Theoretical Model and Experimental Study on Influence of Bearing Inner Clearance on Bearing Vibration

-

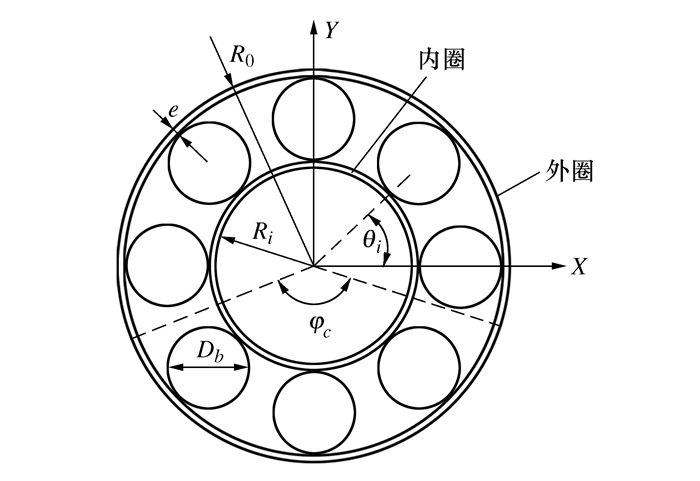

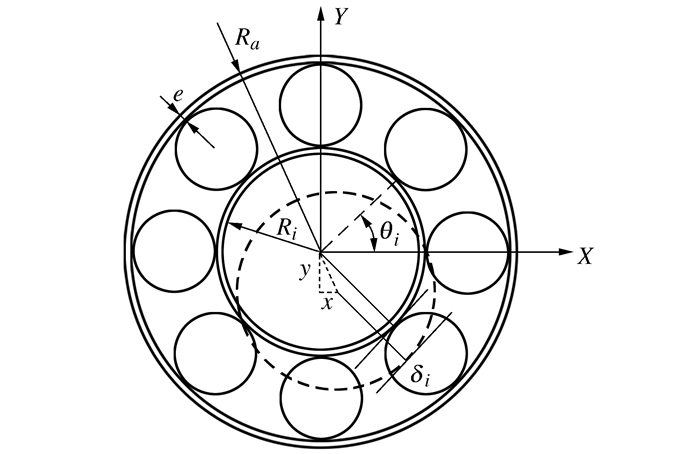

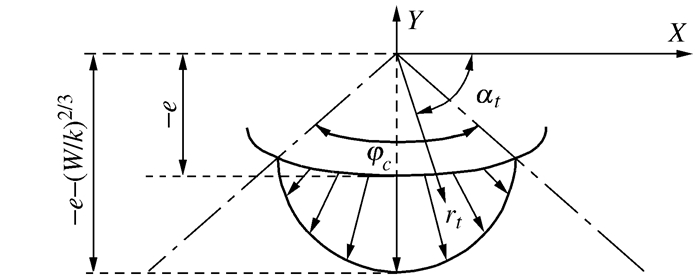

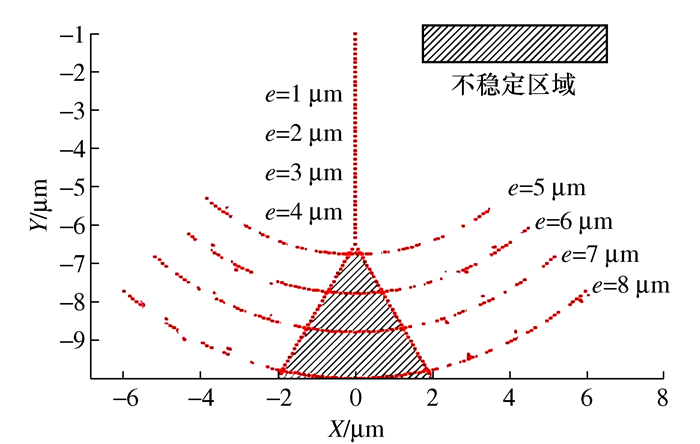

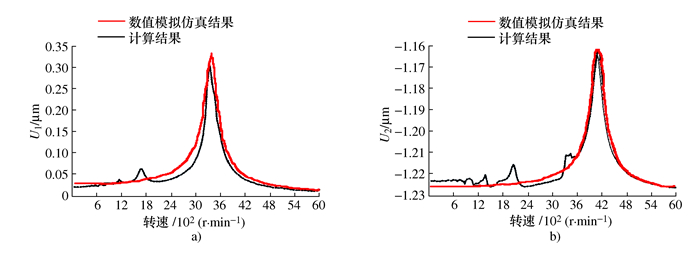

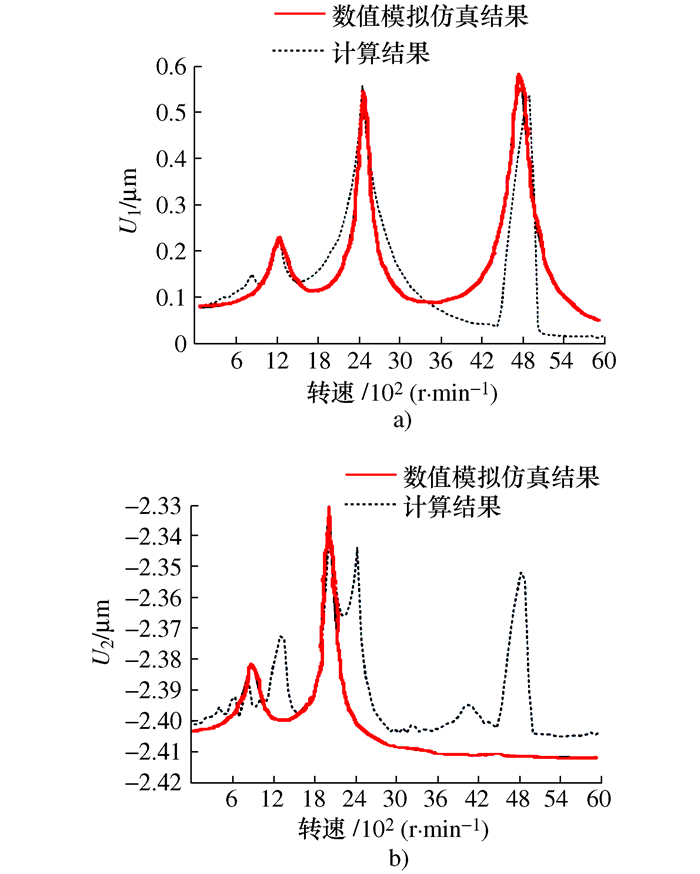

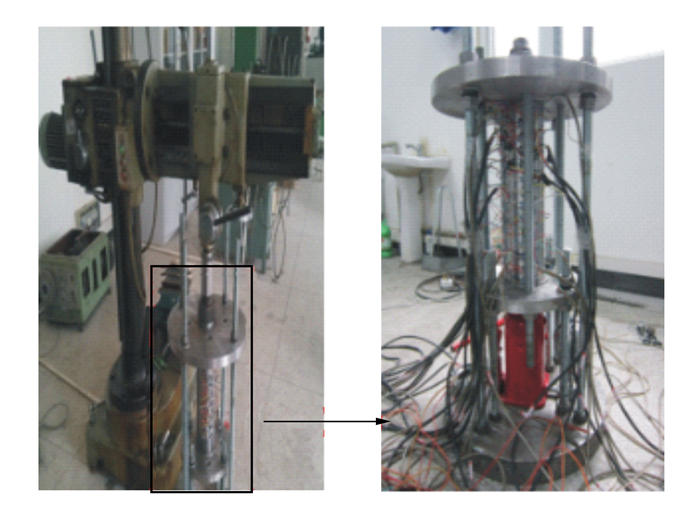

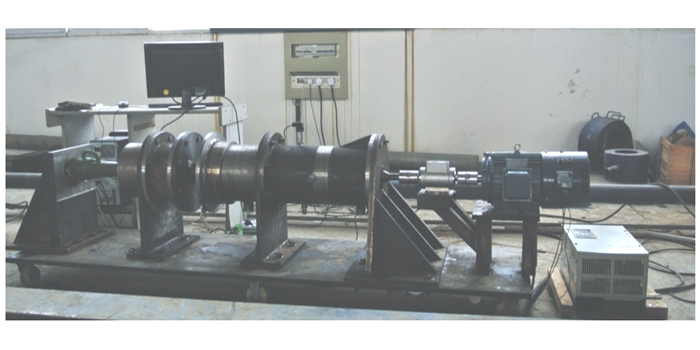

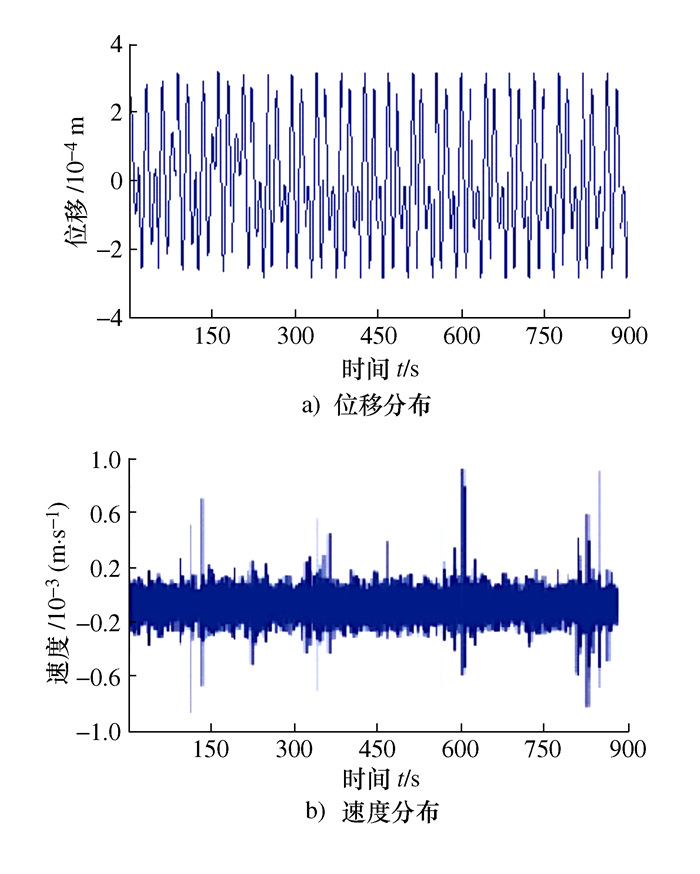

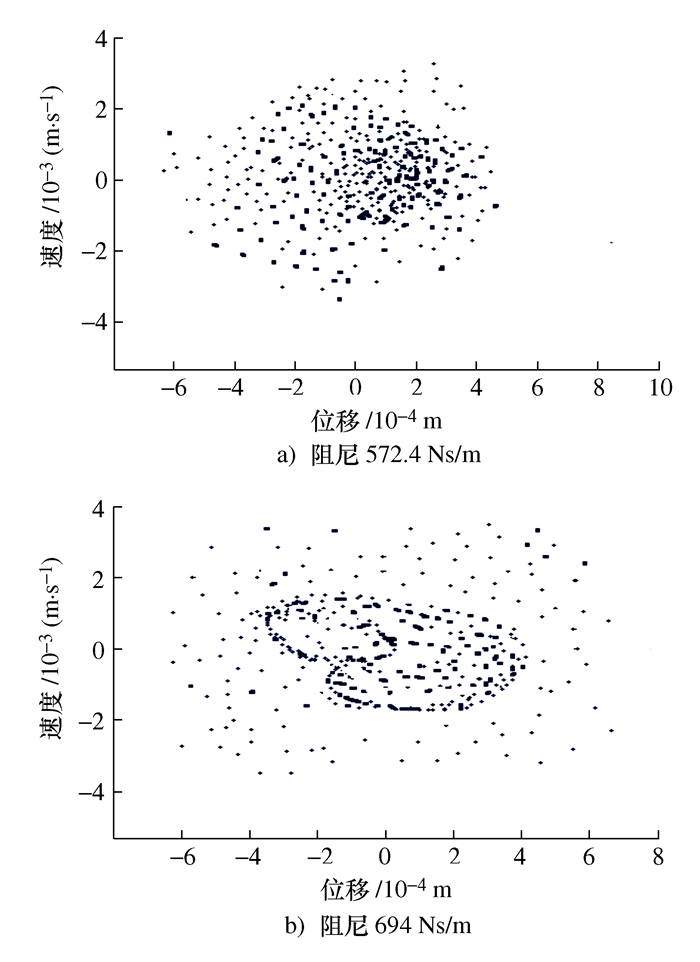

摘要: 传动设备在安装和运行过程中,都会存在轴承间隙问题,它是影响轴承使用性能的因素之一,因此对轴承间隙的研究具有重要的理论意义与工程价值。为了确定轴承内间隙对轴承振动的影响,从轴承振动的动力学特性入手,建立了2-DOF滚动轴承的理论模型。对测试的轴承,基于赫兹弹性接触理论分析滚动轴承动力学特性,轴承内圈平衡点的个数取决于轴承间隙的大小。当轴承间隙e<4.5 μm时,有一个稳定的平衡点,而且在平衡点中心附近,轴承内圈存在周期振动;当轴承间隙e≥4.5 μm时,随着轴承间隙和转速的不断增加,系统会产生混沌振动,发生混沌振动的区域也不断增多。同时,对Ø127滚动轴承的台架实验结果表明:在相同的阻尼参数、轴承尺寸和转速下,由实验数据得到的奇异吸引子的结果与通过求解运动方程结果接近,这种定性的结果不仅证实了轴承混沌行为的存在,而且验证了理论模型的可靠性。Abstract: During the installation and operation of transmission equipment, there always are bearing clearance problems, which is also one of the main reasons for bearing failure. Therefore, the research on the bearing clearance has important theoretical significance and engineering value. In order to determine the influence of bearing clearance on bearing vibration, the theoretical model of 2-DOF rolling bearing was established based on the dynamic characteristics of bearing vibration. For the tested bearing, the dynamic characteristics of the rolling bearing is analyzed based on the Hertz-elastic contact theory. It is known that the number of balance points of the inner ring of the bearing depends on the clearance of the bearing. When there is a gap (e < 4.5 μm) in the bearing, there is the stable equilibrium point, and near the center of the balance point, there is periodic vibration in the inner ring of the bearing. When there is a gap(e≥4.5 μm), as the gap and the rotational speed of the bearing increase continuously, the system will generate chaotic vibration, and the area where chaotic vibration occurs is also increasing. At the same time, the experimental results of the Ø127 rolling bearing shows that under the same damping parameters, bearing size and rotational speed, the results of the singular attractors obtained from the experimental data are close to those obtained by solving the equation of motion. This qualitative result not only confirms the existence of bearing chaotic behavior, but also verifies the reliability of the theoretical model.

-

Key words:

- bearing clearance /

- chaos /

- dynamics /

- test verification

-

表 1 Ø127涡轮钻具轴承的具体参数

材料 内圈直径 外圈直径 滚珠数目 滚珠直径 刚度 55SiMoVA 60 mm 113 mm 15 16.67 mm 9.81×109 Nm 表 2 测试轴承的具体参数

参数名称 轴承A Ø127轴承 滚动体直径/mm 7.938 16.670 内圈直径/mm 25.562 0 60.500 外圈直径/mm 41.438 0 113.000 节径/mm 33.5 55.000 轴承间隙/μm 20 20 滚动体数目 8 15 刚度(N·m-1) 9.21×109 9.81×109 -

[1] TALLIAN T E, GUSTAFSSON O G. Progress in rolling bearing vibration research and control[J]. ASLE Transactions, 1965, 8(3): 195-207 doi: 10.1080/05698196508972094 [2] AKTVRK N, UNEEB M, GOHAR R. The effects of number of balls and preload on vibrations associated with ball bearings[J]. Journal of Tribology, 1997, 119(4): 747-753 doi: 10.1115/1.2833880 [3] 白长青, 许庆余. 滚动轴承-偏置转子系统动力特性数值分析与实验研究[J]. 应用力学学报, 2007, 24(4): 540-543 doi: 10.3969/j.issn.1000-4939.2007.04.010BAI C Q, XU Q Y. Numerical and experimental research on dynamic performance of ball bearings-offset disk rotor system[J]. Chinese Journal of Applied Mechanics, 2007, 24(4): 540-543 (in Chinese) doi: 10.3969/j.issn.1000-4939.2007.04.010 [4] GAD E H, FUKATA S, TAMURA H. Computer simulation of rotor radial vibration due to ball bearings[J]. Memoirs of the Faculty of Engineering, Kyushu University, 1984, 44(1): 83-111 [5] 孙军, 桂长林, 李志远. 轴变形产生的轴颈倾斜对滑动轴承润滑影响的试验研究[J]. 机械工程学报, 2006, 42(7): 159-163 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200607029.htmSUN J, GUI C L, LI Z Y. Experimental research for effect of journal misalignment on performances of journal bearing[J]. Chinese Journal of Mechanical Engineering, 2006, 42(7): 159-163 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200607029.htm [6] 李洪亮, 陈予恕. 含间隙球轴承-转子系统的主共振研究[J]. 航空学报, 2013, 34(6): 1356-1362 https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201306015.htmLI H L, CHEN Y S. Primary resonance research on ball bearing-rotor system with bearing clearance[J]. Acta Aeronautica et Astronautica Sinica, 2013, 34(6): 1356-1362 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201306015.htm [7] 陈予恕. 非线性振动[J]. 北京: 高等教育出版社, 2002CHEN Y S. Nonlinear vibrations[M]. Beijing: Higher Education Press, 2002 (in Chinese) [8] 郭瑞, 赵国瑶, 王志芳东等. 润滑油中不凝结气体对滑动轴承间隙流场特性影响研究[J]. 机械工程学报, 2016, 52(12): 152-157 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201612020.htmGUO R, ZHAO G Y, WANG Z F, et al. Studies on the influence of non-condensable gas contended in lubricating oil on performance of hydrodynamic journal bearing[J]. Journal of Mechanical Engineering, 2016, 52(12): 152-157 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201612020.htm [9] 魏维, 郭文勇, 吴新跃, 等. 考虑间隙影响的滑动轴承稳定性分析[J]. 润滑与密封, 2018, 43(10): 18-22 https://www.cnki.com.cn/Article/CJFDTOTAL-RHMF201810006.htmWEI W, GUO W Y, WU X Y, et al. Stability analysis on sliding bearing with consideration of clearance[J]. Lubrication Engineering, 2018, 43(10): 18-22 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-RHMF201810006.htm [10] 陈果. 带碰摩耦合故障的转子-滚动轴承-机匣耦合动力学模型[J]. 振动工程学报, 2007, 20(4): 361-368 https://www.cnki.com.cn/Article/CJFDTOTAL-ZDGC200704007.htmCHEN G. Rotor-ball bearing-stator coupling dynamic model including rubbing coupling faults[J]. Journal of Vibration Engineering, 2007, 20(4): 361-368 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDGC200704007.htm [11] 杨金福, 刘占生, 于达仁, 等. 滑动轴承非线性动态油膜力及稳定性的研究[J]. 动力工程, 2004, 24(4): 501-504+597 https://www.cnki.com.cn/Article/CJFDTOTAL-DONG200404010.htmYANG J F, LIU Z S, YU D R, et al. Research on nonlinear oil film force and its stability of journal bearing[J]. Power Engineering, 2004, 24(4): 501-504+597 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DONG200404010.htm [12] 熊万里, 侯志泉, 吕浪, 等. 基于动网格模型的液体动静压轴承刚度阻尼计算方法[J]. 机械工程学报, 2012, 48(23): 118-126 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201223019.htmXIONG W L, HOU Z Q, LYU L, et al. Method for calculating stiffness and damping coefficients of hybrid bearings based on dynamic mesh model[J]. Journal of Mechanical Engineering, 2012, 48(23): 118-126 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201223019.htm [13] 李元生, 敖良波, 李磊, 等. 滑动轴承动力特性系数动态分析方法[J]. 机械工程学报, 2010, 46(21): 48-53 https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201021009.htmLI Y S, AO L B, LI L, et al. Dynamic analysis method of dynamic character coefficient of hydrodynamic journal bearing[J]. Journal of Mechanical Engineering, 2010, 46(21): 48-53 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201021009.htm -

下载:

下载: