200: 106414. doi: 10.1016/j.ijmecsci.2021.106414 [14] 杨建华, 张定华, 吴宝海. 考虑加工过程的复杂薄壁件加工综合误差补偿方法[J]. 航空学报, 2014, 35(11): 3174-3181. https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201411028.htmYANG J H, ZHANG D H, WU B H. A comprehensive error compensation approach considering machining process for complex thin-wall parts machining[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(11): 3174-3181. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201411028.htm [15] CHO D S, KIM B H, KIM J H, et al. Forced vibration analysis of arbitrarily constrained rectangular plates and stiffened panels using the assumed mode method[J]. Thin-Walled Structures, 2015, 90: 182-190. [16] NGUYEN-THOI T, BUI-XUAN T, PHUNG-VAN P, et al. Static, free vibration and buckling analyses of stiffened plates by CS-FEM-DSG3 using triangular elements[J]. Computers & Structures, 2013, 125: 100-113. [17] SU Z, WANG L F, SUN K P, et al. Vibration characteristic and flutter analysis of elastically restrained stiffened functionally graded plates in thermal environment[J]. International Journal of Mechanical Sciences, 2019, 157-158: 872-884. [18] ESMAEILZADEH M, KADKHODAYAN M. Dynamic analysis of stiffened bi-directional functionally graded plates with porosities under a moving load by dynamic relaxation method with kinetic damping[J]. Aerospace Science and Technology, 2019, 93: 105333. [19] SU J P, HE W P, ZHOU K. Study on vibration behavior of functionally graded porous material plates immersed in liquid with general boundary conditions[J]. Thin-Walled Structures, 2023, 182: 110166. [20] RAD H K, SHARIATMADAR H, GHALEHNOVI M. Simplification through regression analysis on the dynamic response of plates with arbitrary boundary conditions excited by moving inertia load[J]. Applied Mathematical Modelling, 2020, 79: 594-623. [21] PIRMORADIAN M, TORKAN E, KARIMPOUR H. Parametric resonance analysis of rectangular plates subjected to moving inertial loads via IHB method[J]. International Journal of Mechanical Sciences, 2018, 142-143: 191-215. [22] DYNIEWICZ B, PISARSKI D, BAJER C I. Vibrations of a mindlin plate subjected to a pair of inertial loads moving in opposite directions[J]. Journal of Sound and Vibration, 2017, 386: 265-282. [23] LIU Z H, NIU J C, JIA R H, et al. An efficient numerical method for dynamic analysis of polygonal plate under moving loads[J]. Thin-Walled Structures, 2021, 167: 108183. [24] SORRENTINO S, CATANIA G. Dynamic analysis of rectangular plates crossed by distributed moving loads[J]. Mathematics and Mechanics of Solids, 2018, 23(9): 1291-1302. [25] LIU L, CORRADI R, RIPAMONTI F, et al. Wave based method for flexural vibration of thin plate with general elastically restrained edges[J]. Journal of Sound and Vibration, 2020, 483: 115468. [26] SONG Q H, SHI J H, LIU Z Q, et al. Dynamic analysis of rectangular thin plates of arbitrary boundary conditions under moving loads[J]. International Journal of Mechanical Sciences, 2016, 117: 16-29. [27] MEIROVITCH L. Analytical methods in vibrations[M]. New York: The Macmillan, 1967. [28] KADIVAR M H, MOHEBPOUR S R. Finite element dynamic analysis of unsymmetric composite laminated beams with shear effect and rotary inertia under the action of moving loads[J]. Finite Elements in Analysis and Design, 1998, 29(3-4): 259-273. [29] PAN W J, LI X P, WANG L L, et al. A normal contact stiffness fractal prediction model of dry-friction rough surface and experimental verification[J]. European Journal of Mechanics-A/Solids, 2017, 66: 94-102. [30] RAO S. Vibration of continuous systems[M]. John Wiley & Sons, Inc, 1969. -

下载:

下载: