A Speed Planning Algorithm for S-type Acceleration and Deceleration Combination

-

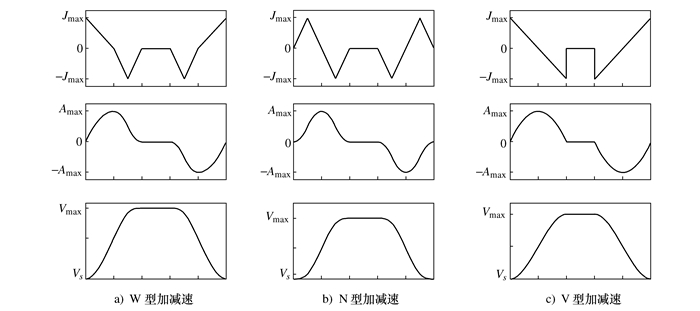

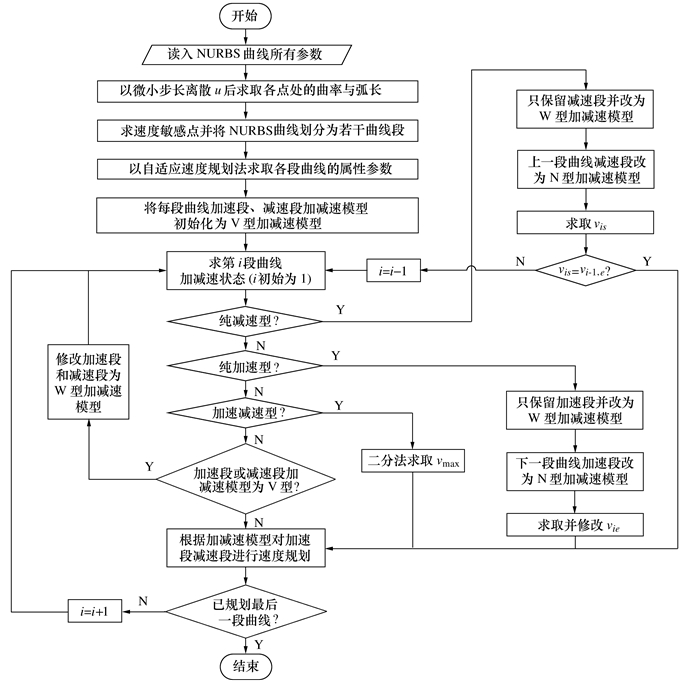

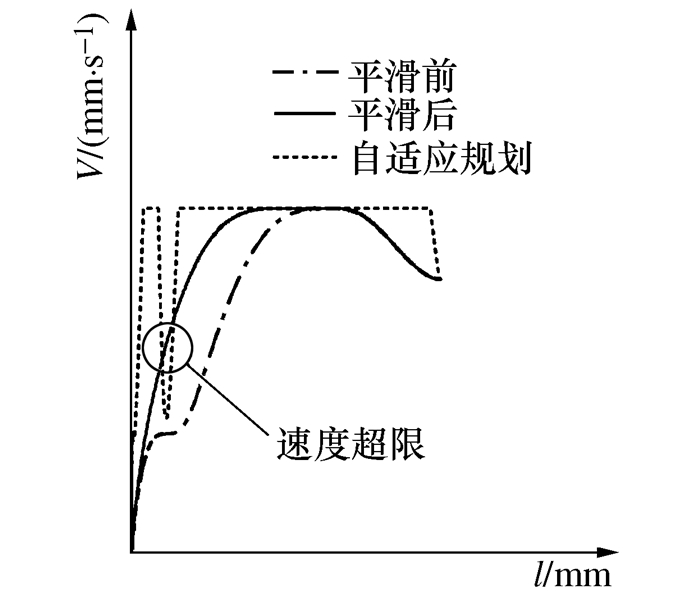

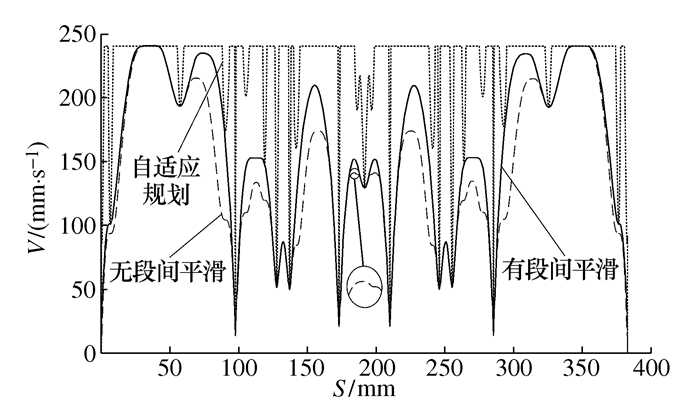

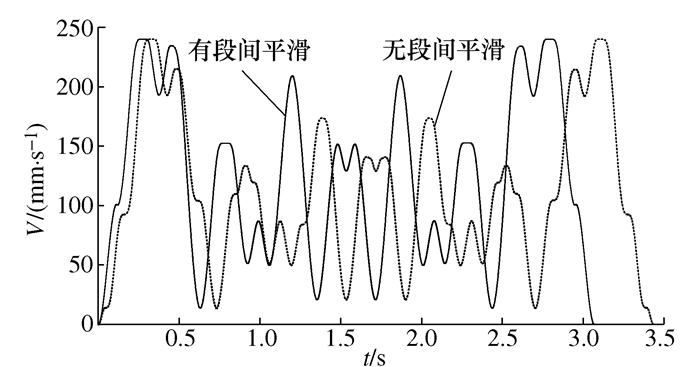

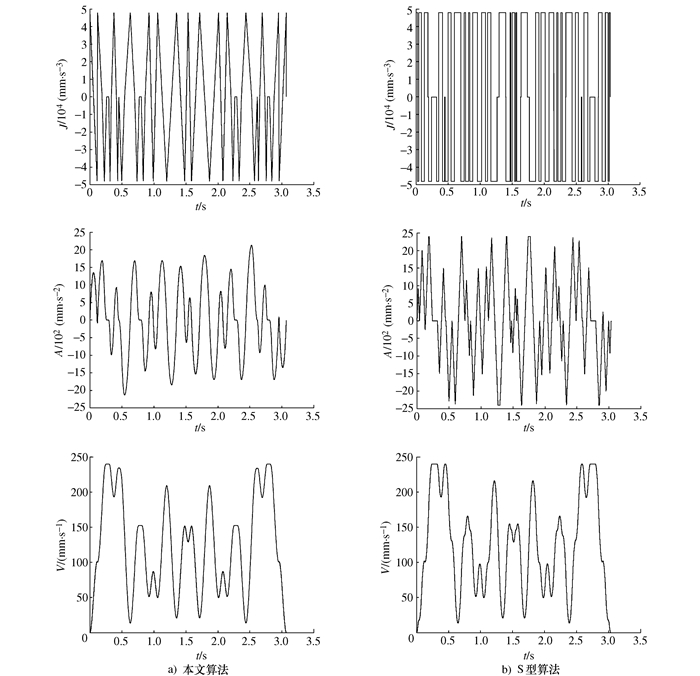

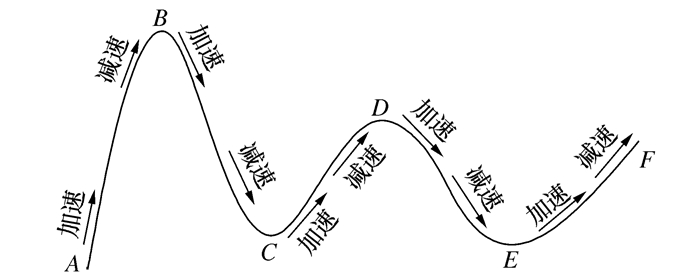

摘要: 针对传统NURBS曲线插补S型加减速的改进难以在加工柔性和加工效率上同时兼顾的问题,提出一种将多种S型加减速组合的速度规划算法。选取分别在加工柔性和加工效率上单独改进的两种S型加减速,并设计了一种兼顾柔性和效率的新改进S型加减速。在速度规划中,根据简化后的4种加减速形式,灵活组合这3种S型加减速,并采取合并曲线分段的速度平滑方式,减少了曲线段间的速度波动。仿真结果表明: 该算法能在提高加工效率的同时满足加加速度的连续,最终实现加工柔性和加工效率的兼得。Abstract: Because it is difficult to take into account the machining flexibility and machining efficiency at the same time in improving the S-type acceleration and deceleration for the traditional NURBS curve interpolation, a speed planning algorithm that combines multiple S-type accelerations and decelerations is proposed. Two S-type acceleration and deceleration models which have been separately improved for machining flexibility and efficiency are selected. A novel and improved S-type acceleration and deceleration model with both flexibility and efficiency considered is designed. According to the simplified four acceleration and deceleration forms, the speed planning algorithm flexibly combines the three models, and the speed smoothing method that merges curve segments is adopted to reduce the velocity fluctuation between the curve segments. The simulation results show that the speed planning algorithm can improve the machining efficiency and satisfy the continuity of jerk, finally achieving both machining flexibility and machining efficiency.

-

表 1 3种S型加减速模型加速段结束时的速度位移变化

Table 1. The velocity and displacement changes at the end of the acceleration segment for the three models

W型加减速 N型加减速 V型加减速 ΔV

ΔS 表 2 W型和N型加减速各加速阶段的速度与位移变化

Table 2. Velocity and displacement changes in each acceleration phase of W type and N type acceleration and deceleration

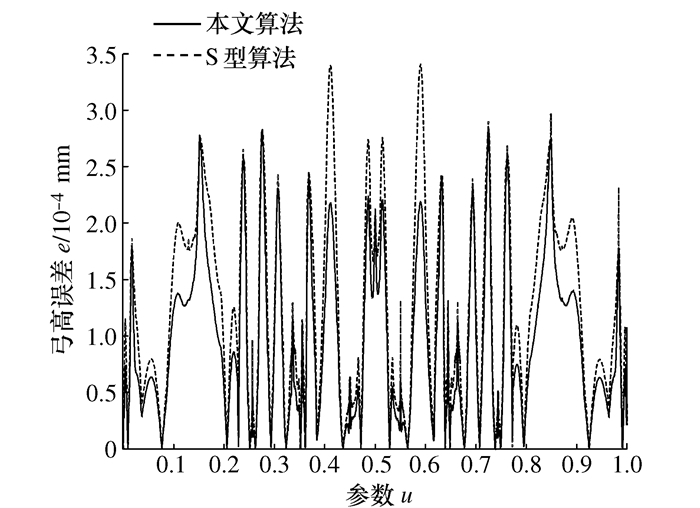

表 3 弓高误差和速度波动率统计表

Table 3. Chord error and speed fluctuation statistical table

参数 本文算法 S型算法 平均弓高误差/mm 8.357 4×10-5 1.105 1×10-4 最大弓高误差/mm 2.831 2×10-4 3.407 9×10-4 平均速度波动率 1.248 3×10-5 1.837 6×10-5 最大速度波动率 6.414 7×10-4 9.341 1×10-4 -

[1] NI H P, ZHANG C R, JI S, et al. A bidirectional adaptive feedrate scheduling method of NURBS interpola-tion based on S-shaped ACC/DEC algorithm[J]. IEEE Access, 2018, 6: 63794-63812. doi: 10.1109/ACCESS.2018.2875403 [2] JI S J, LEI L G, ZHAO J, et al. An adaptive real-time NURBS curve interpolation for 4-axis polishing machine tool[J]. Robotics and Computer-Integrated Manufacturing, 2021, 67: 102025. doi: 10.1016/j.rcim.2020.102025 [3] LUO H M, ZHAO D B, FU W Q. Speed planning algorithm based on improved S-type acceleration and deceleration model[J]. Journal of Shanghai Jiaotong University (Science), 2021, 26(6): 786-793. doi: 10.1007/s12204-021-2322-4 [4] 赵国勇, 徐志祥, 赵福令. 高速高精度数控加工中NURBS曲线插补的研究[J]. 中国机械工程, 2006, 17(3): 291-294. doi: 10.3321/j.issn:1004-132X.2006.03.020ZHAO G Y, XU Z X, ZHAO F L. Study on NURBS curve interpolator in the high speed and high accuracy CNC machining[J]. China Mechanical Engineering, 2006, 17(3): 291-294. (in Chinese) doi: 10.3321/j.issn:1004-132X.2006.03.020 [5] 冷洪滨, 邬义杰, 潘晓弘. 三次多项式型微段高速自适应前瞻插补方法[J]. 机械工程学报, 2009, 45(6): 73-79.LENG H B, WU Y J, PAN X H. Adaptive prospective interpolation method for high speed machining of micro line blocks based on the cubic polynomial model[J]. Journal of Mechanical Engineering, 2009, 45(6): 73-79. (in Chinese) [6] ZHANG J, GAO W Q, HU Z H, et al. The applied research of four polynomial acceleration and deceleration control method in multi-axis DSP motion controller[J]. Advanced Materials Research, 2012, 542-543: 567-572. doi: 10.4028/www.scientific.net/AMR.542-543.567 [7] ZHU H, WANG M L, WANG B S. Research on interpola-tion of NURBS curve based on fractional power[J]. Journal of Physics: Conference Series, 2020, 1633(1): 012005. doi: 10.1088/1742-6596/1633/1/012005 [8] 王允森, 盖荣丽, 孙一兰, 等. 高质量加工中四次多项式速度规划算法研究[J]. 中国机械工程, 2014, 25(5): 636-641. doi: 10.3969/j.issn.1004-132X.2014.05.013WANG Y S, GAI R L, SUN Y L, et al. Research on quartic polynomial velocity planning algorithm for high-quality machining[J]. China Mechanical Engineering, 2014, 25(5): 636-641. (in Chinese) doi: 10.3969/j.issn.1004-132X.2014.05.013 [9] LI M X, WU W J, GAI R L, et al. Research on quartic polynomial velocity planning algorithm based on filtering[C]//Proceedings of the 2020 Chinese Control and Decision Conference (CCDC). Hefei, China: IEEE, 2020: 5249-5254. [10] 石川, 赵彤, 叶佩青, 等. 数控系统S曲线加减速规划研究[J]. 中国机械工程, 2007, 18(12): 1421-1425. doi: 10.3321/j.issn:1004-132X.2007.12.009SHI C, ZHAO T, YE P Q, et al. Study on S-shape curve acceleration and deceleration control on NC system[J]. China Mechanical Engineering, 2007, 18(12): 1421-1425. (in Chinese) doi: 10.3321/j.issn:1004-132X.2007.12.009 [11] 潘海鸿, 杨微, 陈琳, 等. 全程S曲线加减速控制的自适应分段NURBS曲线插补算法[J]. 中国机械工程, 2010, 21(2): 190-195.PAN H H, YANG W, CHEN L, et al. Adaptive piecewise NURBS curve interpolator algorithm for entireness process S-curve ACC/DEC control[J]. China Mechanical Engineering, 2010, 21(2): 190-195. (in Chinese) [12] YEH S S, HSU P L. Adaptive-feedrate interpolation for parametric curves with a confined chord error[J]. Computer-Aided Design, 2002, 34(3): 229-237. doi: 10.1016/S0010-4485(01)00082-3 [13] JIA Z Y, SONG D N, MA J W, et al. A NURBS interpolator with constant speed at feedrate-sensitive regions under drive and contour-error constraints[J]. International Journal of Machine Tools and Manufacture, 2017, 116: 1-17. doi: 10.1016/j.ijmachtools.2016.12.007 [14] 林峰, 张正红, 陈胜. 基于进给速度敏感点识别的NURBS曲线平滑插补算法研究[J]. 中国机械工程, 2012, 23(9): 1060-1064. doi: 10.3969/j.issn.1004-132X.2012.09.012LIN F, ZHANG Z H, CHEN S. Research on smooth NURBS interpolation algorithm based on feedrate sensitive point identification[J]. China Mechanical Engineering, 2012, 23(9): 1060-1064. (in Chinese) doi: 10.3969/j.issn.1004-132X.2012.09.012 [15] SEKAR M, NARAYANAN V N, YANG S H. Design of jerk bounded feedrate with ripple effect for adaptive NURBS interpolator[J]. The International Journal of Advanced Manufacturing Technology, 2008, 37(5-6): 545-552. doi: 10.1007/s00170-007-0992-1 [16] WANG T Y, ZHANG Y B, DONG J C, et al. NURBS interpolator with adaptive smooth feedrate scheduling and minimal feedrate fluctuation[J]. International Journal of Precision Engineering and Manufacturing, 2020, 21(2): 273-290. doi: 10.1007/s12541-019-00288-6 -

下载:

下载: