Development and Application of Digital Twin Geometric Model Framework for Metallic Sealing Rings

-

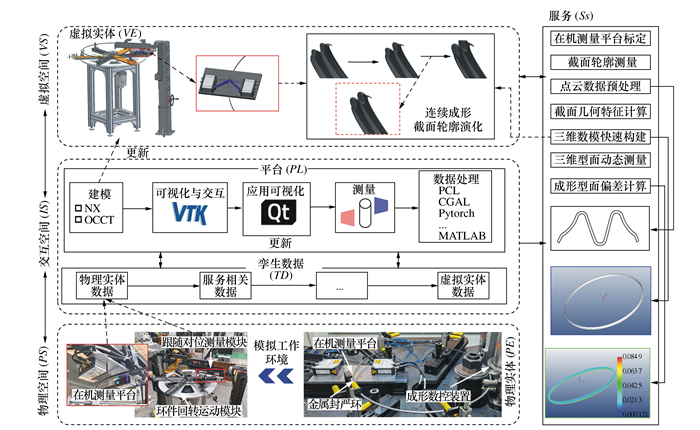

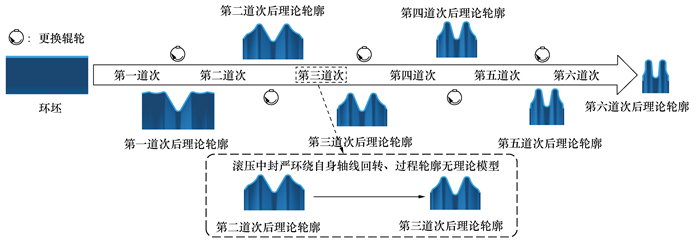

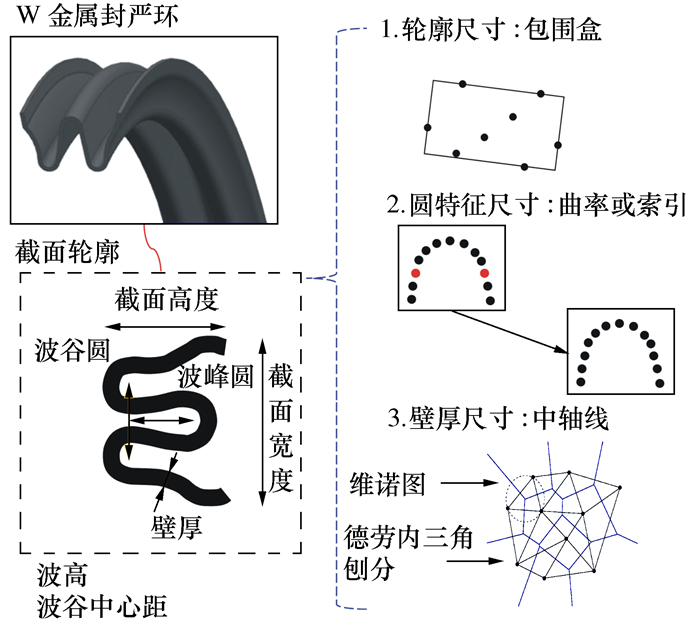

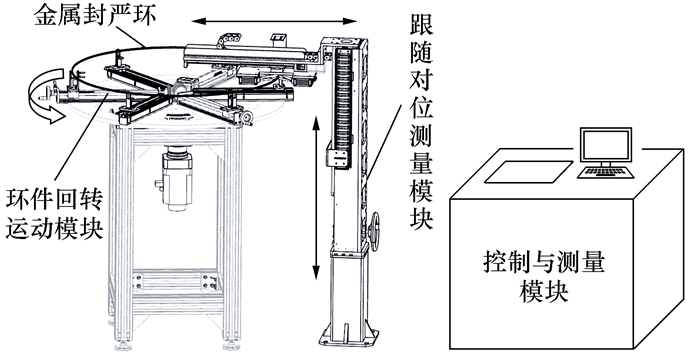

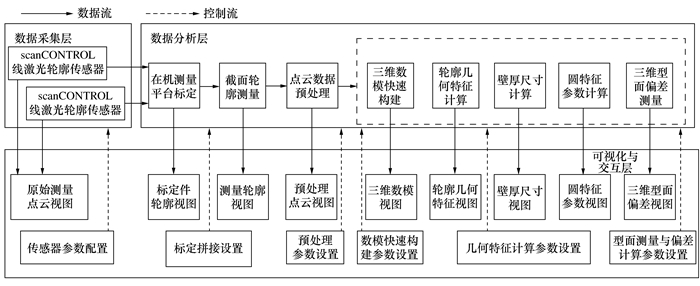

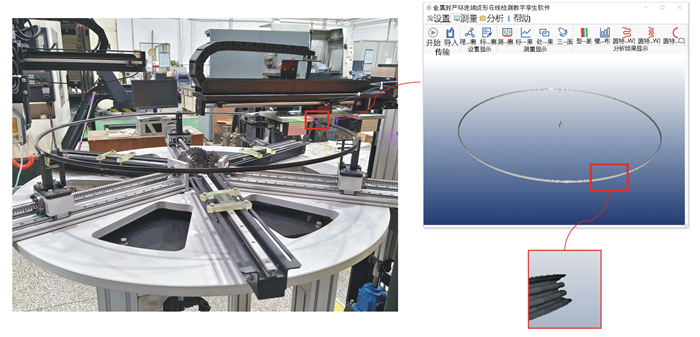

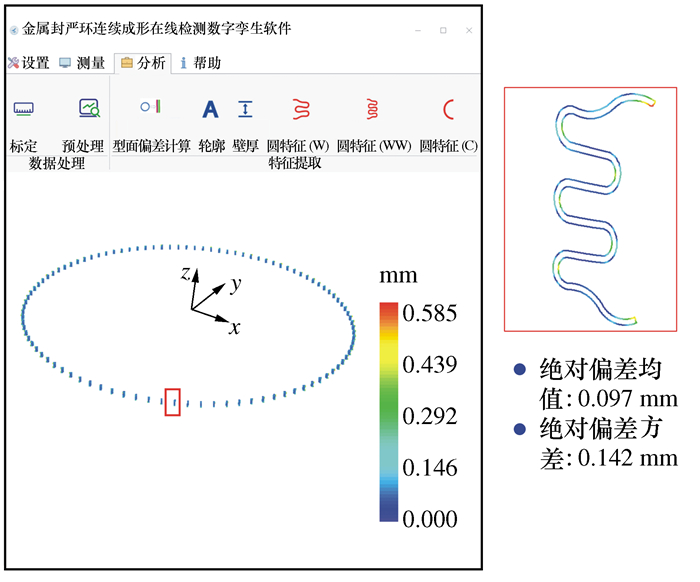

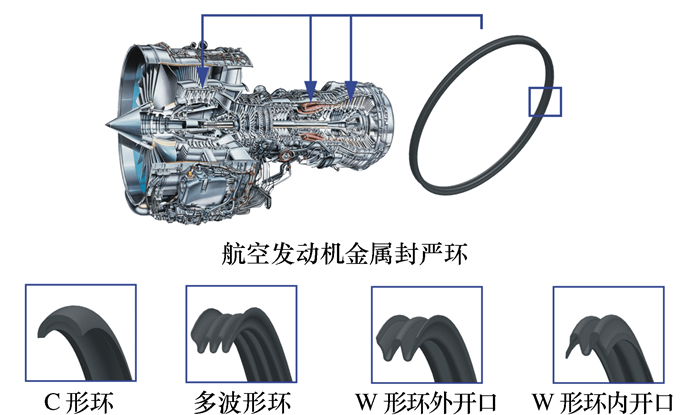

摘要: 金属封严环广泛应用于航空发动机密封系统,其型面成形质量对飞行器高性能、高可靠服役具有重要影响。然而,薄壁、复杂的异形截面与封闭的环形结构等导致其在几何质量检测方面存在以下问题:其一,成形结果严重依赖于破坏性抽样终检,实际产品均未经过完整质量检测;其二,成形过程无几何质量检测手段,无法及时发现成形缺陷,轮廓几何数据的缺失,使工艺优化设计困难。因此,提出一种金属封严环数字孪生几何模型框架,该框架包括:物理空间、虚拟空间、交互空间与服务,可提供在机测量平台标定、截面轮廓测量、点云数据预处理、截面几何特征计算、三维数模快速构建、三维型面动态测量与偏差计算等连续成形质量在线检测技术,建立起反映金属封严环成形过程中变化的数字孪生几何模型,从而为金属封严环成形质量的检测、分析、预测以及后续工艺优化设计所需的基础数据获取等提供支撑。在此基础上,研制了在线检测模拟试验装置与数字孪生软件,介绍了金属封严环数字孪生几何模型的应用情况。Abstract: Metallic sealing ring is widely used in aero-engine sealing systems, and its formed quality has an important impact on the aircraft service reliability. However, the thin-walled, complex irregular section and closed ring structure of sealing rings lead to the following problems: first, the formed results are heavily dependent on final destructive sampling inspection, and the actual products have not undergone complete quality inspection; second, there is no means of geometric quality inspection during the forming process, which makes it impossible to inspect defects in time, and the lack of geometric data makes the process optimization difficult. Therefore, a digital twin geometric model framework for metallic sealing rings is proposed, which includes four parts: physical space, virtual space, interaction space and services, and it can provide on-machine measurement platform calibration, section profile measurement, point cloud preprocessing, section geometric features computation, 3-D digital model construction, 3-D surface dynamic measurement, forming deviation computation and other continuous forming quality on-line inspection techniques, so as to build a digital twin geometric model that reflects the changes in the forming process and provides support for the inspection, analysis and prediction of the forming quality, as well as the acquisition of the basic data required for the subsequent process optimization and design. On this basis, an on-line inspection simulation test device and a digital twin software are developed, and their applications are introduced.

-

Key words:

- digital twin /

- geometric model /

- metallic sealing ring /

- forming quality /

- on-line inspection

-

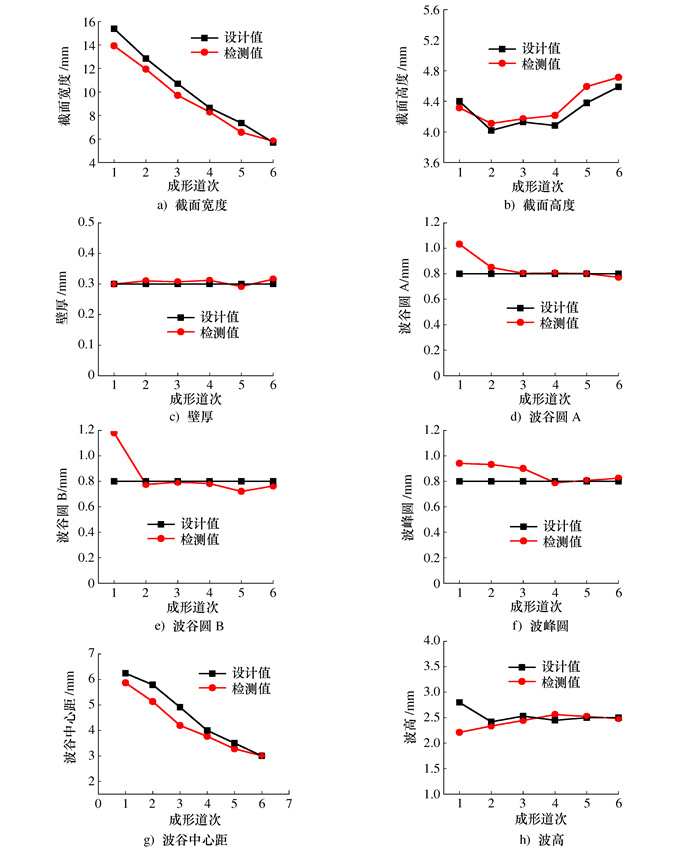

表 1 金属封严环几何尺寸检测值与设计值的偏差

Table 1. The deviations between geometric dimension inspection values and design values of metallic sealing ring

道次 截面宽度/mm 截面高度/mm 壁厚/mm 波谷圆A/mm 波谷圆B/mm 波峰圆/mm 波谷中心距/mm 波高/mm 第一道次 -1.452 -0.085 0.000 0.232 0.380 0.142 -0.374 -0.589 第二道次 -0.911 0.092 0.010 0.050 -0.024 0.132 -0.658 -0.084 第三道次 -0.985 0.043 0.007 0.004 -0.007 0.101 -0.716 -0.083 第四道次 -0.346 0.132 0.012 0.007 -0.018 -0.011 -0.232 0.112 第五道次 -0.784 0.214 -0.008 0.002 -0.079 0.007 -0.219 0.024 第六道次 0.117 0.123 0.016 -0.027 -0.037 0.024 0.004 -0.017 表 2 金属封严环几何尺寸公差

Table 2. The tolerances of metallic sealing ring geometric dimensions

截面宽度/mm 截面高度/mm 壁厚/mm 波谷圆A/mm 波谷圆B/mm 波峰圆/mm 波谷中心距/mm 波高/mm ±0.2 ±0.24 ±0.025 ±0.2 ±0.2 ±0.2 ±0.20 ±0.20 -

[1] 李留柱, 李智军, 李宏伟, 等. 高温合金薄壁W截面密封环滚压成形壁厚变化研究[J]. 精密成形工程, 2019, 11(5): 43-49. doi: 10.3969/j.issn.1674-6457.2019.05.006LI L Z, LI Z J, LI H W, et al. Wall thickness variation of a superalloy thin-walled W-section seal ring during roll forming[J]. Journal of Netshape Forming Engineering, 2019, 11(5): 43-49. (in Chinese) doi: 10.3969/j.issn.1674-6457.2019.05.006 [2] 朱宇, 万敏. 航空发动机薄壁W形封严环动模外压成形[J]. 航空学报, 2015, 36(7): 2457-2467. https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201507037.htmZHU Y, WAN M. External pressure forming of thin walled W-shaped sealing rings in aircraft engines using movable dies[J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(7): 2457-2467. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201507037.htm [3] 陈昭明, 邹劲松. 智能制造领域的数字孪生技术研究可视化知识图谱分析[J]. 机械科学与技术, 2023, 42(8): 1249-1260. doi: 10.13433/j.cnki.1003-8728.20220080CHEN Z M, ZOU J S. Analysis of visual knowledge mapping in intelligent manufacturing via digital twin technology[J]. Mechanical Science and Technology for Aerospace Engineering, 2023, 42(8): 1249-1260. (in Chinese) doi: 10.13433/j.cnki.1003-8728.20220080 [4] 庄存波, 刘检华, 熊辉, 等. 产品数字孪生体的内涵、体系结构及其发展趋势[J]. 计算机集成制造系统, 2017, 23(4): 753-768. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201704010.htmZHUANG C B, LIU J H, XIONG H, et al. Connotation, architecture and trends of product digital twin[J]. Computer Integrated Manufacturing Systems, 2017, 23(4): 753-768. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201704010.htm [5] 陶飞, 刘蔚然, 刘检华, 等. 数字孪生及其应用探索[J]. 计算机集成制造系统, 2018, 24(1): 1-18. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201801001.htmTAO F, LIU W R, LIU J H, et al. Digital twin and its potential application exploration[J]. Computer Integrated Manufacturing Systems, 2018, 24(1): 1-18. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201801001.htm [6] 张映锋, 张党, 任杉. 智能制造及其关键技术研究现状与趋势综述[J]. 机械科学与技术, 2019, 38(3): 329-338. doi: 10.13433/j.cnki.1003-8728.20180300ZHANG Y F, ZHANG D, REN S. Survey on current research and future trends of smart manufacturing and its key technologies[J]. Mechanical Science and Technology for Aerospace Engineering, 2019, 38(3): 329-338. (in Chinese) doi: 10.13433/j.cnki.1003-8728.20180300 [7] WANG P, LUO M. A digital twin-based big data virtual and real fusion learning reference framework supported by industrial internet towards smart manufacturing[J]. Journal of Manufacturing Systems, 2021, 58: 16-32. doi: 10.1016/j.jmsy.2020.11.012 [8] ZHU Z X, XI X L, XU X, et al. Digital twin-driven machining process for thin-walled part manufacturing[J]. Journal of Manufacturing Systems, 2021, 59: 453-466. doi: 10.1016/j.jmsy.2021.03.015 [9] ZHENG Y, CHEN L, LU X Y, et al. Digital twin for geometric feature online inspection system of car body-in-white[J]. International Journal of Computer Integrated Manufacturing, 2021, 34(7-8): 752-763. doi: 10.1080/0951192X.2020.1736637 [10] STOJADINOVIC S M, ZIVANOVIC S, SLAVKOVIC N, et al. Digital measurement twin for CMM inspection based on step-NC[J]. International Journal of Computer Integrated Manufacturing, 2021, 34(12): 1327-1347. doi: 10.1080/0951192X.2021.1972460 [11] TANG Y P, WANG Y N, TAN H R, et al. A digital twin-based intelligent robotic measurement system for freeform surface parts[J]. IEEE Transactions on Instrumentation and Measurement, 2023, 72: 7003013. [12] 王艳青, 闫月晖, 马嵩华, 等. 滚动轴承数字孪生几何模型精细建模[J]. 计算机集成制造系统, 2023, 29(6): 1882-1893. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ202306008.htmWANG Y Q, YAN Y H, MA S H, et al. Fine modeling method of digital twin geometric model for rolling bearing[J]. Computer Integrated Manufacturing Systems, 2023, 29(6): 1882-1893. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ202306008.htm [13] 陶飞, 张萌, 程江峰, 等. 数字孪生车间——一种未来车间运行新模式[J]. 计算机集成制造系统, 2017, 23(1): 1-9. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201701001.htmTAO F, ZHANG M, CHENG J F, et al. Digital twin workshop: a new paradigm for future workshop[J]. Computer Integrated Manufacturing Systems, 2017, 23(1): 1-9. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201701001.htm [14] 陶飞, 刘蔚然, 张萌, 等. 数字孪生五维模型及十大领域应用[J]. 计算机集成制造系统, 2019, 25(1): 1-18. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201901001.htmTAO F, LIU W R, ZHANG M, et al. Five-dimension digital twin model and its ten applications[J]. Computer Integrated Manufacturing Systems, 2019, 25(1): 1-18. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201901001.htm [15] YANG H, ZHAN M, LIU Y L, et al. Some advanced plastic processing technologies and their numerical simulation[J]. Journal of Materials Processing Technology, 2004, 151(1-3): 63-69. doi: 10.1016/j.jmatprotec.2004.04.015 [16] PEI H N, ZHANG P Y, DU S Z, et al. A point cloud preprocessing method for complicated thin-walled ring parts with irregular section[J]. Measurement, 2023, 214: 112807. [17] PEI H N, LUO M, DU S Z. Research on profile geometric feature parameters extraction of complicated thin-walled ring parts with irregular section[J]. Computer-Aided Design & Applications, 2023, 20(6): 1271-1287. [18] BIASOTTI S, ATTALI D, BOISSONNAT J D, et al. Skeletal structures[M]//FLORIANI L, SPAGNUOLO M. Shape Analysis and Structuring. Heidelberg: Springer, 2008: 145-183. [19] PEI H N, ZHOU W J, LUO M. Vibration errors compensation method based on self-feature registration for the 3-D dynamic measurement of metallic sealing ring forming surface[J]. Measurement and Control, 2024, 57(5): 500-509. -

下载:

下载: