Study on Cutting Temperature-vibration Correlation of Titanium Alloys and Machining Optimization

-

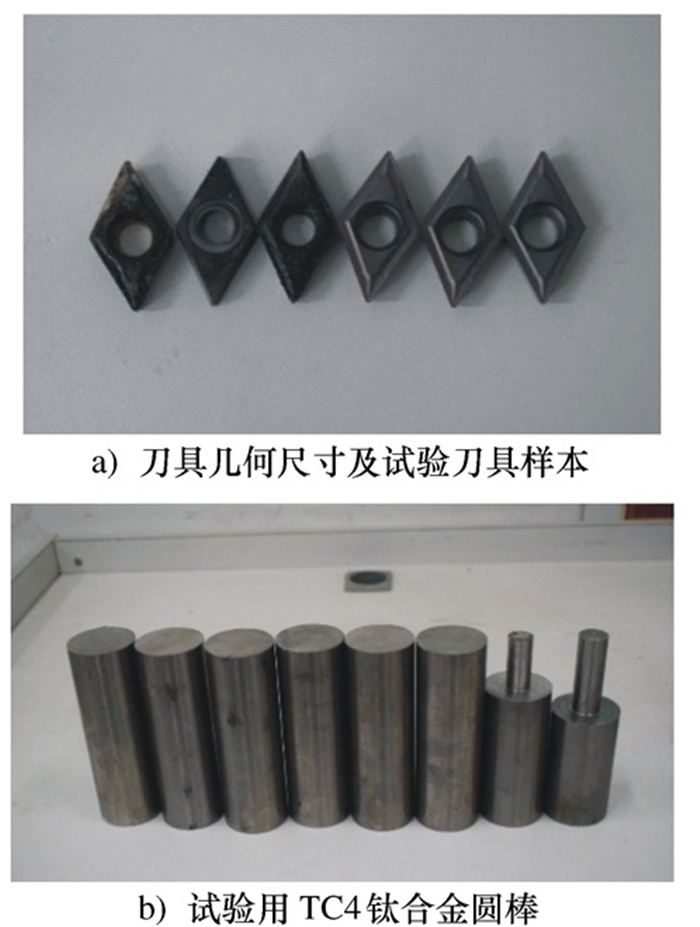

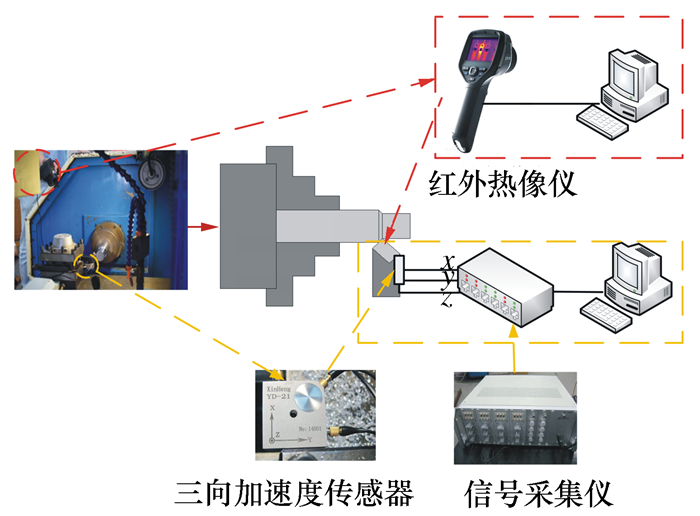

摘要: 钛合金作为"21世纪战略金属"在航空领域应用广泛, 其加工质量至关重要。因此, 对钛合金进行切削加工优化具有重要的研究意义。本文搭建切削温度和切削振动同步测量系统。通过红外热像仪和三向加速度传感器采集车刀尖端附近的温度和振动信号。建立基于切削温度和切削振动多特征融合优化模型, 并运用粒子群优化灰狼算法对多特征融合优化模型进行求解, 获得最优的切削参数。研究表明: 在试验设计的切削参数范围内, 切削参数的最优解为: 切削速度753.98 m/s, 进给速度30 mm/min, 切削深度0.4 mm, 所做研究为优化钛合金加工质量提供理论指导。Abstract: As a "21st century strategic metal", titanium alloy is widely used in the aviation field, and its processing quality is very important. Therefore, it is of great significance to optimize the machining of titanium alloys. In this paper, a synchronous measurement system for cutting temperature and vibration is built. The temperature and vibration signals near the tip of the turning tool are collected by an infrared thermal imager and a three-way acceleration sensor. A multi-feature fusion optimization model based on the cutting temperature and vibration is established, and the particle swarm optimization gray wolf algorithm is used to solve the multi-feature fusion optimization model to obtain the optimal cutting parameters. The study shows that within the range of cutting parameters designed by the experiment, the optimal solution of cutting parameters is 753.98 m/s of cutting speed, 30 mm/min of feed rate, 0.4 mm of cutting depth, and provides a theoretical basis for optimizing the machining quality of titanium alloys.

-

表 1 试验方案

Table 1. Test scheme

切削参数 因子等级 1 2 3 4 5 主轴转速n/(r·min-1) 300 400 600 900 70 进给速度vf/(mm·min-1) 30 40 50 60 70 切削深度ap/mm 0.1 0.2 0.3 0.4 70 表 2 钛合金切削试验数据

Table 2. Titanium alloy cutting test data

序号 v/(mm·s-1) vf/(mm·min-1) ap/mm T/℃ ax, RMS/(mm·s-2) ay, RMS/(mm·s-2) az, RMS/(mm·s-2) ac, RMS/(mm·s-2) Q/(cm3·mm-1) 1 753.98 30 0.1 97.30 0.23 0.24 0.35 0.27 452.39 2 1 005.31 30 0.1 152.96 0.24 0.25 0.39 0.29 452.39 3 1 507.96 30 0.1 142.06 0.25 0.27 0.40 0.31 452.39 4 2 261.95 30 0.1 177.80 0.25 0.26 0.37 0.29 452.39 5 753.98 30 0.2 162.50 0.33 0.32 0.57 0.41 904.78 6 1 005.31 30 0.2 139.27 0.32 0.35 0.61 0.43 904.78 7 1 507.96 30 0.2 172.00 0.32 0.38 0.60 0.44 904.78 8 2 261.95 30 0.2 160.01 0.30 0.36 0.49 0.39 904.78 9 753.98 30 0.3 155.30 0.43 0.37 0.68 0.49 1 357.17 10 1 005.31 30 0.3 165.92 0.39 0.41 0.75 0.52 1 357.17 11 1 507.96 30 0.3 156.08 0.36 0.42 0.72 0.50 1 357.17 12 2 261.95 30 0.3 240.94 0.33 0.41 0.59 0.45 1 357.17 13 753.98 30 0.4 196.66 0.48 0.37 0.65 0.50 1 809.56 14 1 005.31 30 0.4 206.54 0.42 0.41 0.76 0.53 1 809.56 15 1 507.96 30 0.4 240.45 0.37 0.42 0.71 0.50 1 809.56 16 2 261.95 30 0.4 142.70 0.34 0.42 0.62 0.46 1 809.56 17 753.98 40 0.1 118.90 0.19 0.20 0.28 0.22 603.19 18 1 005.31 40 0.1 150.70 0.26 0.28 0.52 0.35 603.19 19 1 507.96 40 0.1 159.00 0.26 0.28 0.51 0.35 603.19 20 2 261.95 40 0.1 163.94 0.23 0.26 0.39 0.29 603.19 21 753.98 40 0.2 169.59 0.44 0.36 0.83 0.54 1 206.37 22 1 005.31 40 0.2 173.27 0.40 0.40 0.88 0.56 1 206.37 23 1 507.96 40 0.2 201.06 0.36 0.40 0.81 0.53 1 206.37 24 2 261.95 40 0.2 238.73 0.33 0.36 0.63 0.44 1 206.37 25 753.98 40 0.3 192.45 0.52 0.37 0.77 0.55 1 809.56 26 1 005.31 40 0.3 206.66 0.46 0.41 0.97 0.61 1 809.56 27 1 507.96 40 0.3 284.70 0.39 0.43 0.93 0.59 1 809.56 28 2 261.95 40 0.3 52.46 0.36 0.41 0.69 0.49 1 809.56 29 753.98 40 0.4 202.06 0.60 0.37 0.64 0.53 2 412.74 30 1 005.31 40 0.4 291.97 0.50 0.38 0.83 0.57 2 412.74 31 1 507.96 40 0.4 339.82 0.39 0.40 0.85 0.55 2 412.74 32 2 261.95 40 0.4 244.86 0.35 0.39 0.71 0.49 2 412.74 33 753.98 50 0.1 107.96 0.33 0.31 0.60 0.41 753.98 34 1 005.31 50 0.1 122.62 0.34 0.36 0.71 0.47 753.98 35 1 507.96 50 0.1 108.98 0.33 0.38 0.68 0.47 753.98 36 2 261.95 50 0.1 266.71 0.32 0.37 0.53 0.41 753.98 37 753.98 50 0.2 187.52 0.50 0.40 0.87 0.59 1 507.96 38 1 005.31 50 0.2 192.92 0.48 0.49 1.23 0.74 1 507.96 39 1 507.96 50 0.2 216.78 0.46 0.58 1.21 0.76 1 507.96 40 2 261.95 50 0.2 324.64 0.43 0.55 0.85 0.61 1 507.96 41 753.98 50 0.3 175.72 0.67 0.46 0.86 0.66 2 261.95 42 1 005.31 50 0.3 167.31 0.56 0.51 1.30 0.79 2 261.95 43 1 507.96 50 0.3 274.00 0.53 0.61 1.55 0.90 2 261.95 44 2 261.95 50 0.3 260.87 0.49 0.64 1.13 0.76 2 261.95 45 753.98 50 0.4 191.21 0.78 0.49 0.74 0.66 3 015.93 46 1 005.31 50 0.4 223.26 0.60 0.48 0.99 0.69 3 015.93 47 1 507.96 50 0.4 319.62 0.48 0.51 1.26 0.75 3 015.93 48 2 261.95 50 0.4 212.73 0.45 0.55 1.11 0.71 3 015.93 49 753.98 60 0.1 98.15 0.34 0.24 0.80 0.46 904.78 50 1 005.31 60 0.1 180.93 0.35 0.30 0.82 0.49 904.78 51 1 507.96 60 0.1 214.77 0.36 0.37 0.93 0.56 904.78 52 2 261.95 60 0.1 223.46 0.34 0.33 0.69 0.45 904.78 53 753.98 60 0.2 208.59 0.45 0.25 0.71 0.47 1 809.56 54 1 005.31 60 0.2 219.61 0.43 0.31 1.11 0.62 1 809.56 55 1 507.96 60 0.2 271.20 0.45 0.44 1.41 0.77 1 809.56 56 2 261.95 60 0.2 303.53 0.44 0.48 1.05 0.66 1 809.56 57 753.98 60 0.3 224.05 0.64 0.38 0.73 0.58 2 714.34 58 1 005.31 60 0.3 254.69 0.56 0.42 1.09 0.69 2 714.34 59 1 507.96 60 0.3 349.00 0.52 0.54 1.54 0.87 2 714.34 60 2 261.95 60 0.3 417.39 0.49 0.48 1.18 0.72 2 714.34 61 753.98 60 0.4 231.94 0.86 0.55 0.85 0.75 3 619.11 62 1 005.31 60 0.4 286.51 0.66 0.52 0.89 0.69 3 619.11 63 1 507.96 60 0.4 302.93 0.62 0.58 1.17 0.79 3 619.11 64 2 261.95 60 0.4 369.65 0.50 0.55 1.14 0.73 3 619.11 65 753.98 70 0.1 215.41 0.32 0.19 0.56 0.36 1 055.58 66 1 005.31 70 0.1 226.25 0.36 0.24 0.78 0.46 1 055.58 67 1 507.96 70 0.1 199.29 0.37 0.29 0.81 0.49 1 055.58 68 2 261.95 70 0.1 317.83 0.33 0.29 0.66 0.43 1 055.58 69 753.98 70 0.2 183.09 0.50 0.23 0.70 0.47 2 111.15 70 1 005.31 70 0.2 241.95 0.53 0.28 1.06 0.62 2 111.15 71 1 507.96 70 0.2 298.62 0.47 0.34 1.49 0.77 2 111.15 72 2 261.95 70 0.2 461.05 0.44 0.39 1.04 0.62 2 111.15 73 753.98 70 0.3 144.41 0.82 0.38 0.93 0.70 3 166.73 74 1 005.31 70 0.3 154.93 0.67 0.44 1.34 0.81 3 166.73 75 1 507.96 70 0.3 151.59 0.66 0.42 1.29 0.79 3 166.73 76 2 261.95 70 0.3 315.56 0.62 0.63 1.52 0.93 3 166.73 77 753.98 70 0.4 352.20 0.83 0.47 0.91 0.73 4 222.30 78 1 005.31 70 0.4 392.31 0.68 0.57 0.94 0.73 4 222.30 79 1 507.96 70 0.4 429.20 0.47 0.92 1.16 0.86 4 222.30 80 2 261.95 70 0.4 337.63 0.57 0.60 1.24 0.81 4 222.30 表 3 切削温度与切削振动的灰色相对关联度

Table 3. Grey correlation degree between cutting temperature and cutting vibration

切削温度均值T 三向切削振动 灰色关联度γ0i 等级 X0 X1 0.93 3 X2 0.86 4 X3 0.98 1 X4 0.97 2 表 4 回归参数和相关系数

Table 4. Regression parameters and correlation coefficients

x1 x2 x3 T ac, RMS Q 753.98 mm/s 30 mm/min 0.4 mm 196.66 ℃ 0.5 mm/s2 1809.56 cm3/mm -

[1] 邵明辉, 喻秋, 李顺才, 等. TC4钛合金高速车削温度与车削振动特性的试验研究[J]. 现代制造工程, 2019(12): 1-8. https://www.cnki.com.cn/Article/CJFDTOTAL-XXGY201912001.htmSHAO M H, YU Q, LI S C, et al. Experimental study on turning temperature and turning vibration characteristics of TC4 titanium alloy under high speed turning[J]. Modern Manufacturing Engineering, 2019(12): 1-8. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-XXGY201912001.htm [2] 肖田, 王怀峰, 武文革. 基于AdvantEdge的钛合金Ti6Al4V的高速铣切削有限元仿真[J]. 煤矿机械, 2012, 33(5): 138-140.XIAO T, WANG H F, WU W G. Finite element method simulation in high speed milling of Ti6Al4V alloy based on AdvantEdge[J]. Coal Mine Machinery, 2012, 33(5): 138-140. (in Chinese) [3] 李飞, 骆骏德, 李楠. 基于abaqus仿真的钛合金切削稳定性分析[J]. 北华航天工业学院学报, 2020, 30(6): 3-6. https://www.cnki.com.cn/Article/CJFDTOTAL-HHGY202006002.htmLI F, LUO J D, LI N. Analysis on cutting stability of titanium alloy based on ABAQUS simulation[J]. Journal of North China Institute of Aerospace Engineering, 2020, 30(6): 3-6. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HHGY202006002.htm [4] 马浩骞, 杨东, 程东化, 等. 基于Abaqus的钛合金Ti6Al4V切削仿真与工艺优化[J]. 制造业自动化, 2020, 42(11): 23-27. https://www.cnki.com.cn/Article/CJFDTOTAL-JXGY202011006.htmMA H Q, YANG D, CHENG D H, et al. Cutting process simulation and process parameters optimization in orthogonal cutting of Ti6Al4V based on Abaqus[J]. Manufacturing Automation, 2020, 42(11): 23-27. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXGY202011006.htm [5] 刘朋和, 姜增辉, 王晓亮. TC4钛合金切削温度的仿真与试验研究[J]. 制造技术与机床, 2013(10): 81-83. https://www.cnki.com.cn/Article/CJFDTOTAL-ZJYC201310028.htmLIU P H, JIANG Z H, WANG X L. Research on the simulation and experiment of cutting temperature in machining TC4 titanium alloy[J]. Manufacturing Technology & Machine Tool, 2013(10): 81-83. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZJYC201310028.htm [6] 王苏东. 基于DEFORM-3D的钛合金切削过程有限元仿真[J]. 装备制造技术, 2009(12): 30-32. https://www.cnki.com.cn/Article/CJFDTOTAL-GXJX200912015.htmWANG S D. Finite element simulation of the process of the titanium alloy cutting based on DEFORM-3D[J]. Equipment Manufacturing Technology, 2009(12): 30-32. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GXJX200912015.htm [7] 宋新华, 高红旺, 田正芳, 等. Ti6Al4V钛合金切削加工的数值模拟[J]. 工具技术, 2020, 54(7): 40-43. https://www.cnki.com.cn/Article/CJFDTOTAL-GJJS202007010.htmSONG X H, GAO H W, TIAN Z F, et al. Numerical simulation of titanium alloy Ti6Al4V in cutting proce[J]. Tool Engineering, 2020, 54(7): 40-43. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GJJS202007010.htm [8] 刘杰, 朱水生, 肖晓兰, 等. AlCrSiN涂层刀具干车削Ti-6Al-4V钛合金的切削性能研究[J]. 广东工业大学学报, 2021, 38(2): 99-106. https://www.cnki.com.cn/Article/CJFDTOTAL-GDGX202102015.htmLIU J, ZHU S S, XIAO X L, et al. Cutting performance of AlCrSiN coated tool in dry turning Ti-6Al-4V Titanium alloy[J]. Journal of Guangdong University of Technology, 2021, 38(2): 99-106. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GDGX202102015.htm [9] 赵甘霖, 冯平法, 张建富. 钛合金超声振动钻削工艺特性仿真及试验研究[J]. 北京航空航天大学学报, 2019, 45(8): 1597-1605. https://www.cnki.com.cn/Article/CJFDTOTAL-BJHK201908015.htmZHAO G L, FENG P F, ZHANG J F. Simulation and experimental study on ultrasonic vibration drilling process characteristics of titanium alloy[J]. Journal of Beijing University of Aeronautics and Astronautics, 2019, 45(8): 1597-1605. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BJHK201908015.htm [10] 杨睿, 李顺才, 袁冠雷, 等. 车削温度多元回归模型的试验研究[J]. 实验技术与管理, 2016, 33(8): 59-62. https://www.cnki.com.cn/Article/CJFDTOTAL-SYJL201608015.htmYANG R, LI S C, YUAN G L, et al. Testing study of multiple regression model based on turning temperature[J]. Experimental Technology and Management, 2016, 33(8): 59-62. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-SYJL201608015.htm [11] 薛国彬, 郑清春, 胡亚辉, 等. 钛合金车削过程中基于遗传算法的切削参数多目标优化[J]. 工具技术, 2017, 51(1): 27-30. https://www.cnki.com.cn/Article/CJFDTOTAL-GJJS201701010.htmXUE G B, ZHENG Q C, HU Y H, et al. Modeling and solution of cutting parameters optimization for titanium alloy turning machining[J]. Tool Engineering, 2017, 51(1): 27-30. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GJJS201701010.htm [12] YU Q, LI S C, ZHANG X, et al. Experimental study on correlation between turning temperature rise and turning vibration in dry turning on aluminum alloy[J]. The International Journal of Advanced Manufacturing Technology, 2019, 103(1-4): 453-469. [13] 李大权, 李顺才, 吴春力. 粒子群算法优化的车削温度组合预测模型研究[J]. 应用力学学报, 2020, 37(6): 2354-2361. https://www.cnki.com.cn/Article/CJFDTOTAL-YYLX202006007.htmLI D Q, LI S C, WU C L. Research on combined prediction model of turning temperature optimized by particle swarm optimization[J]. Chinese Journal of Applied Mechanics, 2020, 37(6): 2354-2361. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-YYLX202006007.htm [14] 贾兴民, 李剑峰, 孙杰, 等. 基于切削力与振动特性钛合金铣切削工艺参数研究[J]. 机械设计与制造, 2014(12): 204-208.JIA X M, LI J F, SUN J, et al. Study on cutting parameter optimization for milling titanium alloys based on cutting force and vibration characteristics[J]. Machinery Design & Manufacture, 2014(12): 204-208. (in Chinese) [15] 王沁军, 孙杰. PCBN刀具高速铣切削TC4钛合金切削性能与工艺参数优化研究[J]. 机床与液压, 2019, 47(7): 57-61. https://www.cnki.com.cn/Article/CJFDTOTAL-JCYY201907013.htmWANG Q J, SUN J. Study on machinability and optimization of cutting parameters for high-speed milling TC4 alloy with PCBN tools[J]. Machine Tool & Hydraulics, 2019, 47(7): 57-61. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JCYY201907013.htm [16] 周培培, 李金泉, 许立福, 等. TA15钛合金切削振动与表面质量关系研究[J]. 工具技术, 2016, 50(5): 21-25. https://www.cnki.com.cn/Article/CJFDTOTAL-GJJS201605008.htmZHOU P P, LI J Q, XU L F, et al. Study on relationship between cutting vibration and surface quality titanium alloy TA15[J]. Tool Engineering, 2016, 50(5): 21-25. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GJJS201605008.htm [17] 陈尔涛, 石莉, 姜增辉. 钛合金车削加工试验切削振动的分析[J]. 制造业自动化, 2015, 37(5): 100-101. https://www.cnki.com.cn/Article/CJFDTOTAL-JXGY201505032.htmCHEN E T, SHI L, JIANG Z H. Analysis of cutting vibration in turning titanium alloy test[J]. Manufacturing Automation, 2015, 37(5): 100-101. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXGY201505032.htm [18] 颜世晶, 徐碧聪, 辛奇, 等. 钛合金切削过程刀具振动特性研究[J]. 制造技术与机床, 2018(8): 129-132. https://www.cnki.com.cn/Article/CJFDTOTAL-ZJYC201808040.htmYAN S J, XU B C, XIN Q, et al. Research on tool vibration characteristics of titanium alloy during the cutting process[J]. Manufacturing Technology & Machine Tool, 2018(8): 129-132. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZJYC201808040.htm [19] 皇攀凌, 李剑峰, 孙杰, 等. 整体硬质合金立铣刀高速加工钛合金振动分析[J]. 粉末冶金材料科学与工程, 2010, 15(6): 574-579. https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201006007.htmHUANG P L, LI J F, SUN J, et al. Vibration analysis in high speed machining titanium alloy with solid cemented carbide end mill[J]. Materials Science and Engineering of Powder Metallurgy, 2010, 15(6): 574-579. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-FMGC201006007.htm [20] 王晨羽, 李金泉. 基于动态力学模型分析的钛合金切削过程进给量对表面质量的影响规律[J]. 表面技术, 2019, 48(6): 370-375. https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201906047.htmWANG C Y, LI J Q. Influence of feed on surface quality in titanium alloy cutting process based on dynamic mechanical model analysis[J]. Surface Technology, 2019, 48(6): 370-375. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BMJS201906047.htm [21] WANG X N, YANG W C, GE Y, et al. The influence of shrinkage-reducing agent solution properties on shrinkage of cementitious composite using grey correlation analysis[J]. Construction and Building Materials, 2020, 264: 120194. [22] HU Y T, LI S C, LI S Y, et al. Research on the combined prediction model of milling sound pressure level based on force-thermal-vibration multi-feature fusion[J]. The International Journal of Advanced Manufacturing Technology, 2021, 115(1): 233-245. -

下载:

下载: