Research on Polishing Roughness Prediction Model of Robot Curved Surface Parts

-

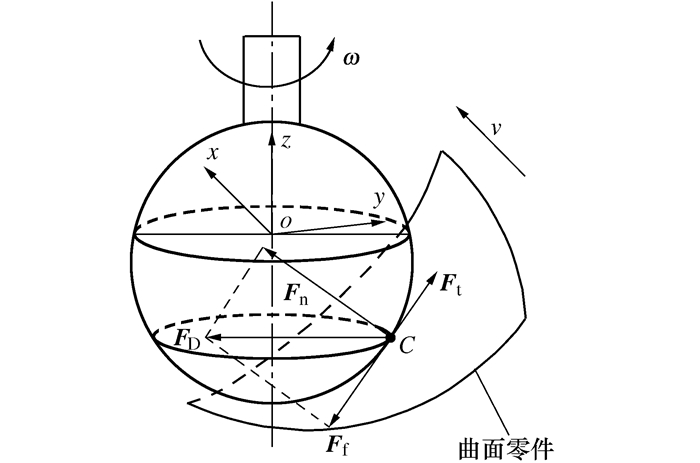

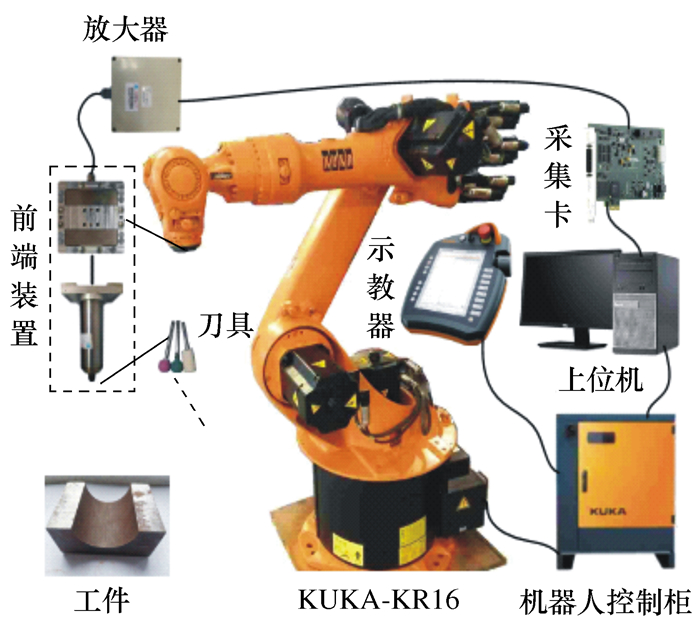

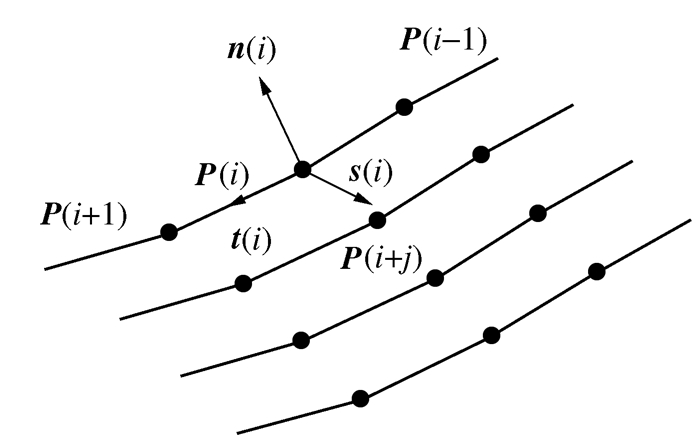

摘要: 为提高抛光后曲面零件的表面质量,应建立粗糙度模型选取合理工艺参数,因此本文提出一种基于支持向量机(SVM)的建模方法。通过对机器人抛光过程及抛光工艺参数的研究,将刀具转速、抛光力、行间距、机器人进给速度等作为输入量,粗糙度作为输出量。结合粒子群算法(PSO)与SVM建立曲面零件抛光粗糙度预测模型,并与回归分析方法作对比。试验结果表明: 回归分析方法的预测误差较大,而基于SVM建立的曲面零件抛光粗糙度预测模型与试验结果高度吻合,试验测量值与预测值间的平均相对误差为2.84%。最后,通过全局寻优获得最佳工艺参数组合,该模型为合理选择抛光工艺参数提供了依据。Abstract: In order to improve the surface quality of polished surface parts, a roughness model should be established to select reasonable process parameters. Therefore, a modeling method based on support vector machine (SVM) is proposed in this paper. Through researching the robot polishing process and polishing process parameters, the tool rotation speed, polishing force, row spacing, robot feed speed, etc. are used as input variables, and roughness is used as output variables. Combined with particle swarm optimization (PSO) and SVM, a prediction model of curved surface parts polishing roughness was established, and compared with the regression analysis method. The experimental results show that the prediction error of the regression analysis method is relatively large, and the prediction model of polishing roughness of curved surface parts established based on SVM is highly consistent with the experimental results. The average relative error between the experimental measured value and the predicted value is 2.84%. The optimal combination of process parameters is obtained by optimization, and the model provides a basis for rational selection of polishing process parameters.

-

表 1 测试集试验数据

Table 1. Test set experimental data

序号 刀具转速/(r·min-1) 抛光力/N 行距/mm 进给速度/(mm·s-1) Ra/μm 1 4 000 6 0.5 6.24 0.561 2 5 000 5 0.3 5.46 0.456 3 6 000 4 0.6 4.68 0.614 4 7 000 3 0.4 3.9 0.569 5 8 000 2 0.2 3.12 0.495 表 2 训练集试验数据

Table 2. Training set experimental data

序号 刀具转速/(r·min-1) 抛光力/N 行距/mm 进给速度/(mm·s-1) Ra/μm 1 4 000 2 0.2 3.12 0.431 2 4 000 3 0.5 3.9 0.478 3 4 000 4 0.3 4.68 0.455 4 4 000 5 0.4 5.46 0.611 5 4 000 6 0.6 6.24 0.634 6 5 000 2 0.3 6.24 0.635 7 5 000 3 0.6 3.12 0.559 8 5 000 4 0.4 3.9 0.388 9 5 000 5 0.2 4.68 0.406 10 5 000 6 0.5 5.46 0.548 11 6 000 2 0.4 5.46 0.616 12 6 000 3 0.2 6.24 0.407 13 6 000 4 0.5 3.12 0.433 14 6 000 5 0.3 3.9 0.459 15 6 000 6 0.6 4.68 0.571 16 7 000 2 0.5 4.68 0.649 17 7 000 3 0.3 5.46 0.562 18 7 000 4 0.6 6.24 0.58 19 7 000 5 0.4 3.12 0.379 20 7 000 6 0.2 3.9 0.402 21 8 000 2 0.6 3.9 0.794 22 8 000 3 0.4 4.68 0.592 23 8 000 4 0.2 5.46 0.441 24 8 000 5 0.5 6.24 0.649 25 8 000 6 0.3 3.12 0.511 表 3 两种方法的预测精度对比

Table 3. Comparison of prediction accuracy between two methods

试验序号 回归分析 PSO-SVM 预测值/μm 相对误差/% 预测值/μm 相对误差/% 1 0.553 1.43 0.528 5.88 2 0.48 5.26 0.462 1.32 3 0.601 2.11 0.621 1.14 4 0.533 6.33 0.554 2.64 5 0.43 13.13 0.511 3.23 平均误差/% 5.65 2.84 表 4 抛光参数水平

Table 4. Polishing parameter levels

抛光工艺参数 水平 1 2 3 4 刀具转速/(r·min-1) 5 000 6 000 7 000 8 000 抛光力/N 2 3 4 5 行距/mm 0.2 0.3 0.4 0.5 进给速度/(mm·s-1) 3.12 3.9 4.68 5.46 -

[1] 陈满意, 樊江龙, 林文访. 基于响应曲面法的曲面抛光工艺参数研究[J]. 数字制造科学, 2019, 17(2): 113-118.CHEN M Y, FAN J L, LIN W F. Investigation on optimization of polishing process based on response surface method[J]. Digital Manufacture Science, 2019, 17(2): 113-118. (in Chinese) [2] CHANG Z, JIA Q, YUAN X, et al. Optimization of the grinding process to improve the surface integrity of bearing raceways[J]. The International Journal of Advanced Manufacturing Technology, 2017, 91(9-12): 4243-4252. doi: 10.1007/s00170-017-0061-3 [3] CHEN Z, SHI Y Y, LIN X J, et al. Analysis and optimization of process parameter intervals for surface quality in polishing Ti-6Al-4V blisk blade[J]. Results in Physics, 2019, 12: 870-877. doi: 10.1016/j.rinp.2018.12.056 [4] 淮文博, 史耀耀, 唐虹, 等. 砂布轮抛光叶片表面粗糙度预测与参数优化[J]. 计算机集成制造系统, 2017, 23(12): 2708-2718.HUAI W B, SHI Y Y, TANG H, et al. Surface roughness prediction and processing parameters optimization in abrasive cloth wheel polishing process for blade[J]. Computer Integrated Manufacturing Systems, 2017, 23(12): 2708-2718. (in Chinese) [5] 朱正清, 陈志同. 钛合金TC4的超硬磨料柔性抛光轮数控抛光试验研究[J]. 航空制造技术, 2022, 65(4): 56-62.ZHU Z Q, CHEN Z T. Experiment on CNC polishing of titanium TC4 using flexible polishing wheel with superhard abrasive[J]. Aeronautical Manufacturing Technology, 2022, 65(4): 56-62. (in Chinese) [6] RAO R V, PAWAR P J. Grinding process parameter optimiza-tion using non-traditional optimization algorithms[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2010, 224(6): 887-898. doi: 10.1243/09544054JEM1782 [7] ZHAO T, SHI Y Y, LIN X J, et al. Surface roughness prediction and parameters optimization in grinding and polishing process for IBR of aero-engine[J]. The International Journal of Advanced Manufacturing Technology, 2014, 74(5-8): 653-663. doi: 10.1007/s00170-014-6020-3 [8] 刘海旭, 武庆东, 曹潇俊, 等. 基于响应曲面法的304不锈钢化学机械抛光工艺参数优化[J]. 金刚石与磨料磨具工程, 2021, 41(2): 89-95.LIU H X, WU Q D, CAO X J, et al. Prediction and optimization of process parameters in chemical mechanical polishing for 304 stainless steel based on response surface methodology[J]. Diamond & Abrasives Engineering, 2021, 41(2): 89-95. (in Chinese) [9] 周恒飞. 面向表面质量的自适应加工参数控制方法研究[D]. 南京: 南京航空航天大学, 2020.ZHOU H F. Research on adaptive control method of machining parameters for surface quality[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2020. (in Chinese) [10] 冯海涛. 机器人自动化拋光系统关键技术的研究[D]. 杭州: 浙江大学, 2015.FENG H T. Research on the key technologies of robotic automatic polishing system[D]. Hangzhou: Zhejiang University, 2015. (in Chinese) [11] 黄嘉沛, 颜廷培, 丁宁, 等. 基于LibSVM激光透射焊接聚碳酸酯的工艺参数优化[J]. 焊接, 2021(3): 39-45.HUANG J P, YAN T P, DING N, et al. Parameters optimization of laser transmission welding polycarbonate based on LibSVM[J]. Welding & Joining, 2021(3): 39-45. (in Chinese) [12] 赵敬川, 赵吉宾, 李论, 等. 基于支持向量机的复杂曲面磨削去除量预测[J]. 组合机床与自动化加工技术, 2021(11): 58-61.ZHAO J C, ZHAO J B, LI L, et al. Prediction of complex surface grinding removal based on support vector machine[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2021(11): 58-61. (in Chinese) [13] 鲁娟, 张振坤, 吴智强, 等. 基于支持向量机的蠕墨铸铁表面粗糙度预测[J]. 表面技术, 2020, 49(2): 339-346.LU J, ZHANG Z K, WU Z Q, et al. Prediction of surface roughness for compacted graphite cast iron based on support vector machine[J]. Surface Technology, 2020, 49(2): 339-346. (in Chinese) [14] WANG W J, XU Z B. A heuristic training for support vector regression[J]. Neurocomputing, 2004, 61: 259-275. [15] 韩晓露, 王家忠, 弋景刚, 等. 基于Preston方程的反射杯抛磨工艺参数研究[J]. 机床与液压, 2018, 46(14): 12-16.HAN X L, WANG J Z, YI J G, et al. Study on polishing processing parameters of reflective cup based on Preston equation[J]. Machine Tool & Hydraulics, 2018, 46(14): 12-16. (in Chinese) [16] 樊江龙. 抛光机器人动力学建模与柔顺控制研究[D]. 武汉: 武汉理工大学, 2019.FAN J L. Research on dynamic modeling and compliance control for polishing robot[D]. Wuhan: Wuhan University of Technology, 2019. (in Chinese) [17] 梁子龙, 丁毓峰. 一种自由曲面抛光机器人轨迹规划方法[J]. 机械科学与技术, 2018, 37(10): 1489-1495. doi: 10.13433/j.cnki.1003-8728.20180071LIANG Z L, DING Y F. A trajectory planning method for free-form surface polishing robot[J]. Mechanical Science and Technology for Aerospace Engineering, 2018, 37(10): 1489-1495. (in Chinese) doi: 10.13433/j.cnki.1003-8728.20180071 [18] NAGATA F, HASE T, HAGA Z, et al. CAD/CAM-based Position/force controller for a mold polishing robot[J]. Mechatronics, 2007, 17(4-5): 207-216. [19] 余剑武, 胡其丰, 文丞, 等. 基于支持向量机的电火花加工8418钢表面粗糙度预测模型[J]. 中国机械工程, 2018, 29(7): 771-774.YU J W, HU Q F, WEN C, et al. Prediction model of surface roughness of 8418 steel by EDM based on SVM[J]. China Mechanical Engineering, 2018, 29(7): 771-774. (in Chinese) -

下载:

下载: