Fluid-structure Interaction Modeling and Vibration Characteristics of Check Valve in High-pressure Diaphragm Pump

-

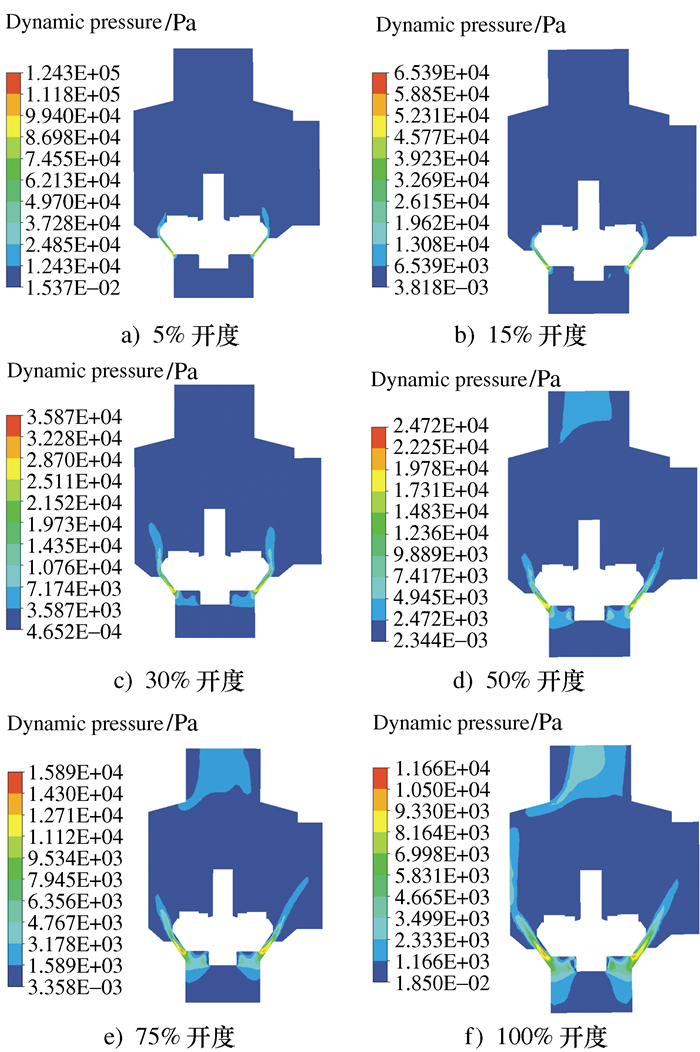

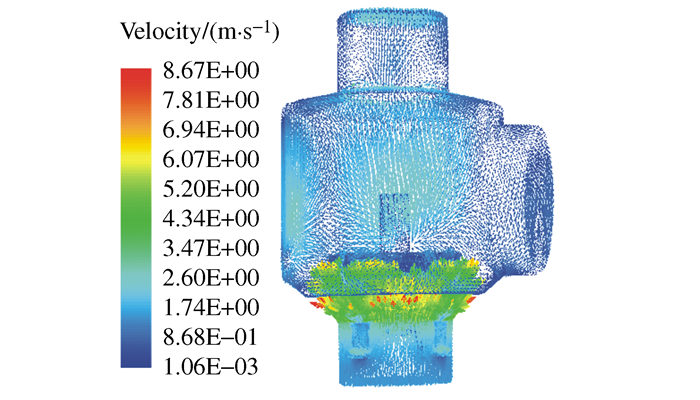

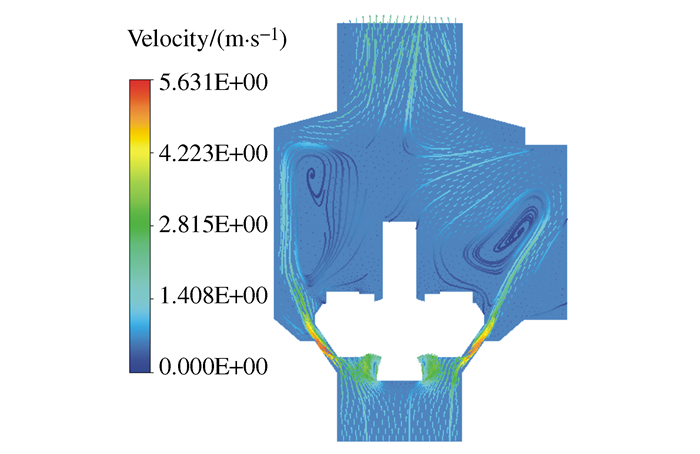

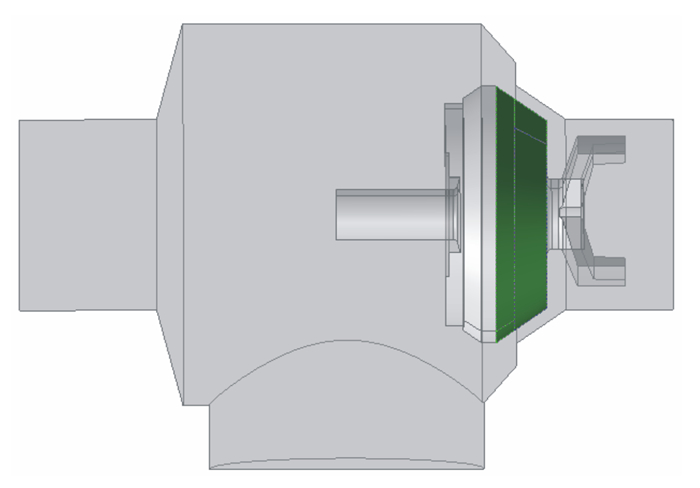

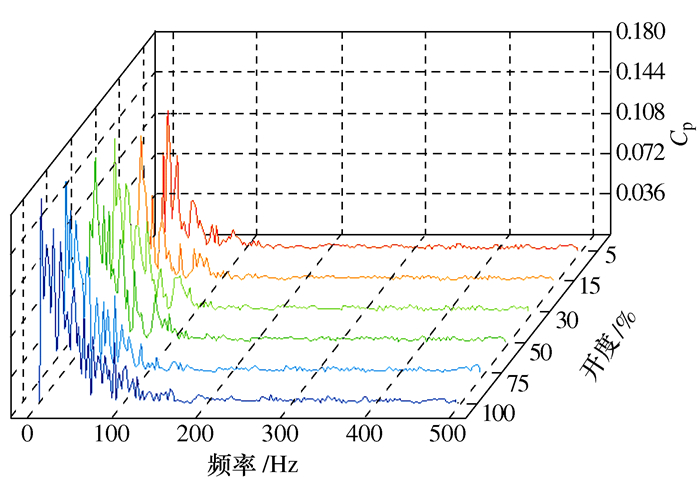

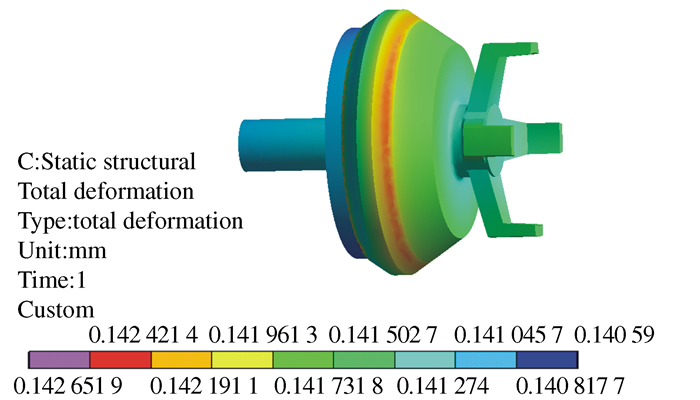

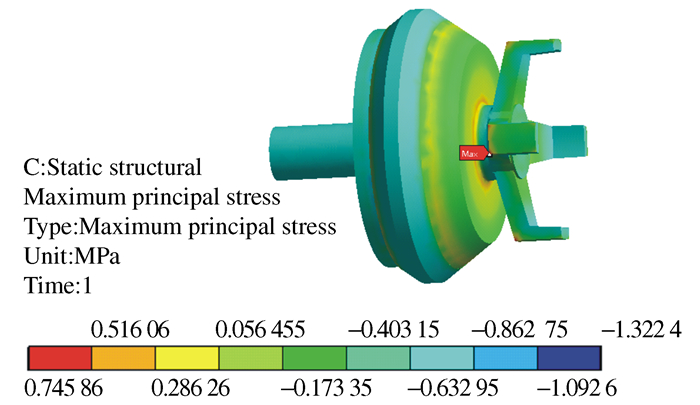

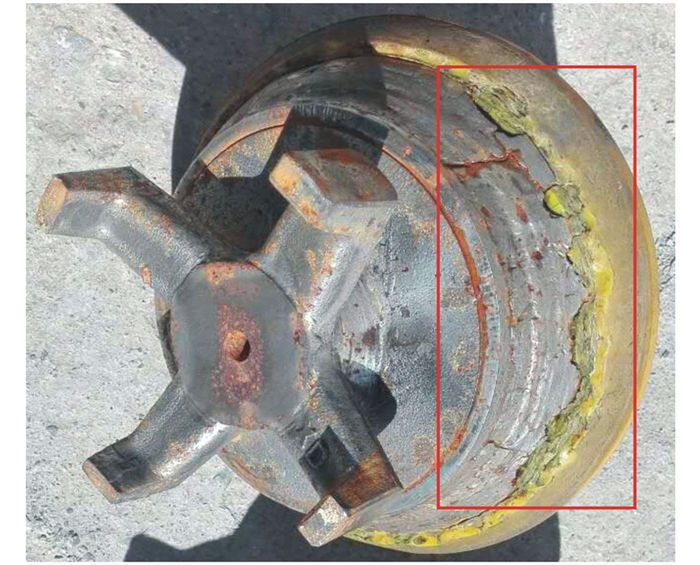

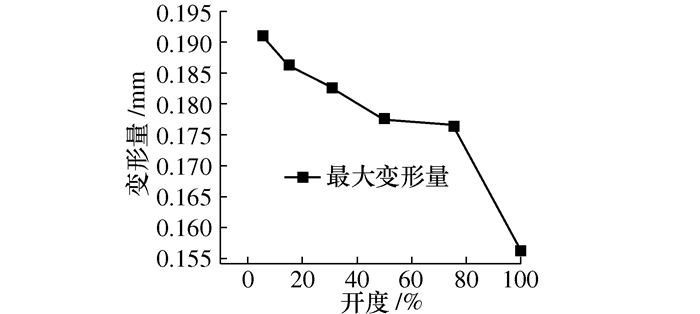

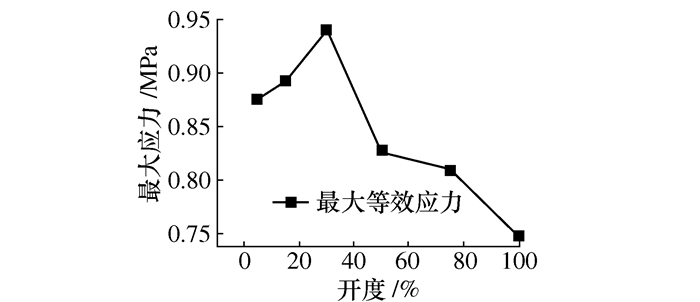

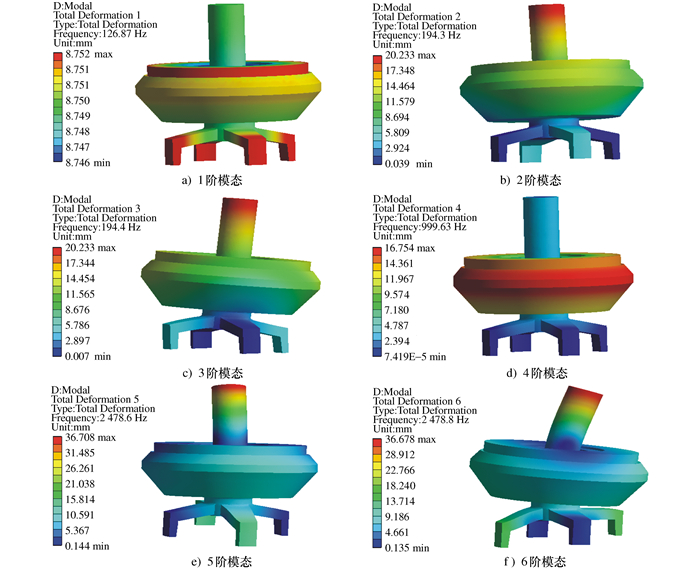

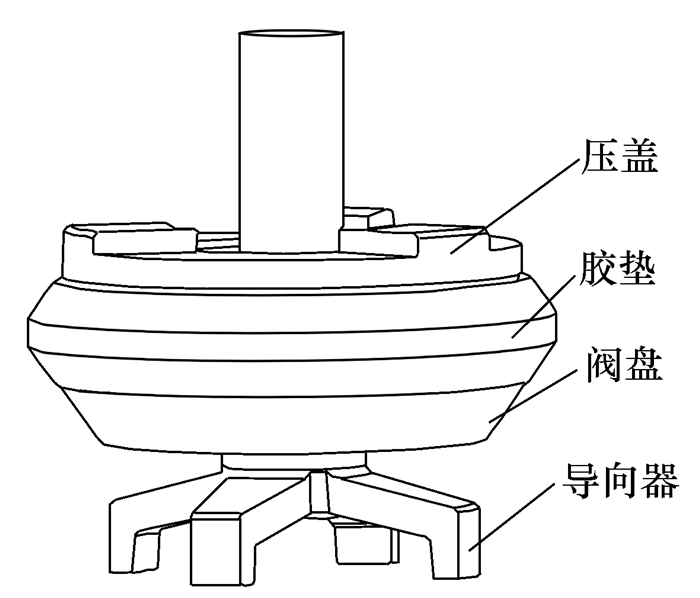

摘要: 针对单向阀开启过程中强迫振动产生的根源和流激振动问题,构建了开度为5%、15%、30%、50%、75%和100%的流固耦合仿真模型,对不同开度情况下的流体与固体场特性以及流体施加于阀芯上的流激振力进行数值分析,得到了流场压力云图、速度矢量云图和流激振力脉动峰值频率以及阀芯在各开度下的模态振型和固有频率。结果表明:单向阀开启过程中,阀芯两侧存在较大的压差,变形区域主要集中于胶垫,阀腔内高速流体与低速流体接触时出现剪切形成涡流,流动涡流周期性变化产生的流激振力导致阀芯被迫振动,阀芯上的流激振力脉动峰值频率分布范围逐渐增加且波动更大。Abstract: Aiming at the root causes of forced vibration and flow-induced vibration problems during the opening process of the check valve, a fluid-structure interaction simulation model with different opening degrees of 5%, 15%, 30%, 50%, 75% and 100% was constructed. The characteristics of the fluid and solid fields and the flow-exciting force exerted by the fluid on the valve spool were numerically analyzed, and the pressure cloud map of the flow field, the velocity vector cloud map, the peak frequency of the flow-induced vibration force, and mode shapes and natural frequencies of the valve core at each opening degree were obtained. The results show that: during the opening process of the check valve, there is a large pressure difference on both sides of the valve core, and the deformation area is mainly concentrated in the rubber pad. When the high-speed fluid in the valve cavity contacts the low-speed fluid, a vortex is formed by shearing, and the flow vortex changes periodically. The flow-exciting force generated by the vortex causes the spool vibration, and the peak frequency distribution of the flow-exciting force pulsation on the spool gradually increases and fluctuates more.

-

表 1 流体域网格无关性检验数据

Table 1. Data for fluid domain grid independence verification

网格单元数 出口流量/(kg·s-1) 出口平均流速/(m·s-1) 652 305 8.890 46 1.531 28 834 665 8.865 54 1.542 75 985 210 8.862 36 1.543 94 表 2 单向阀零部件材料参数

Table 2. Material parameters of check valve components

材料 密度/(kg·m-3) 弹性模量/MPa 泊松比 20CrNiMo 7.870×103 2.08×105 0.295 PU 1.26×103 2.41×103 0.450 表 3 单向阀各开度下固有频率

Table 3. Natural frequencies of the check valve at various openings

开度/ % 固有频率/Hz 1阶 2阶 3阶 4阶 5阶 6阶 5 126.82 193.99 194.05 998.81 2 478.12 2 478.21 15 126.85 194.12 194.14 999.42 2 478.14 2 478.32 30 126.85 194.25 194.32 999.38 2 478.56 2 478.65 50 126.87 194.31 194.41 999.63 2 478.61 2 478.82 75 126.88 194.53 194.45 999.59 2 478.32 2 478.75 100 126.89 194.56 194.52 999.75 2 478.36 2 478.85 表 4 单向阀的固有频率仿真值与理论值对比

Table 4. Comparison of simulated and theoretical values of natural frequencies of the check valve

开度/% 仿真值/Hz 理论值/Hz 误差/% 5 126.82 120.56 5.19 15 126.85 120.61 5.17 30 126.85 120.66 5.13 50 126.87 120.74 5.08 75 126.88 120.78 5.05 100 126.89 120.81 5.03 -

[1] 周成江. 矿浆管道输送系统的隔膜泵单向阀故障诊断研究[D]. 昆明: 昆明理工大学, 2020.ZHOU C J. Research on fault diagnosis of diaphragm pump check valve in slurry pipeline transportation system[D]. Kunming: Kunming University of Science and Technology, 2020. (in Chinese) [2] GUIDARA M A, TAIEB L H, TAÏEB E H. Determina- tion of natural frequencies in piping systems using transfer matrix method[C]//Proceedings of the Sixth Conference on Design and Modeling of Mechanical Systems on Design and Modeling of Mechanical Systems-Ⅱ. Hammamet, Tunisia: Springer, 2015: 765-774. [3] WU S, WEI X H. A new integrated numerical modeling approach toward piston diaphragm pump simulation: Three-dimensional model simplification and characteristic analysis[J]. Advances in Mechanical Engineering, 2019, 11(6): 1-11. [4] BAZSÓ C, HÓS C J. An experimental study on the stability of a direct spring loaded poppet relief valve[J]. Journal of Fluids and Structures, 2013, 42: 456-465. doi: 10.1016/j.jfluidstructs.2013.08.008 [5] YI D Y, LU L, ZOU J, et al. Interactions between poppet vibration and cavitation in relief valve[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2015, 229(8): 1447-1461. doi: 10.1177/0954406214544304 [6] 张伟政, 赵鹏博, 张作丽, 等. 大口径蝶阀流固耦合特性及共振特性的研究[J]. 振动与冲击, 2021, 40(9): 278-284. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202109037.htmZHANG W Z, ZHAO P B, ZHANG Z L, et al. Fluid-structure interaction and resonance characteristics of large diameter butterfly valve[J]. Journal of Vibration and Shock, 2021, 40(9): 278-284. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202109037.htm [7] 闵为, 王东, 郑直, 等. 压力调节锥阀开启过程振动特性研究[J]. 振动与冲击, 2020, 39(18): 181-187. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202018024.htmMIN W, WANG D, ZHENG Z, et al. Vibration characteristics of a pressure regulating poppet valve during opening process[J]. Journal of Vibration and Shock, 2020, 39(18): 181-187. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202018024.htm [8] 王雯, 傅卫平, 孔祥剑, 等. 单座式调节阀阀芯-阀杆系统流固耦合振动研究[J]. 农业机械学报, 2014, 45(5): 291-298. https://www.cnki.com.cn/Article/CJFDTOTAL-NYJX201405045.htmWANG W, FU W P, KONG X J, et al. Research on fluid-structure coupling vibration of valve core-stem system in a single-type control valve[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(5): 291-298. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-NYJX201405045.htm [9] 肖斌, 周玉龙, 高超, 等. 考虑流体附加质量的输流管道振动特性分析[J]. 振动与冲击, 2021, 40(15): 182-188. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202115023.htmXIAO B, ZHOU Y L, GAO C, et al. Analysis of vibration characteristics of pipeline with fluid added mass[J]. Journal of Vibration and Shock, 2021, 40(15): 182-188. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202115023.htm [10] YU C G, YU Z B, LIU Z Z, et al. The research on vibration analysis of blow-down wind tunnel pressure regulating valves[J]. Applied Mechanics and Materials, 2013, 397-400: 621-624. doi: 10.4028/www.scientific.net/AMM.397-400.621 [11] LI S X, ZHU L, WANG W B, et al. Analysis of thermal-fluid-structure coupling and resonance forecast for link butterfly valve under small opening[J]. Journal of Shanghai Jiaotong University (Science), 2019, 24(3): 341-350. doi: 10.1007/s12204-019-2061-y [12] 王伟波, 郝娇山, 刘柏圻, 等. LNG超低温调节阀阀杆流激共振分析[J]. 振动与冲击, 2021, 40(3): 218-225. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202103030.htmWANG W B, HAO J S, LIU B Q, et al. Flow-inducedresonance analysis of valve stem for LNG ultra-low temperature control valve[J]. Journal of Vibration and Shock, 2021, 40(3): 218-225. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202103030.htm [13] 王海芳, 任明, 王晨炜, 等. 单向阀阀芯的振动可靠性分析[J]. 中国工程机械学报, 2019, 17(1): 85-89. https://www.cnki.com.cn/Article/CJFDTOTAL-GCHE201901018.htmWANG H F, REN M, WANG C W, et al. Vibration reliability analysis of the check valve spool[J]. Chinese Journal of Construction Machinery, 2019, 17(1): 85-89. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GCHE201901018.htm [14] LISOWSKI E, FILO G. Analysis of a proportional control valve flow coefficient with the usage of a CFD method[J]. Flow Measurement and Instrumentation, 2017, 53: 269-278. doi: 10.1016/j.flowmeasinst.2016.12.009 [15] 徐海良, 周卓, 杨放琼, 等. 矿浆泵内转速对固液流体速度矢量分布的影响分析[J]. 机械科学与技术, 2017, 36(3): 329-334. doi: 10.13433/j.cnki.1003-8728.2017.0301XU H L, ZHOU Z, YANG F Q, et al. Analysis on influence of rotational speed on solid-liquid flow velocity vector distribution in slurry pump[J]. Mechanical Science and Technology for Aerospace Engineering, 2017, 36(3): 329-334. (in Chinese) doi: 10.13433/j.cnki.1003-8728.2017.0301 [16] 钱锦远, 吴嘉懿, 金志江. 调节阀振动特征的研究进展[J]. 振动与冲击, 2020, 39(11): 1-13. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202011001.htmQIAN J Y, WU J Y, JIN Z J. Research progress on vibration characteristics of regulation valve[J]. Journal of Vibration and Shock, 2020, 39(11): 1-13. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202011001.htm [17] CAO F, WANG Y. Modal analysis on fluid-structure interaction system of a large-scale gas control valve[J]. Advanced Materials Research, 2011, 305: 15-18. doi: 10.4028/www.scientific.net/AMR.305.15 [18] 朱红钧. ANSYS 14.5热流固耦合实战指南[M]. 北京: 人民邮电出版社, 2014.ZHU H J. ANSYS 14.5 heat-fluid-structure interaction practical guide[M]. Beijing: People Post Press, 2014. (in Chinese) -

下载:

下载: