Noise Analysis and Optimization Design of Restriction Orifice Plate in Aircraft Air Conditioning Duct

-

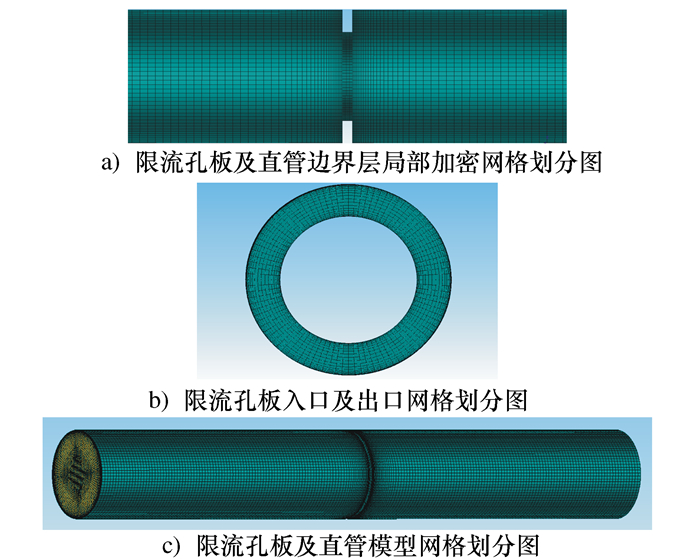

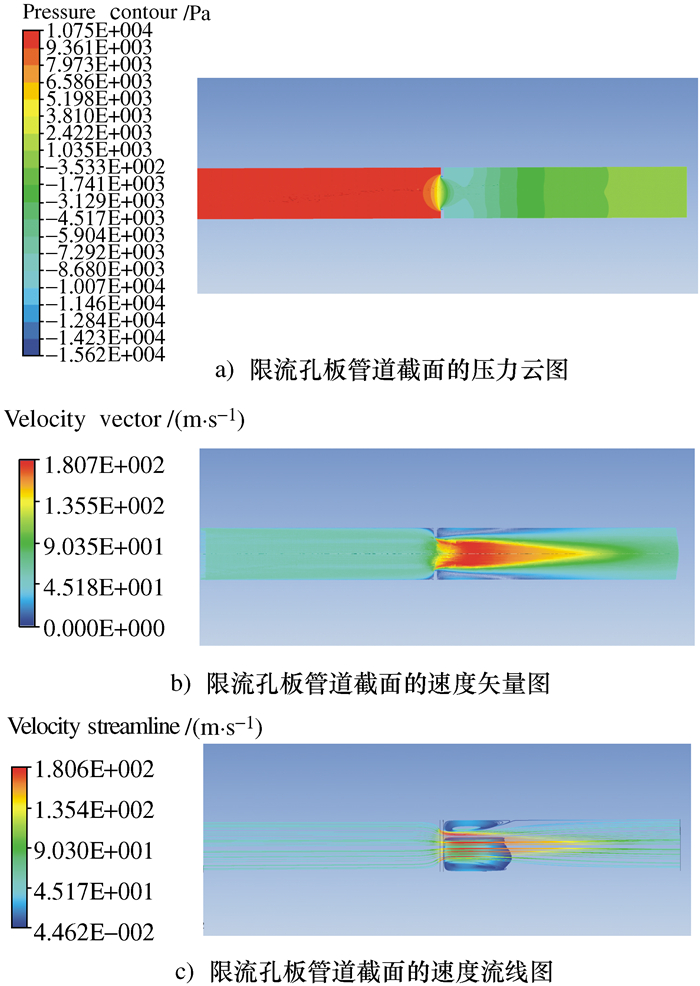

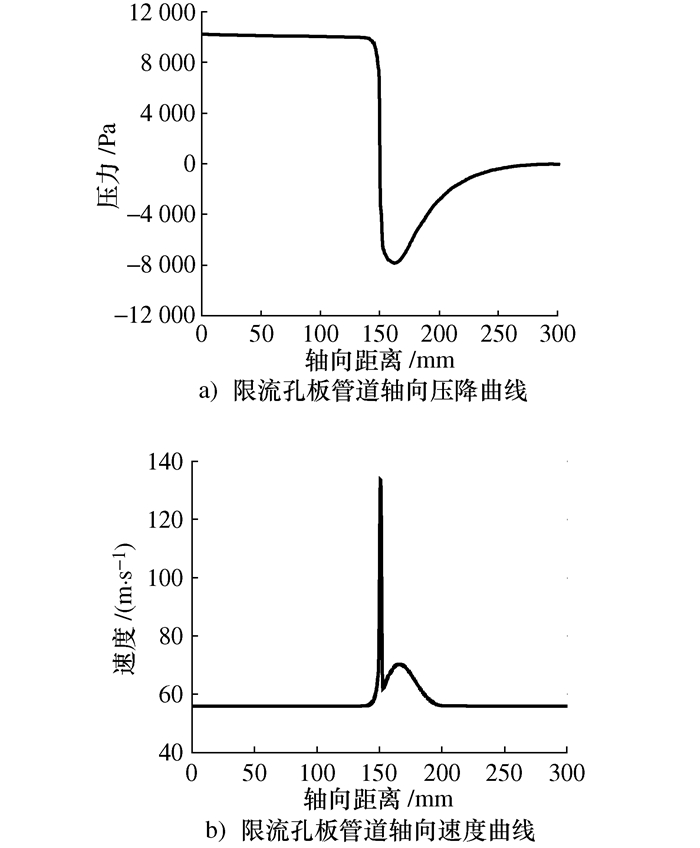

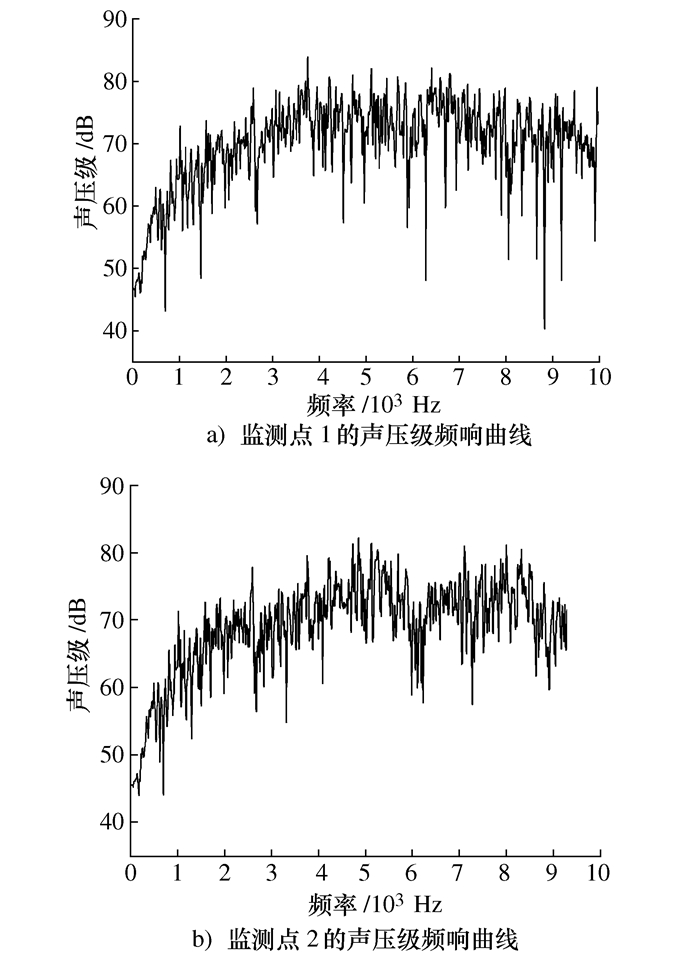

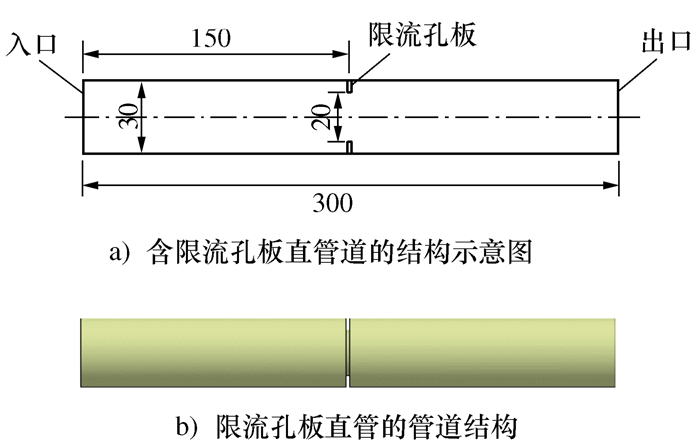

摘要: 为分析限流孔板在飞机空调管道系统中的噪声特性以及对限流孔板进行降噪优化设计, 本文首先运用CFD方法对含限流孔板的直管进行稳态流场数值计算, 探究气流流经限流孔板的流动状态; 然后基于大涡模拟法和FW-H方程, 对管道进行瞬态流场以及声场计算, 分析限流孔板在飞机驾驶舱监测点的流致噪声特性; 最后, 对比分析不同通流孔径的限流孔板对驾驶舱监测点噪声的影响规律, 从而提出较优的限流孔板低噪声结构设计形式。研究结果表明: 增大通流孔径可提高降噪效果, 但压降性能降低, 限流孔板降噪需结合其压降性能综合考虑。Abstract: To analyze the noise characteristics of restriction orifice in aircraft air conditioning duct system and carry out the noise reduction optimization design of restriction orifice plate, the computational fluid dynamics method is used to calculate the steady flow field of a straight duct with the restrictor orifice at first and explore the flow state of the airflow through the orifice. Then, according to the large eddy simulation method and the Ffowcs Williams and Hawkings(FW-H) equation, the transient flow field and acoustic calculation of the duct are carried out, and the flow-induced noise characteristics of restriction orifice at the aircraft cockpit monitoring point are analyzed. Finally, the effects of restriction orifices with different aperture on the cockpit monitoring points are compared and studied, and a better low-noise structure design form of the orifice plate is proposed. The research results show that increasing the flow aperture can improve the noise reduction effect, but the pressure drop performance is reduced, and the noise reduction of the restriction orifice needs to be considered comprehensively with its pressure drop performance.

-

Key words:

- restriction orifice plate /

- CFD method /

- noise characteristics /

- optimization design

-

表 1 不同工况的限流孔板通流孔径参数

Table 1. Parameters of restriction orifice through-flow aperture in different operating conditions

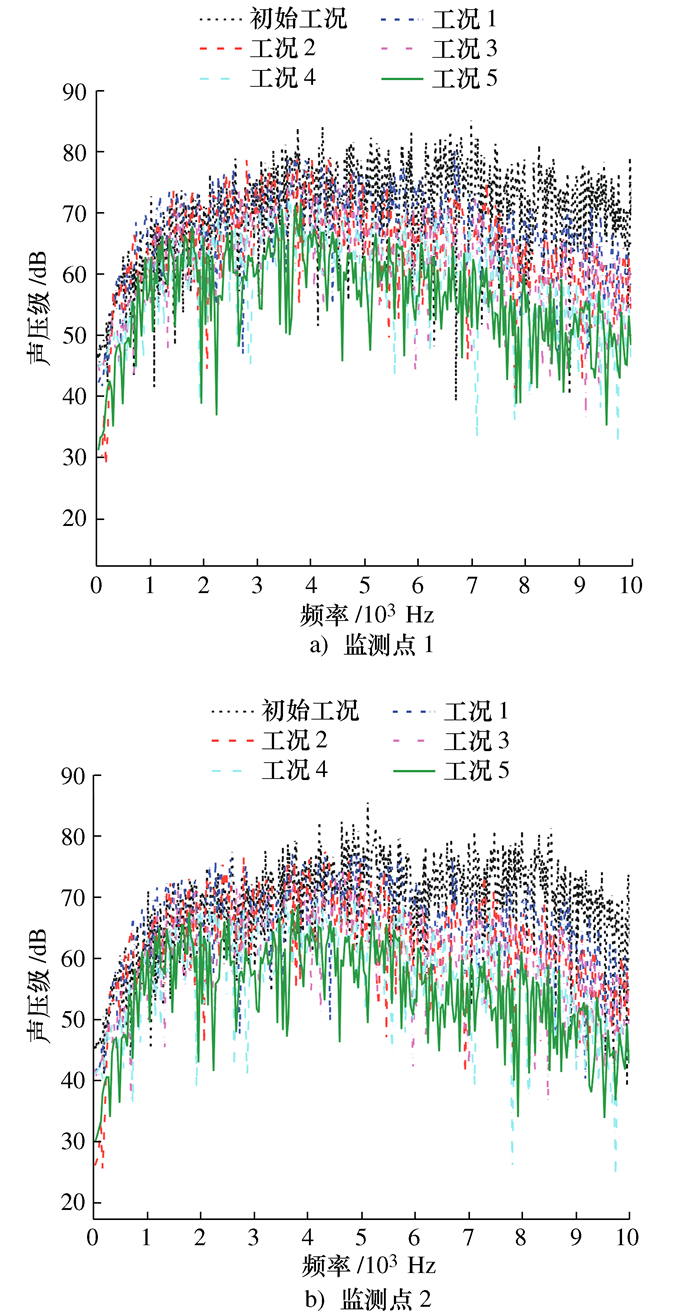

工况 通流孔径/mm 初始 20 1 21 2 22 3 23 4 24 5 25 表 2 监测点1在各工况下的总声压级及降噪效果对比

Table 2. Comparison of total sound pressure level and noise reduction effect of monitoring point 1 under various operating conditions

工况 总声压级/dB 相对前一工况的降噪效果/dB 相对前一工况的降噪幅度/% 相对初始工况的降噪效果/dB 相对初始工况的降噪幅度/% 初始工况 103.17 - - - - 工况1 95.66 -7.51 7.28 -7.51 7.28 工况2 94.03 -1.63 1.70 -9.14 8.86 工况3 91.51 -2.52 2.68 -11.66 11.30 工况4 88.37 -3.14 3.43 -14.80 14.35 工况5 85.41 -2.96 3.35 -17.75 17.21 表 3 监测点2在各工况下的总声压级及降噪效果对比

Table 3. Comparison of total sound pressure level and noise reduction effect of monitoring point 2 under various operating conditions

工况 总声压级/dB 相对前一工况的降噪效果/dB 相对前一工况的降噪幅度/% 相对初始工况的降噪效果/dB 相对初始工况的降噪幅度/% 初始工况 101.76 - - - - 工况1 94.30 -7.46 7.33 -7.46 7.33 工况2 92.46 -1.84 1.95 -9.30 9.14 工况3 89.94 -2.52 2.73 -11.82 11.62 工况4 86.87 -3.07 3.41 -14.89 14.63 工况5 84.02 -2.85 3.28 -17.74 17.43 表 4 各工况的总压降性能对比

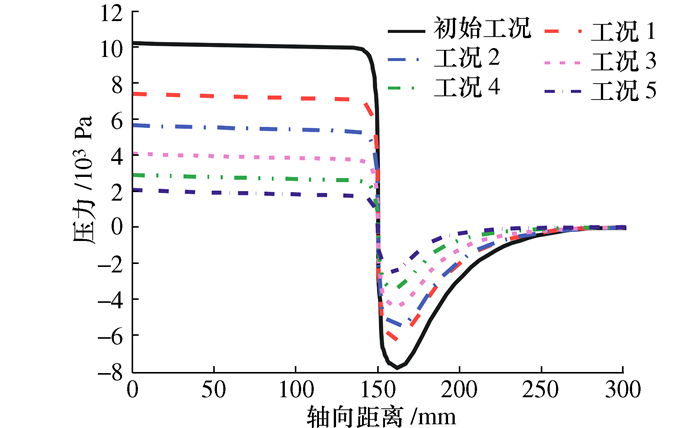

Table 4. Comparison of total pressure drop performance in vanous operating condition

工况 总压降/Pa 孔板前后最大压差/Pa 初始工况 10 265 18 060 工况1 7 426 13 699 工况2 5 693 11 248 工况3 4 101 8 520 工况4 2 924 6 305 工况5 2 066 4 554 -

[1] WANG H H. Study on flow characteristics and noise of pipeline system[M]. Wuhan: Huazhong University of Science and Technology, 2017. (in Chinese) [2] SACK S, ÅBOM M. Investigation of orifice aeroacoustics by means of multi-port methods[J]. Journal of Sound and Vibration, 2017, 407: 32-45. doi: 10.1016/j.jsv.2017.06.026 [3] ARAOYE A A, BADR H M, AHMED W H. Investigation of flow through multi-stage restricting orifices[J]. Annals of Nuclear Energy, 2017, 104: 75-90. doi: 10.1016/j.anucene.2017.02.002 [4] BARROS FILHO J A, SANTOS A A C, NAVARRO M A, et al. Effect of chamfer geometry on the pressure drop of perforated plates with thin orifices[J]. Nuclear Engineering and Design, 2015, 284: 74-79. doi: 10.1016/j.nucengdes.2014.12.009 [5] YAU K H, KUA E C, BALVINDER S. Numerical investigation of a thick plate restriction orifice on the pressure drop performance[J]. IOP Conference Series: Materials Science and Engineering, 2017, 243: 012028. doi: 10.1088/1757-899X/243/1/012028 [6] QIAN J Y, HOU C W, WU J Y, et al. Aerodynamics analysis of superheated steam flow through multi-stage perforated plates[J]. International Journal of Heat and Mass Transfer, 2019, 141: 48-57. doi: 10.1016/j.ijheatmasstransfer.2019.06.061 [7] 欧达毅, 麦卓明. 管道内部扰流板流噪声分析方法综述[J]. 建筑科学, 2014, 30(4): 115-120.OU D Y, MAK C. Review of analytical methods for in-duct spoiler flow noise[J]. Building Science, 2014, 30(4): 115-120. (in Chinese) [8] 白兆亮. 有压输水管道孔板局部阻力相邻影响研究[D]. 乌鲁木齐: 新疆农业大学, 2015.BAI Z L. The study on orifice's local resistance adjacent impact in pressure water pipe[D]. Urumqi: Xinjiang Agricultural University, 2015. (in Chinese) [9] 张鹰, 吴如凡. 基于流场分析的限流孔板设计[J]. 广州化工, 2015, 43(23): 209-211.ZHANG Y, WU R F. Design of restriction orifice based on flow field analysis[J]. Guangzhou Chemical Industry, 2015, 43(23): 209-211. (in Chinese) [10] 王天豪, 吉华, 李倩, 等. 孔中心距对限流孔板压降的影响[J]. 机械, 2020, 47(2): 59-63.WANG T H, JI H, LI Q, et al. Influence of hole center distance on pressure drop of restriction orifice[J]. Machinery, 2020, 47(2): 59-63. (in Chinese) [11] 刘国勇. 流体仿真与应用-基于Fluent仿真计算与应用实例[M]. 北京: 冶金工业出版社, 2017.LIU G Y. Fluid simulation and application-simulation calculation and application example based on fluent[M]. Beijing: Metallurgical Industry Press, 2017. (in Chinese) [12] 杨林谦, 魏雅川, 宋国磊, 等. 湍流模型的选择与评价[C]// 中国航天电子技术研究院科学技术委员会2020年学术年会论文集. 北京: 中国航天电子技术研究院科学技术委员会, 2020: 742-747.YANG L Q, WEI Y C, SONG G L, et al. Selection and evaluation of turbulence models[C]//China Academy of Aerospace Electronics Technology Science and Technology Committee 2020 Annual Conference. Beijing: Science and Technology Committee of China Academy of Aerospace Electronics Technology, 2020: 742-747. (in Chinese) [13] 李淼. 幂律流体圆管湍流流动的大涡模拟[D]. 大庆: 东北石油大学, 2020.LI M. Large eddy simulation of turbulent flow of power-law fluid in circular pipe[D]. Daqing: Northeast Petroleum University, 2020. (in Chinese) [14] 周志腾, 王洪平, 王士召, 等. 基于关联速度的FW-H积分四极子声源修正模型[J]. 空气动力学学报, 2020, 38(6): 1129-1135.ZHOU Z T, WANG H P, WANG S Z, et al. Quadrupole source term corrections based on correlation functions for ffowcs williams and hawkings integrals[J]. Acta Aerodynamica Sinica, 2020, 38(6): 1129-1135. (in Chinese) [15] ZHANG N, XIE H, WANG X, et al. Computation of vortical flow and flow induced noise by large eddy simulation with FW-H acoustic analogy and Powell vortex sound theory[J]. Journal of Hydrodynamics, 2016, 28(2): 255-266. doi: 10.1016/S1001-6058(16)60627-3 -

下载:

下载: