Study on Die Repairing Technology Using Additive/Subtractive Hybrid Manufacturing

-

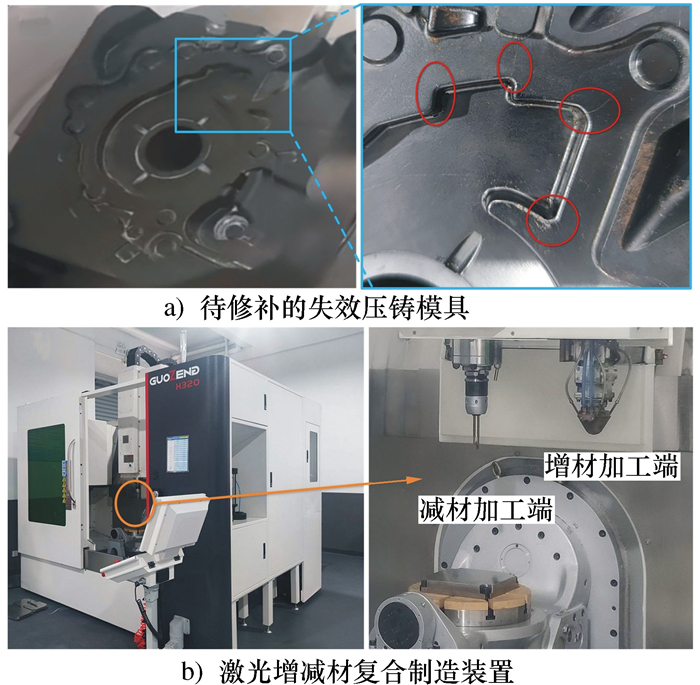

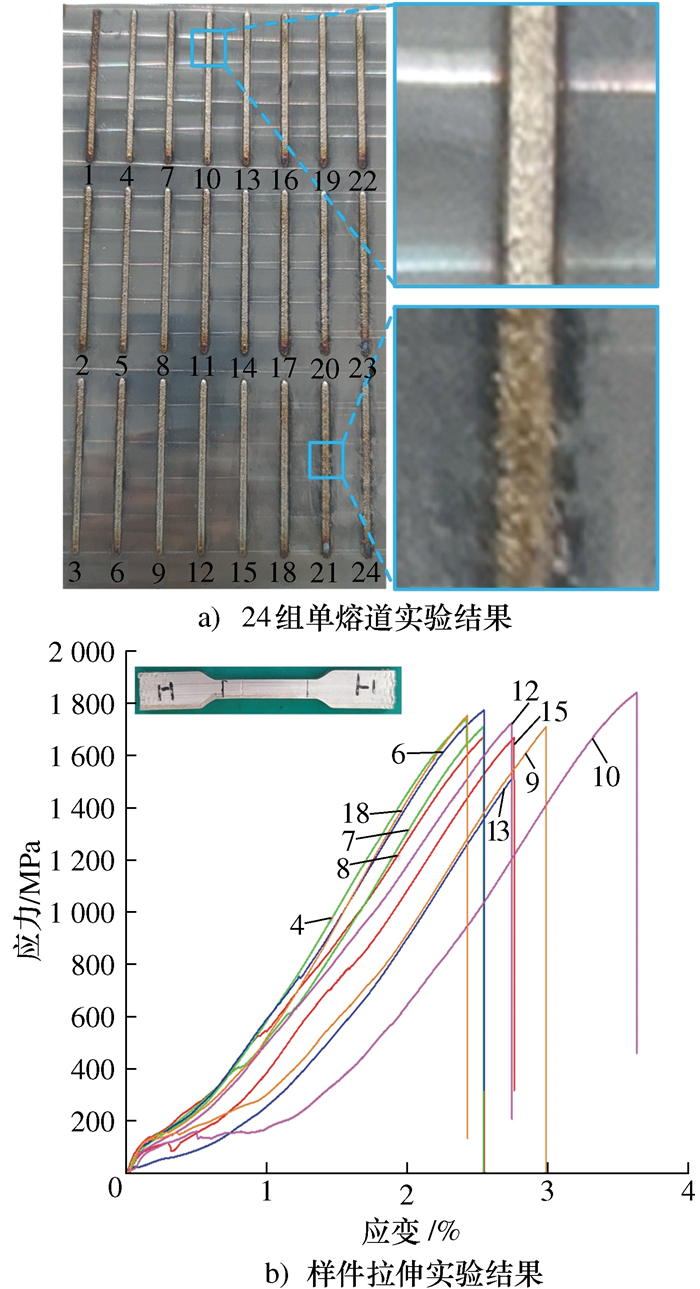

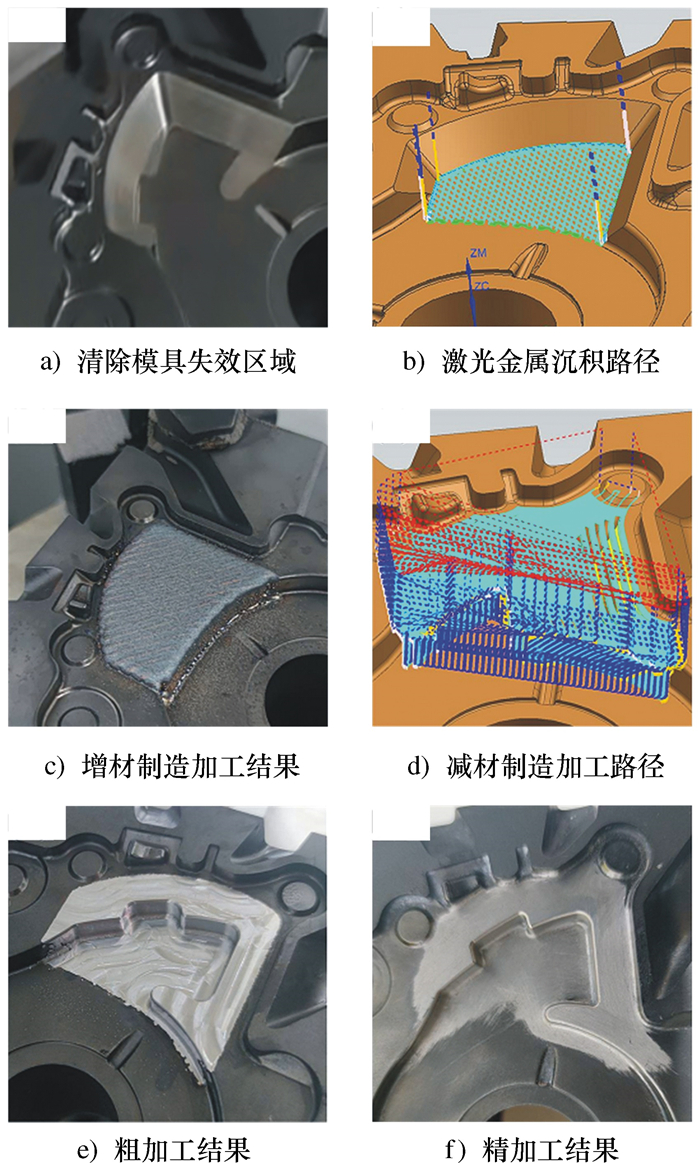

摘要: 激光金属沉积增减材复合制造技术是实现模具等高附加值部件修复与再制造的理想候选工艺之一。为了提高模具修复的效率和精度,本文将增减材复合制造技术应用于模具修复领域,并且对修复工艺进行研究。首先根据具体使用工况和材料性能要求,确定了最佳模具修复参数,随后讨论了该模具修复工艺的应用条件和应用范围。实验结果表明: 利用本文提出工艺方案进行模具修复时可以实现修复区域无拼接痕迹,并且修复区域硬度提升7.4 HRC,能够有效提升模具的使用性能。Abstract: Laser metal deposition with powder additive/subtractive hybrid manufacturing technology is an ideal candidate processing for repairing and remanufacturing of high value tools and dies. In order to improve the efficiency and accuracy of die repairing, the process of die repairing by using the additive/subtractive hybrid manufacturing technology is studied. In the first, the optimal repairing parameters are determined according to the specific operating conditions and material performance requirements. In addition, the application conditions and scope of the repairing process are also discussed. It is demonstrated through the experimental results that when the present technological plan is applied, the die can be repaired without stitching traces, and the hardness increased by 7.4 HRC, the performance of the die is improved.

-

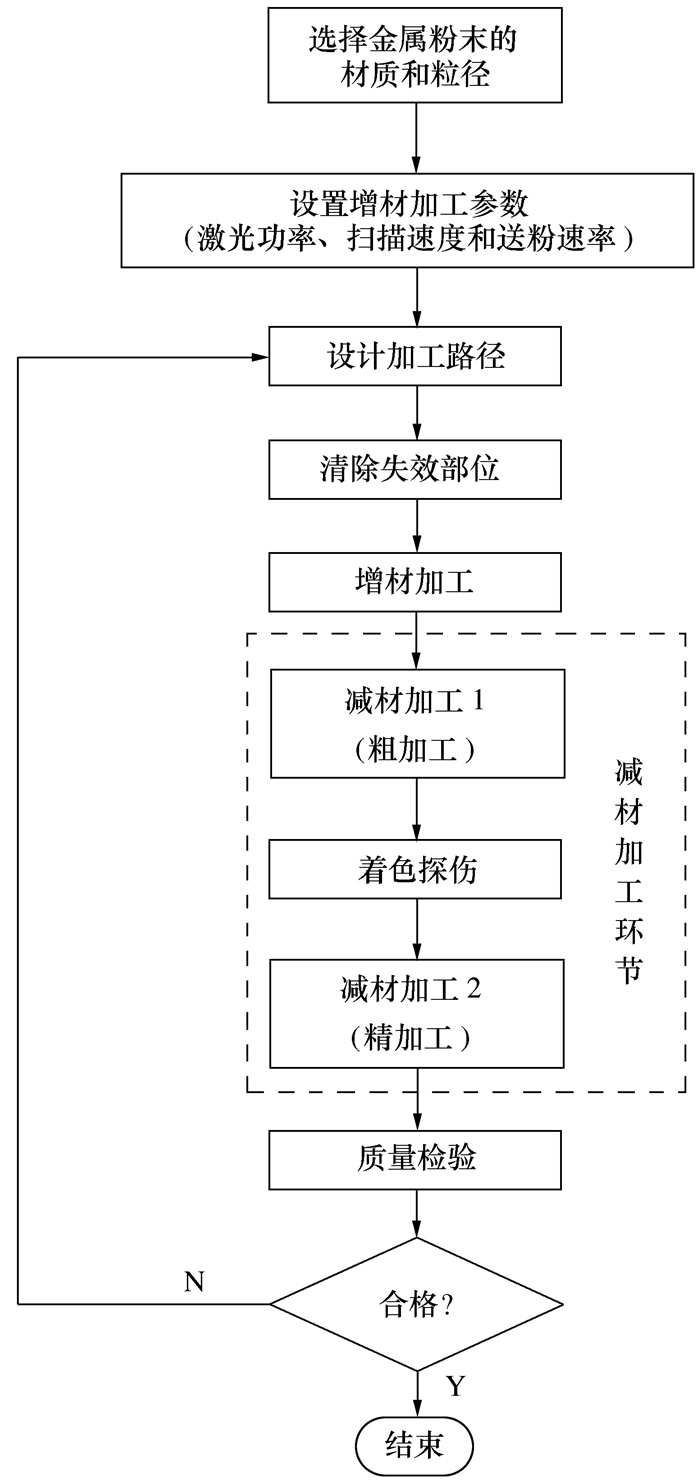

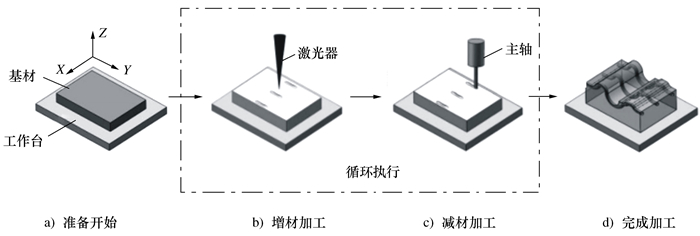

图 1 激光增减材复合制造工艺流程示意图[2]

Figure 1. Schematic diagram of laser additive and subtractive composite manufacturing process

表 1 参数优化实验使用的具体参数值

Table 1. Specific parameter values used in parameter optimization experiments

实验序号 激光功率/W 扫描速度/(mm·min-1) 送粉速率/(g·min-1) 1 1 000 500 7 2 1 000 600 7 3 1 000 700 7 4 1 000 500 9 5 1 000 600 9 6 1 000 700 9 7 1 100 500 7 8 1 100 600 7 9 1 100 700 7 10 1 100 500 9 11 1 100 600 9 12 1 100 700 9 13 1 200 500 7 14 1 200 600 7 15 1 200 700 7 16 1 200 500 9 17 1 200 600 9 18 1 200 700 9 19 1 300 500 7 20 1 300 600 7 21 1 300 700 7 22 1 300 500 9 23 1 300 600 9 24 1 300 700 9 -

[1] 卢秉恒. 增材制造技术——现状与未来[J]. 中国机械工程, 2020, 31(1): 19-23. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGJX202001008.htmLU B H. Additive manufacturing-current situation and future[J] China Mechanical Engineering, 2020, 31(1): 19-23. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGJX202001008.htm [2] 高孟秋, 赵宇辉, 赵吉宾, 等. 增减材复合制造技术研究现状与发展[J]. 真空, 2019, 56(6): 68-74. https://www.cnki.com.cn/Article/CJFDTOTAL-ZKZK201906014.htmGAO M Q, ZHAO Y H, ZHAO J B, et al. Research status and development of additive/subtractive hybrid manufacturing (A/SHM)[J]. Vacuum, 2019, 56(6): 68-74. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZKZK201906014.htm [3] 李永超. 增减材复合制造技术的研究现状与关键问题[J]. 冶金管理, 2021(5): 109-110. https://www.cnki.com.cn/Article/CJFDTOTAL-YJGL202105057.htmLI Y C. Research status and key problems of additive and subtractive hybrid manufacturing[J]. China Steel Focus, 2021(5): 109-110. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YJGL202105057.htm [4] 陈峰, 宋长辉, 杨永强, 等. 送粉式激光增材和铣削减材复合制造316L不锈钢的表面质量及力学性能[J]. 激光与光电子学进展, 2022, 59(1): 0114009. https://www.cnki.com.cn/Article/CJFDTOTAL-JGDJ202201030.htmCHEN F, SONG C H, YANG Y Q, et al. Surface quality and mechanical properties of 316L stainless steel manufactured by powder feeding laser additive and milling subtractive hybrid manufacturing[J]. Laser & Optoelectronics Progress, 2022, 59(1): 0114009. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JGDJ202201030.htm [5] 黄鑫. 钛合金增减材复合制造工艺研究[D]. 大连: 大连理工大学, 2017.HUANG X. The study on processing of additive/subtractive hybrid manufacturing for titanium alloy[D]. Dalian: Dalian University of Technology, 2017. (in Chinese) [6] 唐成铭, 赵吉宾, 田同同, 等. 基于激光选区熔化与高速切削的增减材复合制造系统开发[J]. 热加工工艺, 2022, 51(19): 118-122. https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY202219026.htmTANG C M, ZHAO J B, TIAN T T, et al. Development of a hybrid additive and subtractive manufacturing system based on selective laser melting and high speed machining[J]. Hot Working Technology, 2022, 51(19): 118-122. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY202219026.htm [7] 邹伟, 黄锦涛, 程春, 等. 基于增材制造技术快速模具制造研究进展[J]. 材料导报, 2022, 36(19): 21020083. https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB202219023.htmZOU W, HUANG J T, CHENG C, et al. Research progress of rapid tooling based on additive manufacturing[J]. Materials Reports, 2022, 36(19): 21020083. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-CLDB202219023.htm [8] LU H F, XUE K N, XU X, et al. Effects of laser shock peening on microstructural evolution and wear property of laser hybrid remanufactured Ni25/Fe104 coating on H13 tool steel[J]. Journal of Materials Processing Technology, 2021, 291: 117016. [9] PHAM THI H N, 张晓伟, 王传琦, 等. H13钢表面TiC/Co基激光修复层的显微组织与力学性能[J]. 焊接学报, 2013, 34(11): 27-31. https://www.cnki.com.cn/Article/CJFDTOTAL-HJXB201311007.htmPHAM THI H N, ZHANG X W, WANG C Q, et al. Microstructure and mechanical properties of TiC/Co composite coating by laser cladding on H13 steel surface[J]. Transactions of the China Welding Institution, 2013, 34(11): 27-31. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HJXB201311007.htm [10] LU J Z, XUE K N, LU H F, et al. Laser shock wave-induced wear property improvement and formation mechanism of laser cladding Ni25 coating on H13 tool steel[J]. Journal of Materials Processing Technology, 2021, 296: 117202. [11] ZHANG X C, LI W, CHEN X Y, et al. Evaluation of component repair using direct metal deposition from scanned data[J]. The International Journal of Advanced Manufacturing Technology, 2018, 95(9-12): 3335-3348. [12] ZHANG X C, PAN T, LI W, et al. Experimental characterization of a direct metal deposited cobalt-based alloy on tool steel for component repair[J]. JOM, 2019, 71(3): 946-955. [13] DEVINE R, CULLEN C, FOSTER J, et al. Remanufacture of hot forging dies by LMD-p using a cobalt based hard-facing alloy[J]. BHM Berg-Und Hüttenmännische Monatshefte, 2021, 166(5): 243-249. [14] 高小勇, 朱启茂, 王斌斌. 弹性模量线的选择对钢材屈服强度Rp0.2测量值的影响[J]. 理化检验-物理分册, 2020, 56(4): 10-13. https://www.cnki.com.cn/Article/CJFDTOTAL-LHJW202004003.htmGAO X Y, ZHU Q M, WANG B B. Effect of elastic modulus line selection on the yield strength Rp0.2 measured value of steels[J] Physical Testing and Chemical Analysis (Part A: Physical Testing), 2020, 56(4): 10-13. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-LHJW202004003.htm [15] 李军伟. 用横梁平台测定规定非比例延伸强度Rp0.2的精度分析[J]. 热加工工艺, 2013, 42(2): 56-57. https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201302016.htmLI J W. Determination precision analysis on proof strength of non-proportional extension 0.2% measured by crosshead[J]. Hot Working Technology, 2013, 42(2): 56-57. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SJGY201302016.htm -

下载:

下载: