Dynamic Analysis and Experimental Study on Crank Slider Mechanism with Flexible Connecting Rod

-

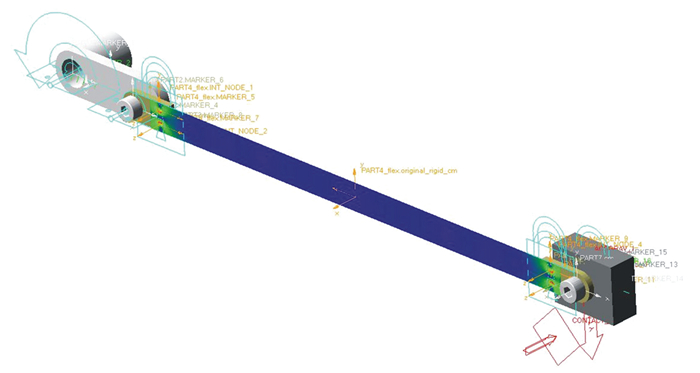

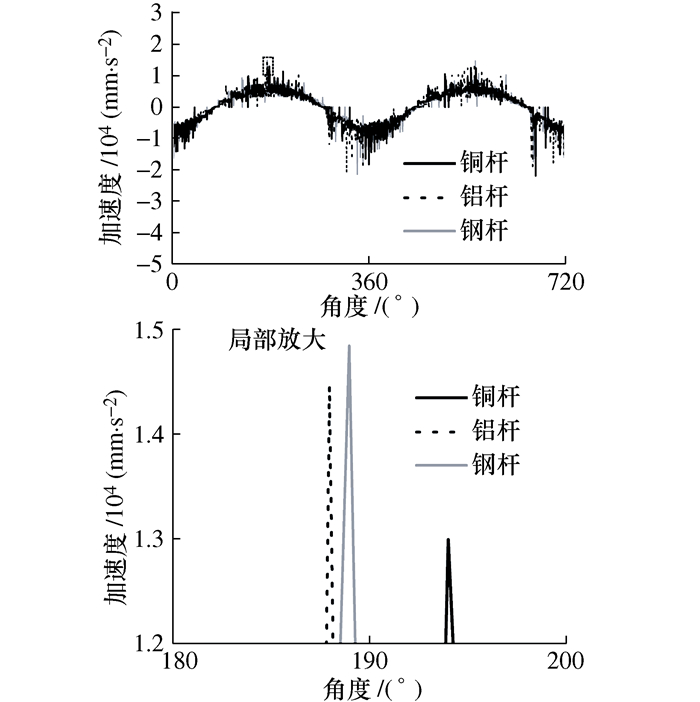

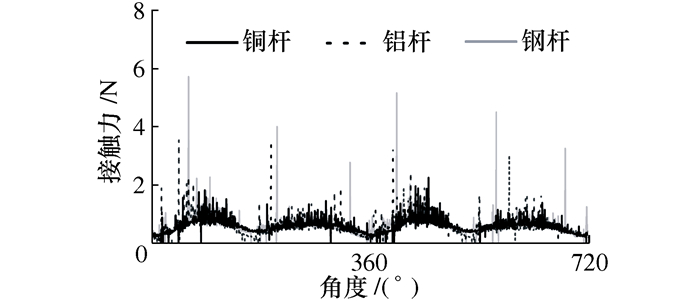

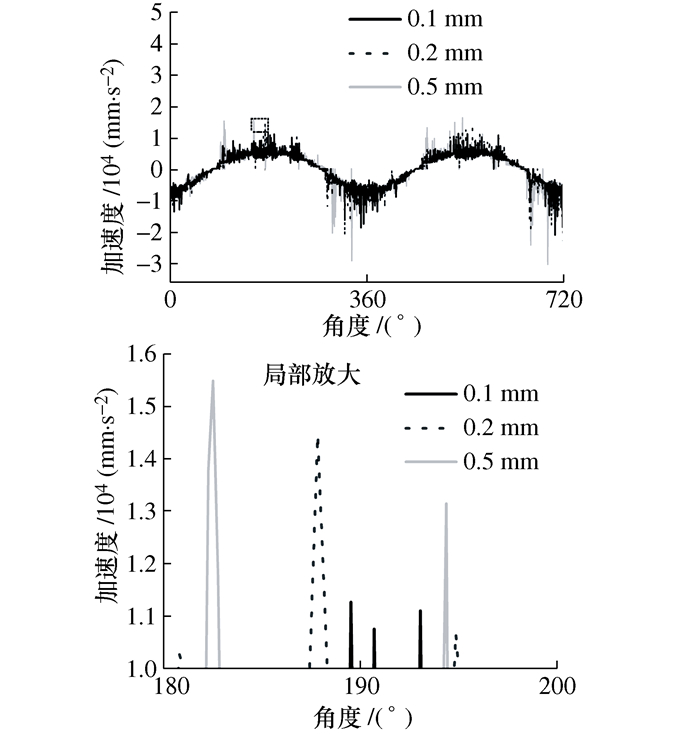

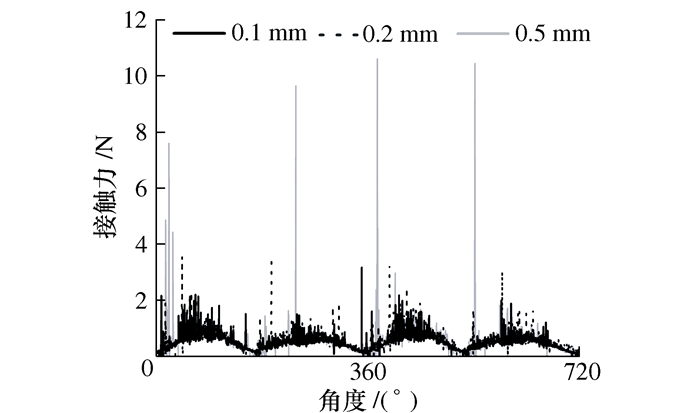

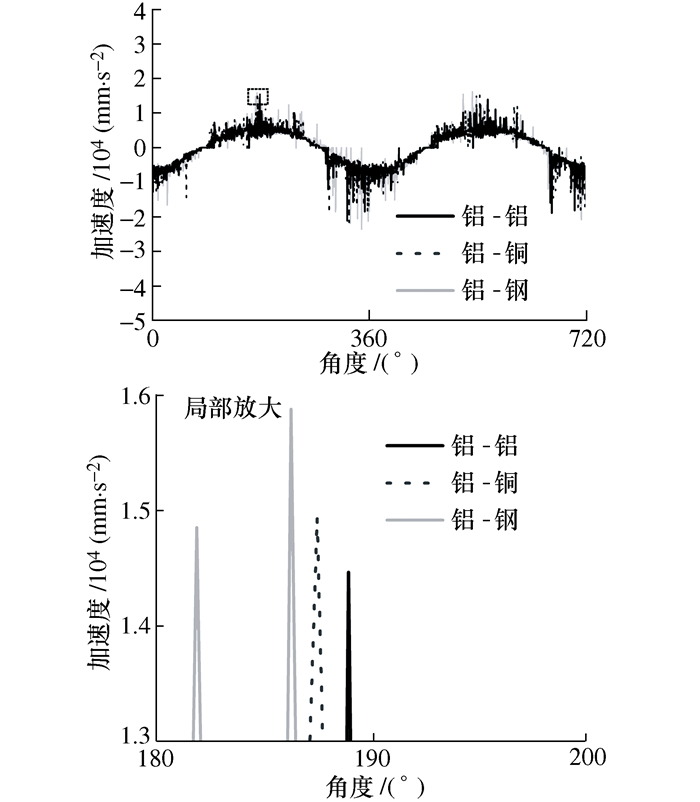

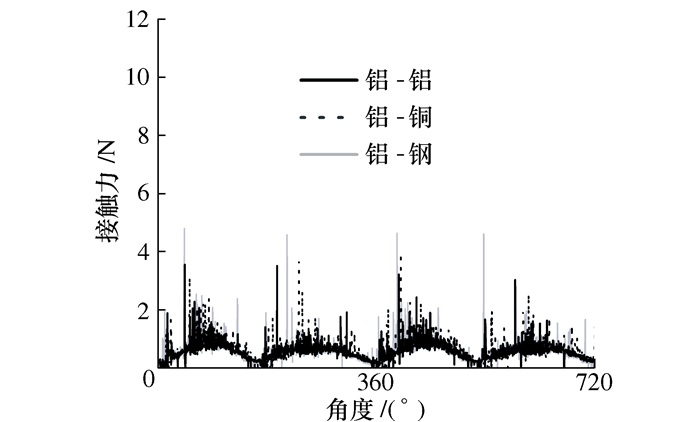

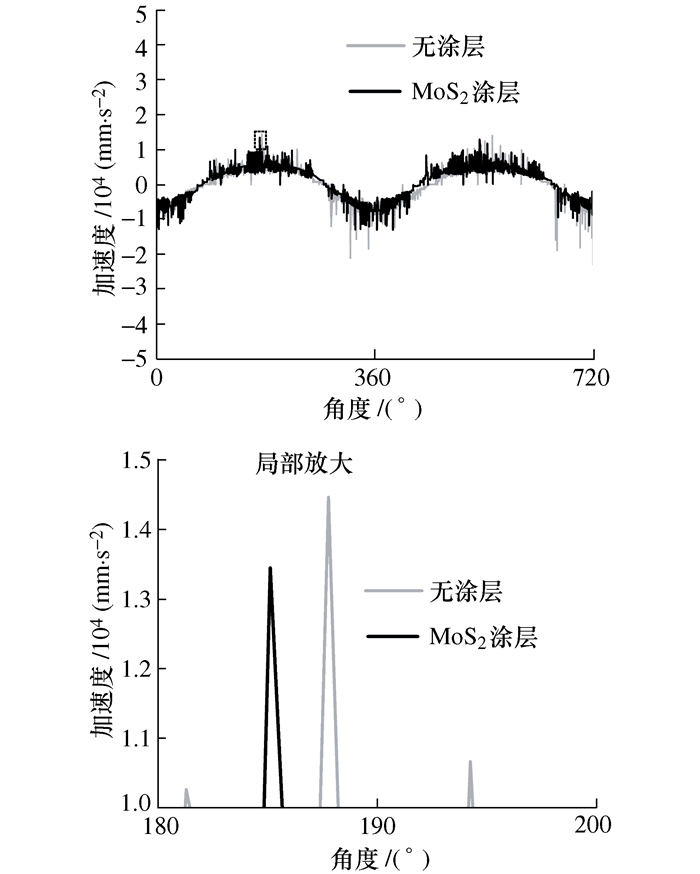

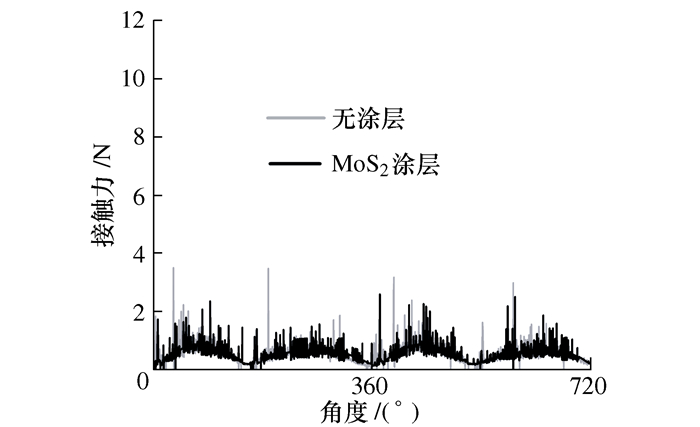

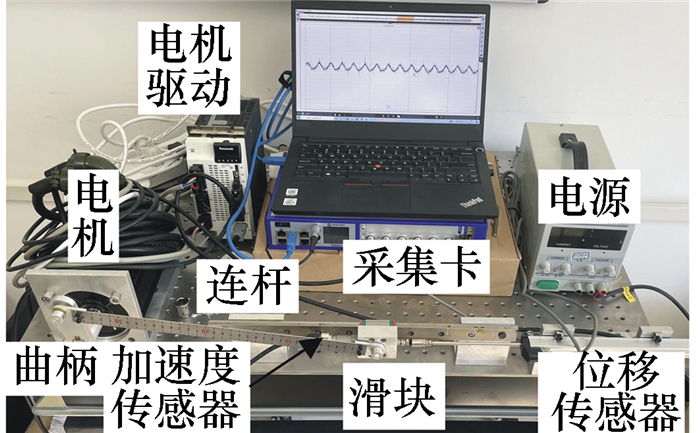

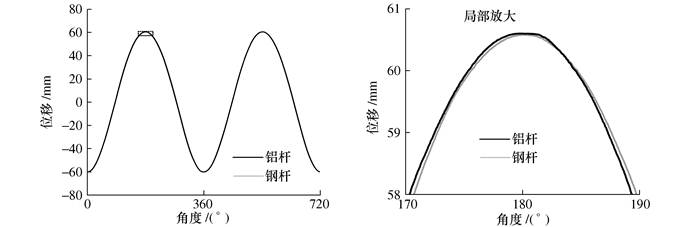

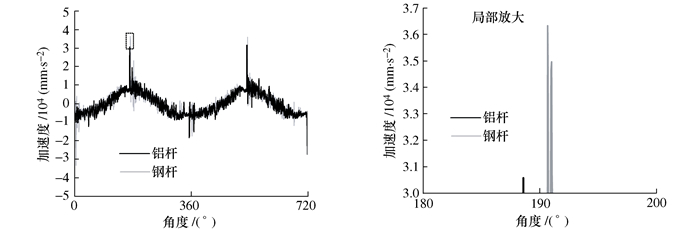

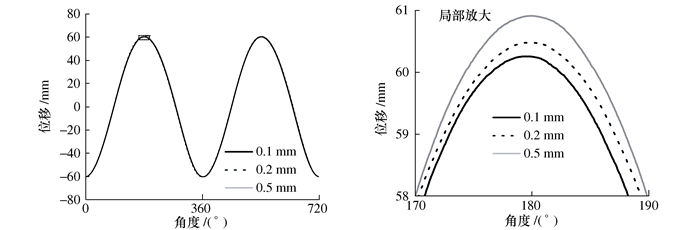

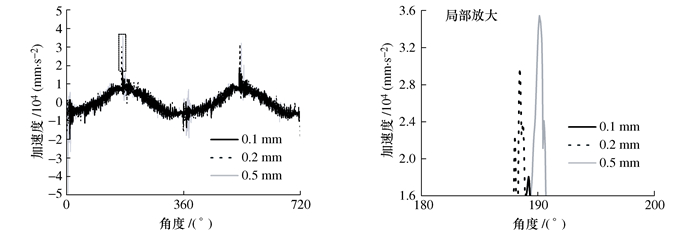

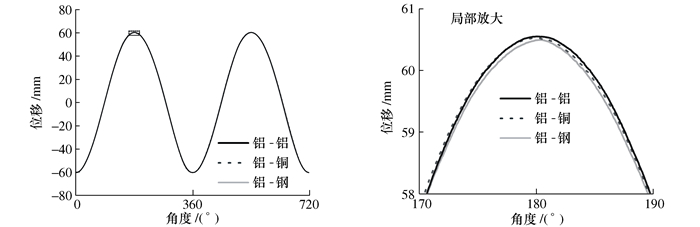

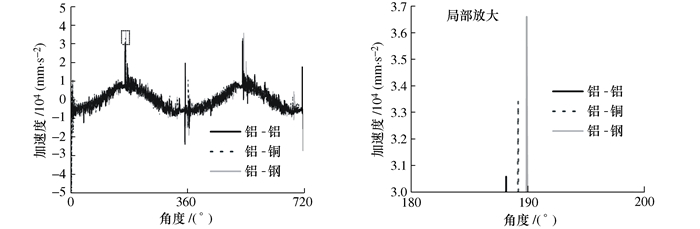

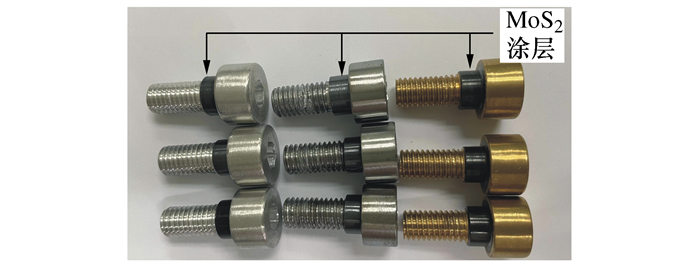

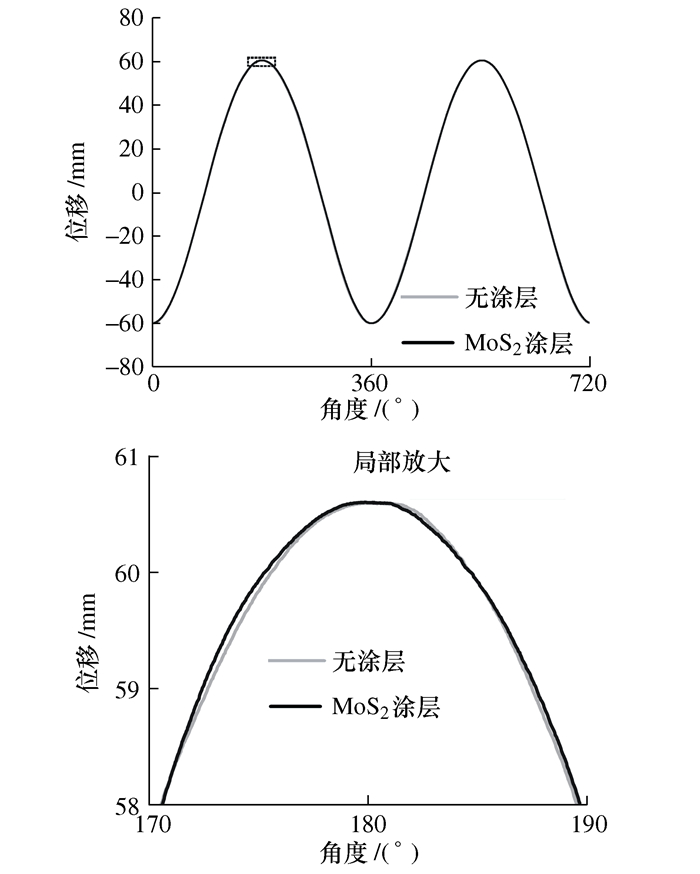

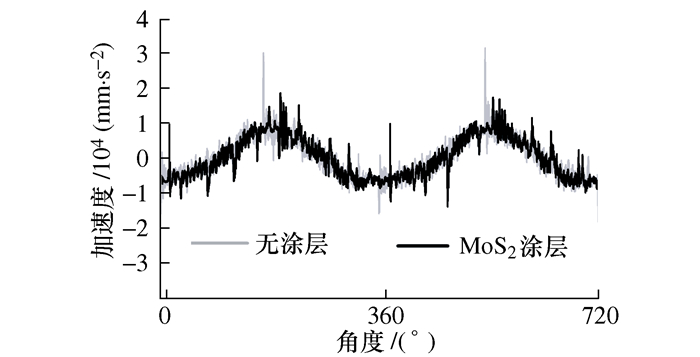

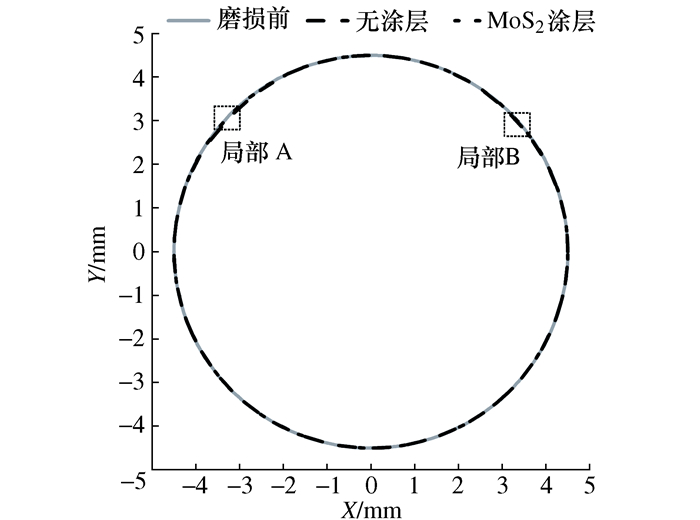

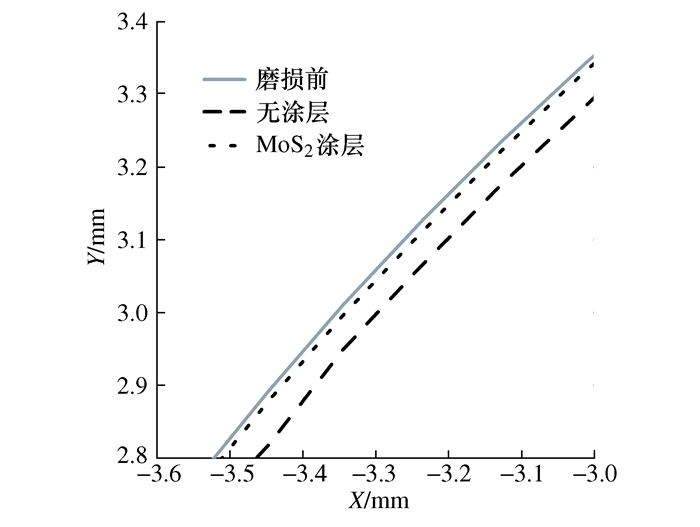

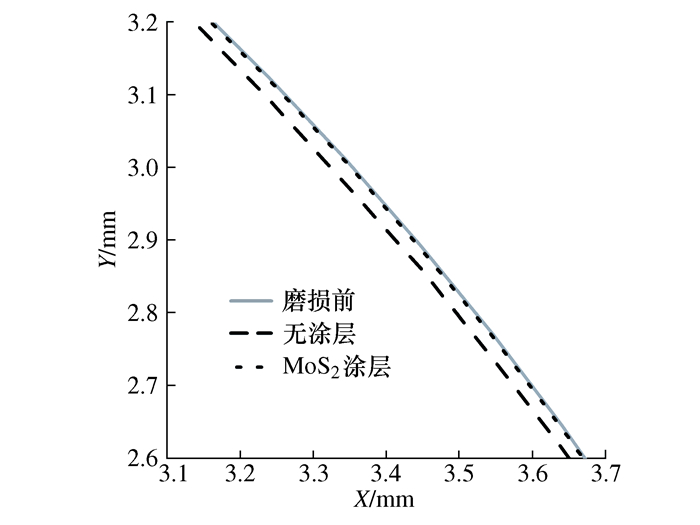

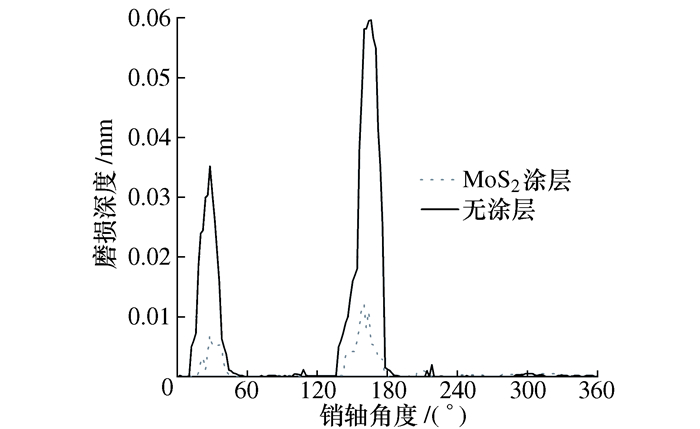

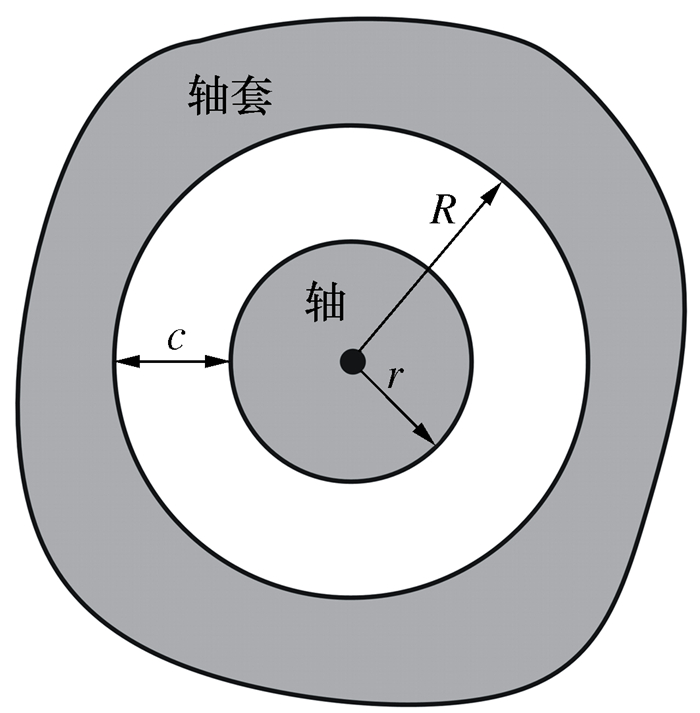

摘要: 为了研究柔性连杆、带有固体润滑涂层MoS2的铰链接触副对含间隙铰链机构的动力学特性的影响规律,以曲柄滑块机构为研究对象,使用Adams软件进行数值仿真分析,研究了柔性连杆材料、铰链间隙、铰链接触副材料和铰链接触副表面固体润滑涂层对曲柄滑块机构动力学特性的影响。通过搭建与数值仿真参数一致的含间隙铰链的曲柄滑块试验台,试验验证了柔性大的连杆、较小的间隙值、接触刚度较小的接触副材料能够减小机构的振动,带有涂层的铰链能够有效减小接触面的磨损量。试验结果和数值仿真结果较为一致,能够有效的反应各种工况对含间隙机构的影响规律,为固体润滑涂层在航天领域中含间隙铰链接触副展开机构的减振抗冲击研究提供理论基础和试验依据。Abstract: In order to study the influence of the flexible connecting rod and hinge contact pair with solid lubrication coating MoS2 on the dynamic characteristics of the hinge mechanism with clearance, the crank slider mechanism was taken as the research object, and Adams software was used for numerical simulation analysis. The influences of the flexible connecting rod material, hinge clearance, hinge contact pair material and solid lubrication coating on the surface of hinge contact pair on the dynamic characteristics of crank slider mechanism were studied. By setting up a crank slide test bench with clearance hinge, which is consistent with the numerical simulation parameters, the test proves that the vibration of the mechanism can be reduced by the flexible connecting rod, the smaller clearance value and the contact pair material with smaller contact stiffness, and the coated hinge can effectively reduce the wear of the contact surface. The experimental results are consistent with the numerical simulation results, which can effectively reflect the influence rule of the various working conditions on the mechanism with clearance, and provide theoretical basis and experimental basis for studying the solid lubrication coating in the aerospace field on the damping and impact resistance of the mechanism with clearance hinge contact pair.

-

Key words:

- clearance /

- hinge /

- flexible connecting rod /

- vibration /

- crank slider

-

表 1 曲柄滑块机构的几何参数

Table 1. Geometric parameters of the crank slider mechanism

构件 尺寸/mm 质量/kg 转动惯量/(kg·mm2) 曲柄 60 8.50 70 连杆 350 2.10 193 滑块 - 2.06 37 表 2 数值仿真的参数

Table 2. Parameters of numerical simulation

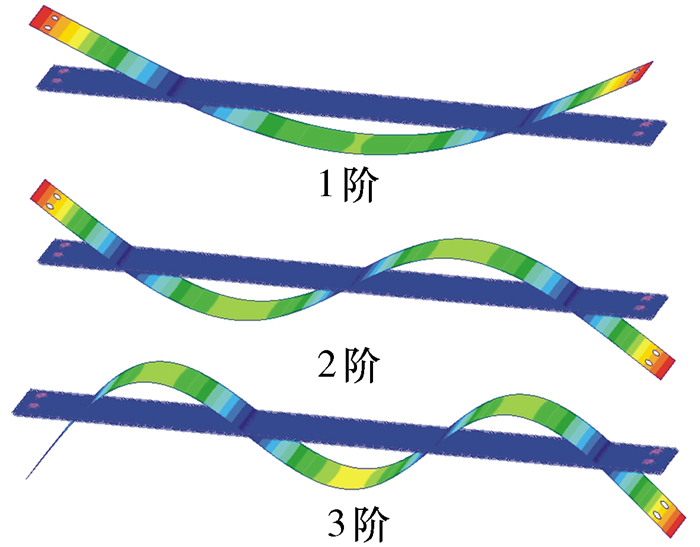

名称 数值 接触刚度系数K/(N·mm-1) 3.46×105 力指数n 1.500 静摩擦力μs 0.270 动摩擦力μd 0.200 刺穿深度δ/mm 0.005 弹性模量/GPa 69.000 泊松比 0.330 步长 0.001 表 3 连杆材料为铜、铝合金、钢的前3阶模态固有频率

Table 3. The connecting rod material is the first three order natural frequencies of copper, aluminum alloy and steel

材料 1阶/Hz 2阶/Hz 3阶/Hz 铜 28.566 78.724 154.384 铝合金 42.552 100.341 188.382 钢 44.578 122.821 240.683 表 4 铰链接触副的材料及参数

Table 4. Materials and parameters of hinge contact pairs

轴套材料 销轴材料 接触刚度/(N·mm-1) 摩擦因数 铝合金 铝合金 3.46×105 0.25/0.20 铝合金 黄铜 4.14×105 0.27/0.25 铝合金 钢 5.17×105 0.27/0.25 表 5 MoS2涂层的参数

Table 5. Parameters of MoS2 coating

涂层材料 接触刚度/(N·mm-1) 摩擦因数 MoS2 4.19×105 0.04 表 6 曲柄滑块机构试验台的结构参数

Table 6. Structural parameters of the test bench of the crank slider mechanism

名称 材料 数值 曲柄 铝合金 60 mm 连杆 铝合金、钢 350 mm 滑块 铝合金 - 销轴 铝合金、铜、钢 9.8 mm、9.6 mm、9.0 mm -

[1] STOENESCU E D, MARGHITU D B. Dynamic analysis of a planar rigid-link mechanism with rotating slider joint and clearance[J]. Journal of Sound and Vibration, 2003, 266(2): 394-404. doi: 10.1016/S0022-460X(03)00053-1 [2] PARENTI-CASTELLI V, VENANZI S. Clearance influence analysis on mechanisms[J]. Mechanism and Machine Theory, 2005, 40(12): 1316-1329. doi: 10.1016/j.mechmachtheory.2005.04.002 [3] FLORES P, AMBRÓSIO J, CLARO J C P, et al. Dynamic behaviour of planar rigid multi-body systems including revolute joints with clearance[J]. Proceedings of the Institution of Mechanical Engineers, Part K: Journal of Multi-Body Dynamics, 2007, 221(2): 161-174. doi: 10.1243/14644193JMBD96 [4] GARCÍA O, ROMERO, GOICOLEA J M. Analysis of joint clearances in multibody systems[C]//Proceedings of Eccomas Multibody Dynamics 2003, International Conference on Advances In Computational Multibody Dynamics. Lisbon, Portugal, 2003(1): 12-36. [5] ERKAYA S, UZMAY I. Determining link parameters using genetic algorithm in mechanisms with joint clearance[J]. Mechanism and Machine Theory, 2009, 44(1): 222-234. doi: 10.1016/j.mechmachtheory.2008.02.002 [6] ZHENG E, ZHU R, ZHU S, et al. A study on dynamics of flexible multi-link mechanism including joints with clearance and lubrication for ultra-precision presses[J]. Nonlinear Dynamics, 2016, 83(1-2): 137-159. doi: 10.1007/s11071-015-2315-7 [7] VAREDI S M, DANIALI H M, DARDEL M, et al. Optimal dynamic design of a planar slider-crank mechanism with a joint clearance[J]. Mechanism and Machine Theory, 2015, 86: 191-200. doi: 10.1016/j.mechmachtheory.2014.12.008 [8] MUVENGEI M, KIHIU J, IKUA B. Effects of clearance size on the dynamic response of planar multi-body systems with differently located frictionless revolute clearance joints[J]. Journal of Energy Technologies and Policy, 2012, 2(3): 7-19. [9] KHEMILI I, ROMDHANE L. Dynamic analysis of a flexible slider-crank mechanism with clearance[J]. European Journal of Mechanics-A/Solids, 2008, 27(5): 882-898. doi: 10.1016/j.euromechsol.2007.12.004 [10] ERKAYA S. Prediction of vibration characteristics of a planar mechanism having imperfect joints using neural network[J]. Journal of Mechanical Science and Technology, 2012, 26(5): 1419-1430. doi: 10.1007/s12206-012-0308-8 [11] ERKAYA S. Investigation of joint clearance effects on welding robot manipulators[J]. Robotics and Computer-Integrated Manufacturing, 2012, 28(4): 449-457. doi: 10.1016/j.rcim.2012.02.001 [12] ERKAYA S, UZMAY I. Investigation on effect of joint clearance on dynamics of four-bar mechanism[J]. Nonlinear Dynamics, 2009, 58(1): 179-198. [13] ERKAYA S, UZMAY I. Effects of balancing and link flexibility on dynamics of a planar mechanism having joint clearance[J]. Scientia Iranica, 2012, 19(3): 483-490. doi: 10.1016/j.scient.2012.04.011 [14] LI Y Y, YANG Y, LI M, et al. Dynamics analysis and wear prediction of rigid-flexible coupling deployable solar array system with clearance joints considering solid lubrication[J]. Mechanical Systems and Signal Processing, 2022, 162: 108059. doi: 10.1016/j.ymssp.2021.108059 [15] 赵子坤. 含间隙机构动力学仿真与实验研究[D]. 大连: 大连理工大学, 2009.ZHAO Z K. Dynamic analysis and experiment research of mechanism with clearance[D]. Dalian: Dalian University of Techhnology, 2009. (in Chinese) [16] 敬谦, 刘宏昭. 考虑圆柱副间隙的连杆机构动力学研究[J]. 振动与冲击, 2021, 40(13): 32-39. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202113005.htmJING Q, LIU H Z. Dynamic characteristics of linkage mechanism considering clearance of cylinder pair[J]. Journal of Vibration and Shock, 2021, 40(13): 32-39. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ202113005.htm [17] 王旭鹏, 刘更, 马尚君, 等. 含间隙运动副机构的动力学特性研究[J]. 振动与冲击, 2016, 35(7): 110-115. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201607018.htmWANG X P, LIU G, MA S J, et al. Dynamic characteristics of mechanisms with revolute clearance joints[J]. Journal of Vibration and Shock, 2016, 35(7): 110-115. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201607018.htm [18] 陈波. 计及柔性构件的平面间隙四杆机构动力学分析与实验研究[D]. 武汉: 武汉科技大学, 2018.CHEN B. Dynamics analysis and experimental research on planar four-bar mechanism with clearance and flexible link[D]. Wuhan: Wuhan University of Science and Technology, 2018. (in Chinese) [19] DUPAC M, BEALE D G. Dynamic analysis of a flexible linkage mechanism with cracks and clearance[J]. Mechanism and Machine Theory, 2010, 45(12): 1909-1923. doi: 10.1016/j.mechmachtheory.2010.07.006 [20] 王旭鹏. 含间隙铰链机构非线性接触力和碰撞动力学研究[D]. 西安: 西北工业大学, 2016WANG X P. Research on nonlinear contact forces and impact dynamics of mechanism with clearance joints[D]. Xi'an: Northwestern Polytechnical University, 2016. (in Chinese) [21] 迟华瑞. 考虑涂层的间隙转动副接触碰撞力模型及其应用[D]. 秦皇岛: 燕山大学, 2019.CHI H R. The contact-impact force model of coated revolute joints with clearance and its application[D]. Qinhuangdao: Yanshan University, 2019. (in Chinese) [22] KHEMILI I, ABDALLAH M A B, AIFAOUI N. Multi-objective optimization of a flexible slider-crank mechanism synthesis, based on dynamic responses[J]. Engineering Optimization, 2018, 51(6): 1-22. [23] 韩建超, 李云, 高鹏, 等. 空间机构MoS2固体润滑真空摩擦特性研究[J]. 机械工程学报, 2017, 53(11): 61-67. https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201711008.htmHAN J C, LI Y, GAO P, et al. Friction performance of space machine with MoS2 solid lubrication coating in vacuum environment[J]. Journal of Mechanical Engineering, 2017, 53(11): 61-67. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXXB201711008.htm -

下载:

下载: