Multi-objective Optimization of Elliptic Opening Offset Parabola Micro-texture in Port Plate Pair of Axial Piston Pump

-

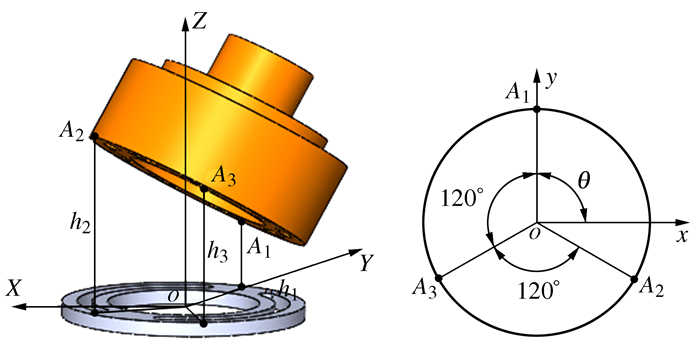

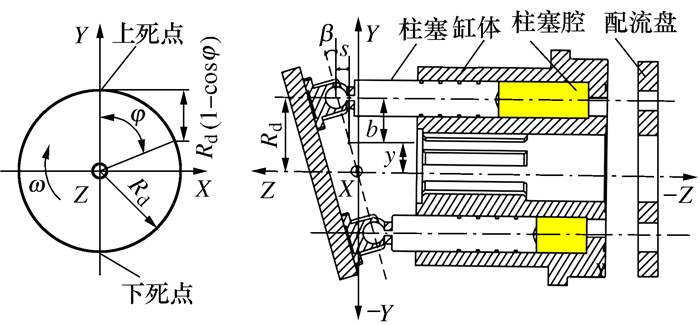

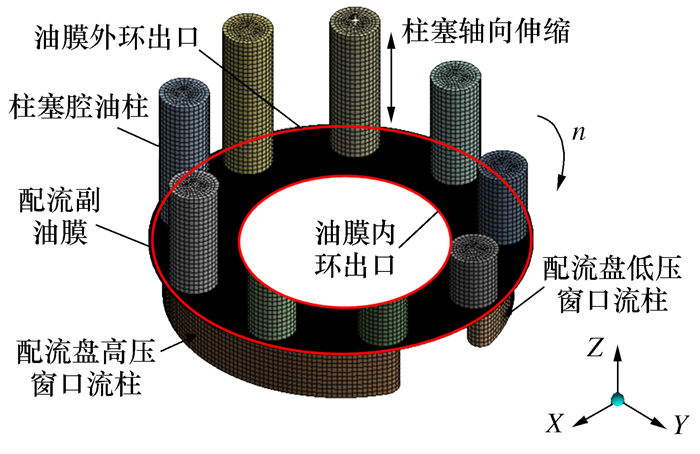

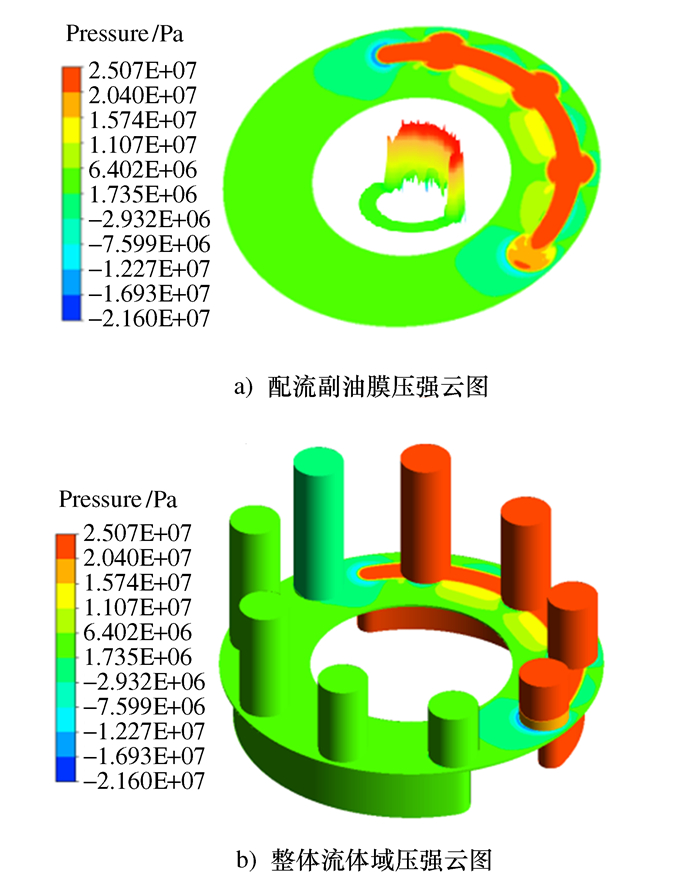

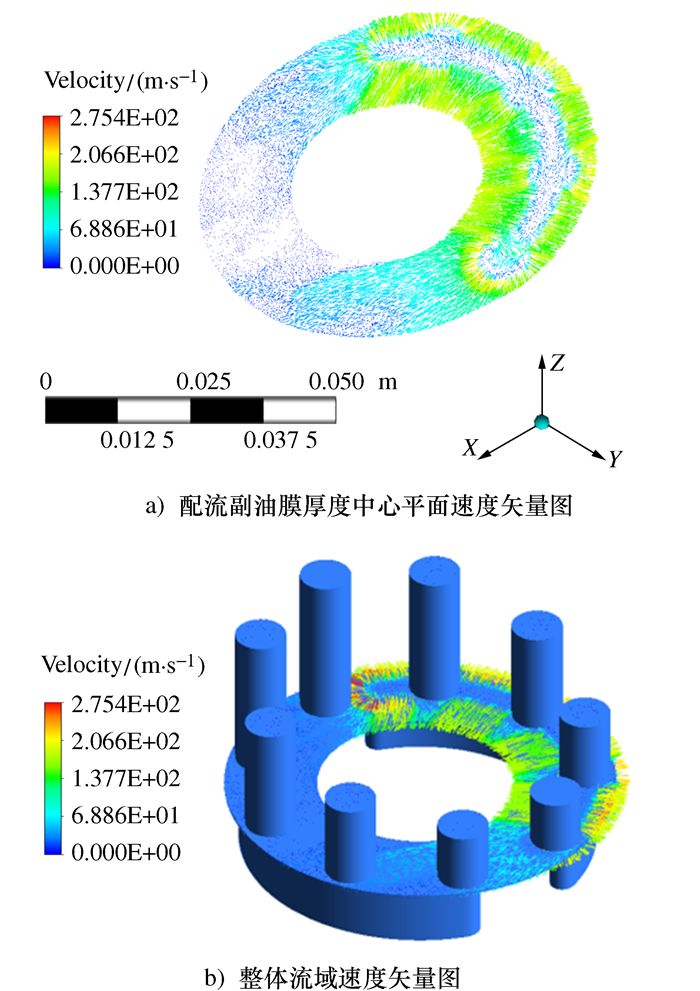

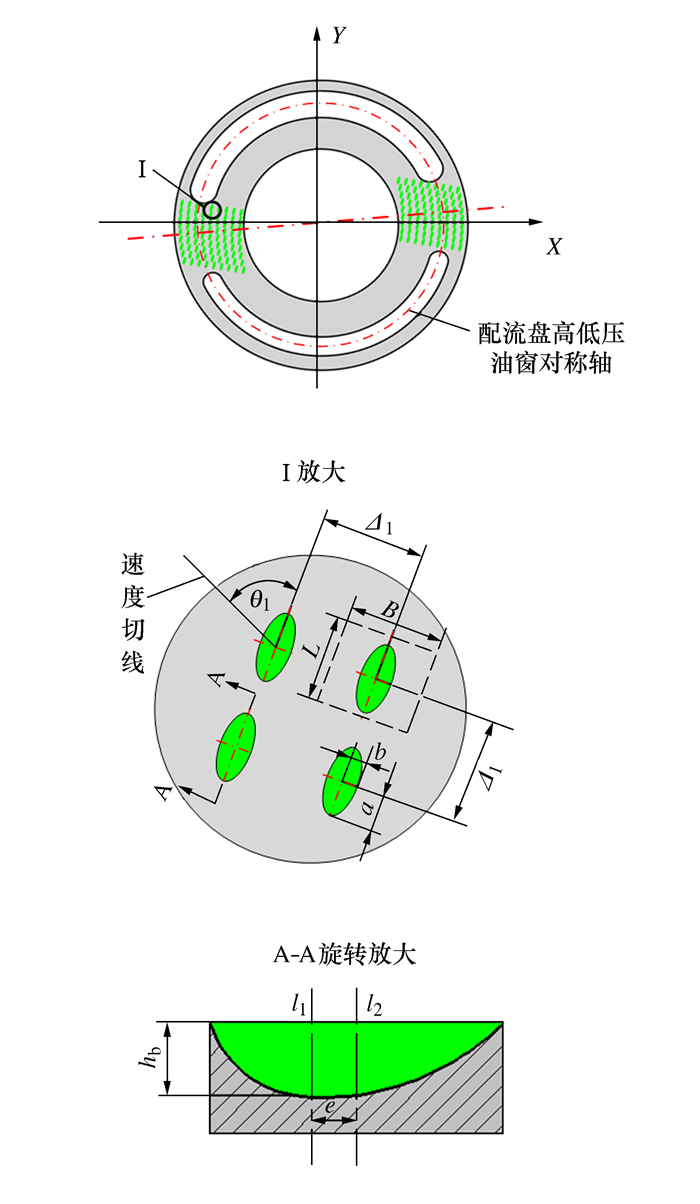

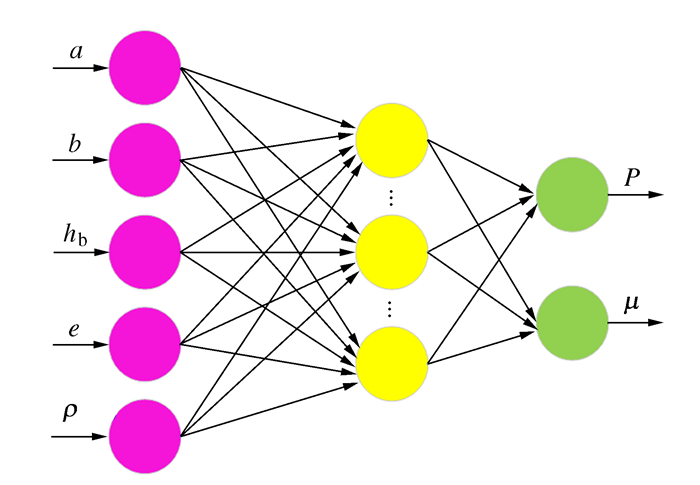

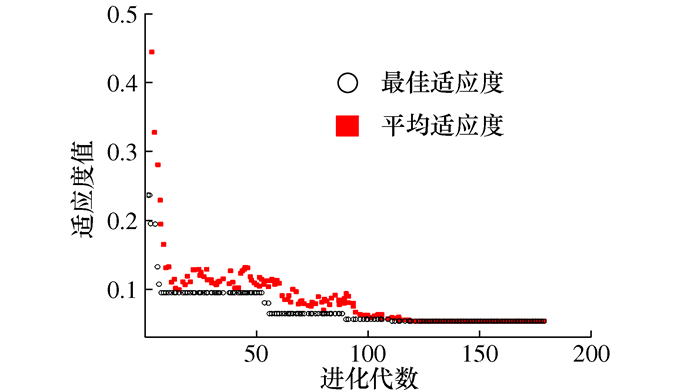

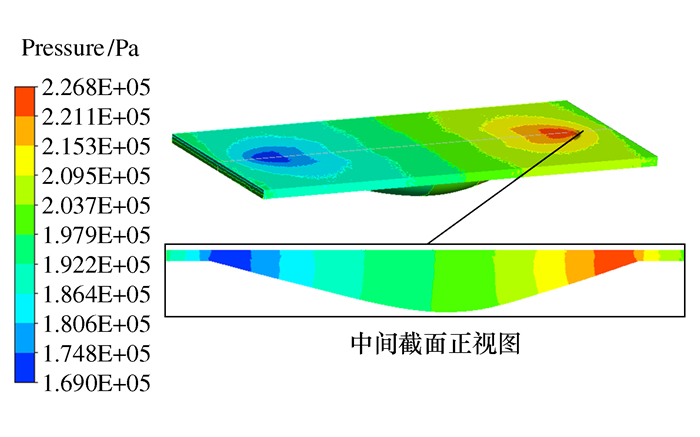

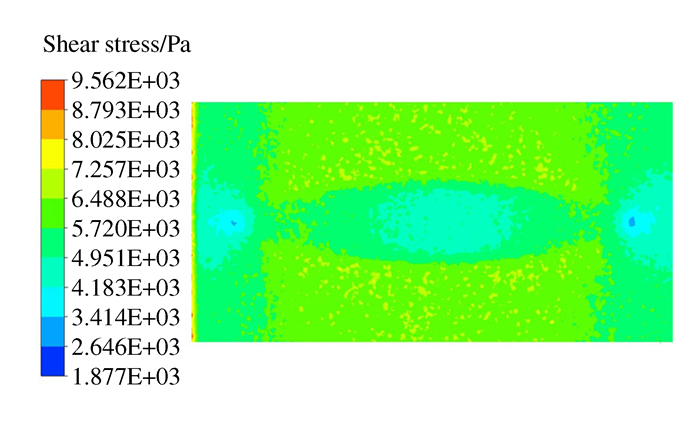

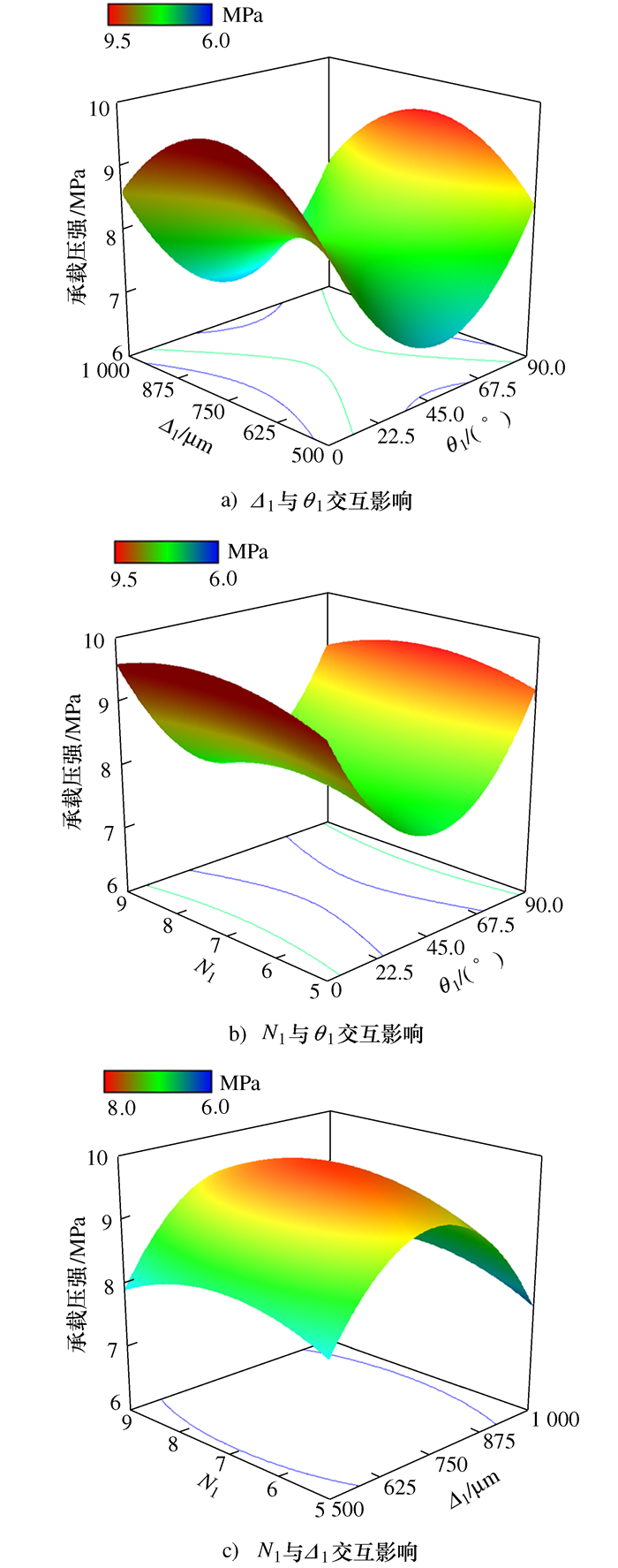

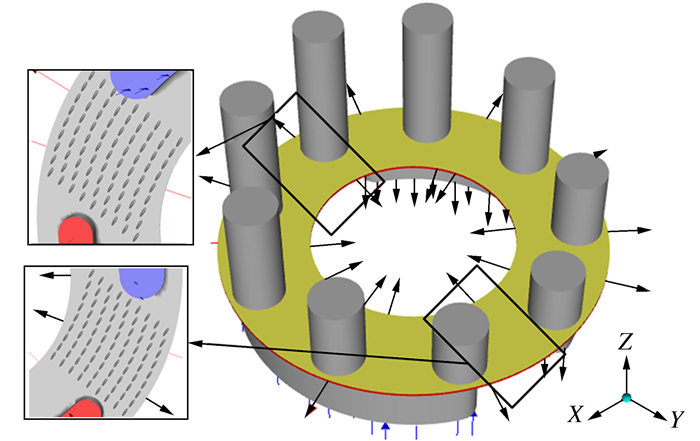

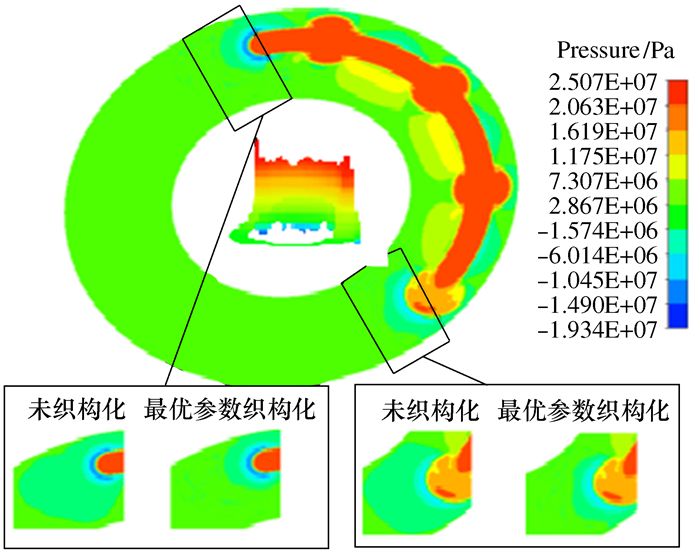

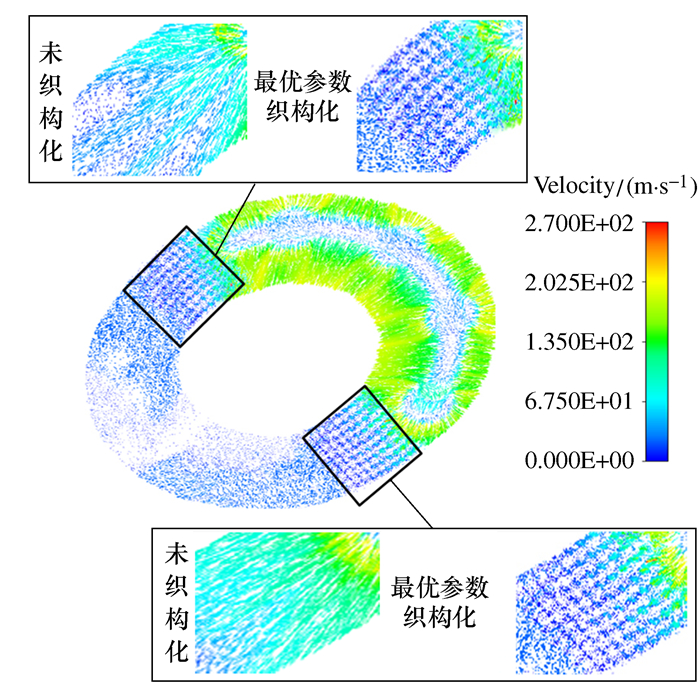

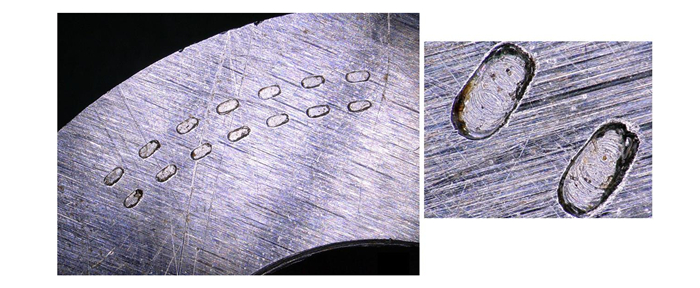

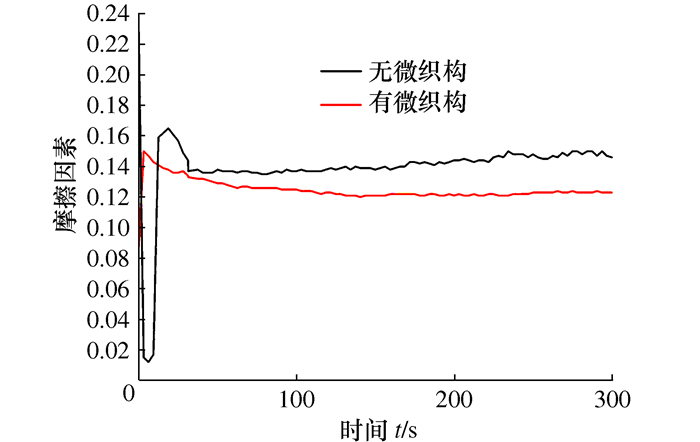

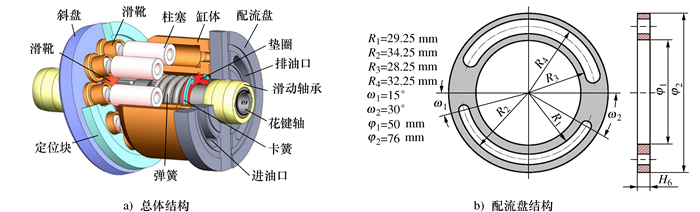

摘要: 为了提高轴向柱塞泵配流副承载性能、抗摩擦磨性能及容积效率,以某型斜盘式轴向柱塞泵配流盘为原型开展研究。首先,依据正交实验理论采用CFD方法研究椭圆开口偏置抛物线微织构(Elliptic opening offset parabola micro texture,EOOPT)形状参数对轴向柱塞泵配流副承载压强、摩擦因数的影响规律,并联合运用神经网络和遗传算法对EOOPT的形状参数进行优化设计。其次,运用响应面分析方法研究EOOPT分布参数对配流副承载压强、摩擦因数和泄漏量的影响规律,并对形状参数进行优化设计。最后对最优特征参数EOOPT织构化的柱塞泵配流副和未织构的相关性能进行对比分析,结果表明,前者的承载压强较后者提高11.23%,摩擦因数和泄漏量分别减低16.67%和2.96%。Abstract: In order to improve the bearing pressure, friction-wear resistance and loss-volume efficiency of the port plate pair of an axial piston pump, the port plate of a swash-plate axial piston pump was taken as the prototype to study the influence of shape parameters of elliptic opening offset parabola micro-texture (EOOPT) on the bearing pressure and friction coefficient of the port plate pair with the CFD method based on the orthogonal experimental theory. The shape parameters of EOOPT are optimized with the neural network and the genetic algorithm jointly. Then, the response surface analysis was used to study the influence of EOOPT distribution parameters on the bearing pressure, friction coefficient and leakage amount of the port plate pair, and the shape parameters were optimized. Finally, the relative performance of the port plate pair with the EOOPT texture is compared with that of the port plate pair without EOOPT texture. The results show that the bearing pressure of the former is 11.23% higher than that of the latter and that the friction coefficient and leakage amount are reduced by 16.67% and 2.96% respectively.

-

Key words:

- port plate pair /

- micro-texture /

- bearing pressure /

- leakage amount /

- multi-objective optimization

-

表 1 主要参数

Table 1. Main parameters

参数 油运动黏度η/(mm2·s-1) 柱塞分布圆半径Rd/mm 柱塞直径d/mm 斜盘倾角β/(°) 泵轴转速n/(r·min-1) 油密度ρ/(kg·m-3) 入口压力Pin/MPa 出口压力Pout/MPa 数值 16×10-6 31.75 20 18 1 500 900 0.2 25 表 2 形状参数正交实验方案及仿真分析结果

Table 2. Orthogonal experimental scheme and simulation analysis results of shape parameters

试验序号 a/μm b/μm hb/μm e/μm ρ0 p/Pa μ 1 240 80 80 0 0.2 210 907 0.033 2 240 120 100 20 0.4 210 707 0.032 3 240 160 120 40 0.6 210 702 0.032 4 240 200 140 60 0.8 56 001 0.188 5 240 240 160 80 1.0 157 032 0.053 6 300 80 100 40 0.8 210 832 0.033 7 300 120 120 60 1.0 112 922 0.073 8 300 160 140 80 0.2 210 349 0.030 9 300 200 160 0 0.4 210 002 0.029 10 300 240 80 20 0.6 210 963 0.030 11 360 80 120 80 0.4 210 805 0.032 12 360 120 140 0 0.6 210 101 0.031 13 360 160 160 20 0.8 210 227 0.030 14 360 200 80 40 1.0 211 250 0.031 15 360 240 100 60 0.2 210 344 0.028 16 420 80 140 20 1.0 211 189 0.032 17 420 120 160 40 0.2 209 897 0.030 18 420 160 80 60 0.4 211 147 0.030 19 420 200 100 80 0.6 211 344 0.028 20 420 240 120 0 0.8 210 223 0.027 21 480 80 160 60 0.6 208 735 0.029 22 480 120 80 80 0.8 211 620 0.031 23 480 160 100 0 1.0 76 446 0.141 24 480 200 120 20 0.2 209 830 0.025 25 480 240 140 40 0.4 210 281 0.023 表 3 极差分析结果

Table 3. Range analysis results

因素 a/μm b/μm hb/μm e/μm ρ0 K11 169 070 21 0494 211 178 183 536 210 265 K12 191 014 19 1049 183 935 210 583 210 589 K13 210 545 18 3774 190 896 210 592 210 369 K14 210 760 17 9685 179 584 159 830 179 780 K15 183 383 19 9769 199 179 200 230 153 768 R1 41 690 30 808 31 593 50 762 56 820 K21 0.068 0.032 0.031 0.052 0.028 K22 0.039 0.039 0.052 0.030 0.029 K23 0.030 0.052 0.038 0.030 0.030 K24 0.029 0.060 0.061 0.070 0.062 K25 0.050 0.032 0.034 0.035 0.066 R2 0.038 0.028 0.030 0.040 0.037 表 4 分布参数正交实验方案及仿真分析结果

Table 4. Distributed parameter orthogonal experiment scheme and simulation analysis results

序号 θ1/(°) Δ1/μm N1 p/MPa Q/(L·s-1) μ 1 45 750 8 7.68 0.136 3 0.003 8 2 45 750 7 7.80 0.136 2 0.003 8 3 90 1 000 9 7.88 0.130 4 0.003 7 4 45 750 7 7.80 0.136 3 0.003 8 5 45 750 7 7.80 0.136 3 0.003 8 6 90 500 9 8.10 0.133 8 0.003 6 7 0 500 5 8.37 0.139 8 0.003 5 8 45 750 6 8.17 0.138 0 0.003 6 9 90 1000 5 7.90 0.136 5 0.003 7 10 45 625 7 7.64 0.136 8 0.003 9 11 22.5 750 7 8.56 0.139 9 0.003 5 12 0 500 9 8.43 0.132 9 0.003 5 13 0 1 000 5 8.07 0.137 5 0.003 6 14 0 1 000 9 8.49 0.132 8 0.003 5 15 45 750 7 7.80 0.136 3 0.003 8 16 90 500 5 8.15 0.136 5 0.003 6 17 45 750 7 7.80 0.136 3 0.003 8 18 45 750 7 7.80 0.136 3 0.003 8 19 45 875 7 7.80 0.136 3 0.003 8 20 67.5 750 7 8.34 0.137 1 0.003 5 -

[1] 郭长虹, 罗进, 权凌霄, 等. 十一柱塞航空泵转子系统轴径比对功重比的影响[J]. 机械科学与技术, 2022, 41(2): 213-219. doi: 10.13433/j.cnki.1003-8728.20200316GUO C H, LUO J, QUAN L X, et al. Influence of shaft diameter ratio of eleven plunger aviation pump rotor system on power to weight ratio[J]. Mechanical Science and Technology for Aerospace Engineering, 2022, 41(2): 213-219. (in Chinese) doi: 10.13433/j.cnki.1003-8728.20200316 [2] CHEN Y, ZHANG J H, XU B, et al. Multi-objective optimization of micron-scale surface textures for the cylinder/valve plate interface in axial piston pumps[J]. Tribology International, 2019, 138: 316-329. doi: 10.1016/j.triboint.2019.06.002 [3] IVANTYSYNOVA M, BAKER J. Power loss in the lubricating gap between cylinder block and valve plate of swash plate type axial piston machines[J]. International Journal of Fluid Power, 2009, 10(2): 29-43. doi: 10.1080/14399776.2009.10780976 [4] ZHAO J A, FU Y L, MA J M, et al. Review of cylinder block/valve plate interface in axial piston pumps: theoretical models, experimental investigations, and optimal design[J]. Chinese Journal of Aeronautics, 2021, 34(1): 111-134. doi: 10.1016/j.cja.2020.09.030 [5] YE S G, TANG H S, REN Y, et al. Study on the load-carrying capacity of surface textured slipper bearing of axial piston pump[J]. Applied Mathematical Modelling, 2020, 77: 554-584. doi: 10.1016/j.apm.2019.07.058 [6] WANG W, HE Y Y, ZHAO J, et al. Optimization of groove texture profile to improve hydrodynamic lubrication performance: theory and experiments[J]. Friction, 2020, 8(1): 83-94. doi: 10.1007/s40544-018-0247-1 [7] 于英华, 王智群, 要金龙, 等. 机床滑动导轨微织构多目标优化设计[J]. 航空制造技术, 2022, 65(6): 36-44. https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ202206003.htmYU Y H, WANG Z Q, YAO J L, et al. Multi-objective optimization design of micro-texture of sliding guideway in machine tool[J]. Aeronautical Manufacturing Technology, 2022, 65(6): 36-44. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKGJ202206003.htm [8] 许长坤, 郭智威, 缪晨炜, 等. 活塞环表面织构密度对缸套-活塞环摩擦性能的影响[J]. 机械科学与技术, 2020, 39(10): 1489-1496. doi: 10.13433/j.cnki.1003-8728.20200133XU C K, GUO Z W, MIAO C W, et al. Effect of texture density in surface of piston ring on tribological performance of cylinder liner-piston ring[J]. Mechanical Science and Technology for Aerospace Engineering, 2020, 39(10): 1489-1496. (in Chinese) doi: 10.13433/j.cnki.1003-8728.20200133 [9] ATWAL J C, PANDEY R K. Film thickness and friction investigations in a fluid film thrust bearing employing a new conceived micro-texture on pads[J]. Journal of Tribology, 2021, 143(6): 061801. doi: 10.1115/1.4048500 [10] DENG H S, HE S J, MAO F Y, et al. Effects of micropit depths on tribology performance of textured port plate pair[J]. Advances in Materials Science and Engineering, 2018, 2018: 9501708. [11] 毋少峰. 仿生非光滑表面配流副润滑承载机理数值模拟及摩擦磨损实验研究[D]. 秦皇岛: 燕山大学, 2017.WU S F. Simulation research on lubrication-bearing mechanism and experiment study on friction-wear for port pair with bionic non smooth surface[D]. Qinhuangdao: Yanshan University, 2017. (in Chinese) [12] 李朝阳, 刘志奇, 仉志强, 等. HMn58-2配流盘摩擦副表面激光加工微阵列对其摩擦磨损性能的影响[J]. 液压与气动, 2020(5): 33-39. https://www.cnki.com.cn/Article/CJFDTOTAL-YYYQ202005008.htmLI C Y, LIU Z Q, ZHANG Z Q, et al. Influence of the laser processing micro array on the friction pair surface of HMn58-2 valve plate to its friction and wear performance[J]. Chinese Hydraulics & Pneumatics, 2020(5): 33-39. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YYYQ202005008.htm [13] 张瑜, 陈国定, 王琳, 等. 空化与惯性效应耦合作用下的非对称表面微织构滑块承载力分析[J]. 西北工业大学学报, 2017, 35(12): 1026-1032. https://www.cnki.com.cn/Article/CJFDTOTAL-XBGD201706014.htmZHANG Y, CHEN G D, WANG L, et al. Analysis of bearing load-carrying capacity with asymmetric surface textures under coupling effects of cavitation and inertia effect[J]. Journal of Northwestern Polytechnical University, 2017, 35(12): 1026-1032. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-XBGD201706014.htm [14] 许路. 高压高速轴向柱塞泵配流副润滑特性研究[D]. 北京: 北京理工大学, 2016.XU L. Study on the lubrication characteristics of the valve plate bearing in hydraulic axial piston pump[D]. Beijing: Beijing Institute of Technology, 2016. (in Chinese) [15] 甘海. 轴向柱塞泵配流副流场仿真及三角减振槽参数特性分析[D]. 哈尔滨: 哈尔滨工业大学, 2014.GAN H. Simulation of flow filed for axial piston pump cylinder block-valve plate interface and parameters characteristic analysis of triangular relief groove[D]. Harbin: Harbin Institute of Technology, 2014. (in Chinese) -

下载:

下载: