Research on FDM Finite Element Simulation and Interlayer Coherent Layered Composite Scanning Path

-

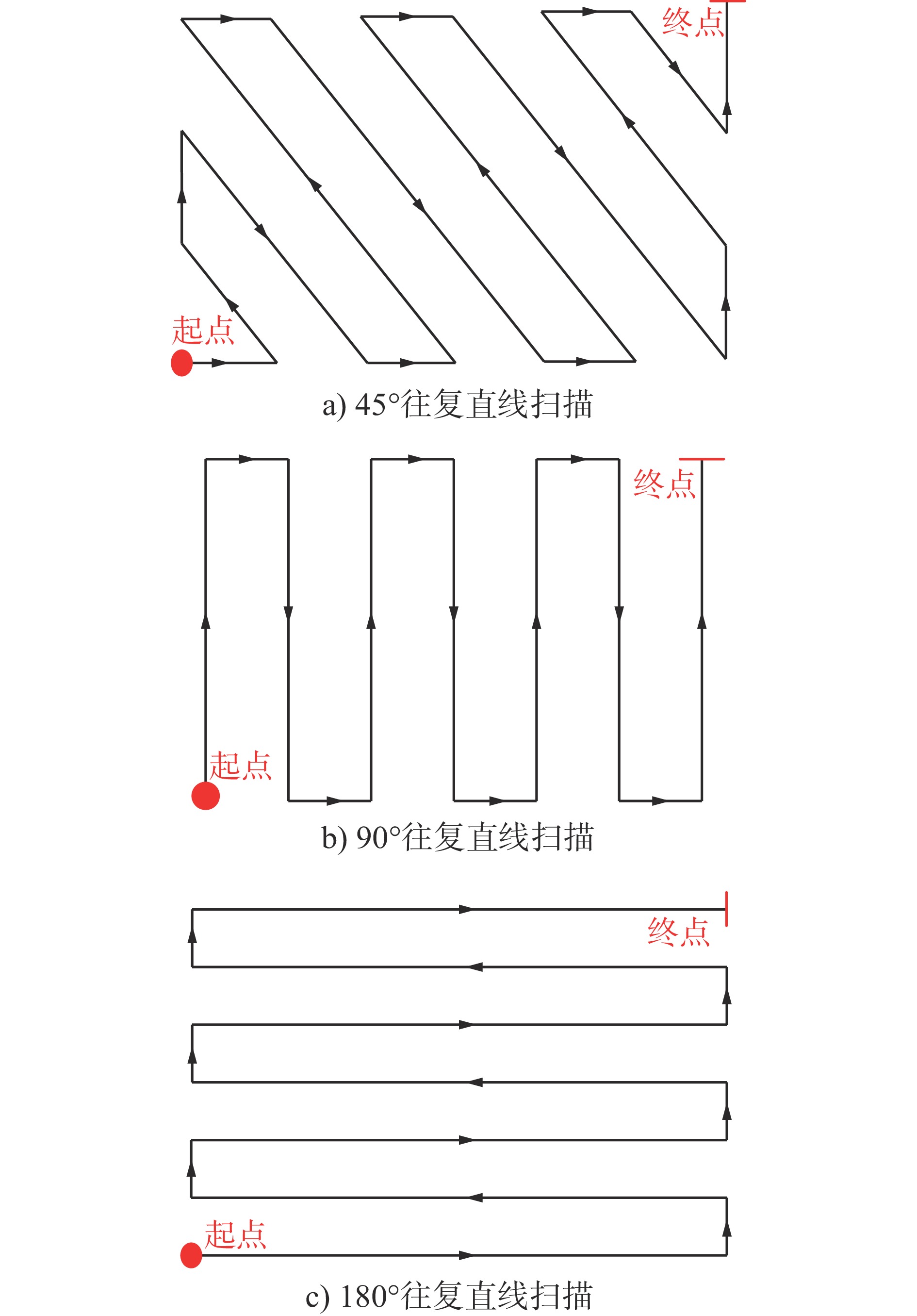

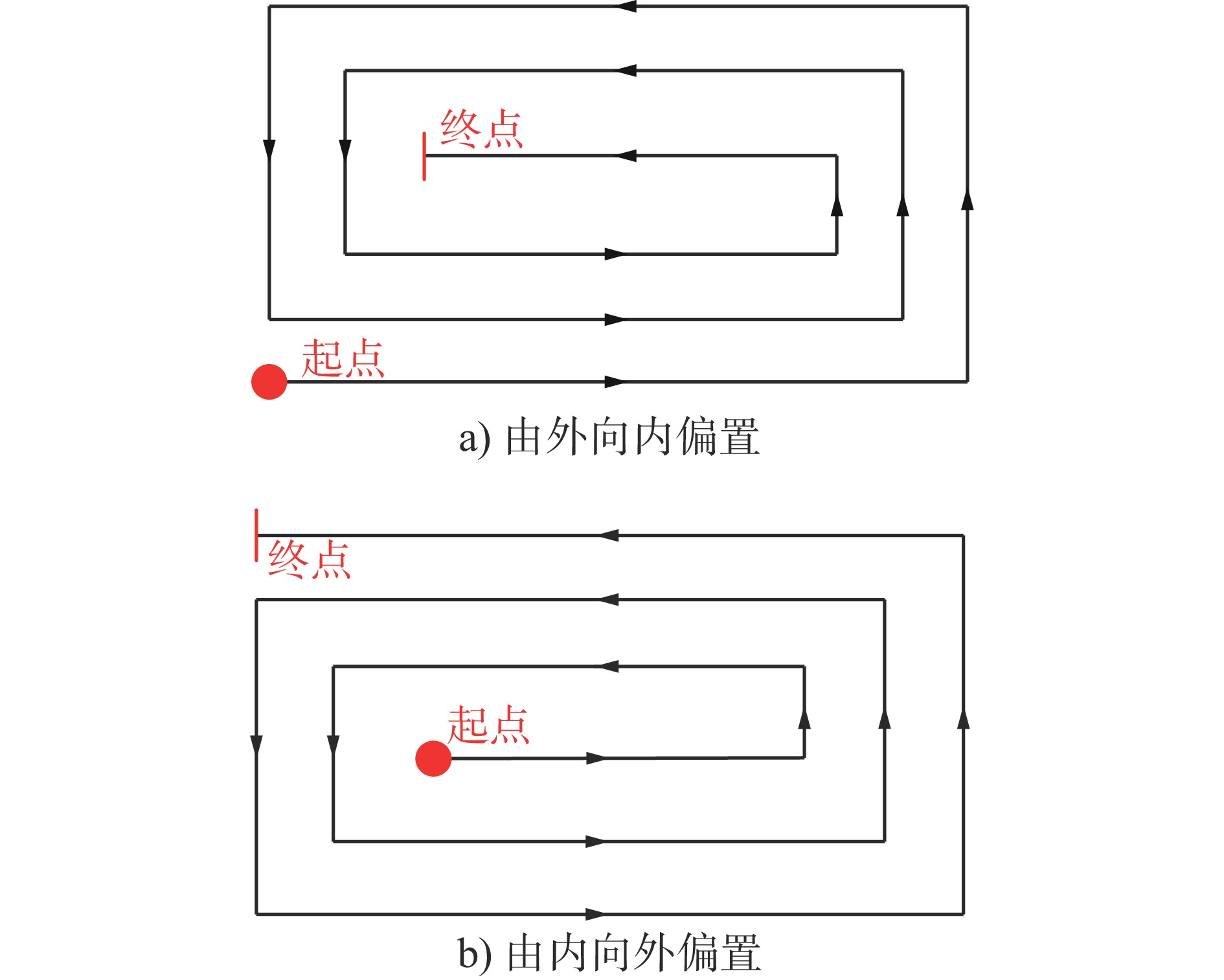

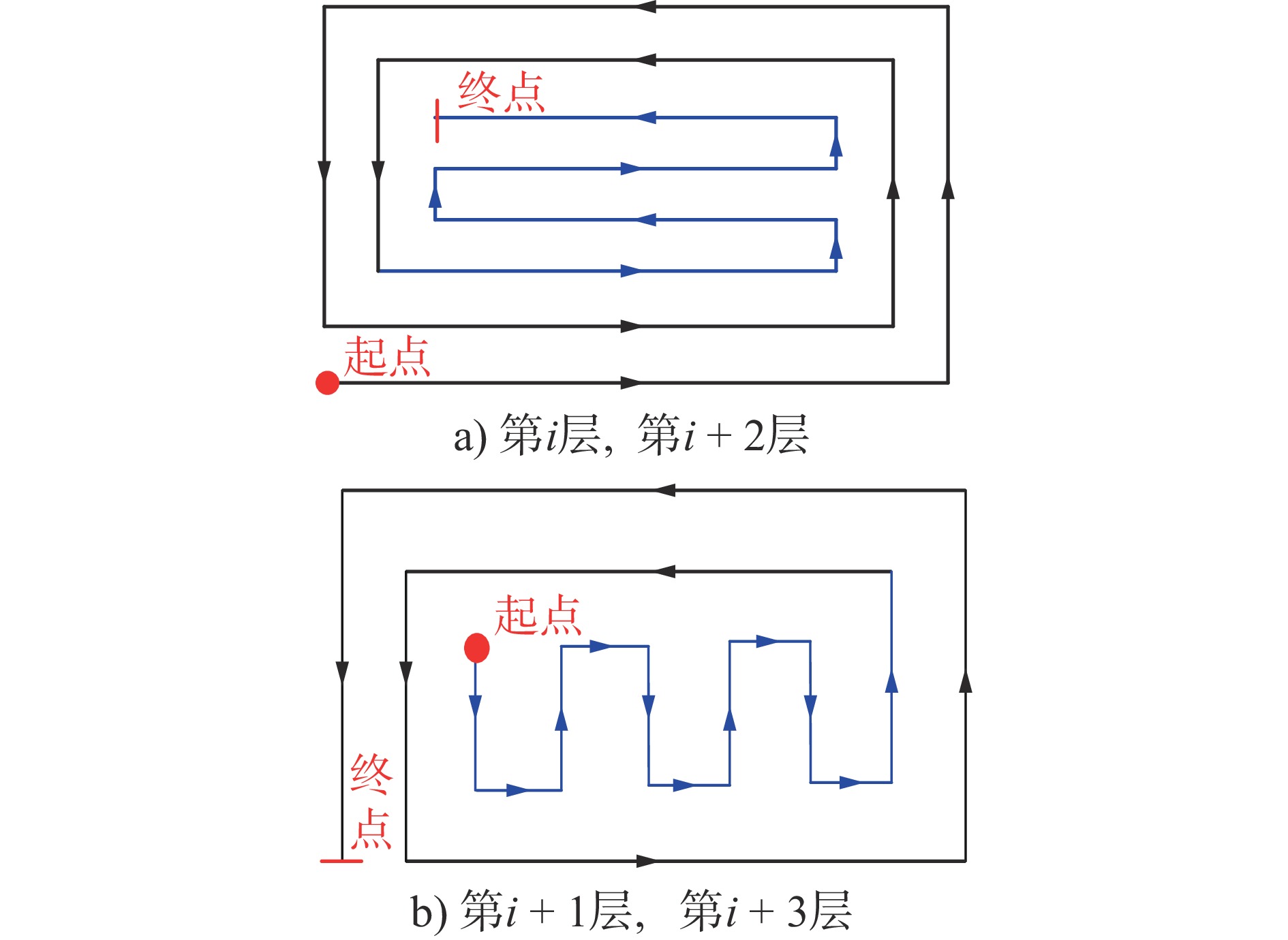

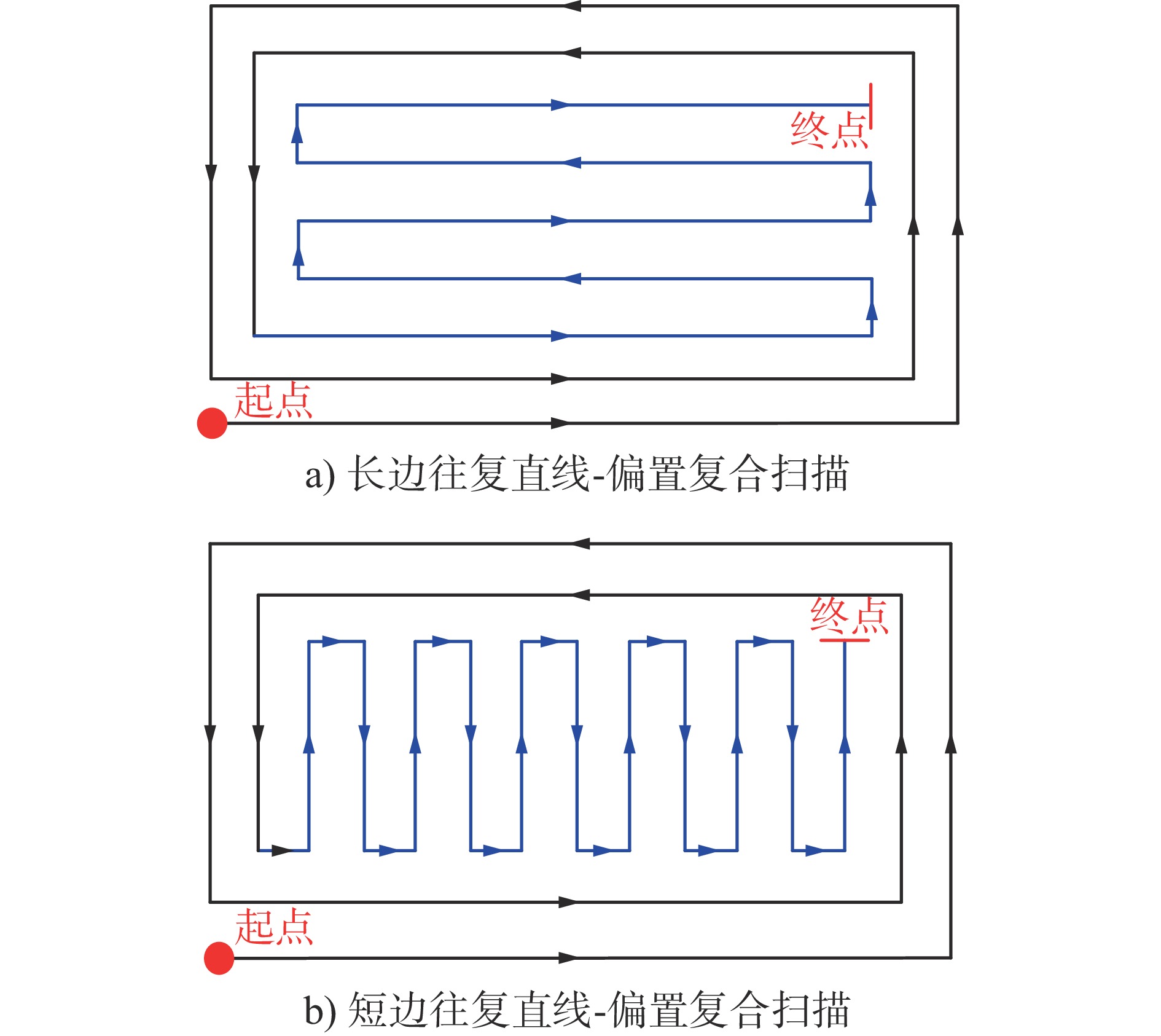

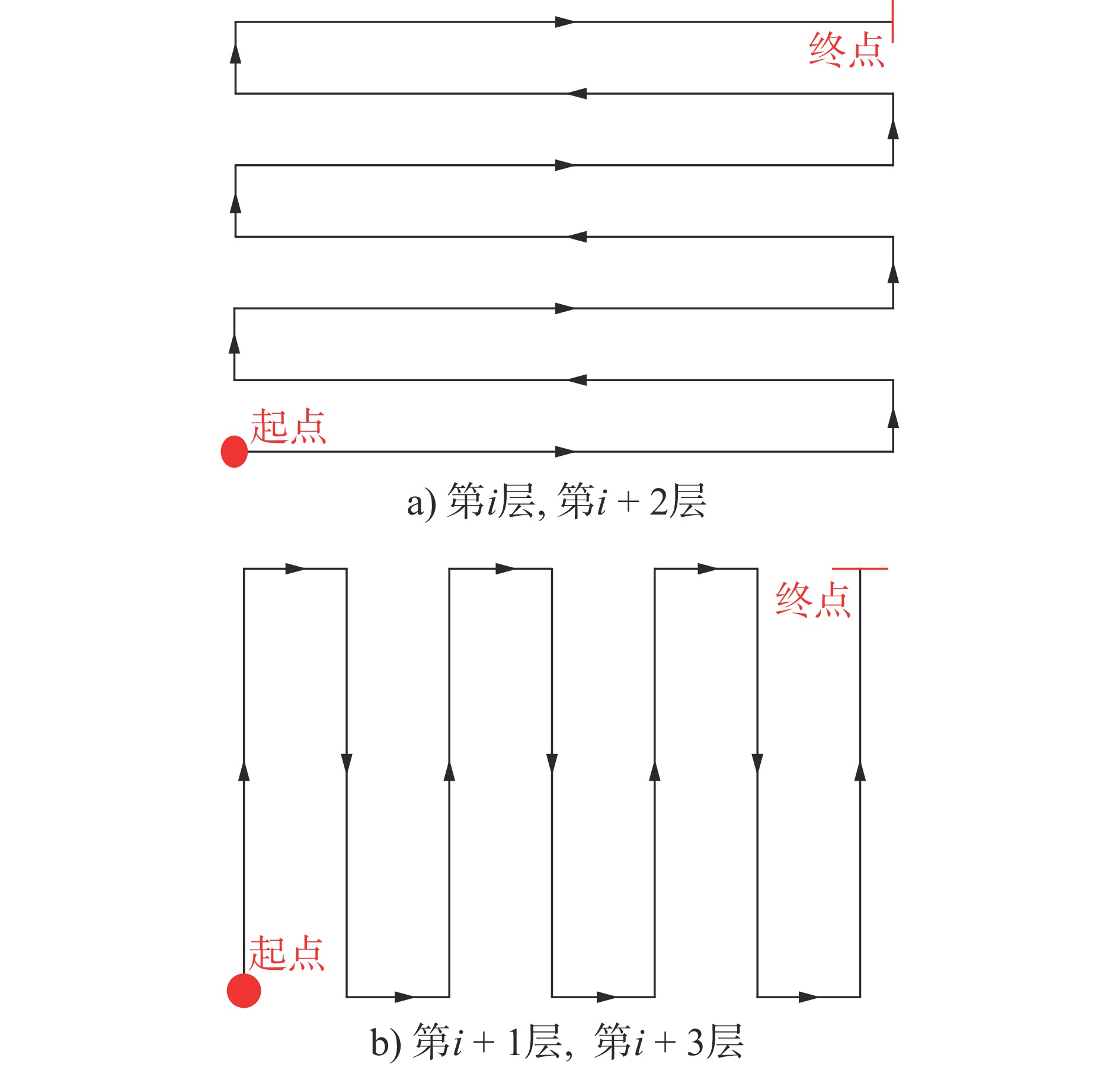

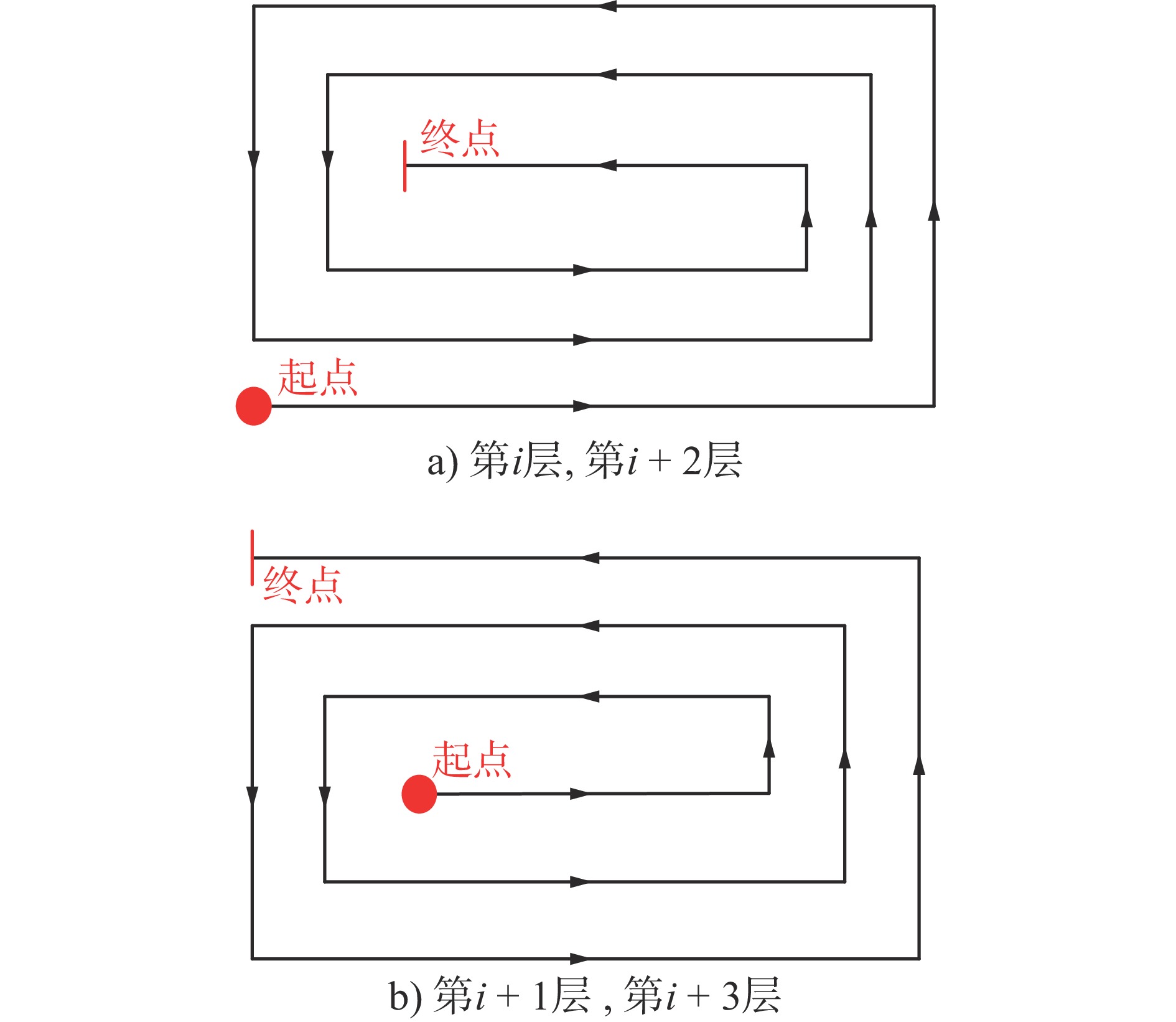

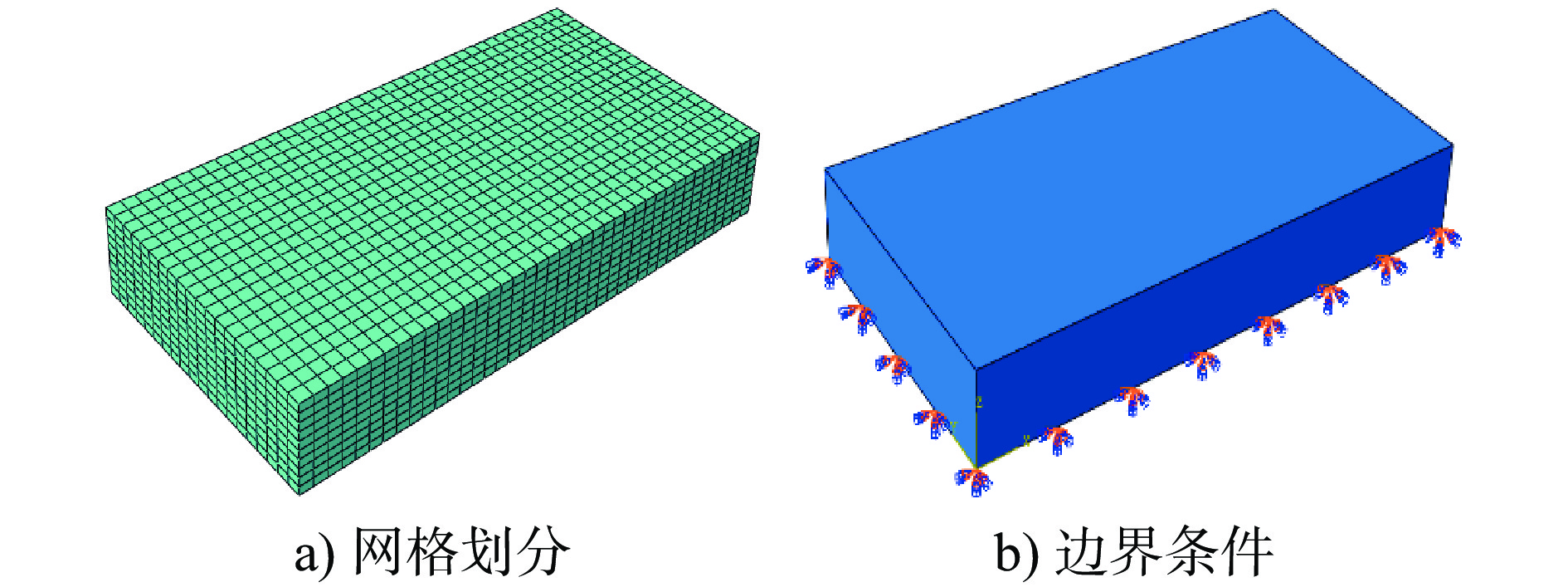

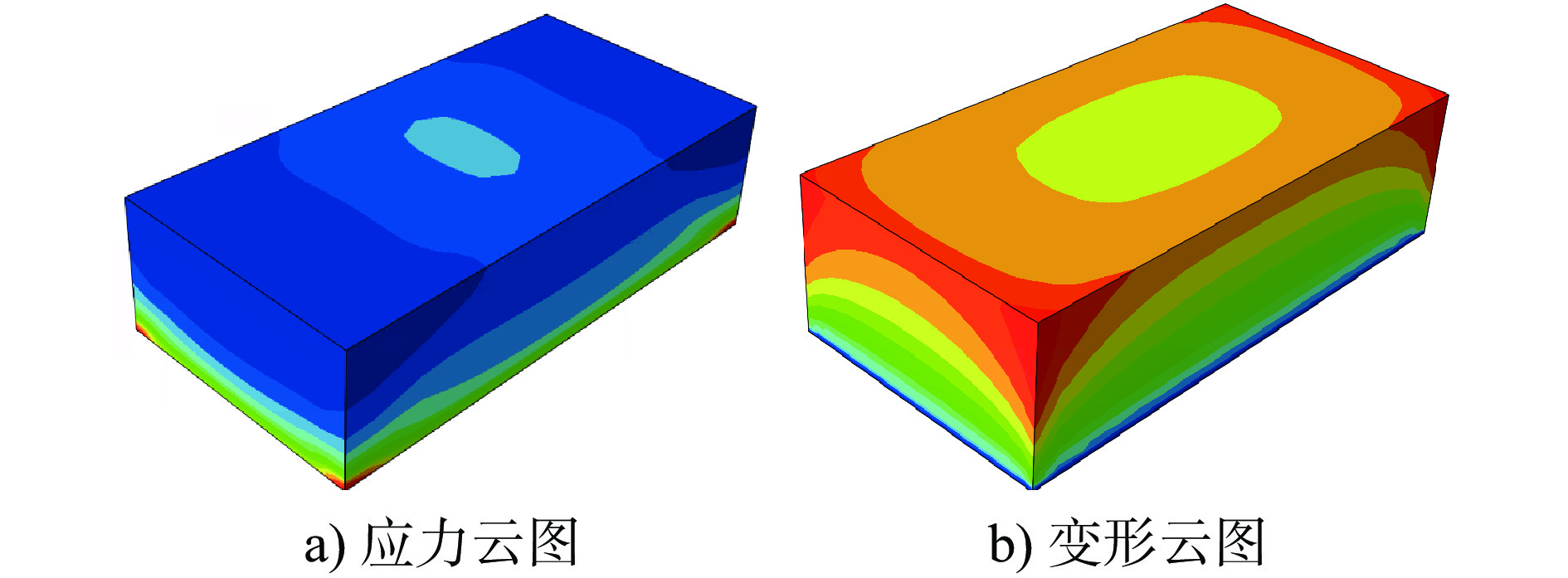

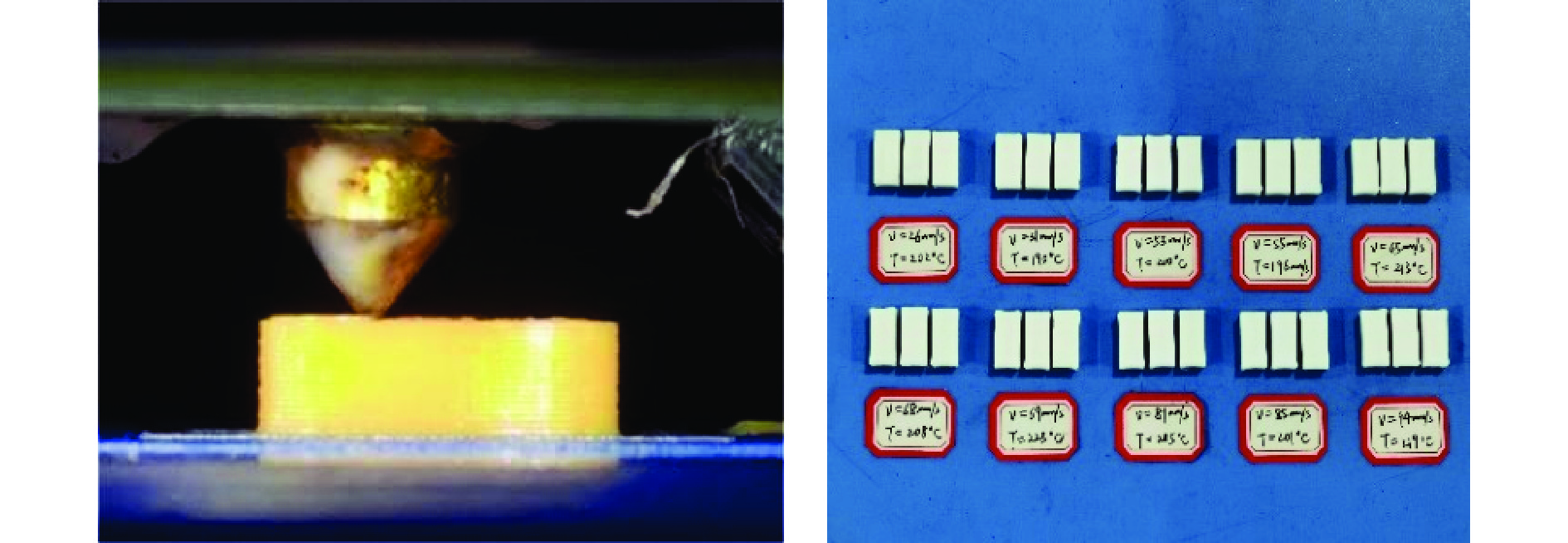

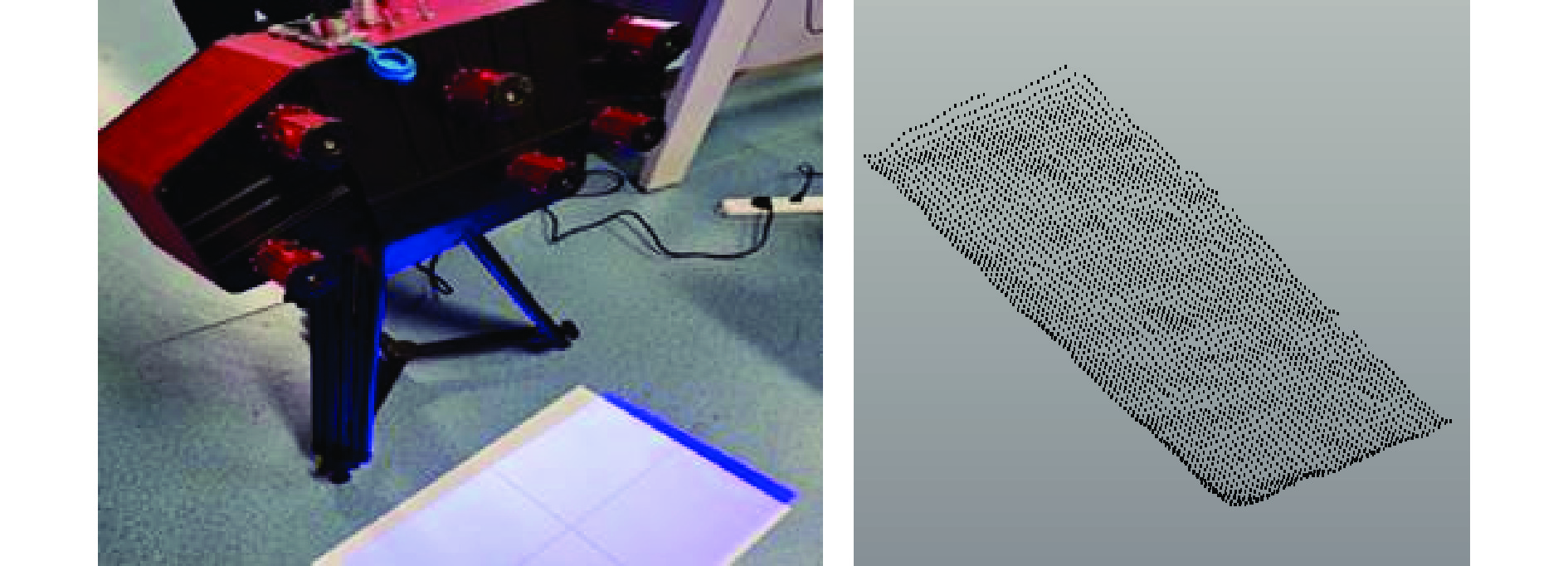

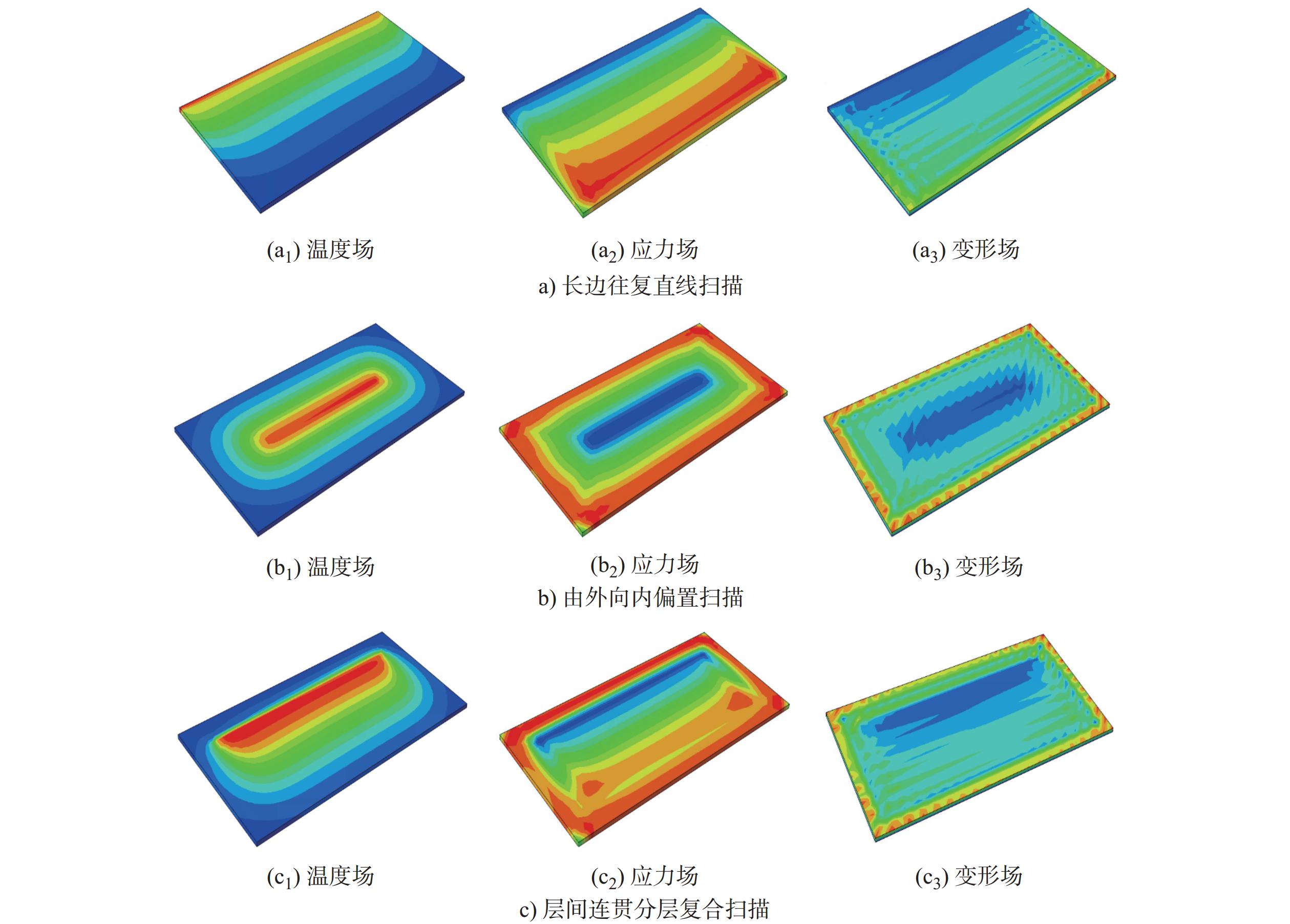

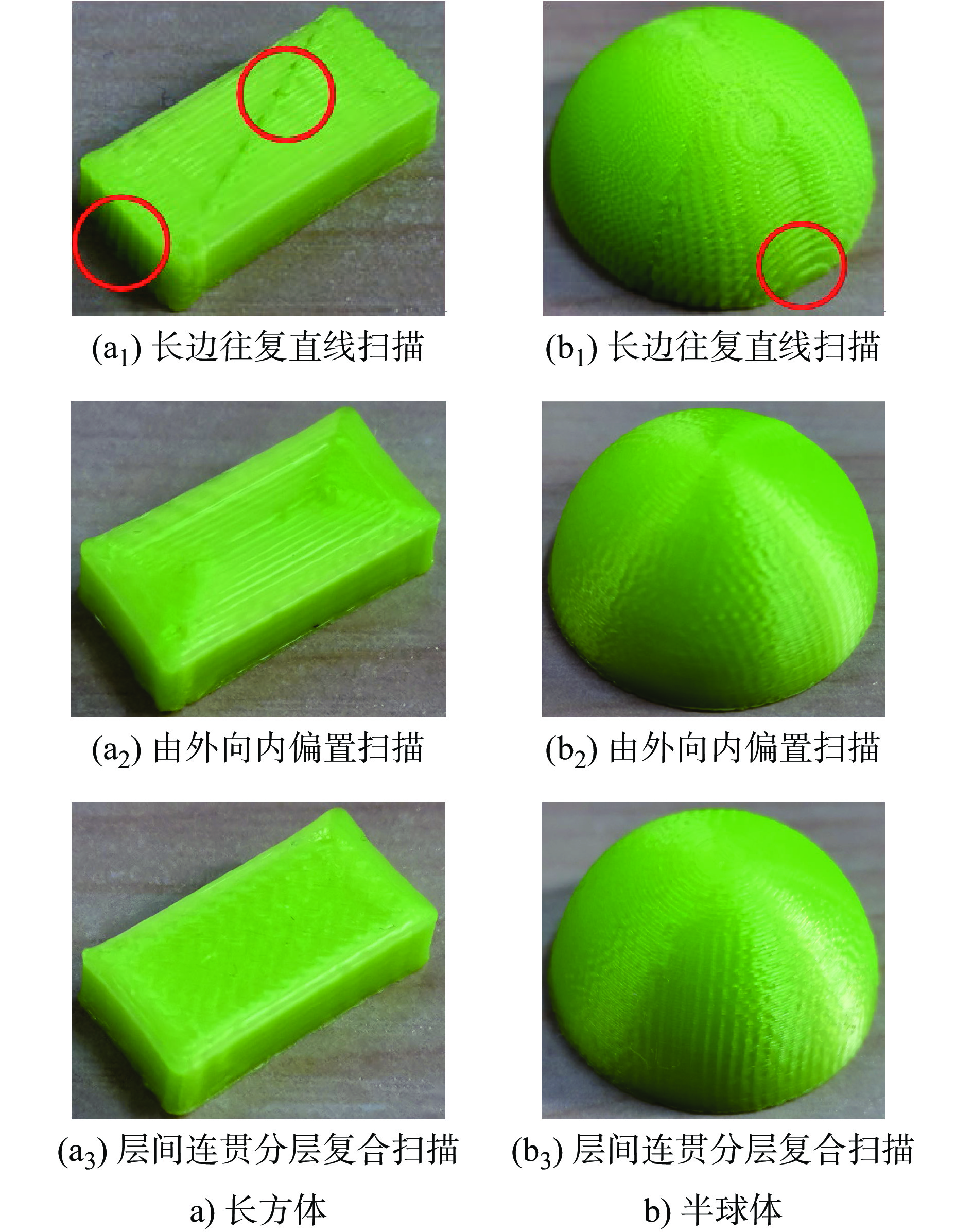

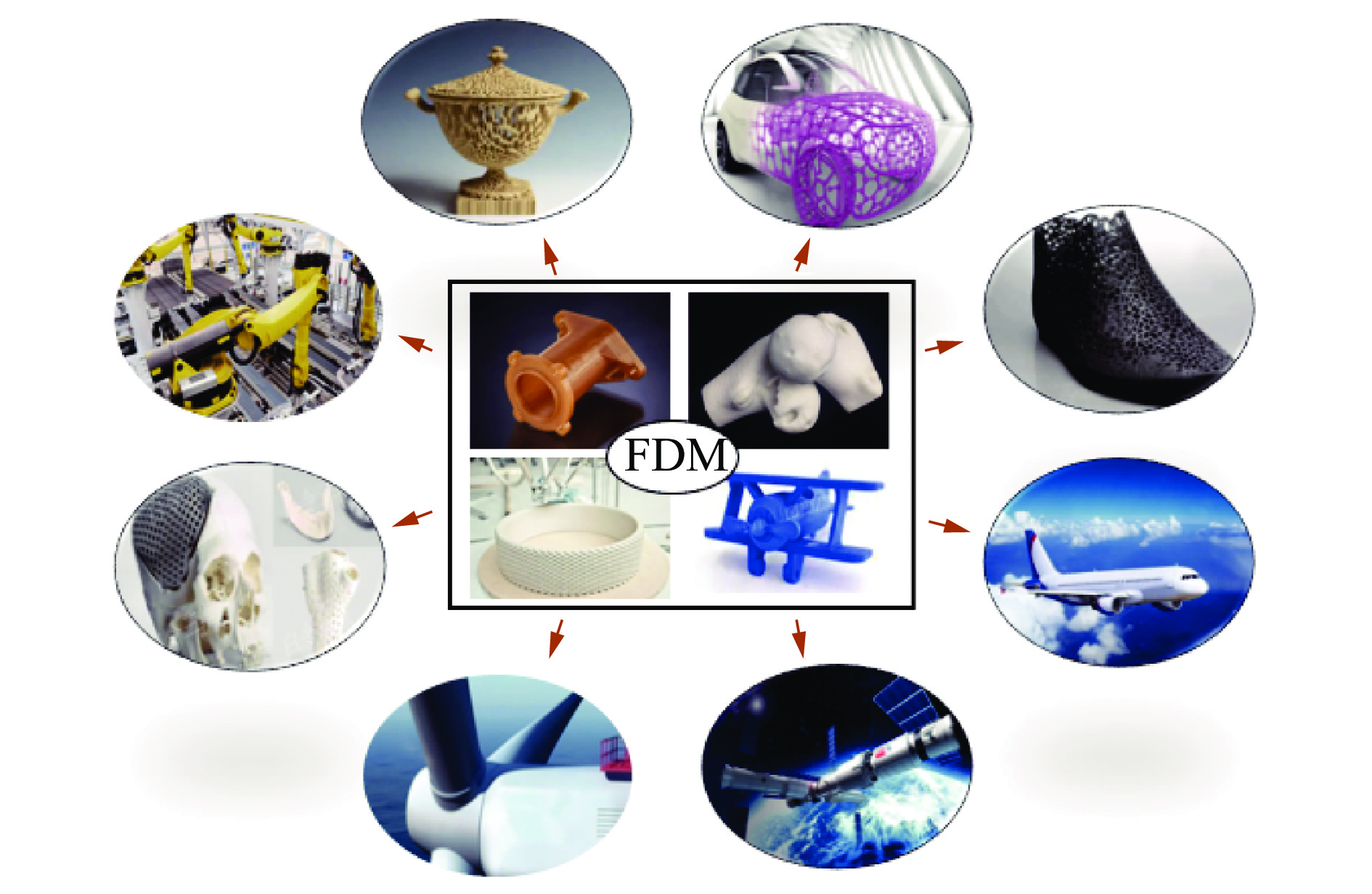

摘要: 3D打印扫描路径是影响打印质量和效率的重要因素。本文在研究熔融沉积成型(Fused deposition modeling,FDM)打印原理及有限元仿真的基础上,旨在给出一种层间连贯分层复合扫描路径方法。首先分析了往复直线扫描与偏置扫描的工艺特点并提出了层间连贯的分层复合扫描路径;然后采用生死单元技术建立了FDM成形过程有限元模型并进行了实验验证。结合有限元仿真与实验,结果表明,本文所提扫描路径不仅将往复直线扫描和偏置扫描的优势融合,且分层复合的挤出方式增加了打印的连贯性和整体性。Abstract: The scanning path of 3D printing is an important factor affecting printing quality and efficiency. On the basis of studying the printing principle and finite element simulation of Fused Deposition Modeling (FDM), this paper aims to give a method of interlayer coherent layered composite scanning path. Firstly, the process characteristics of reciprocating linear scanning and offset scanning were analyzed, and a layered composite scanning path with interlayer coherence was proposed; Then, a finite element model of the FDM forming process was established using the life and death element technology and experimentally verified. Combining finite element simulation and experiments, the results show that the scanning path proposed in this paper not only integrates the advantages of reciprocating linear scanning and offset scanning, but also enhances the coherence and integrity of printing through the extrusion method of interlayer coherence and layered composite.

-

Key words:

- FDM /

- finite element simulation /

- path planning /

- interlayer coherent /

- layered composite

-

表 1 材料参数

Table 1. Material parameters

密度/(kg·m−3) 传导率/[W·(m·℃)−1] 弹性模量/MPa 泊松比 1250 0.25 3.5 × 103 0.35 表 2 材料相变属性

Table 2. Material phase change properties

比热容/[J·(kg·℃)−1] 温度/℃ 1560 47.5 1700 54.9 1 820 60.3 1 900 109.3 2320 134.9 4360 145.6 2100 152.0 1 980 172.3 表 3 打印参数

Table 3. Printing parameters

热床温度/℃ 填充率/% 间距/mm 层高/mm 喷嘴直径/mm 70 100 0.4 0.2 0.4 表 4 实验与有限元仿真数据对比

Table 4. Comparison of experimental and finite element simulation data

参数名 编号 1 2 3 4 5 v/(mm·s−1) 65 26 53 81 69 T/℃ 213 202 200 205 223 实验最大变形/mm 0.0472 0.0329 0.0439 0.0508 0.0543 仿真最大变形/mm 0.0434 0.0284 0.0379 0.0450 0.0463 相对误差/% 8.05 13.68 13.67 11.42 14.73 表 5 不同扫描路径的最大应力与最大变形

Table 5. The maximum deformation and stress under different scanning paths

扫描路径 最大应力/MPa 最大变形/mm 长边往复直线扫描 15.21 1.43 × 10−2 由外向内偏置扫描 14.28 1.12 × 10−2 层间连贯分层复合扫描 12.12 9.98 × 10−3 表 6 成型效率对比

Table 6. Comparison of printing efficiency

扫描路径 打印耗时/s 长方体 半球体 长边往复直线扫描 177 2 008 由外向内偏置扫描 202 2179 层间连贯分层复合扫描 189 2076 表 7 半球体表面粗糙度分析

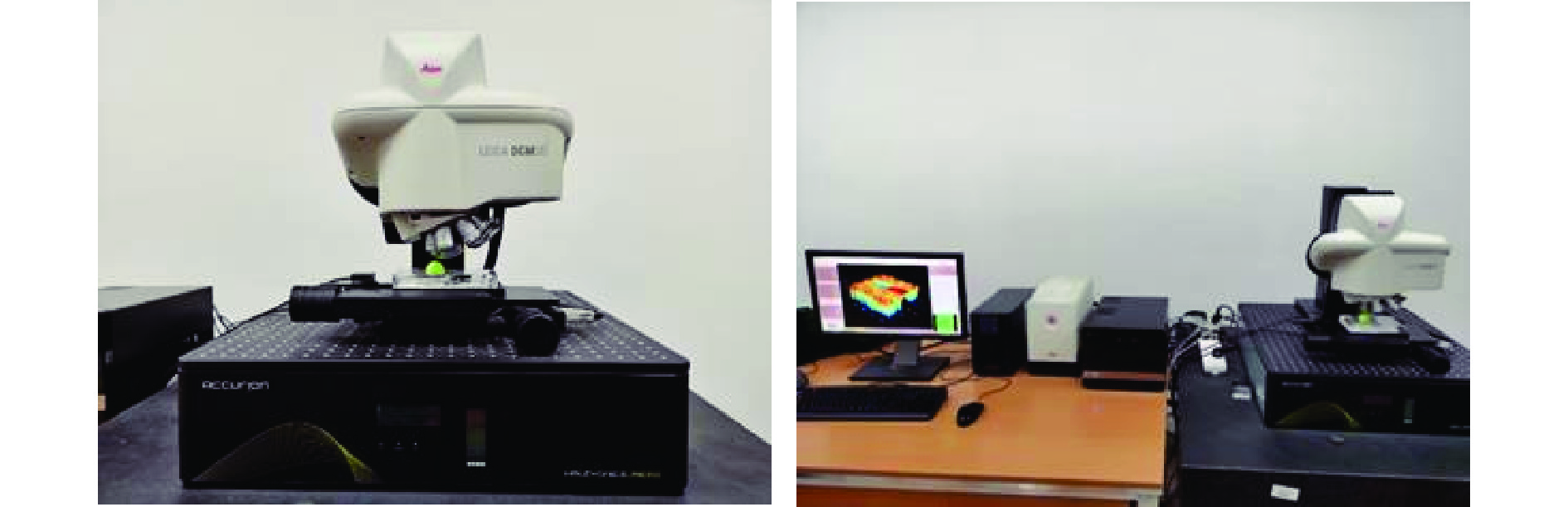

Table 7. Analysis of surface roughness of hemisphere

扫描路径 Ra/μm 1 2 3 均值 长边往复直线扫描 9.110 12.085 10.975 10.723 由外向内偏置扫描 4.203 6.682 6.198 5.694 层间连贯分层复合扫描 3.342 4.371 3.739 3.817 -

[1] 卢秉恒. 增材制造技术-现状与未来[J]. 中国机械工程, 2020, 31(1): 19-23.LU B H. Additive manufacturing-current situation and future[J]. China Mechanical Engineering, 2020, 31(1): 19-23. (in Chinese) [2] 李涤尘, 鲁中良, 田小永, 等. 增材制造-面向航空航天制造的变革性技术[J]. 航空学报, 2022, 43(4): 525387.LI D C, LU Z L, TIAN X Y, et al. Additive manufacturing-revolutionary technology for leading aerospace manufacturing[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(4): 525387. (in Chinese) [3] 李东来, 李丁, 张明哲, 等. 喷丸路径的设计、优化及等效有限元模拟[J]. 航空制造技术, 2018, 61(12): 86-91.LI D L, LI D, ZHANG M Z, et al. Design and optimization of shot peening path for aircraft panel and equivalent finite element simulation[J]. Aeronautical Manufacturing Technology, 2018, 61(12): 86-91. (in Chinese) [4] 叶总一, 薛迪强, 薛迪亮, 等. 工艺路径规划算法对FDM打印质量与效率的影响[J]. 工程塑料应用, 2018, 46(8): 46-51.YE Z Y, XUE D Q, XUE D L, et al. Influences of process path planning algorithm on FDM printing quality and efficiency[J]. Engineering Plastics Application, 2018, 46(8): 46-51. (in Chinese) [5] 王占礼, 晁艳艳, 胡艳娟, 等. 改进的Hilbert曲线在FDM路径规划中的应用[J]. 机械设计与制造, 2016(3): 186-188.WANG Z L, CHAO Y Y, HU Y J, et al. Application of improved Hilbert curve in the path planning of FDM[J]. Machinery Design & Manufacture, 2016(3): 186-188. (in Chinese) [6] 侯章浩. 熔融沉积成型的路径规划研究[D]. 乌鲁木齐: 新疆大学, 2015.HOU Z H. Research on the path planning of fused deposition modeling[D]. Urumqi: Xinjiang University, 2015. (in Chinese) [7] 张森. FDM成型过程有限元模拟及工艺参数优化研究[D]. 保定: 华北电力大学, 2018.ZHANG S. Research on finite element simulation and process parameter optimization based on FDM[D]. Baoding: North China Electric Power University, 2018. (in Chinese) [8] 江志伟, 李耀棠. 面向耗材节省的三维打印路径规划算法研究[J]. 计算机应用研究, 2020, 37(3): 750-753.JIANG Z W, LI Y T. Research on 3D printing path planning for material cost saving[J]. Application Research of Computers, 2020, 37(3): 750-753. (in Chinese) [9] 孙晓燕, 唐归, 王海龙, 等. 3D打印路径对混凝土拱桥结构力学性能的影响[J]. 浙江大学学报(工学版), 2020, 54(11): 2085-2091.SUN X Y, TANG G, WANG H L, et al. Effect of 3D printing path on mechanical properties of arch concrete bridge[J]. Journal of Zhejiang University (Engineering Science), 2020, 54(11): 2085-2091. (in Chinese) [10] 姜世杰, 史银芳, SIYAJEU Y, 等. 路径宽度对FDM薄板固有特性的影响机理研究[J]. 机械工程学报, 2019, 55(15): 226-232. doi: 10.3901/JME.2019.15.226JIANG S J, SHI Y F, SIYAJEU Y, et al. Investigation on the effect of road width on the inherent characteristics of FDM plates[J]. Journal of Mechanical Engineering, 2019, 55(15): 226-232. (in Chinese) doi: 10.3901/JME.2019.15.226 [11] 高进伟, 张立强, 周波. FDM打印路径拐角速度控制算法[J]. 计算机时代, 2019(8): 44-48.GAO J W, ZHANG L Q, ZHOU B. FDM print path corner speed control algorithm[J]. Computer Era, 2019(8): 44-48. (in Chinese) [12] 汪国强, 石志良, 熊林杰, 等. 基于FDM的自适应分区路径规划算法研究[J]. 数字制造科学, 2020, 18(3): 214-220.WANG G Q, SHI Z L, XIONG L J, et al. Research on adaptive partition path planning algorithm based on FDM[J]. Digital Manufacture Science, 2020, 18(3): 214-220. (in Chinese) [13] BI D J, XIE F B, TANG K. Generation of efficient iso-planar printing path for multi-axis FDM printing[J]. Journal of Manufacturing and Materials Processing, 2021, 5(2): 59. doi: 10.3390/jmmp5020059 [14] 吕宁, 李云旭. 熔融沉积式3D打印切片轮廓路径优化算法[J]. 机械设计与研究, 2021, 37(3): 122-125.LYU N, LI Y X. Research on contour path optimization algorithm of fused deposition 3D printing slice[J]. Machine Design and Research, 2021, 37(3): 122-125. (in Chinese) [15] 杨德成, 李凤岐, 王祎, 等. 智能3D打印路径规划算法[J]. 计算机科学, 2020, 47(8): 267-271.YANG D C, LI F Q, WANG Y, et al. Intelligent 3D printing path planning algorithm[J]. Computer Science, 2020, 47(8): 267-271. (in Chinese) [16] SHAIKH S, KUMAR N, JAIN P K, et al. Hilbert curve based toolpath for FDM process[M]//MANDAL D K, SYAN C S. CAD/CAM, Robotics and Factories of the Future. New Delhi: Springer, 2016: 751-759. [17] HUANG X M, CHUNSHENG Y, YONGJUN H. Tool path planning based on endpoint build-in optimization in rapid prototyping[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2011, 225(12): 2919-2926. [18] 王祎, 葛静怡, 薛昕惟, 等. 改进Q学习的薄壁结构3D打印路径规划[J]. 计算机工程与应用, 2022, 58(12): 299-303.WANG Y, GE J Y, XUE X W, et al. Path planning for complex thin-Walled structures in 3D printing: improved Q-learning method[J]. Computer Engineering and Applications, 2022, 58(12): 299-303. (in Chinese) [19] 侯章浩, 乌日开西•艾依提. 3D打印的路径规划研究综述[J]. 机床与液压, 2016, 44(5): 179-182.HOU Z H, AIYITI W. Review of studies on path planning of 3D printing[J]. Machine Tool & Hydraulics, 2016, 44(5): 179-182. (in Chinese) -

下载:

下载: