Research on Joint Vibration Solution of Industrial Robot for Current Information and Modal Analysis

-

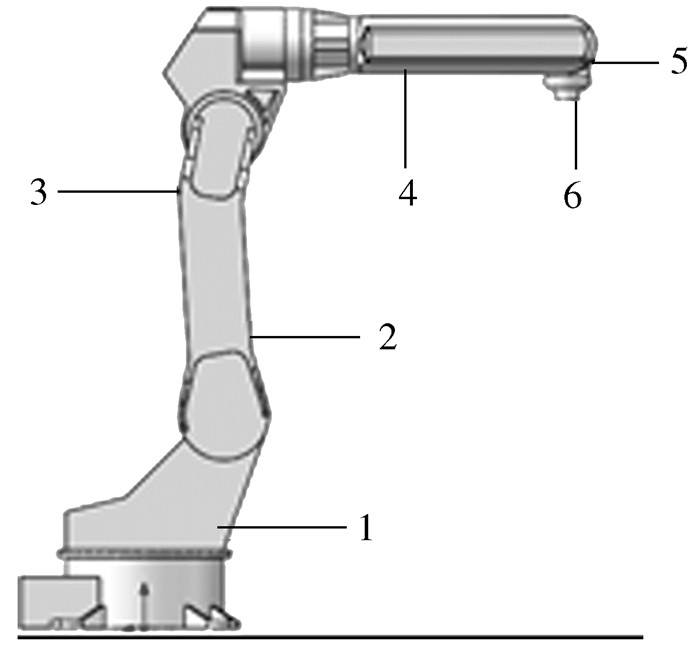

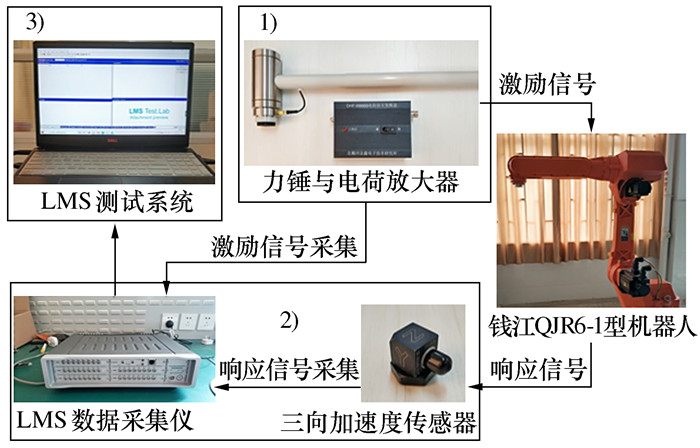

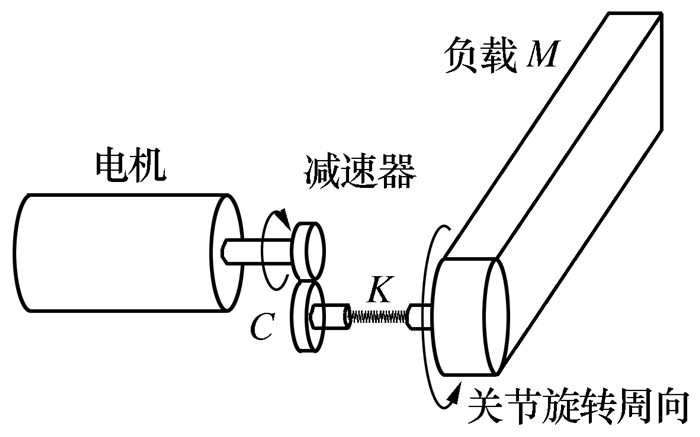

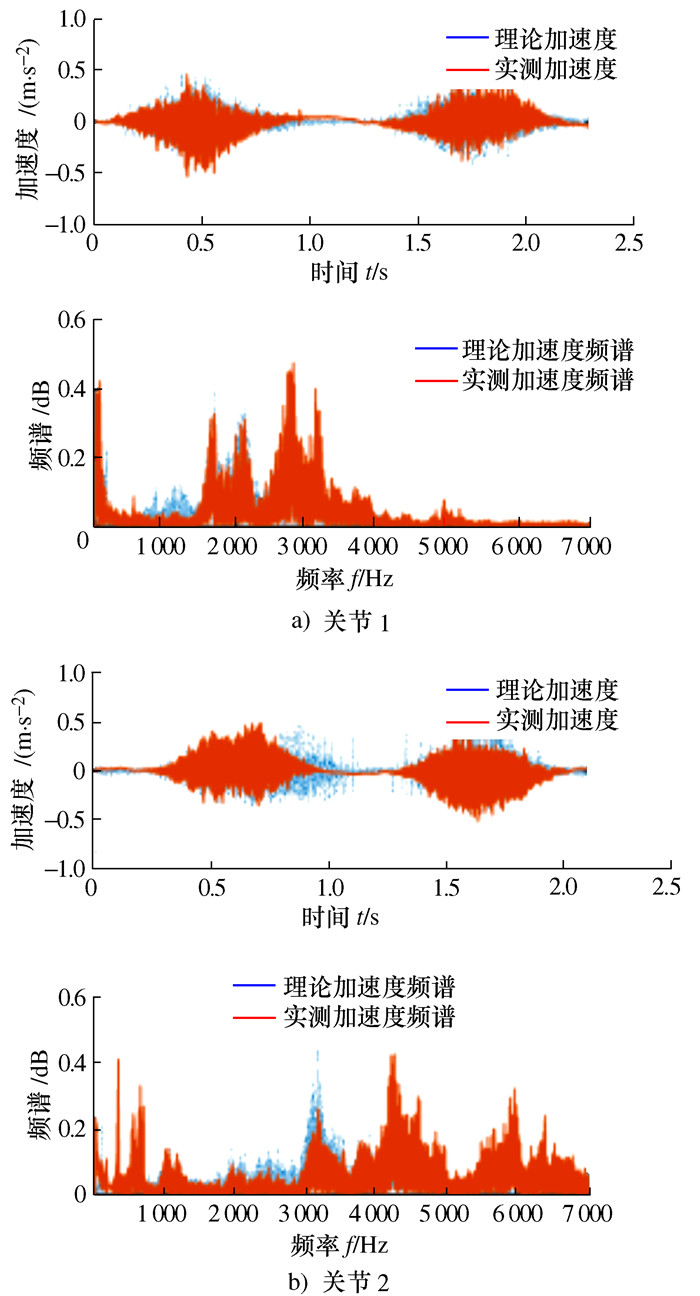

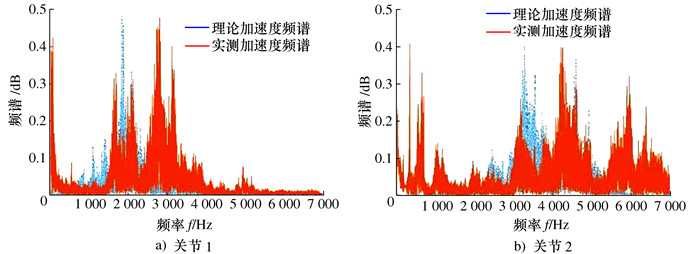

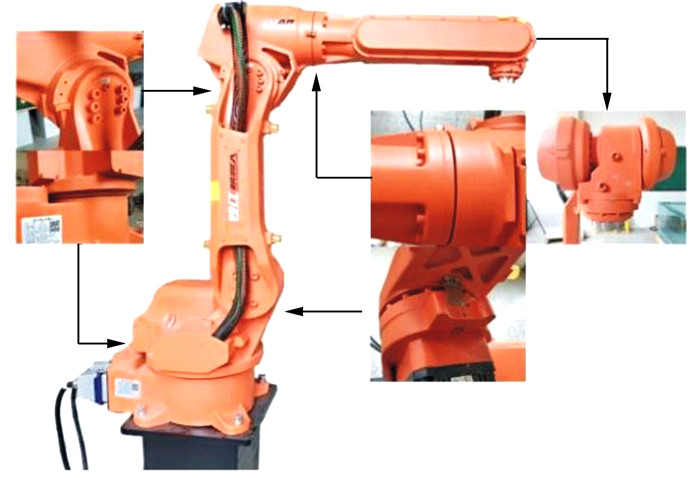

摘要: 在工业机器人健康监测中,针对需采用振动传感器对机器人各关节逐一检测而引起测试成本剧增问题,提出一种基于电流信息与模态分析的关节振动求解方法,该方法可由关节电流经模态转换直接获取关节振动信息。首先,将关节电流信息引入,建立基于关节电流的工业机器人振动模型。然后,由有限元法进行模态分析获取机器人前6阶振型,便于后续模态试验优化测点布置。接着,在力锤激励试验中,基于优化后的测点,测取工业机器人系统质量、刚度等模态参数。之后,将驱动力矩与模态参数带入该模型进行龙格库塔数值求解,得到机器人各关节振动响应。最后,在指定关节转角运行的关节单动与联动实测振动数据验证了本文提出算法的正确性。Abstract: In health monitoring of industrial robots, a joint vibration solution method based on current information and modal analysis was proposed to solve the problem of increasing testing cost caused by the need to use vibration sensors to detect each joint one by one. Firstly, the joint current information is introduced to establish the vibration model of industrial robot based on joint current. Then, the modal analysis is carried out by the finite element method to obtain the first 6 vibration modes of the robot, so as to optimize the layout of measuring points for subsequent modal tests. Then, in the force hammer excitation experiment, based on the optimized measuring points, the modal parameters such as mass and stiffness of the industrial robot system are measured. After that, the driving torque and modal parameters were put into the model to solve the Runge-Kutta numerical solution, and the vibration response of each joint of the robot was obtained. Finally, the proposed algorithm is validated by the measured vibration data of single and linkage joints running at a specified joint angle.

-

Key words:

- industrial robot /

- joint current /

- finite element method /

- joint vibration /

- modal analysis

-

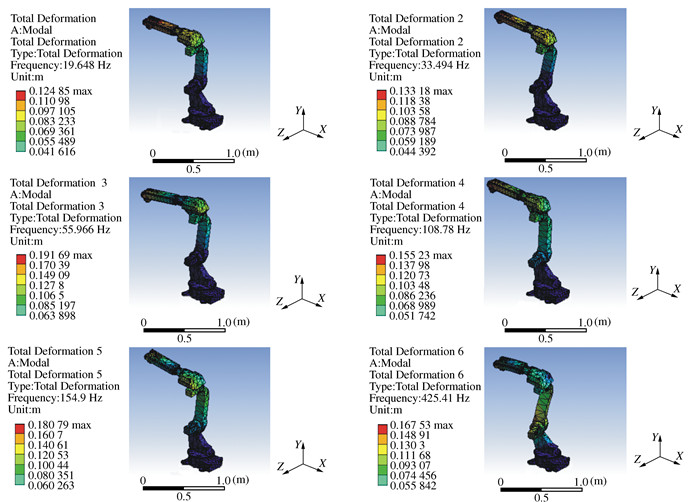

表 1 机器人前6阶仿真模态分析

Table 1. Mode analysis of the first 6 stages of robot simulation

阶数 固有频率ωn/Hz 振型情况 1 19.65 绕关节5的转动 2 33.5 绕关节5的前后摆动 3 55.96 绕关节4的扭动 4 108.78 小臂的上下摆动 5 154.9 大臂的前后摆动 6 425.41 绕大臂的自身扭动 表 2 机器人模态试验前6阶模态参数

Table 2. Six-order modal parameters before the robot modal test

阶数 固有频率ωn/Hz 阻尼比ζi/% 模态质量mri/kg 模态刚度kri/103 (N·m-1) 1 11.58 6.78 0.50 2.92 2 28.27 1.94 0.50 17.53 3 50.73 3.25 0.25 27.42 4 112.62 6.56 0.56 59.41 5 158.17 2.65 0.46 88.75 6 422.04 2.39 0.08 135.62 表 3 工业机器人路径规划

Table 3. Path planning of industrial robots

机器人关节i 一 二 三 四 五 六 角度/(°) 90 60 60 90 30 90 表 4 机器人关节数据采集设备

Table 4. Robot joint data acquisition equipment

设备 单向加速度传感器 电流互感器 采集卡 型号 PCB306C01 ZHTK25 NI9234 表 5 机器人关节运动的理论与实测振动MSE

Table 5. Theoretical and measured vibration MSE of robot joint motion

MSE 关节一 关节二 单关节运动时域 0.0 325 0.0 084 单关节运动频域 0.0 003 0.0 010 多关节联动频域 0.0 012 0.0 017 -

[1] SEGRETO T, KARAM S, TETI R, et al. Feature extraction and pattern recognition in acoustic emission monitoring of robot assisted polishing[J]. Procedia CIRP, 2015, 28: 22-27. doi: 10.1016/j.procir.2015.04.005 [2] KIM Y, PARK J, NA K, et al. Phase-based time domain averaging (PTDA) for fault detection of a gearbox in an industrial robot using vibration signals[J]. Mechanical Systems and Signal Processing, 2020, 138: 106544. doi: 10.1016/j.ymssp.2019.106544 [3] 刘颖. 工业机器人重复定位精度预测与关节典型故障诊断[D]. 上海: 上海交通大学, 2021.LIU Y. Prediction of repetitive accuracy and typical joint fault diagnosis of industrial robot[D]. Shanghai: Shanghai Jiao Tong University, 2021. (in Chinese) [4] LI F, PANG X Y, YANG Z J. Motor current signal analysis using deep neural networks for planetary gear fault diagnosis[J]. Measurement, 2019, 145: 45-54. doi: 10.1016/j.measurement.2019.05.074 [5] 郭闯强, 倪风雷, 孙敬颋, 等. 具有力矩传感器的柔性关节的振动抑制[J]. 机器人, 2011, 33(4): 449-454.GUO C Q, NI F L, SUN J T, et al. Vibration suppression for the flexible joint with torque sensor[J]. Robot, 2011, 33(4): 449-454. (in Chinese) [6] 强艳辉. 工业机器人关节柔性分析与减振控制[D]. 北京: 中国科学院自动化研究所中, 2012.QIANG Y H. Analysis of joint flexiblity and vibration reduction for an industrial robot[D]. Beijing: Institute of Automation, Chinese Academy of Sciences, 2012. (in Chinese) [7] KVRGIC V, VIDAKOVIC J. Efficient method for robot forward dynamics computation[J]. Mechanism and Machine Theory, 2020, 145: 103680. doi: 10.1016/j.mechmachtheory.2019.103680 [8] 樊懿葳, 朱涛, 王明猛, 等. 一种多自由度振动系统动载荷识别的时域方法[J]. 机械科学与技术, 2019, 38(4): 493-498. doi: 10.13433/j.cnki.1003-8728.20180216FAN Y W, ZHU T, WANG M M, et al. A dynamic load identification method for a multiple DOF vibration system in time domain[J]. Mechanical Science and Technology for Aerospace Engineering, 2019, 38(4): 493-498. (in Chinese) doi: 10.13433/j.cnki.1003-8728.20180216 [9] MANSFELD N, OTT C, HADDADIN S. Maximal input limits for independent SISO control in modal space under consideration of actuator constraints[C]//Proceedings of 2016 American Control Conference. Boston: IEEE, 2016: 6721-6728. [10] 魏巍, 杨志东, 韩俊伟. 超冗余液压振动台的模态空间解耦控制[J]. 哈尔滨工业大学学报, 2015, 47(1): 48-53.WEI W, YANG Z D, HAN J W. Modal space decoupling control for a hyper-redundant hydraulic shaking table[J]. Journal of Harbin Institute of Technology, 2015, 47(1): 48-53. (in Chinese) [11] 周俊, 欧阳志民, 伍星, 等. 一种关节型机器人电流耦合信号分离提取方法: 中国, CN111469128A[P]. 2020-07-31.ZHOU J, OUYANG Z M, WU X, et al. A method for separating and extracting current coupling signals of joint robot: CN, CN111469128A[P]. 2020-07-31. (in Chinese) [12] 孔凡, 韩仁杰, 张远进. 确定性周期与随机激励联合作用下非线性系统非平稳响应的统计线性化方法[J]. 振动工程学报, 2022, 35(3): 625-634.KONG F, HAN R J, ZHANG Y J. Non-stationary response of non-linear systems subjected to combined periodic and non-stationary stochastic excitation via the statistical linearization method[J]. Journal of Vibration Engineering: 2022, 35(3): 625-634. (in Chinese) [13] 李阳, 武之剑, 朱学斌, 等. 特种汽车轮边减速系统齿轮传动力学特性分析[J]. 机电工程技术, 2021, 50(4): 166-168.LI Y, WU Z J, ZHU X B, et al. Analysis of dynamic characteristics of gear transmission in wheel side reduction system of special vehicle[J]. Mechanical & Electrical Engineering Technology, 2021, 50(4): 166-168. (in Chinese) [14] 王济, 胡晓. MATLAB在振动信号处理中的应用[M]. 北京: 知识产权出版社, 2006.WANG J, HU X. Application of MATLAB in vibration signal processing[M]. Beijing: Intellectual Property Press, 2006. (in Chinese) [15] 张铁, 覃彬彬, 刘晓刚. 柔体动力学模型的机器人关节振动分析与抑制[J]. 振动、测试与诊断, 2019, 39(2): 242-248.ZHANG T, QIN B B, LIU X G. Vibration analysis and suppression of robot joints based on flexible dynamics model[J]. Journal of Vibration, Measurement & Diagnosis, 2019, 39(2): 242-248. (in Chinese) [16] RAFIEIAN F, LIU Z H, HAZEL B. Dynamic model and modal testing for vibration analysis of robotic grinding process with a 6DOF flexible-joint manipulator[C]//Proceedings of 2009 International Conference on Mechatronics and Automation. Changchun: IEEE, 2009: 2793-2798. [17] LIU J Y, FAN Q L, DENG T, et al. Mechanical analysis and design of a light weight and high stiffness space manipulator[C]//Proceedings of 2016 IEEE International Conference on Mechatronics and Automation. Harbin: IEEE, 2016: 1495-1500. [18] 高绪欣, 卢宁. 基于ANSYS WORKBENCH某重型跨缆吊机满载水平提升工况下的结构分析[J]. 北京建筑大学学报, 2021, 37(4): 75-85.GAO X X, LU N. Structural analysis of a heavy-duty deck erection gantry under full load and horizontal lifting conditions based on ANSYS WORKBENCH[J]. Journal of Beijing University of Civil Engineering and Architecture, 2021, 37(4): 75-85. (in Chinese) [19] 王洋, 刘倩倩, 穆晓彪, 等. 谐波减速器柔轮模态分析与优化方法[J]. 机械传动, 2021, 45(12): 107-111.WANG Y, LIU Q Q, MU X B, et al. Modal analysis and optimization method of flexspline of harmonic reducer[J]. Journal of Mechanical Transmission, 2021, 45(12): 107-111. (in Chinese) [20] LIU Z, SONG L B, LI Y, et al. Comparison of finite element and experimental modal analysis of multi-joint flexible robotic arm[C]//Proceedings of 2017 International Conference on Mechanical, System and Control Engineering. St. Petersburg: IEEE, 2017: 96-100. [21] 吴震宇, 袁惠群, 罗宝佳, 等. 关节型工业机器人扭转振动的伺服补偿技术研究[J]. 振动与冲击, 2020, 39(9): 132-137.WU Z Y, YUAN H Q, LUO B J, et al. Servo compensation technology for the torsional vibration of industry robots[J]. Journal of Vibration and Shock, 2020, 39(9): 132-137. (in Chinese) -

下载:

下载: