Multiaxial Fatigue Analysis of Casting Crane Considering Wheel Pressure Loads

-

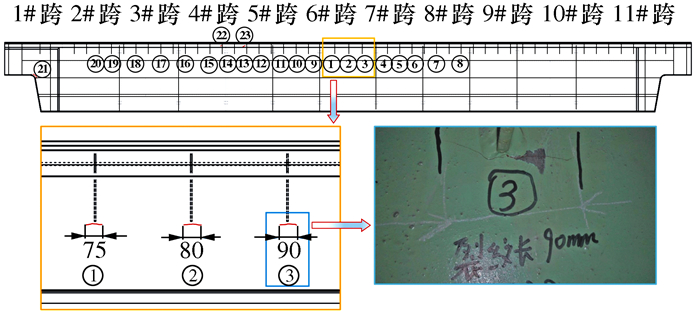

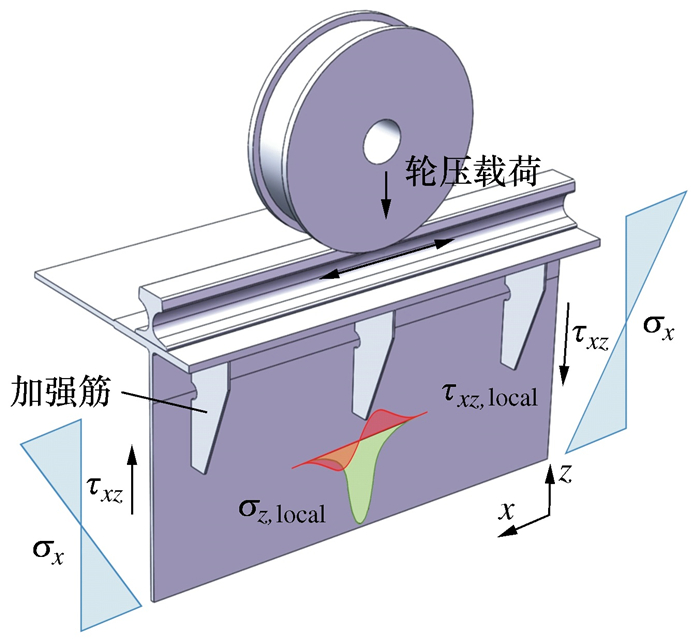

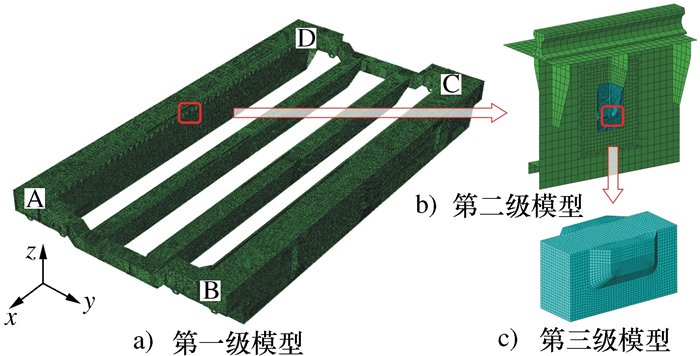

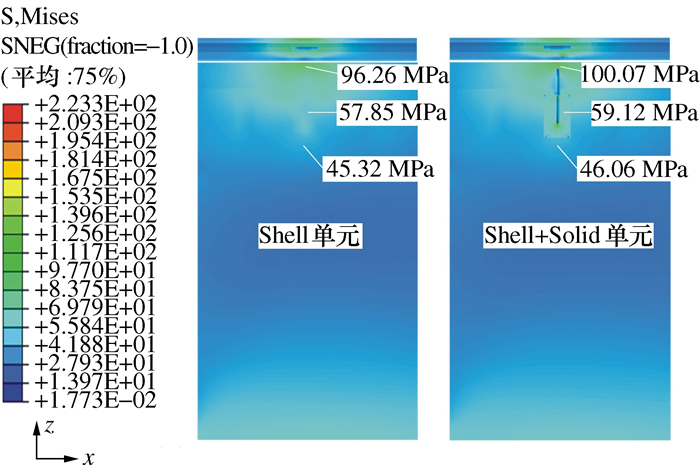

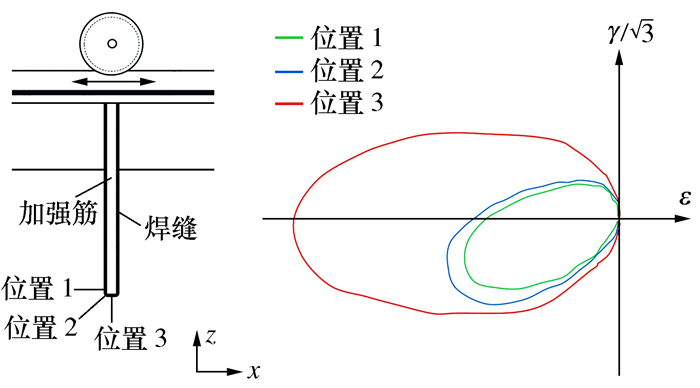

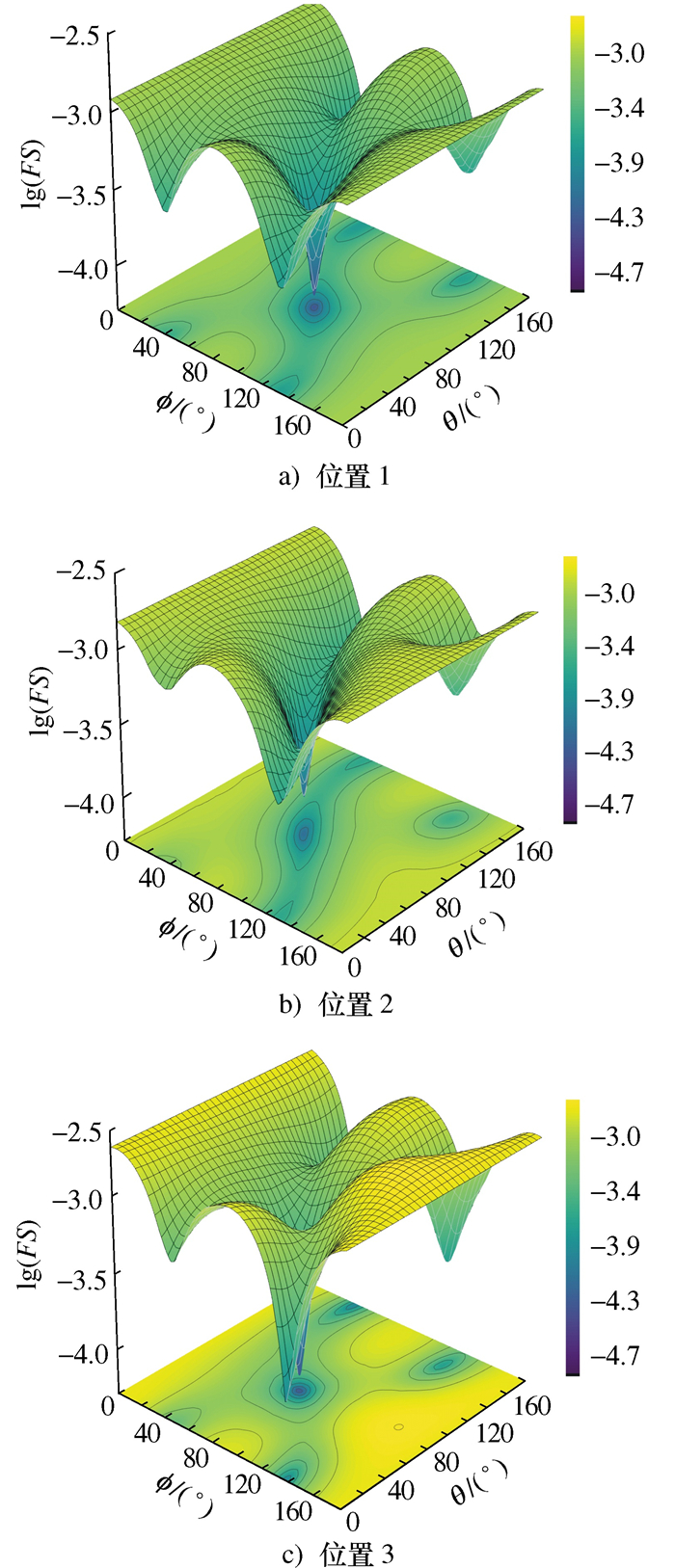

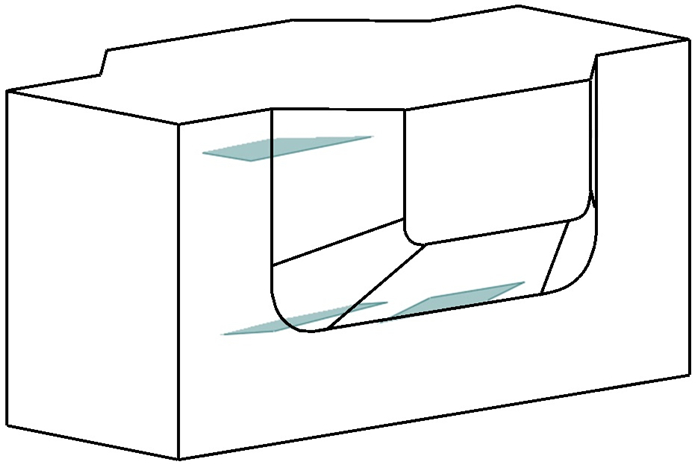

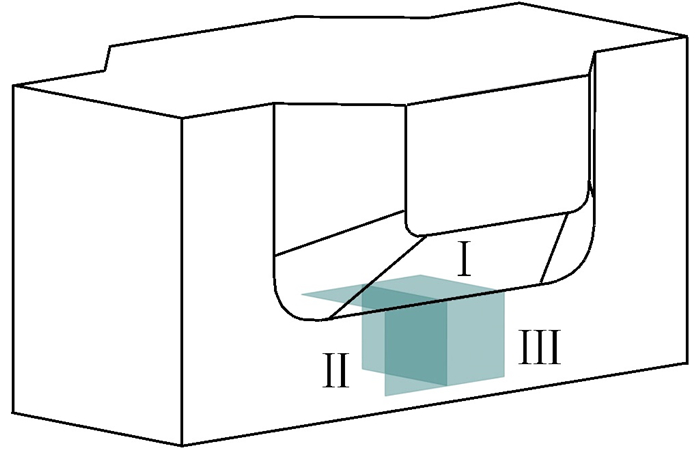

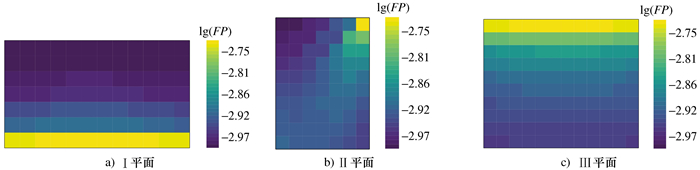

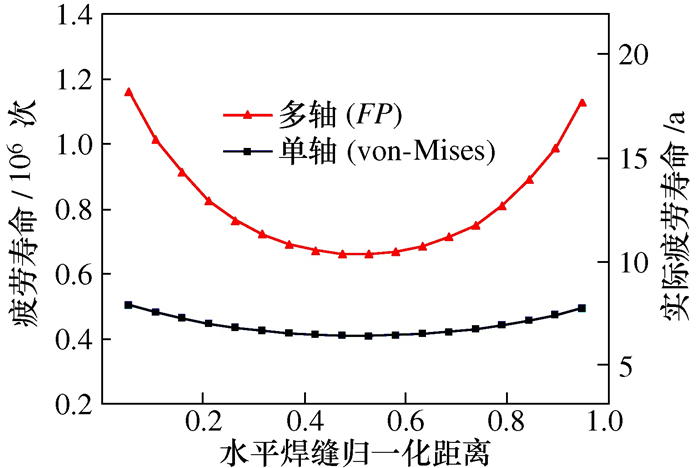

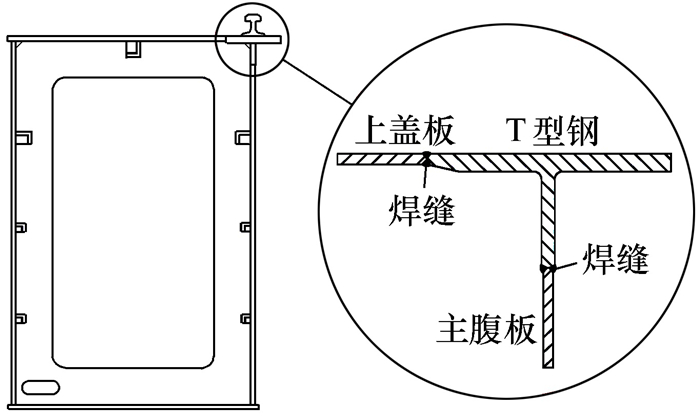

摘要: 铸造起重机金属结构是一种典型的复杂焊接结构,在移动轮压载荷和复杂焊缝几何的共同作用下,一些非常规部位时常出现疲劳裂纹。针对某在役铸造起重机主梁轨道下方T型钢与小筋板连接焊缝区域发生的密集疲劳裂损问题,采用Soild-Shell混合单元和子模型技术,建立了裂损局部区域的精细有限元模型,模拟了移动轮压载荷作用下整体金属结构的完整应力时间历程,分析了裂损部位的多轴特性。采用基于临界平面法的多轴疲劳模型,计算并讨论了裂损区域的疲劳性能。结果表明:多轴应力是导致裂损部位萌生裂纹的主要原因,F-S多轴疲劳模型可以有效评估裂损部位的疲劳性能。Abstract: The metal structure of casting crane is a typical complex welding structure. Under the combined action of moving wheel pressure load and complex weld geometry, fatigue cracks often appear in several unconventional locations. In view of the intensive fatigue damage problem in the connection area of T-shaped steel and small rib plate under the main beam track of an in-service casting crane, the Soild-Shell mixed element and sub-model technology were used to establish the fine finite element model for crack area. The complete stress change process of the whole metal structure under the action of moving wheel pressure load was simulated, and the obvious multiaxial characteristics of the crack area were analyzed. The multiaxial fatigue model based on the critical plane method were used to calculate and discuss the fatigue performance of the crack area. The results show that the multiaxial stress is the main reason for the initiation of cracks at the crack area, and the F-S multiaxial fatigue model can effectively evaluate the fatigue performance of the crack area.

-

Key words:

- casting crane /

- wheel pressure load /

- multiaxial fatigue /

- life prediction

-

表 1 Q345弹塑性本构模型参数

Table 1. Parameters of Q345 elastoplastic constitutive model

E/MPa ν K/MPa n 2.05×105 0.3 679.933 0.109 -

[1] 渠晓刚, 温鑫, 张晓康. 基于损伤力学的桥式起重机疲劳寿命分析[J]. 安全与环境学报, 2021, 21(3): 1012-1016. https://www.cnki.com.cn/Article/CJFDTOTAL-AQHJ202103013.htmQU X G, WEN X, ZHANG X K. Assessing and analysis of the fatigue life of the bridge-type crane based on the damage mechanics[J]. Journal of Safety and Environment, 2021, 21(3): 1012-1016. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-AQHJ202103013.htm [2] 辛运胜, 董青, 徐格宁. 轨道连接处缺陷对起重机运行冲击系数及疲劳剩余寿命的影响[J]. 机械工程学报, 2020, 56(14): 254-264. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202014026.htmXIN Y S, DONG Q, XU G N. Influence of rail joint defects on the running impact coefficient and fatigue residual life of crane[J]. Journal of Mechanical Engineering, 2020, 56(14): 254-264. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202014026.htm [3] 杨正茂, 孟文俊. 基于支持向量机的桥式起重机金属结构非概率可靠性分析[J]. 机械科学与技术, 2015, 34(3): 381-385. doi: 10.13433/j.cnki.1003-8728.2015.0312YANG Z M, MENG W J. Non-probabilistic reliability analysis of bridge crane metal structure based on support vector machine[J]. Mechanical Science and Technology for Aerospace Engineering, 2015, 34(3): 381-385. (in Chinese) doi: 10.13433/j.cnki.1003-8728.2015.0312 [4] 魏国前, 施棋博, 刘京. 铸造起重机金属结构的疲劳评定方法研究[J]. 机械设计与制造, 2018(9): 128-131. https://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ201809037.htmWEI G Q, SHI Q B, LIU J. Investigation on fatigue evaluation method for casting crane metal structure[J]. Machinery Design & Manufacture, 2018(9): 128-131. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSYZ201809037.htm [5] 周超, 万金镇, 郑健. 基于等效结构应力法的起重机箱形结构焊缝疲劳强度分析[J]. 机械设计与制造, 2013(5): 232-234. doi: 10.3969/j.issn.1001-3997.2013.05.071ZHOU C, WAN J Z, ZHENG J. The weld fatigue strength analysis of box girder with equivalent stress method[J]. Machinery Design & Manufacture, 2013(5): 232-234. (in Chinese) doi: 10.3969/j.issn.1001-3997.2013.05.071 [6] 焦学勇. 大车轨道对铸造起重机开裂的影响[J]. 起重运输机械, 2022(7): 45-49. https://www.cnki.com.cn/Article/CJFDTOTAL-QZJJ202207006.htmJIAO X Y. Influence of cart track on cracking of casting crane[J]. Hoisting and Conveying Machinery, 2022(7): 45-49. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-QZJJ202207006.htm [7] 平克楠. 铸造起重机主要结构易发生损伤破坏的部位类型危害及控制[J]. 科技与创新, 2019(6): 11-13. https://www.cnki.com.cn/Article/CJFDTOTAL-KJYX201906004.htmPING K N. Damage and control of parts of main structure of casting crane that are prone to damage[J]. Science and Technology & Innovation, 2019(6): 11-13. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-KJYX201906004.htm [8] KETTLER M, DERLER C, SCHÖRGHOFER A, et al. Laboratory and numerical tests on real crane runway girder with box section[J]. Journal of Constructional Steel Research, 2019, 160: 540-558. doi: 10.1016/j.jcsr.2019.06.002 [9] EULER M, KUHLMANN U. Crane runways-Fatigue evaluation of crane rail welds using local concepts[J]. International Journal of Fatigue, 2011, 33(8): 1118-1126. doi: 10.1016/j.ijfatigue.2011.02.010 [10] RETTENMEIER P, ROOS E. Fatigue assessment of full-scale welded crane runway girders[J]. Materials Testing, 2015, 57(2): 110-118. doi: 10.3139/120.110687 [11] RETTENMEIER P, ROOS E, WEIHE S. Fatigue analysis of multiaxially loaded crane runway structures including welding residual stress effects[J]. International Journal of Fatigue, 2016, 82: 179-187. doi: 10.1016/j.ijfatigue.2015.04.009 [12] KHERKHAR A, CHIBA Y, TLEMANI A, et al. Thermal investigation of a thermoelectric cooler based on Arduino and PID control approach[J]. Case Studies in Thermal Engineering, 2022, 36: 102249. doi: 10.1016/j.csite.2022.102249 [13] FATEMI A, SOCIE D F. A critical plane approach to multiaxial fatigue damage including out-of-phase loading[J]. Fatigue & Fracture of Engineering Materials & Structures, 1988, 11(3): 149-165. [14] LI J, LIU J, SUN Q, et al. A modification of Smith-Watson-Topper damage parameter for fatigue life prediction under non-proportional loading[J]. Fatigue & Fracture of Engineering Materials & Structures, 2012, 35(4): 301-316. [15] HOBBACHER A. Recommendations for fatigue design of welded joints and components; IIW Doc. IIW-1823-07 (rev of. IIW XIII 1539-96)[Z]. The International Institute of Welding (IIW), 2008. -

下载:

下载: