Local Energy Smoothing and Singularity Avoidance Method of Five-axis Linear Toolpath

-

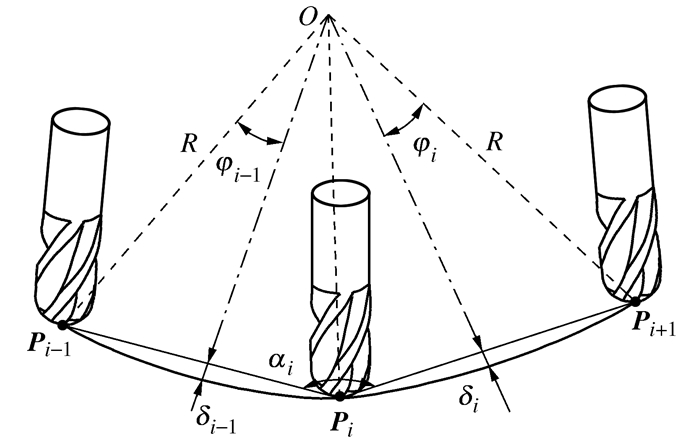

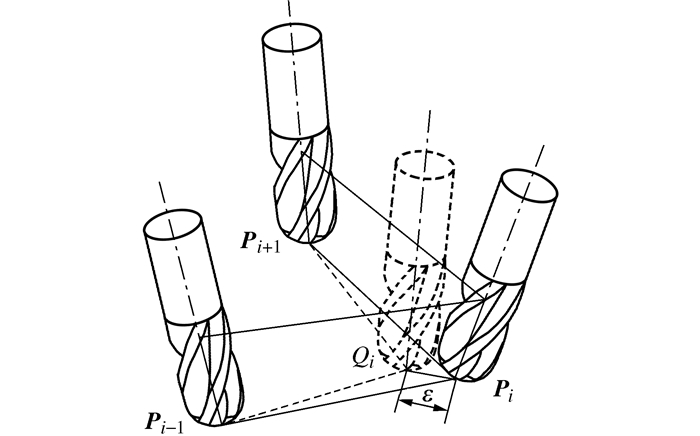

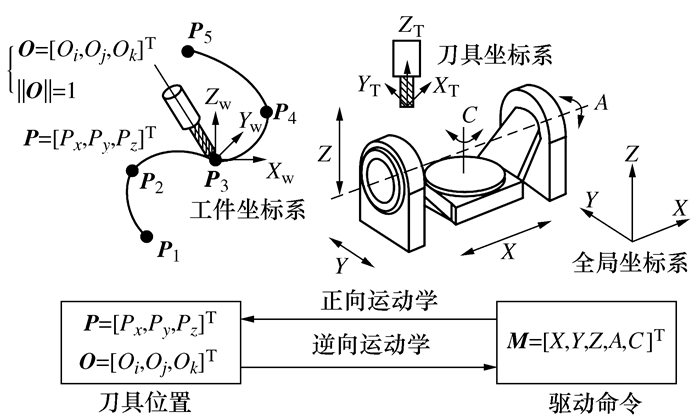

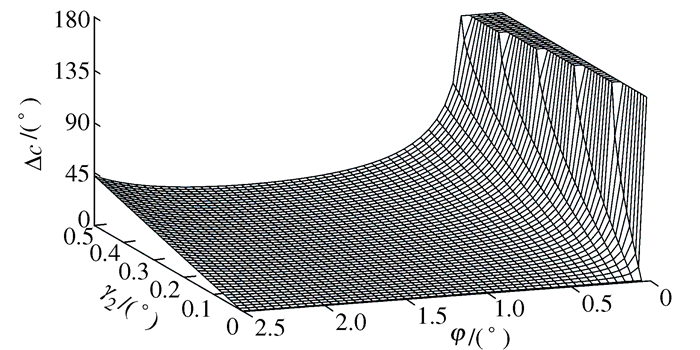

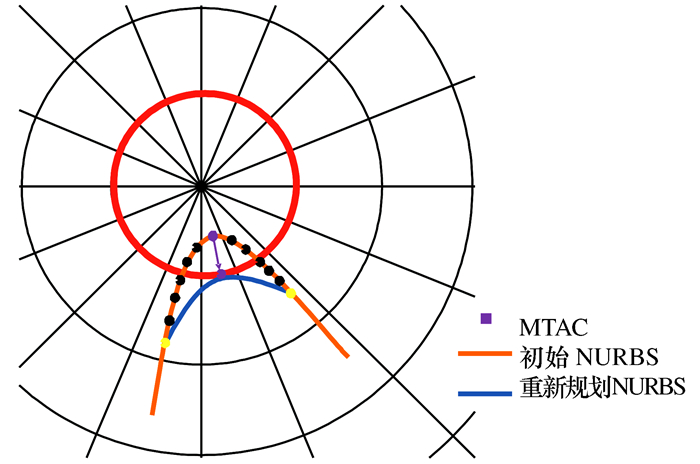

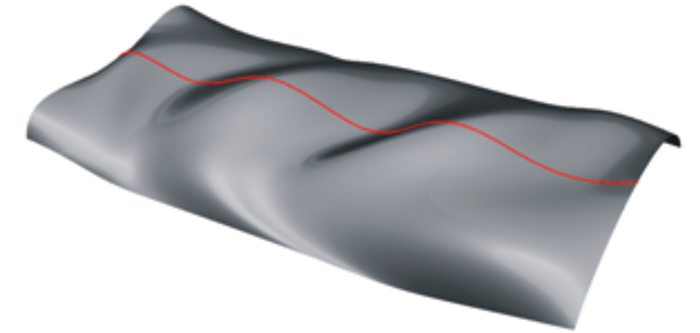

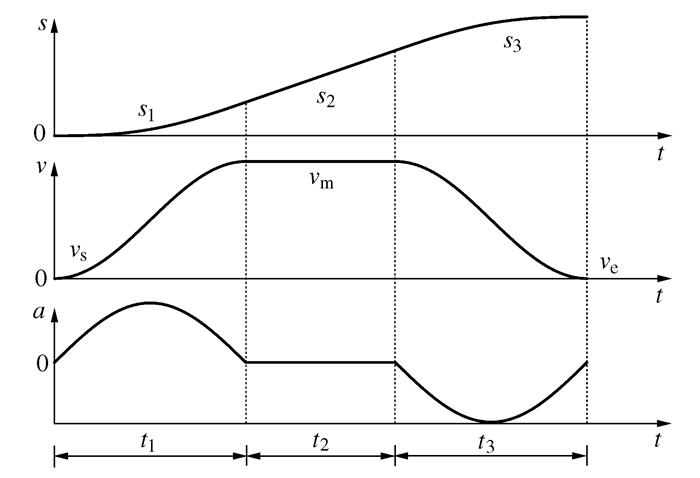

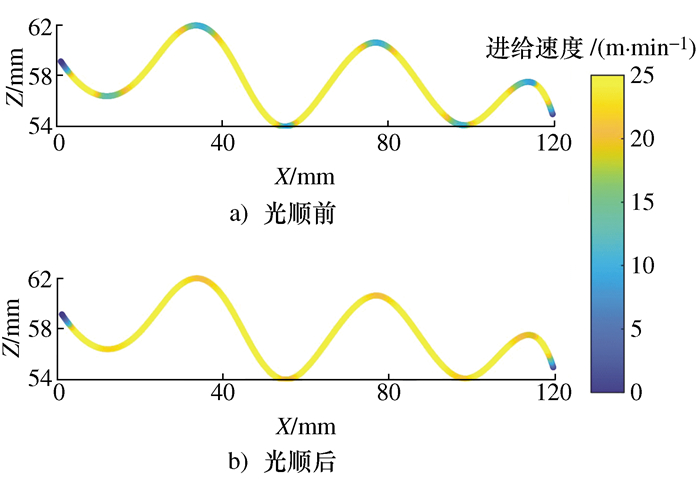

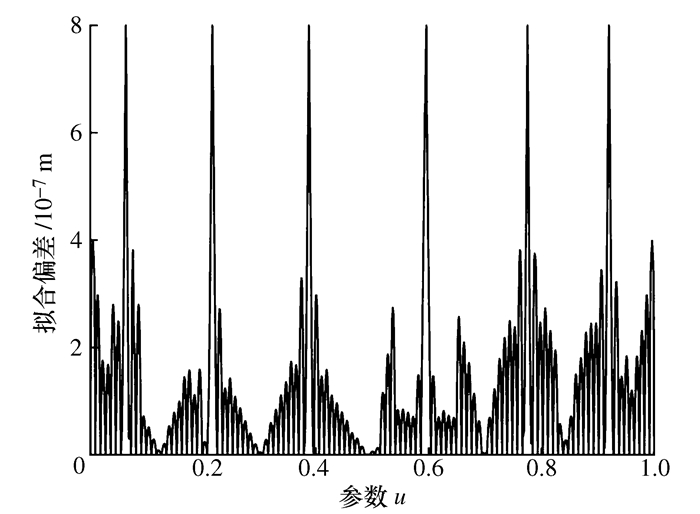

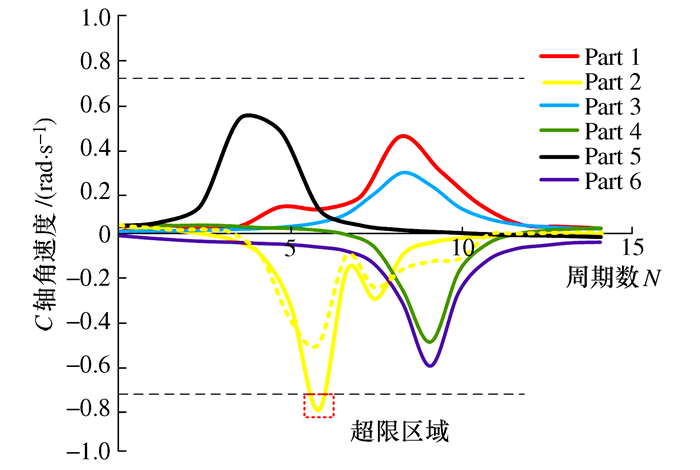

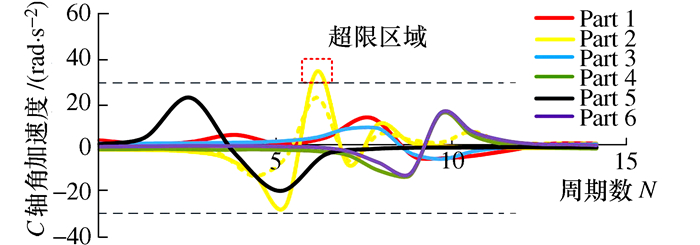

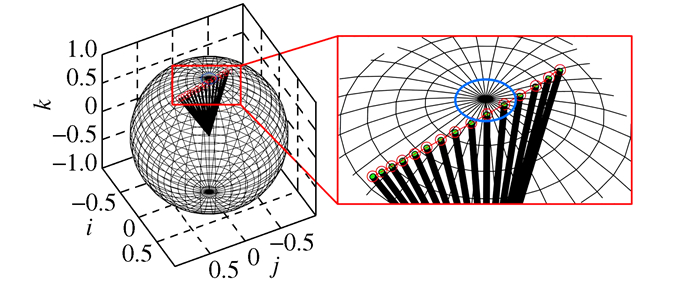

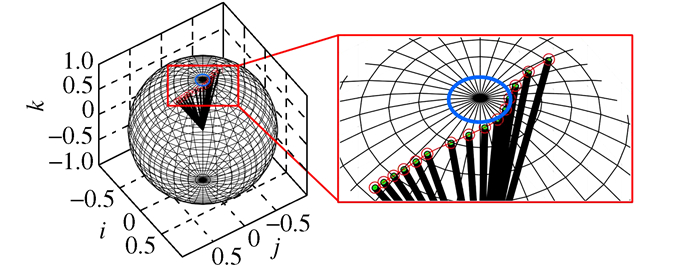

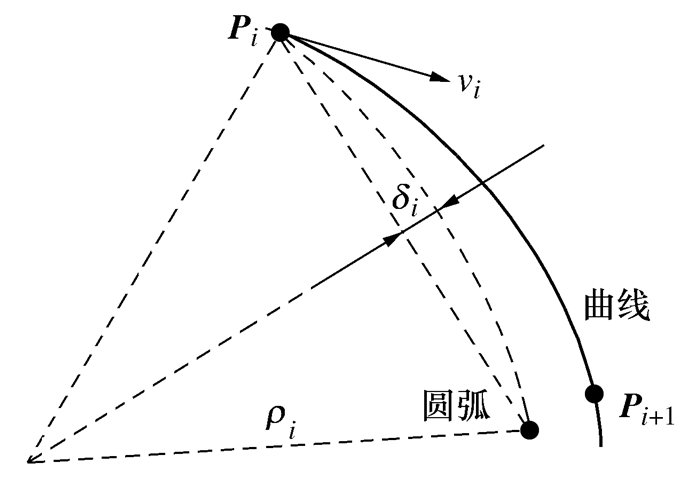

摘要: 针对现行五轴加工中存在的路径拐角处平动轴减速过度, 奇异区域旋转轴角度变化剧烈的问题, 以AC双转台五轴机床为研究对象, 提出一种满足机床运动学约束的路径优化方法。该方法首先以刀心点光顺前后最大许用偏移量作为约束, 利用转角向量和双弦弓高进行建模, 寻求微小线段拐角处局部能量最优解。并对奇异范围内部和边缘的刀轴矢量点二次规划, 使得矢量末端刚好绕过单位球面上的奇异区域, 极大地保留原有加工特性。通过结合三角函数加减速控制算法, 对优化效果进行评估。仿真结果表明: 该路径优化方法在拟合偏差与弓高误差均没有超过许用值的同时, 平均进给速度提升了10.64%, 而且能有效避免加工中奇异现象的发生。可见本文所提出的方法在提高五轴加工效率和加工质量等方面具有较高的理论意义和实际应用价值。Abstract: Aiming at the problems existing in the current five-axis machining that the translation axis at the corner of the toolpath decelerates excessively and the angle of the rotation axis changes drastically in the singular area. This paper takes the AC dual-table five-axis machine tool as the research object and proposes a path optimization method that satisfies the kinematics constraints of the machine tool. Firstly, the method takes the maximum allowable offset before and after the smoothing of the tool center point as a constraint, and uses the corner vector and the double-chord bow height for modeling to seek the local energy optimal solution at the corner of the micro-line segment. Then the cutter axis vector points inside and at the edges of the singular range are planned again so that the end of the vector just bypasses the singular region on the unit sphere; thus the original machining characteristics are greatly preserved. Finally, the optimization effect is evaluated by the trigonometric function acceleration and deceleration control algorithm. The simulation results show that the path optimization method improves the average feed rate by 10.64% while the fitting deviation and bow height error do not exceed the allowable values, and can effectively avoid the occurrence of singularities in machining. Consequently, the proposed method has high theoretical significance and practical application value in improving the efficiency and quality of five-axis machining.

-

Key words:

- five-axis machining /

- local energy smoothing /

- singular regions /

- motion control

-

表 1 机床约束条件

Table 1. Constraint conditions of machine tool

参数 数值 最大进给速度vm 25 m/min 最大加速度am 3 000 mm/s2 许用弓高误差δmax 4×10-7 m 最大拟合偏差εmax 8×10-7 m 数控系统采样插补周期ΔT 0.02 s A、C轴最大角速度 0.73 rad/s A、C轴最大角加速度 30 rad/s2 权重系数λ 0.6 表 2 光顺前后拐点处的进给速度

Table 2. Feed rates at turning points before and after smoothing

拐点位置 光顺前进给速度/(m·min-1) 光顺后进给速度/(m·min-1) D1 9.382 20.987 D2 8.979 20.085 D3 8.624 19.291 D4 8.410 18.811 D5 9.411 21.051 D6 9.682 21.659 -

[1] 杨敏, 赵现朝, 钟泽杉, 等. 复杂约束下的五轴数控系统自适应速度规划[J]. 机械工程学报, 2020, 56(11): 161-171. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202011019.htmYANG M, ZHAO X C, ZHONG Z S, et al. Adaptive velocity planning under complex constraints for 5-axis CNC systems[J]. Journal of Mechanical Engineering, 2020, 56(11): 161-171. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB202011019.htm [2] 蔡安江, 赵丹, 叶向东, 等. 五轴加工奇异问题机理分析及其避免策略[J]. 机械科学与技术, 2017, 36(8): 1237-1243. doi: 10.13433/j.cnki.1003-8728.2017.0815 CAI A J, ZHAO D, YE X D, et al. Mechanism analysis and avoiding strategy of singular problem in five-axis machining[J]. Mechanical Science and Technology for Aerospace Engineering, 2017, 36(8): 1237-1243. (in Chinese) doi: 10.13433/j.cnki.1003-8728.2017.0815 [3] 胡涞, 查俊, 朱永生, 等. 基础装备制造及高档集成数控机床研究进展[J]. 中国机械工程, 2021, 32(16): 1891-1903. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGJX202116001.htmHU L, ZHA J, ZHU Y S, et al. Research progresses of basic equipment manufacturing and high-grade integrated CNC machine tools[J]. China Mechanical Engineering, 2021, 32(16): 1891-1903. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGJX202116001.htm [4] 王峰, 林浒, 刘峰, 等. 五轴加工奇异区域内的刀具路径优化[J]. 机械工程学报, 2011, 47(19): 174-180. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201119027.htmWANG F, LIN H, LIU F, et al. Tool path optimization of five-axis machining in singular area[J]. Journal of Mechanical Engineering, 2011, 47(19): 174-180. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201119027.htm [5] 罗明, 吴宝海, 李山, 等. 自由曲面五轴加工刀轴矢量的运动学优化方法[J]. 机械工程学报, 2009, 45(9): 158-163. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200909025.htmLUO M, WU B H, LI S, et al. Five-axis tool orientation optimization based on kinematical method[J]. Journal of Mechanical Engineering, 2009, 45(9): 158-163. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB200909025.htm [6] BI Q Z, SHI J, WANG Y H, et al. Analytical curvature- continuous dual-Bézier corner transition for five-axis linear tool path[J]. International Journal of Machine Tools and Manufacture, 2015, 91: 96-108. doi: 10.1016/j.ijmachtools.2015.02.002 [7] SHI J, BI Q Z, ZHU L M, et al. Corner rounding of linear five-axis tool path by dual PH curves blending[J]. International Journal of Machine Tools and Manufacture, 2015, 88: 223-236. doi: 10.1016/j.ijmachtools.2014.09.007 [8] ZHANG J, ZHANG L Q, ZHANG K, et al. Double NURBS trajectory generation and synchronous interpolation for five- axis machining based on dual quaternion algorithm[J]. The International Journal of Advanced Manufacturing Technology, 2016, 83(9-12): 2015-2025. doi: 10.1007/s00170-015-7723-9 [9] TULSYAN S, ALTINTAS Y. Local toolpath smoothing for five-axis machine tools[J]. International Journal of Machine Tools and Manufacture, 2015, 96: 15-26. doi: 10.1016/j.ijmachtools.2015.04.014 [10] YANG J X, YUEN A. An analytical local corner smoothing algorithm for five-axis CNC machining[J]. International Journal of Machine Tools and Manufacture, 2017, 123: 22-35. doi: 10.1016/j.ijmachtools.2017.07.007 [11] 蔡安江, 杜金健, 宋仁杰, 等. 五轴加工刀具轨迹NURBS插补技术的研究[J]. 机械科学与技术, 2017, 36(3): 402-408. doi: 10.13433/j.cnki.1003-8728.2017.0313 CAI A J, DU J J, SONG R J, et al. Study on NURBS interpolation technology of five-axis machining tool path[J]. Mechanical Science and Technology for Aerospace Engineering, 2017, 36(3): 402-408. (in Chinese) doi: 10.13433/j.cnki.1003-8728.2017.0313 [12] 周续, 张定华, 吴宝海, 等. 非正交双转台五轴机床后置处理通用方法[J]. 机械工程学报, 2014, 50(15): 198-204. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201415029.htmZHOU X, ZHANG D H, WU B H, et al. General method of post-processing for non-orthogonal five-axis machine tools with dual rotary tables[J]. Journal of Mechanical Engineering, 2014, 50(15): 198-204. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201415029.htm [13] 李冬冬, 张为民, 隋浩楠, 等. 五轴加工奇异问题分析与非线性误差控制[J]. 计算机集成制造系统, 2019, 25(5): 1112-1118. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201905010.htmLI D D, ZHANG W M, SUI H N, et al. Singularity analysis and non-linear error control of five-axis machining[J]. Computer Integrated Manufacturing Systems, 2019, 25(5): 1112-1118. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201905010.htm [14] 张立强, 张守军, 王宇晗. 基于对偶四元数的五轴等距双NURBS刀具路径规划[J]. 计算机集成制造系统, 2014, 20(1): 128-133. https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201401017.htmZHANG L Q, ZHANG S J, WANG Y H. Double NURBS five-axis tool path planning with equal distance based on dual quaternion[J]. Computer Integrated Manufacturing Systems, 2014, 20(1): 128-133. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201401017.htm [15] 耿军晓, 李立伟, 李友刚, 等. 五轴联动加工中进给速度的控制算法[J]. 表面技术, 2018, 47(7): 8-14. https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201807003.htmGENG J X, LI L W, LI Y G, et al. Control algorithm of feed rate in five-axis linkage machining[J]. Surface Technology, 2018, 47(7): 8-14. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201807003.htm [16] 李晓东, 宁涛, 陈志同. 改善机床运动的五轴刀轨光顺方法[J]. 北京航空航天大学学报, 2016, 42(2): 406-412. https://www.cnki.com.cn/Article/CJFDTOTAL-BJHK201602026.htmLI X D, NING T, CHEN Z T. 5-Axis tool path smoothing to improve machine tool motion[J]. Journal of Beijing University of Aeronautics and Astronautics, 2016, 42(2): 406-412. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BJHK201602026.htm -

下载:

下载: