Numerical Simulation and Experimental Study on Secondary Cold Extrusion Strengthening of Pressed Bush

-

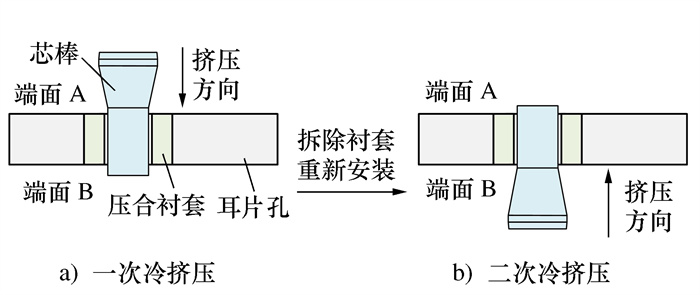

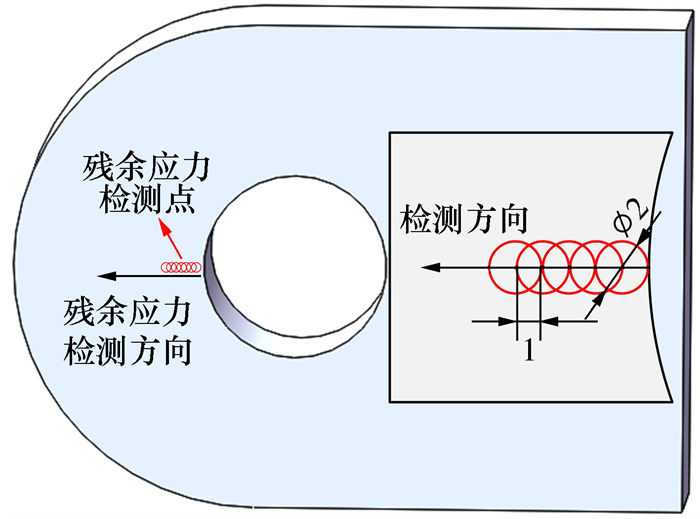

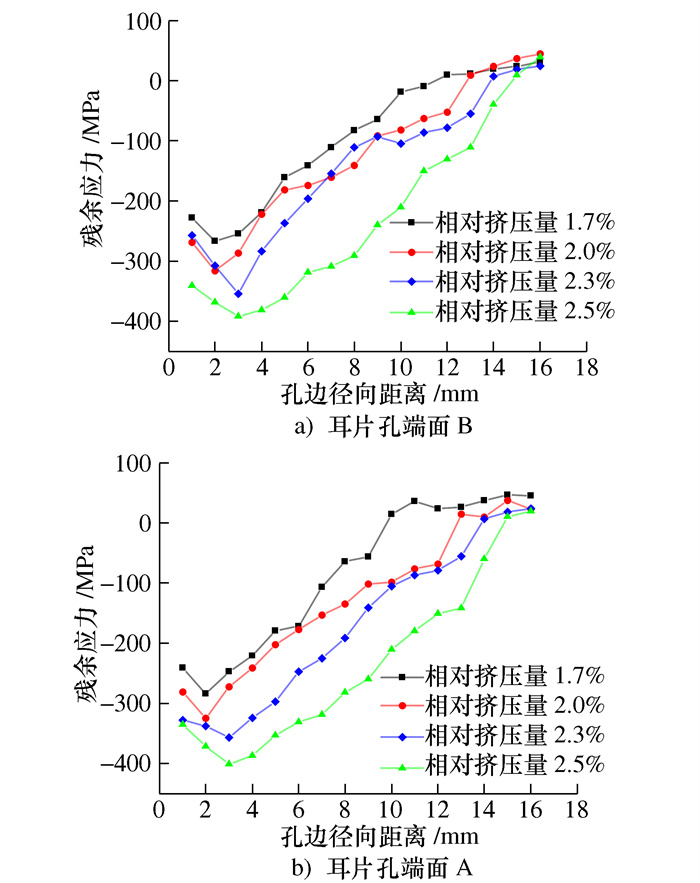

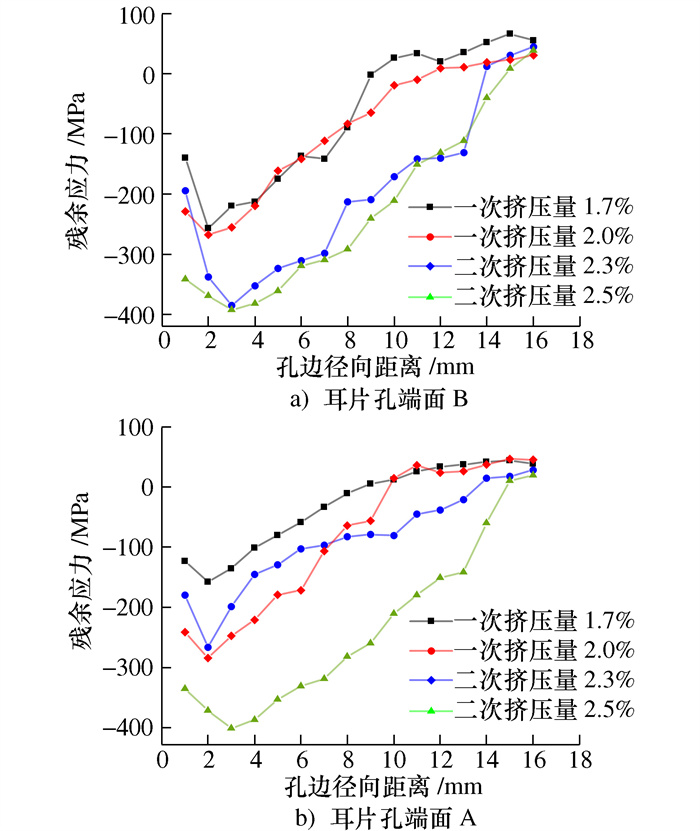

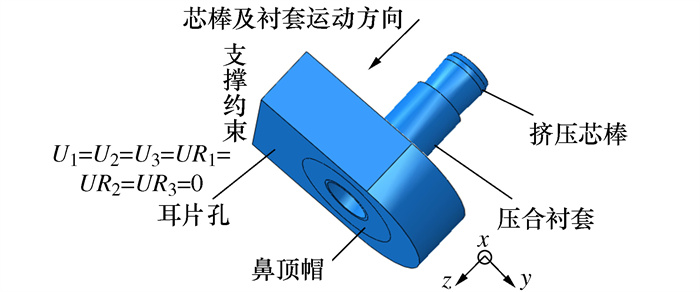

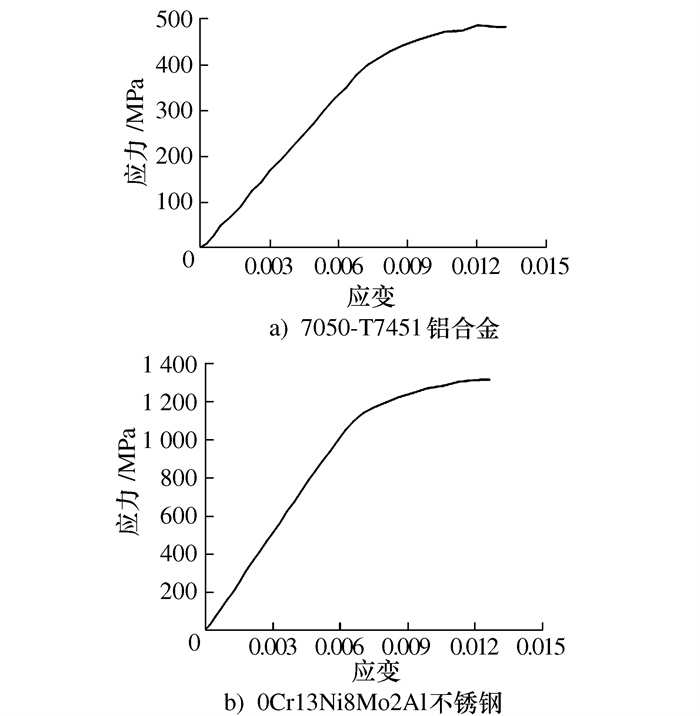

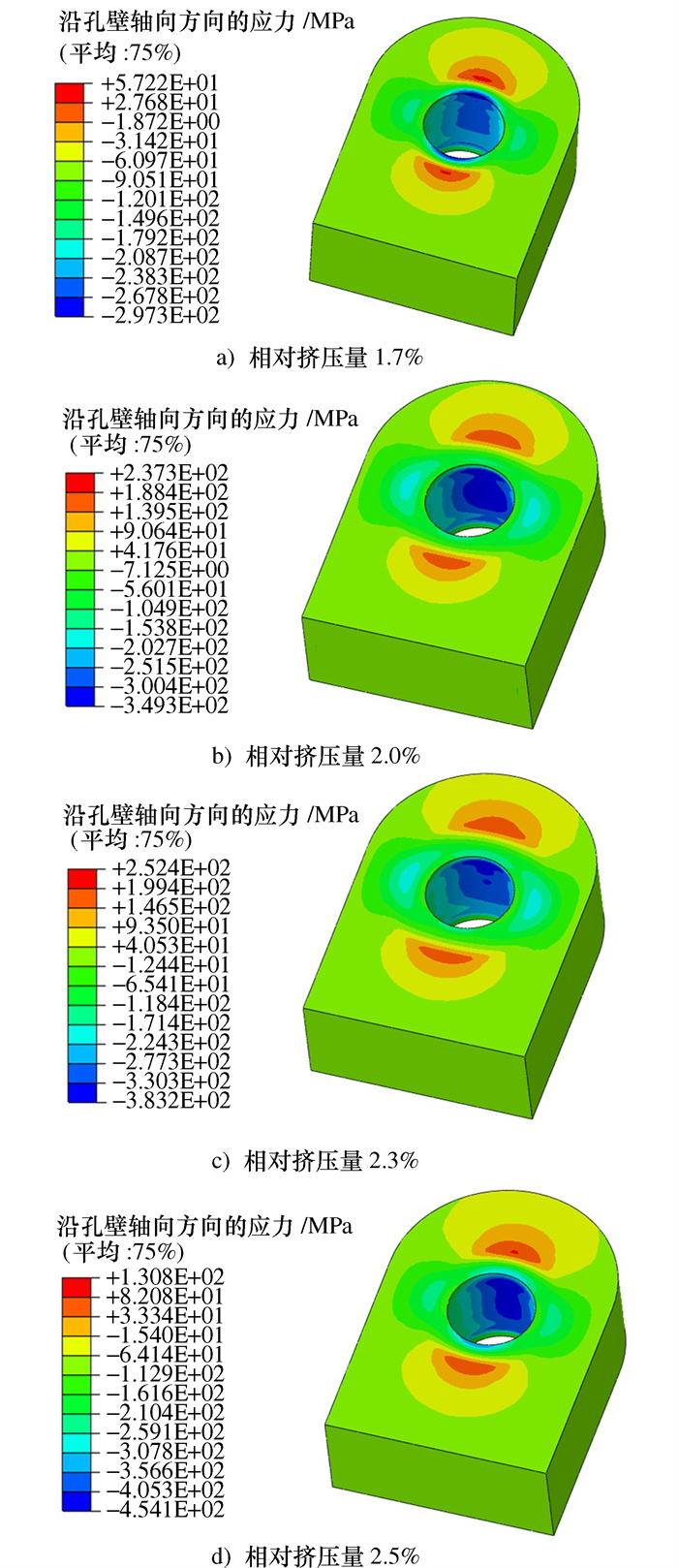

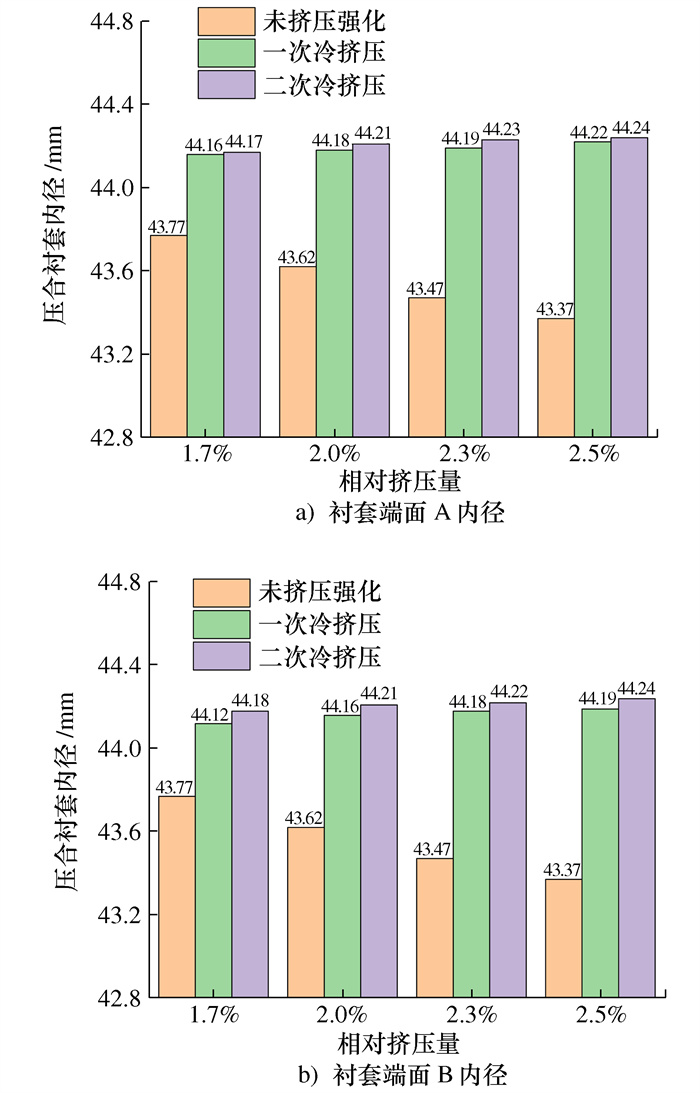

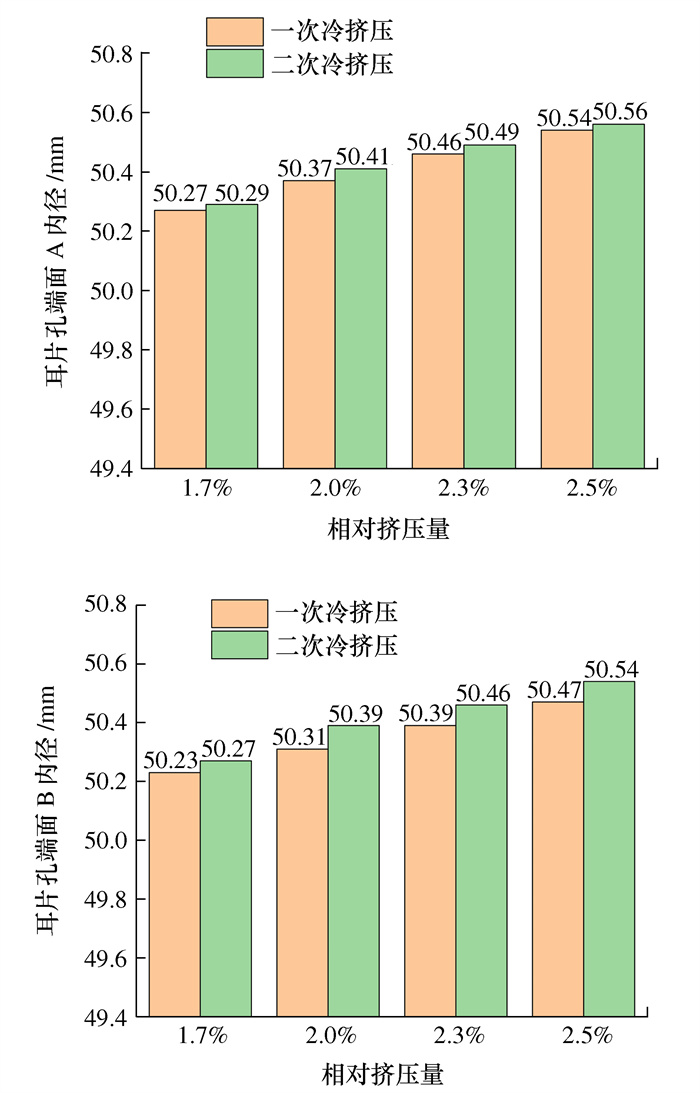

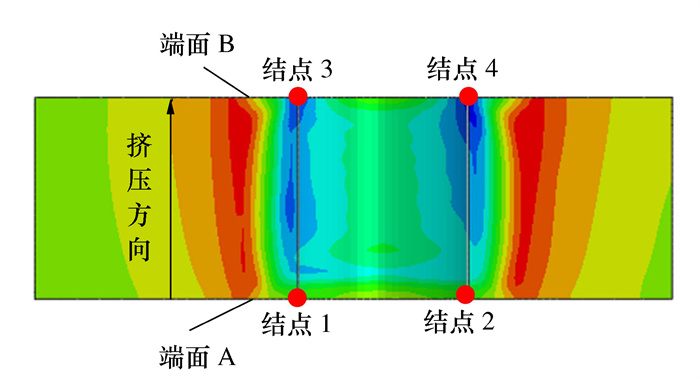

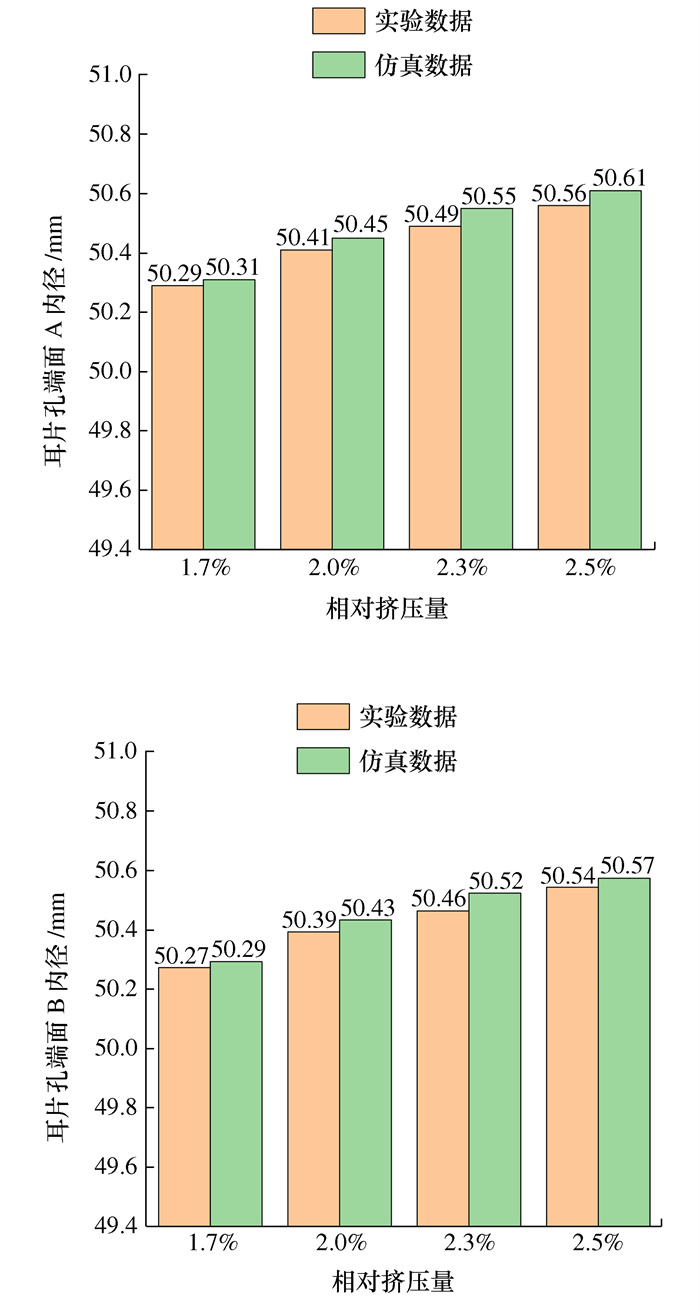

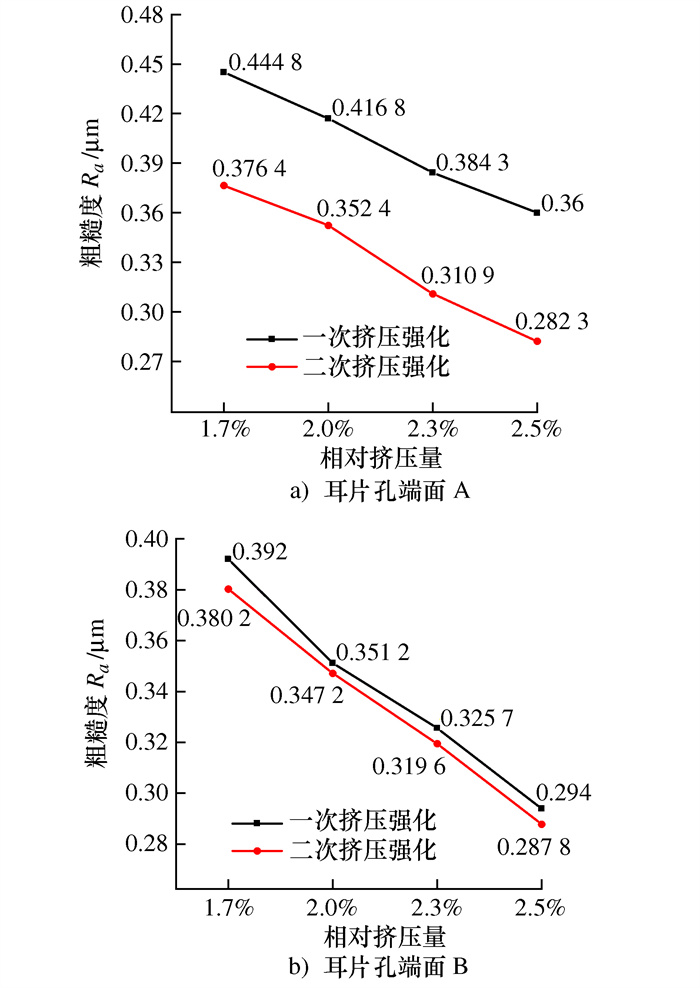

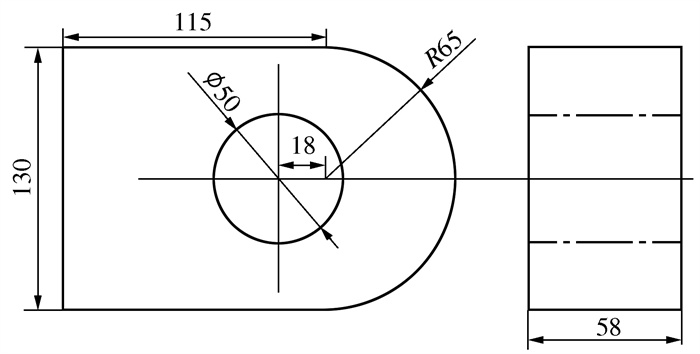

摘要: 采用压合衬套二次冷挤压工艺对7050铝合金耳片孔进行挤压强化; 通过X射线衍射仪、三坐标测量机和粗糙度仪, 研究二次冷挤压对耳片孔内表面的残余应力、塑性变形以及粗糙度的影响, 并通过有限元仿真进行验证。实验结果表明: 相较于一次冷挤压, 压合衬套二次冷挤压可有效改善试样两端残余应力的不均匀性。随着二次冷挤压相对挤压量增大, 残余压应力峰值和应力层深度都进一步增大, 塑性变形程度也更大, 同时降低了孔壁表面粗糙度。在相对挤压量为2.5%时, 最大残余压应力可达-400.3 MPa, 并形成了约14 mm的残余压应力层; 试样端面A与端面B内径分别增大了0.56 mm和0.54 mm; 孔壁表面粗糙度降低幅度达到71.0%。相较于一次冷挤压, 二次冷挤压强化后孔壁沿径向形成了更深的残余压应力层和塑性变形层, 显著提高了耳片孔的整体服役性能。Abstract: The ear hole of 7050 aluminum alloy was strengthened by using the second cold extrusion of pressed bush; The effects of the second cold extrusion on the residual stress, plastic deformation, and roughness of the inner surface of the ear hole were studied via X-ray diffractometer, coordinate measuring machine, and roughness meter, and which were verified through finite element simulation. The experimental results show that comparing with that in first cold extrusion, the second cold extrusion of the pressed sleeve can effectively improve the non-uniformity of residual stress at both ends of the sample. As the relative extrusion amount of the second cold extrusion increases, the peak residual compressive stress and the depth of the stress layer increase, and the degree of the plastic deformation increases too, meanwhile the surface roughness of the hole wall decreases. When the relative extrusion amount is 2.5%, the maximum residual compressive stress can reach -400.3 MPa, and there is a residual compressive stress layer of about 14 mm. The inner diameters of the sample end face A and end face B increased by 0.56 mm and 0.54 mm, respectively; the surface roughness of the hole wall decreased by 71.0%. Comparing with the first cold extrusion, the second cold extrusion strengthening forms a deeper residual compressive stress layer and plastic deformation layer along the radial direction of the hole wall, significantly improving the overall service performance of the ear hole.

-

Key words:

- second cold extrusion /

- pressed bush /

- relative extrusion amount /

- residual stress /

- plastic deformation

-

表 1 7050铝合金材料各元素的质量分数

Table 1. Chemical composition of 7050 aluminum alloy material

% Zn Mg Cu Zr Si Fe Mn Cr Al 6.02 2.31 2.04 0.10 0.03 0.11 0.003 0.009 剩余 表 2 7050铝合金及压合衬套基本力学性能

Table 2. Basic mechanical properties of 7050 aluminum alloy and compression bushing

试样 材料 抗拉强度σb/MPa 屈服强度σs/MPa 弹性模量E/GPa 泊松比λ 耳片 7050铝合金 510 441 70 0.32 压合衬套 0Cr13Ni8Mo2A1 1 515 1 415 210 0.30 表 3 二次冷挤压后孔壁表面粗糙度测量结果

Table 3. Measurement results of surface roughness of hole wall after secondary cold extrusion

相对挤压量 Ra/μm 挤压前 端面A 端面B 1.7% 0.974 5 0.376 4 0.380 2 2.0% 0.973 2 0.352 4 0.347 2 2.3% 0.977 3 0.310 9 0.319 6 2.5% 0.974 9 0.282 3 0.287 8 -

[1] 陈忱, 曹瑶琴, 宋颖刚, 等. 直升机旋翼关键零件孔挤压强化工艺应用研究[J]. 直升机技术, 2016(4): 38-42. doi: 10.3969/j.issn.1673-1220.2016.04.009CHEN C, CAO Y Q, SONG Y G, et al. Application research about hole extrusion process of key component of helicopter rotor hub[J]. Helicopter Technique, 2016(4): 38-42. (in Chinese) doi: 10.3969/j.issn.1673-1220.2016.04.009 [2] 万里, 邓运来, 范世通. 时效处理对7050铝合金厚板材料组织、性能及残余应力的影响[J]. 中国有色金属学报, 2018, 28(7): 1277-1283. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201807001.htmWAN L, DENG Y L, FAN S T. Effects of aging on microstructures, properties and residual stress of 7050 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(7): 1277-1283. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201807001.htm [3] KIM H K, CARLSON S S, STANFIELD M L, et al. Mitigating cutting-induced plasticity errors in the determination of residual stress at cold expanded holes using the contour method[J]. Experimental Mechanics, 2022, 62(1): 3-18. doi: 10.1007/s11340-021-00756-z [4] KUMAR S A, BABU N C M. Effect of proximity hole on induced residual stresses during cold expansion of adjacent holes[J]. Materials Today: Proceedings, 2018, 5(2): 5709-5715. doi: 10.1016/j.matpr.2017.12.165 [5] 张铁亮, 王卓, 宋镝冲, 等. 紧固件防松性能定量评价方法[J]. 机械工程学报, 2021, 57(15): 71-79. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202115008.htmZHANG T L, WANG Z, SONG D C, et al. Quantitative evaluation method of anti-loosening performance for fasteners[J]. Journal of Mechanical Engineering, 2021, 57(15): 71-79. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202115008.htm [6] WARNER J J, CLARK P N, HOEPPNER D W. Cold expansion effects on cracked fastener holes under constant amplitude and spectrum loading in the 2024-T351 aluminum alloy[J]. International Journal of Fatigue, 2014, 68: 209-216. doi: 10.1016/j.ijfatigue.2014.05.002 [7] WEN S Z, LIU C Y, WU R L, et al. Effect of cold expansion on high cycle fatigue of 7A85 aluminum alloy straight lugs[J]. Rare Metal Materials and Engineering, 2015, 44(10): 2358-2362. doi: 10.1016/S1875-5372(16)30020-0 [8] WANG Y L, ZHU Y L, HOU S, et al. Investigation on fatigue performance of cold expansion holes of 6061-T6 aluminum alloy[J]. International Journal of Fatigue, 2017, 95: 216-228. doi: 10.1016/j.ijfatigue.2016.10.030 [9] 王燕礼, 卞小芳, 符彬, 等. 光整滚光和开缝衬套挤压孔结构表面完整性及疲劳行为研究[J]. 表面技术, 2019, 48(9): 336-345. https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201909042.htmWANG Y L, BIAN X F, FU B, et al. Surface integrity and fatigue behaviour of holes treated by finishing & burnishing and split sleeve cold expansion[J]. Surface Technology, 2019, 48(9): 336-345. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201909042.htm [10] 王燕礼, 朱有利, 曹强, 等. 孔挤压强化技术研究进展与展望[J]. 航空学报, 2018, 39(2): 021336. https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201802001.htmWANG Y L, ZHU Y L, CAO Q, et al. Progress and prospect of research on hole cold expansion technique[J]. Acta Aeronautica et Astronautica Sinica, 2018, 39(2): 021336. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201802001.htm [11] 张志贤, 张立新, 王凡. 压合衬套强化耳片的疲劳寿命评估[J]. 航空科学技术, 2022, 33(3): 97-105. https://www.cnki.com.cn/Article/CJFDTOTAL-HKKX202203013.htmZHANG Z X, ZHANG L X, WANG F. Evaluation of fatigue life of lug with cold expanded bushing[J]. Aeronautical Science & Technology, 2022, 33(3): 97-105. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKKX202203013.htm [12] 唐伟, 林忠亮, 吴保全, 等. 孔结构压合衬套冷挤压强化的疲劳寿命试验研究[J]. 航空精密制造技术, 2022, 58(4): 11-15. https://www.cnki.com.cn/Article/CJFDTOTAL-HJZJ202204003.htmTANG W, LIN Z L, WU B Q, et al. Test study on fatigue life of cold extrusion strengthening bushings for hole structure[J]. Aviation Precision Manufacturing Technology, 2022, 58(4): 11-15. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HJZJ202204003.htm [13] 杨广勇, 李萌, 宋颖刚, 等. 二次孔挤压强化对Ti1023钛合金孔疲劳性能影响[J]. 航空材料学报, 2016, 36(6): 68-73. https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201606012.htmYANG G Y, LI M, SONG Y G, et al. Effect of twice hole expansion on fatigue property of Ti1023 alloy[J]. Journal of Aeronautical Materials, 2016, 36(6): 68-73. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201606012.htm [14] 姜廷宇, 王洋, 王鹏, 等. TB6钛合金孔二次挤压残余应力及疲劳寿命仿真研究[J]. 航空制造技术, 2021, 64(9): 77-84. https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ202109010.htmJIANG T Y, WANG Y, WANG P, et al. Simulation study on residual stress and fatigue life of TB6 titanium alloy hole after double cold expansion[J]. Aeronautical Manufacturing Technology, 2021, 64(9): 77-84. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ202109010.htm [15] 罗学昆, 艾莹珺, 王欣, 等. 二次孔挤压强化对TB6钛合金疲劳性能的影响[J]. 航空材料学报, 2017, 37(6): 88-94. https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201706015.htmLUO X K, AI Y J, WANG X, et al. Effect of double cold expansion of hole on fatigue property of TB6 titanium alloy[J]. Journal of Aeronautical Materials, 2017, 37(6): 88-94. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKCB201706015.htm [16] Battelle Memorial Institute. Metallic materials properties development and standardization (MMPDS-09)[M]. America: Federal Aviation Administration, 2014. [17] 王强, 赵勇, 倪孟龙. 高干涉量压合衬套强化铝合金孔结构的疲劳性能[J]. 机械工程材料, 2020, 44(7): 46-50. https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC202007011.htmWANG Q, ZHAO Y, NI M L. Fatigue properties of aluminum alloy hole structure strengthened by high interference fit bushing technique[J]. Materials for Mechanical Engineering, 2020, 44(7): 46-50. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC202007011.htm [18] ACHARD V, DAIDIE A, PAREDES M, et al. Optimization of the cold expansion process for titanium holes[J]. Advanced Engineering Materials, 2017, 19(6): 1500626. [19] 于洋, 罗学昆, 刘勇军, 等. 孔挤压强化对FGH95合金室温及高温疲劳性能的影响[J]. 航空制造技术, 2019, 62(18): 76-82. https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ201918021.htmYU Y, LUO X K, LIU Y J, et al. Effect of hole cold expansion on fatigue property of FGH95 superalloy under room and high temperature[J]. Aeronautical Manufactur-ing Technology, 2019, 62(18): 76-82. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ201918021.htm [20] BORREGO L P, COSTA J M, SILVA S, et al. Microstructure dependent fatigue crack growth in aged hardened aluminium alloys[J]. International Journal of Fatigue, 2004, 26(12): 1321-1331. -

下载:

下载: