Influence of Process Parameters on Solidification Process in Vertical Continuous Casting of C70600 White Copper Hollow Ingot

-

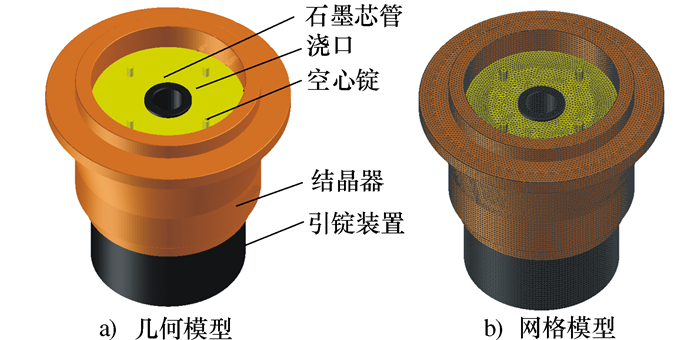

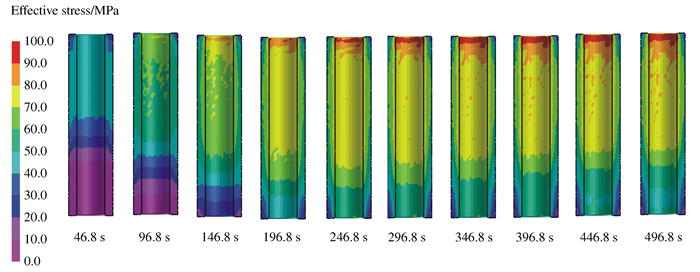

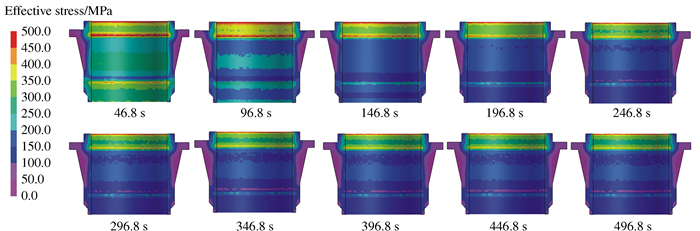

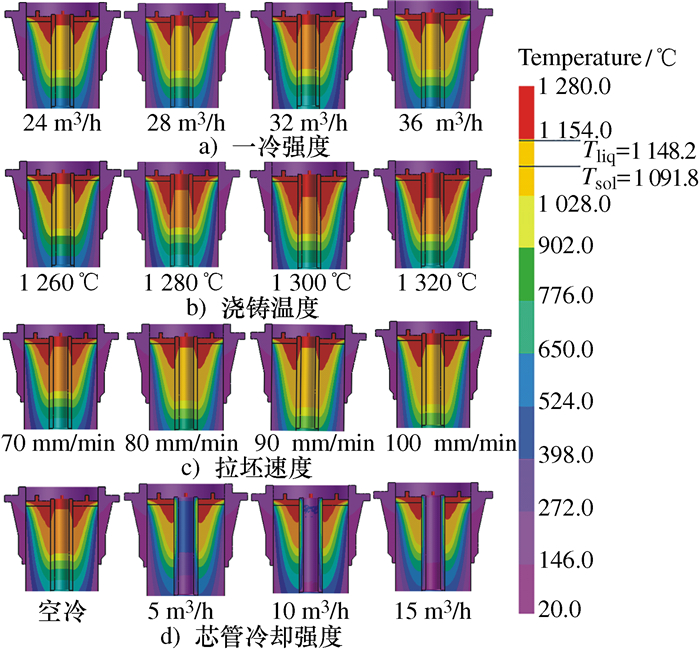

摘要: 为了获得Ø260 × Ø80 C70600白铜空心锭立式连铸合理的工艺参数,通过数值模拟定量分析了各种工艺参数对温度场和应力场的影响。结果表明: 浇铸温度每提高20 ℃, 液穴深度增加10 mm; 拉坯速度每提高10 mm/min,液穴深度增加20 mm; 液穴深度随着石墨芯管冷却强度的增大而减小。基于正交试验和方差分析发现,FA>F0.01(3, 3),FB>FD>F0.1(3, 3),FC<F0.1(3, 3),因此,拉坯速度对液穴深度的影响最显著,一冷强度对其影响不显著。根据模拟结果提出了合理工艺参数为:一冷强度24 m3/h、拉坯速度80 mm/min、浇铸温度1 280 ℃、芯管采用空冷。在此基础上成功试制出了合格的C70600白铜空心锭成品。Abstract: In order to obtain the reasonable process parameters in the vertical continuous casting of large diameter Ø260×Ø80 C70600 cupronickel alloy hollow ingot, the effects of the processing parameters on the temperature field and stress field were quantitatively analyzed by using numerical simulation. The results show that the sump depth increases by 10 mm when the casting temperature increases by 20 ℃, and the sump depth increases by 20 mm when the drawing speed increases by 10 mm/min. The sump depth decreases with the increasing of cooling strength of the graphite core tube. Based on the orthogonal test and variance analysis: FA > F0.01(3, 3), FB > FD > F0.1(3, 3), FC < F0.1(3, 3), therefore, the sump depth is extremely sensitive to the drawing speed, the sump depth is not sensitive to the drawing speed primary cold strength. According to the simulation results, the reasonable processing parameters are as follows: primary cooling strength of 24 m3/h, drawing speed of 80 mm/min, casting temperature of 1 280 ℃, and air cooling for core tube, on this basis, the C70600 cupronickel alloy hollow ingots were successfully produced.

-

Key words:

- vertical continuous casting /

- process parameters /

- hollow ingot /

- sump depth /

- stress field /

- numerical simulation

-

表 1 因素水平表

Table 1. Factor level table

水平 A B C D 1 70 24 空冷 1 260 2 80 28 5 1 280 3 90 32 10 1 300 4 100 36 15 1 320 表 2 液穴深度正交表

Table 2. Orthogonal table of sump depth

实验号 因素 液穴深度

dcenter/mmA B C D 1 1 1 1 1 289 2 1 2 2 2 294 3 1 3 3 3 289 4 1 4 4 4 291 5 2 1 2 3 303 6 2 2 1 4 305 7 2 3 4 1 310 8 2 4 3 2 313 9 3 1 3 4 322 10 3 2 4 3 328 11 3 3 1 2 328 12 3 4 2 1 333 13 4 1 4 2 345 14 4 2 3 1 362 15 4 3 2 4 347 16 4 4 1 3 353 K1 1 163 1 259 1 275 1 294 K2 1 231 1 289 1 277 1 280 K3 1 311 1 274 1 286 1 273 K4 1 407 1 290 1 274 1 265 k1 290.75 314.75 318.75 323.50 k2 307.75 322.25 319.25 320 k3 327.75 318.50 321.50 318.25 k4 351.75 322.50 318.50 316.25 表 3 液穴深度方差分析

Table 3. Variance analysis of sump depth

方差来源 偏差平方和S 自由度f 平均偏差平方和MS F值 显著性 拉坯速度(A) 8 291 3 2 763.67 448.16 ** 一冷强度(B) 160.5 3 53.50 8.68 * 芯管冷却强度(C) 22.5 3 668.33 1.22 浇铸温度(D) 113.5 3 7.50 6.13 * 误差 18.5 3 6.17 Total 8 583.5 15 注: F0.01(3, 3)=29.457;F0.05(3, 3)=9.28;F0.1(3, 3)=5.39。 -

[1] CINCERA S, BARELLA S, BELLOGINI M, et al. De-nickelification of 70/30 cupronickel tubing in a cooling heat exchanger[J]. Journal of Failure Analysis and Prevention, 2012, 12(3): 300-304. doi: 10.1007/s11668-012-9565-1 [2] DROLENGA L J P, IJSSELING F P, KOLSTER B H. The influence of alloy composition and microstructure on the corrosion behaviour of Cu-Ni alloys in seawater[J]. Materials and Corrosion, 2015, 34(4): 167-178. [3] BAUTISTA B E T, WIKIEŁ A J, DATSENKO I, et al. Influence of extracellular polymeric substances (EPS) from Pseudomonas NCIMB 2021 on the corrosion behaviour of 70Cu-30Ni alloy in seawater[J]. Journal of Electroanalytical Chemistry, 2015, 737: 184-197. doi: 10.1016/j.jelechem.2014.09.024 [4] WEI M, YANG B, LIU Y, et al. Research progress and prospect on erosion-corrosion of Cu-Ni alloy pipe in seawater[J]. Journal of the Chinese Society of Corrosion and Protection, 2016, 36(6): 513-521. [5] 甘春雷, 刘雪峰, 黄海友, 等. BFe10-1-1合金管材连续定向凝固制备工艺及组织力学性能[J]. 金属学报, 2010, 46(12): 1549-1556.GAN C L, LIU X F, HUANG H Y, et al. Fabrication process, microstructure and mechanical properties of BFe10-1-1 alloy tubes by continuous unidirectional solidification[J]. Acta Metallurgica Sinica, 2010, 46(12): 1549-1556. (in Chinese) [6] 李新涛, 赵祥伟, 马秀荣, 等. 水平连铸BFe30-1-1白铜管坯凝固过程的数值模拟[J]. 铸造, 2007, 56(8): 841-844.LI X T, ZHAO X W, MA X R, et al. Numerical simulation of solidification process of horizontal continuously cast BFe30-1-1 hollow billets[J]. Foundry, 2007, 56(8): 841-844. (in Chinese) [7] 汤世云, 刘金刚, 韦生, 等. 不同壁厚UNS C70600铜镍合金管的焊接工艺研究[J]. 中国船舶 2019, 60(4): 247-254.TANG S Y, LIU J G, WEI S, et al. Study on welding process of UNS C70600 Cu-Ni alloy pipes with different wall thickness[J]. Shipbuilding of China, 2019, 60(4): 247-254. (in Chinese) [8] 卢强, 赵帆, 雷宇, 等. 连铸速度和轧制变形对HCCM立式连铸铝白铜棒材组织性能的影响[J]. 中国有色金属学报, 2021, 31(6): 1475-1484.LU Q, ZHAO F, LEI Y, et al. Effect of continuous casting speed and cold rolling on microstructure and properties of aluminium white copper bars produced by HCCM vertical continuous casting[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(6): 1475-1484. (in Chinese) [9] 许冠浩. 铜及铜合金带坯立式连铸工艺应用分析[J]. 有色金属加工, 2020, 49(5): 12-13.XU G H. Application analysis of vertical continuous casting process of copper and copper alloy strip[J]. Nonferrous Metals Processing, 2020, 49(5): 12-13. (in Chinese) [10] 张衬新, 余学德, 王彤彤. 水平连铸在铜管生产中的应用进展[J]. 有色冶金设计与研究, 2014, 35(5): 53-55.ZHANG C X, YU X D, WANG T T. Development on application of horizontal continuous casting in copper tube production[J]. Nonferrous Metals Engineering & Research, 2014, 35(5): 53-55. (in Chinese) [11] 吴恒, 张鸿, 吕佳峰, 等. 连续柱状晶组织纯铜室温超延展变形机理[J]. 中国有色金属学报, 2017, 27(12): 2426-2433.WU H, ZHANG H, LYU J F, et al. Extreme plastic extensibility mechanism of continuous columnar-grained copper at ambient temperature[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(12): 2426-2433. (in Chinese) [12] 刘新华, 付新彤, 付华栋, 等. 大断面铜包铝棒坯立式连铸成形工艺参数对连铸复合过程影响的数值模拟[J]. 中国有色金属学报, 2017, 27(3): 514-524.LIU X H, FU X T, FU H D, et al. Numerical simulation analysis of effects of processing parameters on forming process of vertical continuous core-filling casting for copper clad aluminum billets with large section[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(3): 514-524. (in Chinese) [13] ZHANG R T, SHEN M G, ZHANG Z S, et al. Coupled mathematical model of thermal stress for initial shell of groove continuous casting mold[J]. Transactions of the Indian Institute of Metals, 2021, 74(7): 1683-1688. doi: 10.1007/s12666-021-02263-0 [14] HAN Y, ZHANG X B, YU E L, et al. Numerical analysis of temperature field and structure field in horizontal continuous casting process for copper pipes[J]. International Journal of Heat and Mass Transfer, 2017, 115: 294-306. doi: 10.1016/j.ijheatmasstransfer.2017.08.037 [15] 沈兰, 尹延国, 成剑峰. 铝合金立式连铸异形结晶器的研究[J]. 机械科学与技术, 2021, 40(7): 1128-1136. doi: 10.13433/j.cnki.1003-8728.20200174SHEN L, YIN Y G, CHENG J F. Study on special-shaped crystallizer for vertical continuous casting of aluminum alloy[J]. Mechanical Science and Technology for Aerospace Engineering, 2021, 40(7): 1128-1136. (in Chinese) doi: 10.13433/j.cnki.1003-8728.20200174 [16] KONG L Y, LIU X Z, SHI Z N, et al. Numerical simula-tion of liquid aluminum leakage in casting process[J]. Transactions of Nonferrous Metals Society of China, 2021, 30(1): 279-305. -

下载:

下载: