Development of a Alexible Hybrid Robot Polishing System for Connecting Rod Molds

-

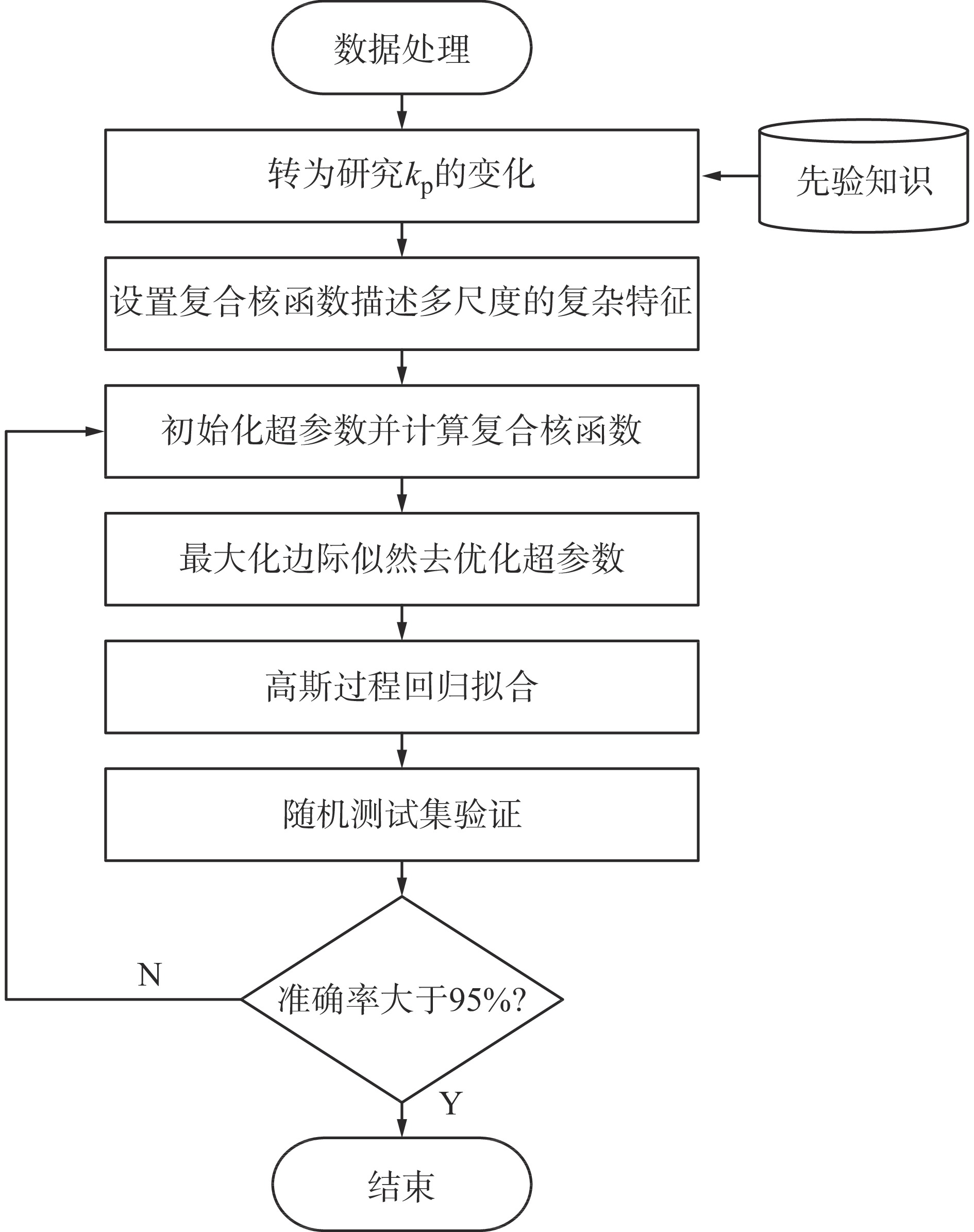

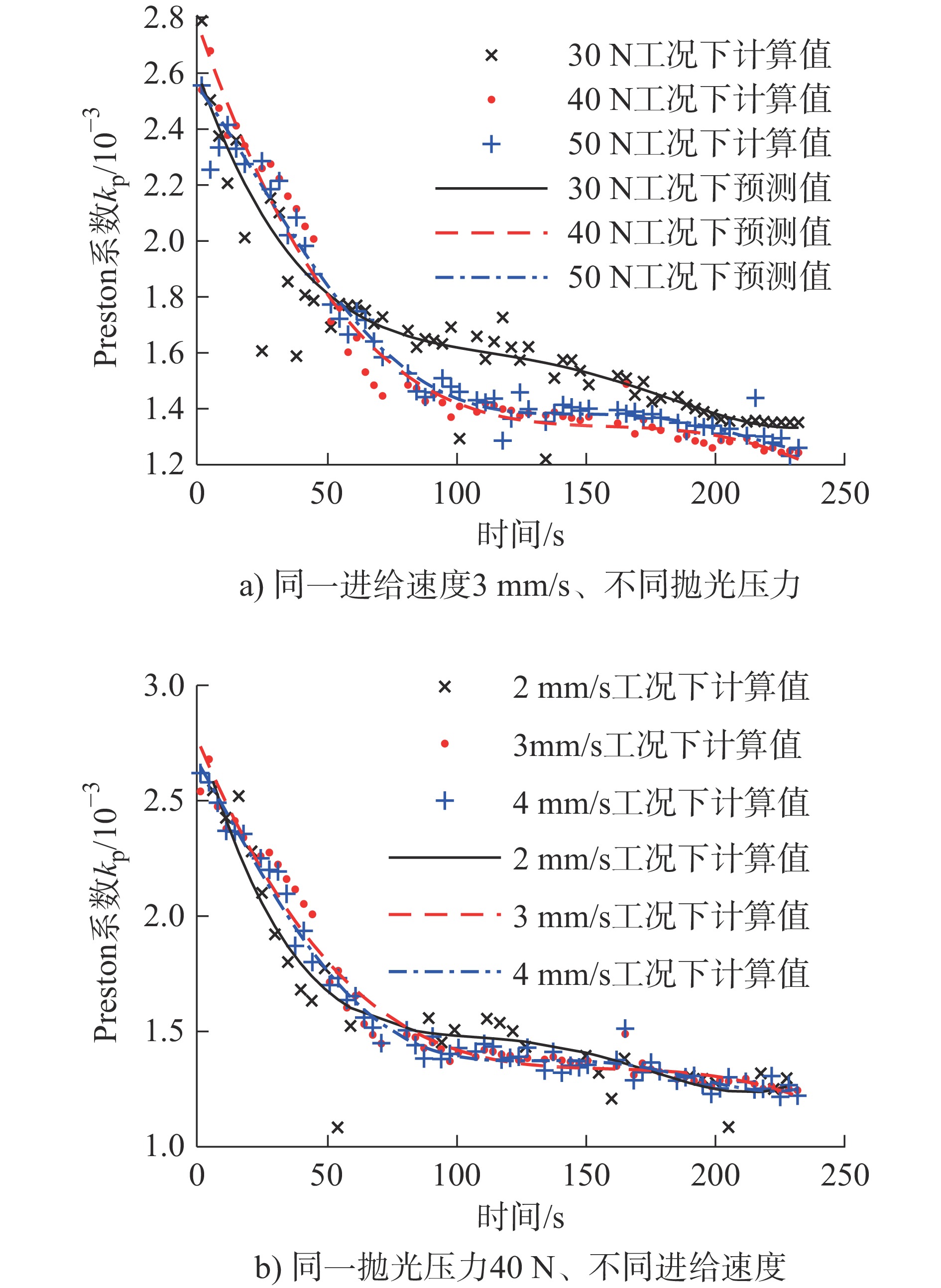

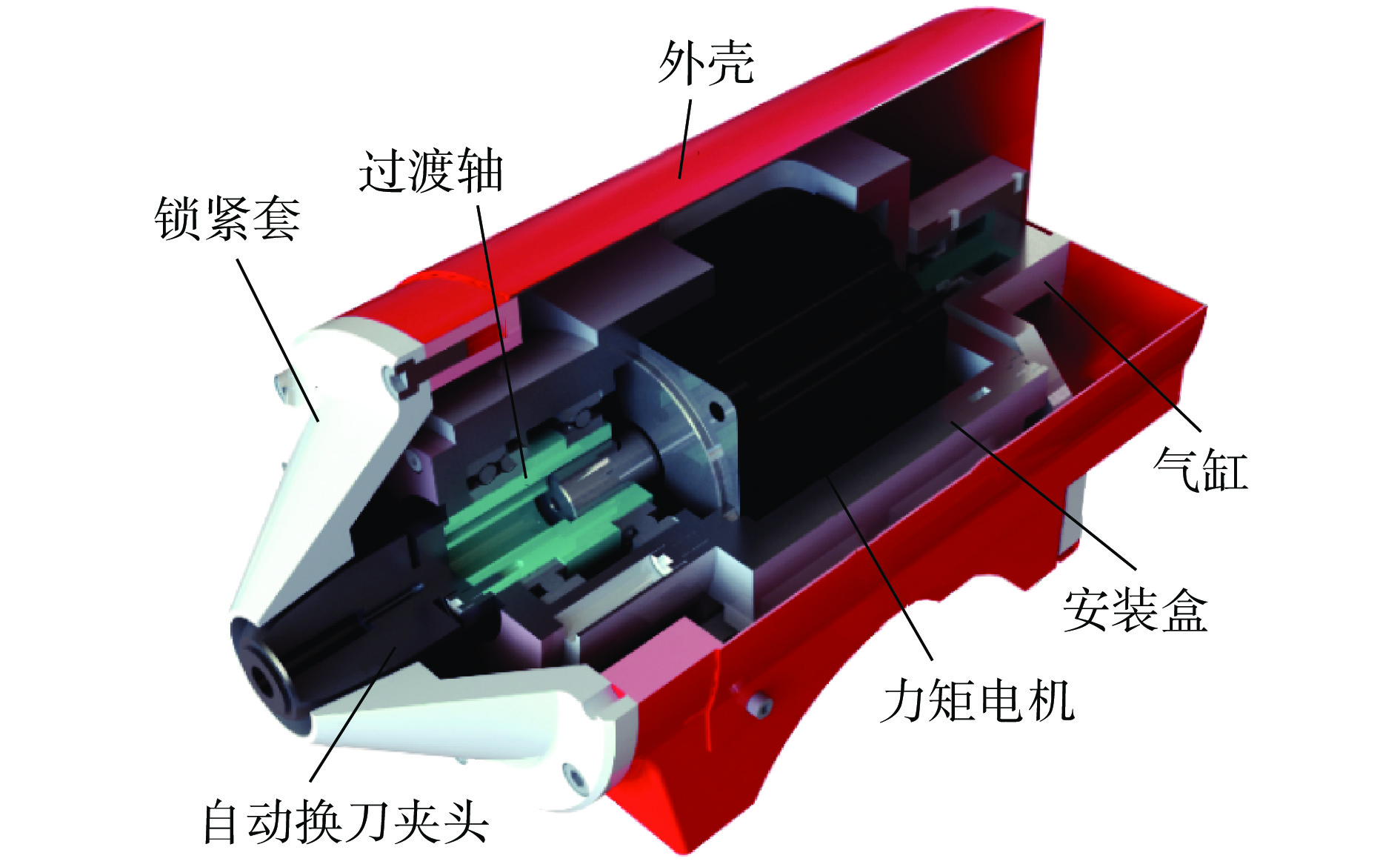

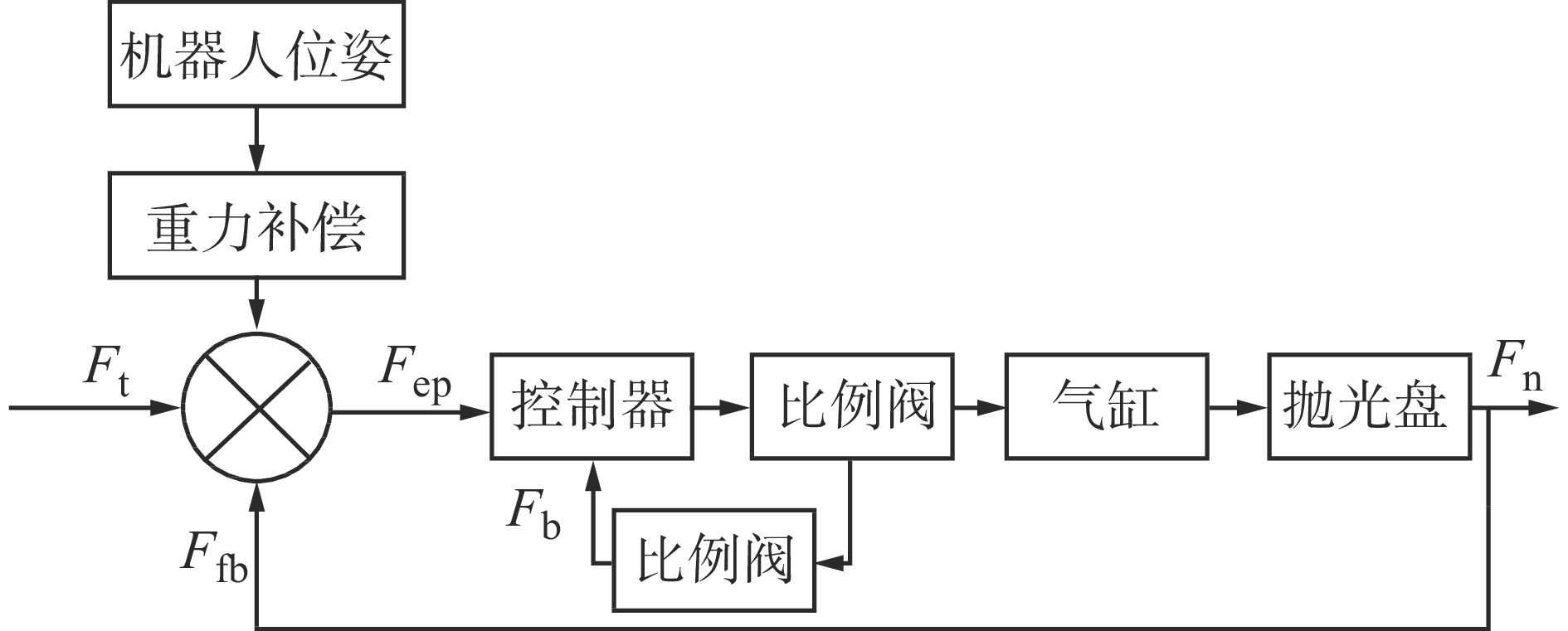

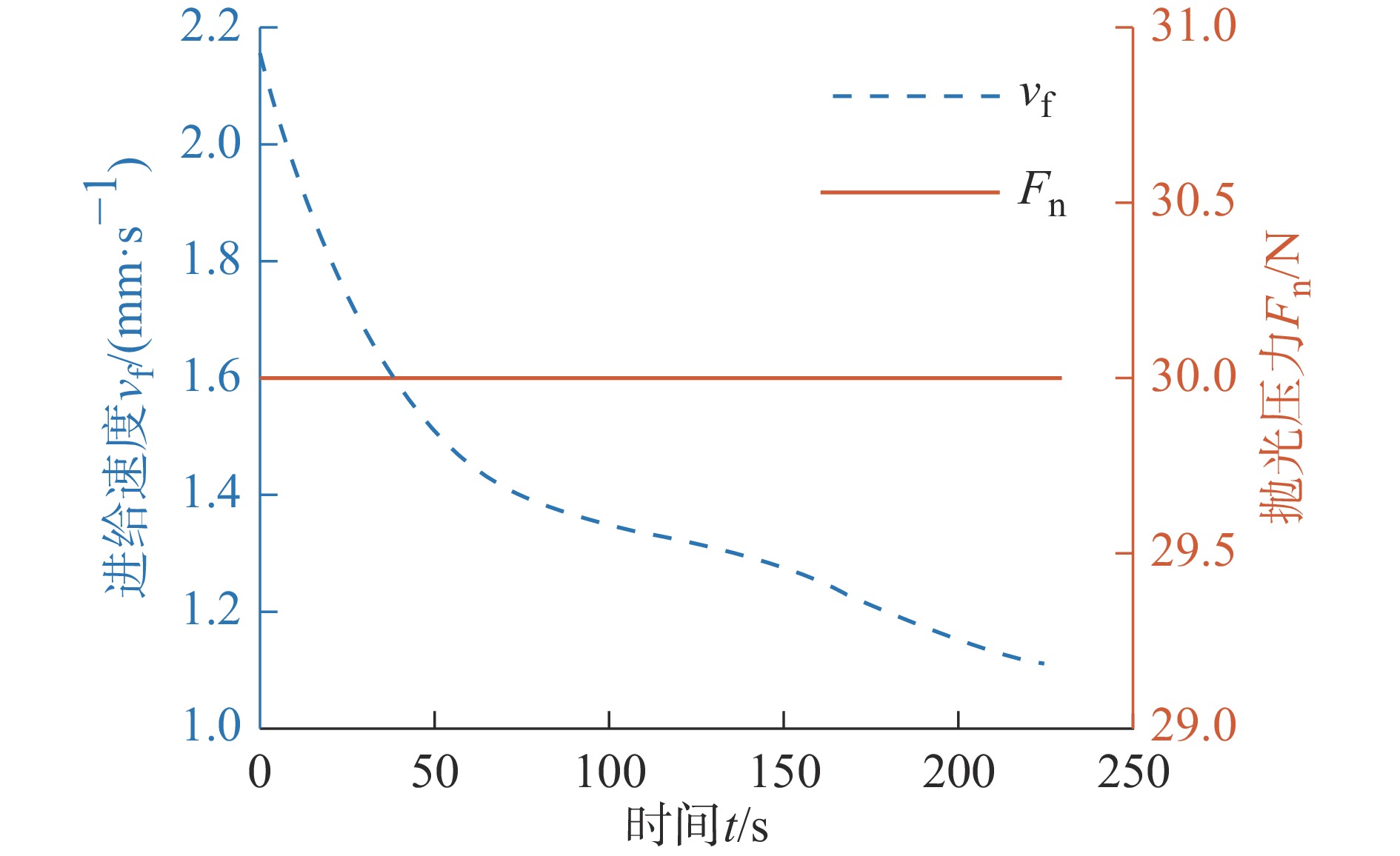

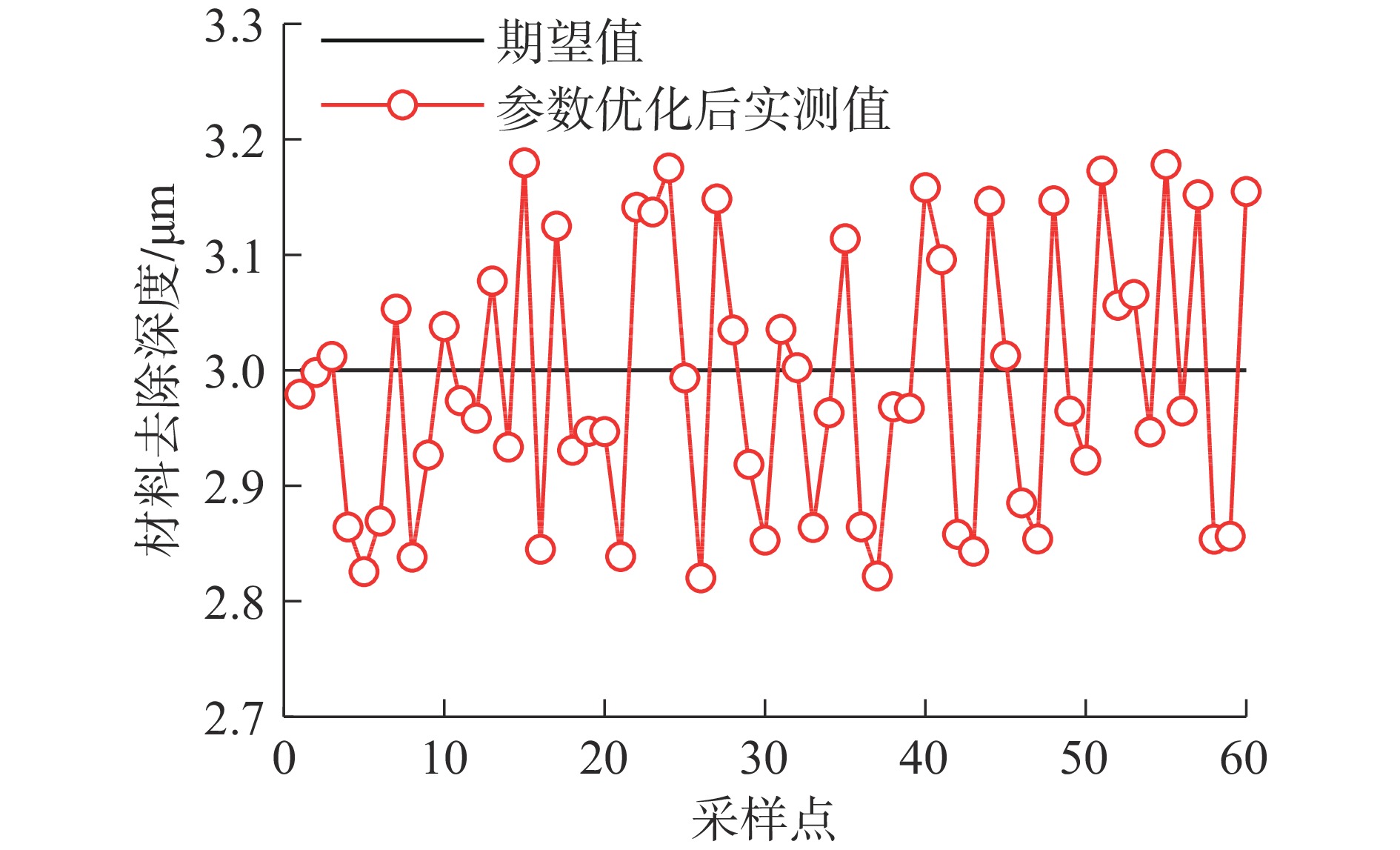

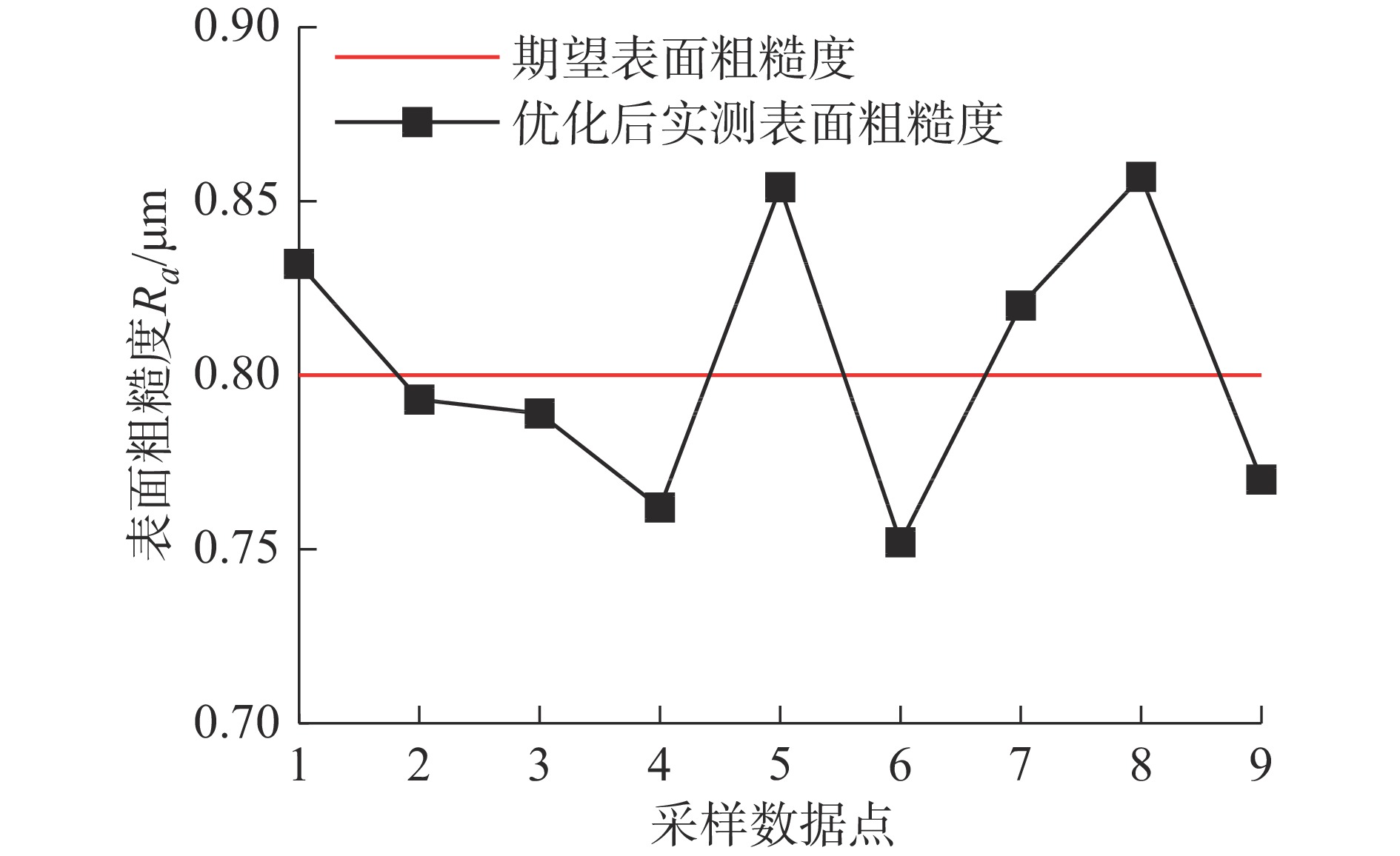

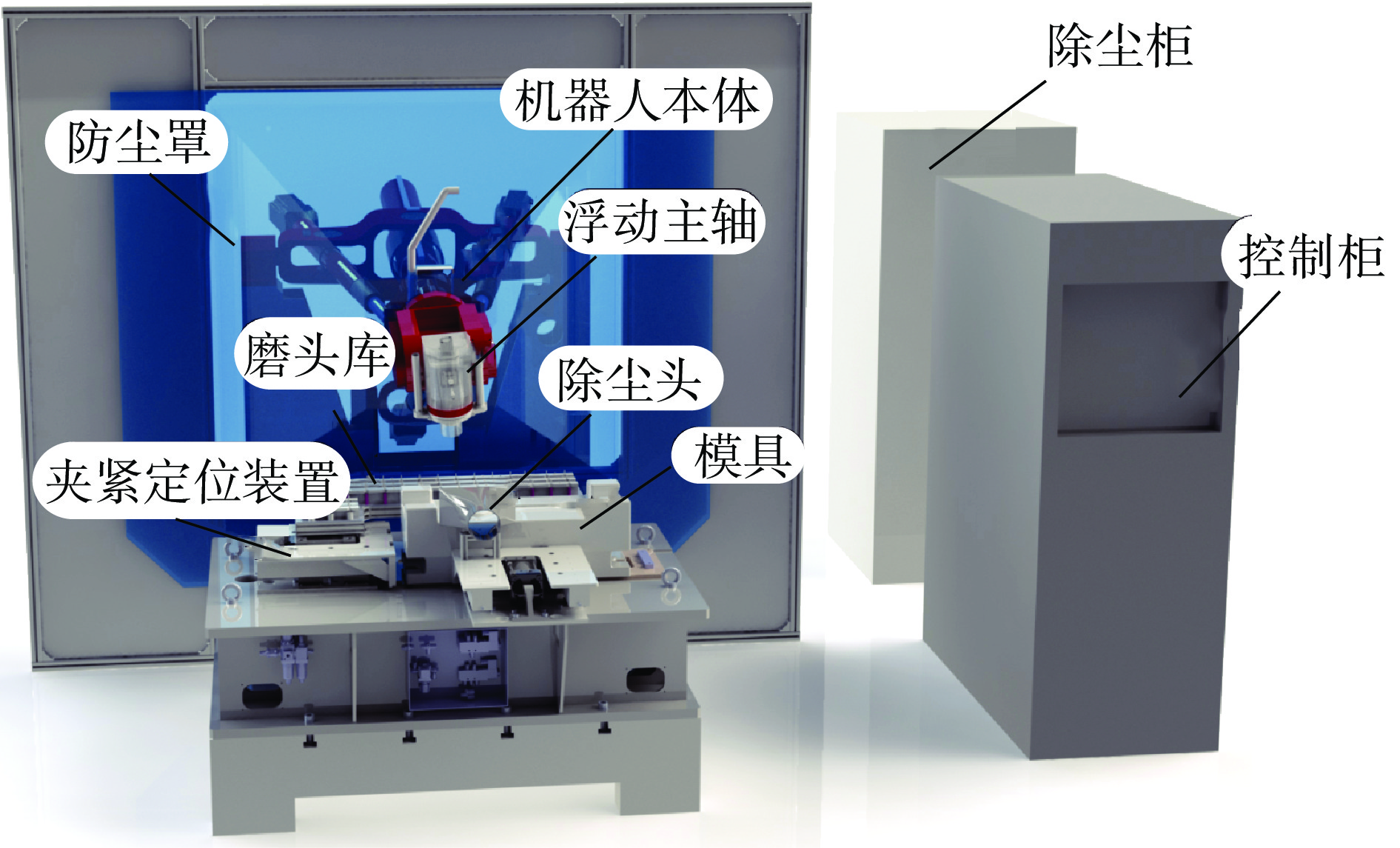

摘要: 为了解决连杆模具抛光过程中人工抛光时间长、劳动强度大等问题,建立了一套混联机器人柔性抛光系统。在该系统上对材料去除模型进行了研究,建立了考虑抛光工具磨损的材料去除模型,能够良好预测一定抛光参数下的材料去除量;在此基础上,对模具型腔表面自动分片,并使用UG和示教相结合的方法生成加工轨迹;根据模具抛光力的控制需要,建立了一套气动控制系统,使用自主设计的浮动恒力抛光主轴结合PID控制算法实现了恒力抛光。最后在该柔性抛光系统上进行了汽车连杆模具抛光实验,实验结果表明了该柔性抛光系统能够较好地完成连杆模具抛光任务,得到较好的抛光效果。Abstract: In order to solve the problems of long manual polishing time and high labor intensity in the polishing process of connecting rod mold, a set of hybrid robot flexible polishing system was established. The material removal model considering the wear of polishing tools is established on this system, which can well predict the material removal amount under certain polishing parameters. Using the combination of UG and teaching methods to generate the processing trajectory. According to the control needs of the mold polishing force, a pneumatic control system is established, and the self-designed floating constant force polishing spindle combined with the PID control algorithm realizes the constant force polishing. Finally, the polishing experiment of automobile connecting rod mold is carried out on the flexible polishing system. The experimental results show that the flexible polishing system can better complete the polishing task of connecting rod mold and obtain better polishing effect.

-

Key words:

- connecting rod mold /

- hybrid robot /

- polishing /

- material removal model /

- trajectory generation

-

表 1 PID控制参数值及其仿真动静态指标

Table 1. PID control parameter values and simulated dynamic and static indicators

P I D 上升时间/s 超调量/ % 稳态误差/N 2.7 30 0.3 0.059 0.052 0.021 表 2 相关抛光工艺参数设置

Table 2. Related polishing process parameter settings

项目 设置 抛光头类型 20 mm直径抛光盘、10 mm直径圆柱形砂纸棒 抛光头材质 砂纸 砂纸粒度 320目 主轴转速 2500 r$/$min 抛光压力 20 ~ 50 N 进给速度 1 ~ 4 mm$/$s -

[1] HUSMANN S, STEMMLER S, HÄHNEL S, et al. Model predictive force control in grinding based on a lightweight robot[J]. IFAC-PapersOnLine, 2019, 52(13): 1779-1784. doi: 10.1016/j.ifacol.2019.11.459 [2] HÄHNEL S, PINI F, LEALI F, et al. Reconfigurable robotic solution for effective finishing of complex surfaces[C]//Proceedings of the 23rd International Conference on Emerging Technologies and Factory Automation. Turin: IEEE, 2018: 1285-1290. [3] EL KHALICK MOHAMMAD A, WANG D W. Electrochemical mechanical polishing technology: recent developments and future research and industrial needs[J]. The International Journal of Advanced Manufacturing Technology, 2016, 86(5): 1909-1924. [4] LUO X C, CHENG K, WEBB D, et al. Design of ultraprecision machine tools with applications to manufacture of miniature and micro components[J]. Journal of Materials Processing Technology, 2005, 167(2-3): 515-528. doi: 10.1016/j.jmatprotec.2005.05.050 [5] 梁迎春, 陈国达, 孙雅洲, 等. 超精密机床研究现状与展望[J]. 哈尔滨工业大学学报, 2014, 46(5): 28-39.LIANG Y C, CHEN G D, SUN Y Z, et al. Research status and outlook of ultra-precision machine tool[J]. Journal of Harbin Institute of Technology, 2014, 46(5): 28-39. (in Chinese) [6] ZHANG X J, ZHANG Z Y, ZHENG L G, et al. Manufacturing and testing SiC aspherical mirrors in space telescopes[C]//Proceedings of SPIE 6024, ICO20: Optical Devices and Instruments. Changchun: SPIE, 2005: 602402. [7] 夏毅敏, 杨添任, 张刚强, 等. Nanosys-1000机床静压止推轴承流场分布规律及承载特性[J]. 光学 精密工程, 2013, 21(1): 144-150. doi: 10.3788/OPE.20132101.0144XIA Y M, YANG T R, ZHANG G Q, et al. Flow field distribution and bearing characteristics of hydrostatic thrust bearing in Nanosys-1000 machine[J]. Optics and Precision Engineering, 2013, 21(1): 144-150. (in Chinese) doi: 10.3788/OPE.20132101.0144 [8] YAO Y S, MA Z, DING J T, et al. Heavy-calibre off-axis aspheric surface polishing by industrial robot[C]//Proceedings of SPIE 10838, 9th International Symposium on Advanced Optical Manufacturing and Testing Technologies. Chengdu: SPIE, 2019: 1083803. [9] KHARIDEGE A, DU T T, ZHANG Y J. A practical approach for automated polishing system of free-form surface path generation based on industrial arm robot[J]. The International Journal of Advanced Manufacturing Technology, 2017, 93(9-12): 3921-3934. doi: 10.1007/s00170-017-0726-y [10] LI J, GUAN Y S, CHEN H W, et al. A high-bandwidth end-effector with active force control for robotic polishing[J]. IEEE Access, 2020, 8: 169122-169135. doi: 10.1109/ACCESS.2020.3022930 [11] LI J, ZHANG T, LIU X N, et al. A survey of robotic polishing[C]//Proceedings of 2018 IEEE International Conference on Robotics and Biomimetics. Kuala Lumpur: IEEE, 2019: 2125-2132. [12] WU J, GAO Y, ZHANG B B, et al. Workspace and dynamic Performance evaluation of the parallel manipulators in a spray-painting equipment[J]. Robotics and Computer-Integrated Manufacturing, 2017, 44: 199-207. doi: 10.1016/j.rcim.2016.09.002 [13] WU J, YE H, YU G, et al. A novel dynamic evaluation method and its application to a 4-DOF parallel manipulator[J]. Mechanism and Machine Theory, 2022, 168: 104627. doi: 10.1016/j.mechmachtheory.2021.104627 [14] LÓPEZ-CUSTODIO P C, FU R, DAI J S, et al. Compliance model of Exechon manipulators with an offset wrist[J]. Mechanism and Machine Theory, 2022, 167: 104558. doi: 10.1016/j.mechmachtheory.2021.104558 [15] DONG C L, LIU H T, HUANG T, et al. A screw theory-based semi-analytical approach for elastodynamics of the tricept robot[J]. Journal of Mechanisms and Robotics, 2019, 11(3): 031005. doi: 10.1115/1.4043047 [16] DONG C L, LIU H T, YUE W, et al. Stiffness modeling and analysis of a novel 5-DOF hybrid robot[J]. Mechanism and Machine Theory, 2018, 125: 80-93. doi: 10.1016/j.mechmachtheory.2017.12.009 [17] ZHENG Q J, XIAO J L, WANG C, et al. A robotic polishing parameter optimization method considering time-varying wear[J]. The International Journal of Advanced Manufacturing Technology, 2022, 121(9-10): 6723-6738. doi: 10.1007/s00170-022-09788-8 [18] 樊成, 赵继, 张雷, 等. 移动抛光自由曲面材料去除的理论建模与试验研究[J]. 机械工程学报, 2014, 50(5): 173-181. doi: 10.3901/JME.2014.05.173FAN C, ZHAO J, ZHANG L, et al. Modeling and experimental study on the material removal in the velocity-dwell-mode polishing process[J]. Journal of Mechanical Engineering, 2014, 50(5): 173-181. (in Chinese) doi: 10.3901/JME.2014.05.173 [19] 于淼, 刘新星. 机器人抛磨自由曲面的分片路径规划研究[J]. 长春大学学报, 2019, 29(4): 6-9.YU M, LIU X X. Research on paths of fragmentation planning for robot polishing free-form surface[J]. Journal of Changchun University, 2019, 29(4): 6-9. (in Chinese) [20] XIAO J L, WANG Y P, Liu S J, et al. Grinding trajectory generation of hybrid robot based on cartesian direct teaching technology[J]. Industrial Robot, 2021, 48(3): 341-351. doi: 10.1108/IR-09-2020-0194 [21] 肖聚亮, 郑乾健, 王超, 等. 一种浮动恒力磨抛装置: 202210622258. X[P]. 2022-08-26.XIAO J L, ZHENG Q J, WANG C, et al. A floating constant force grinding and polishing device: 202210622258. X[P]. 2022-08-26. (in Chinese) -

下载:

下载: