Analysis of Fatigue Life for Multi-spot Welding

-

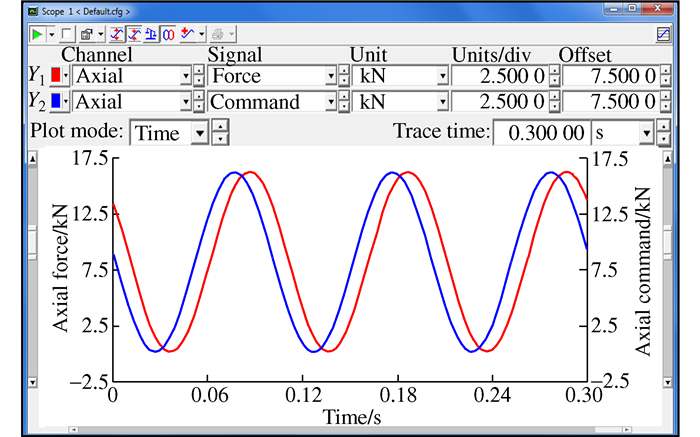

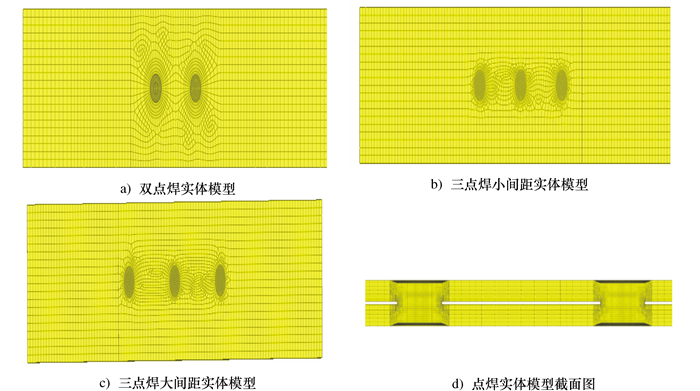

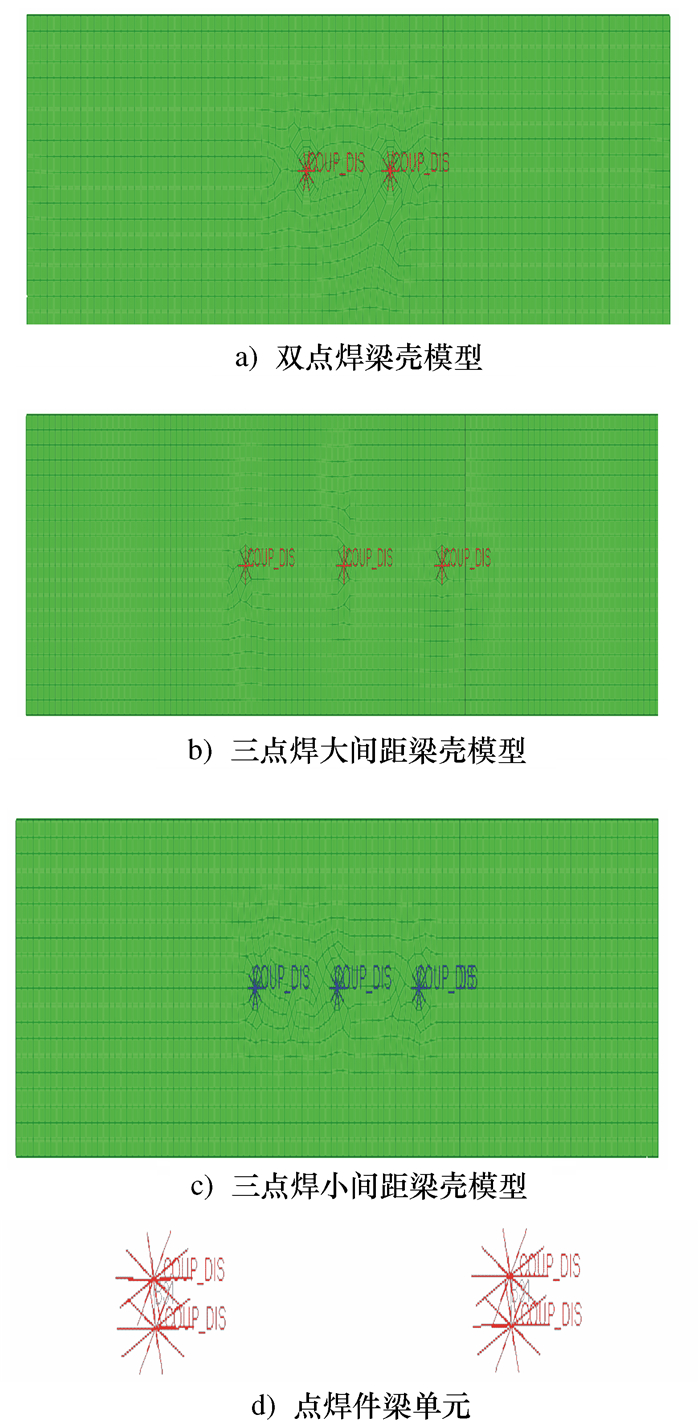

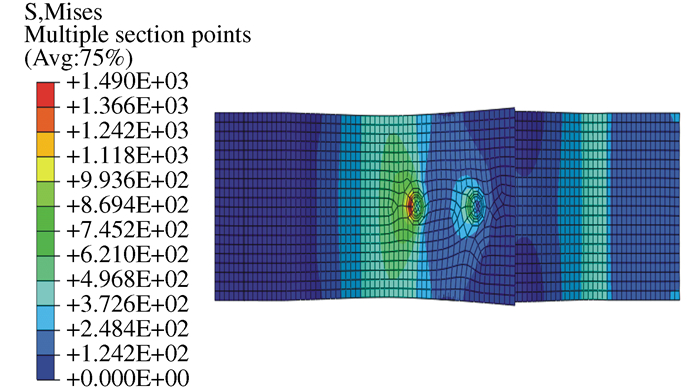

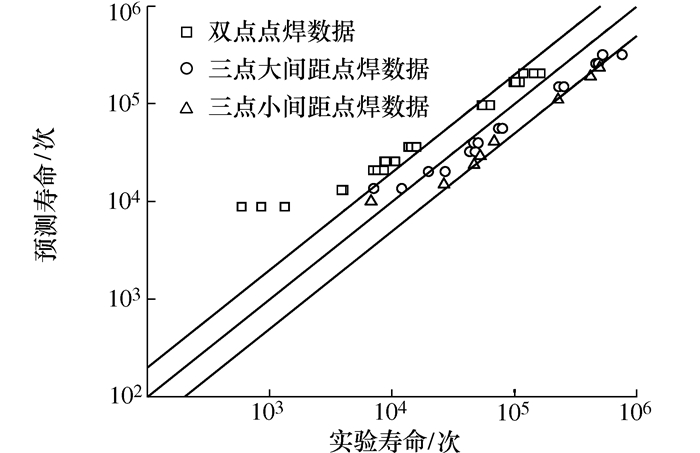

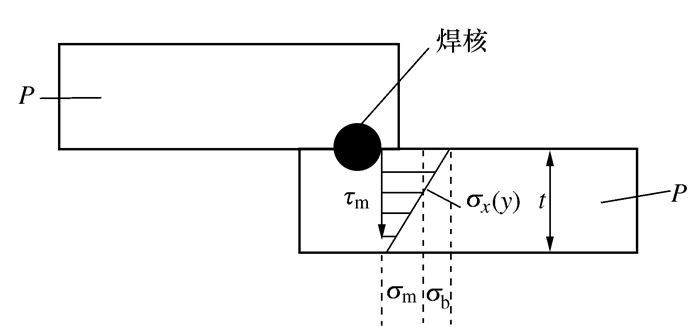

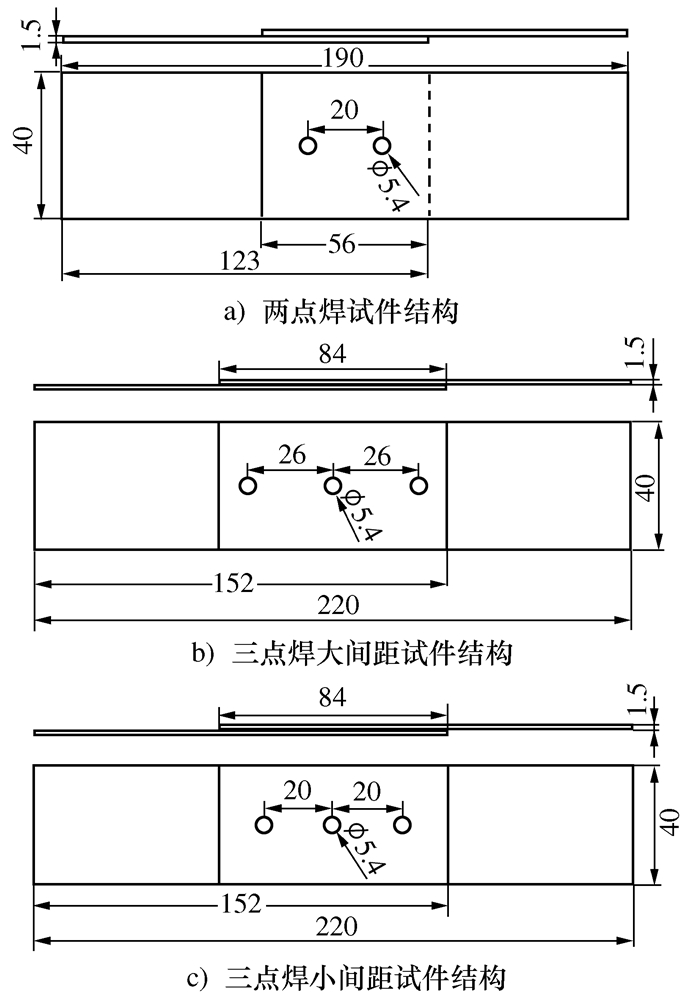

摘要: 根据ST12钢的双点及三点拉剪电阻点焊试件的恒幅疲劳测试结果,分别使用缺口应力法和等效结构应力法进行疲劳寿命预测。在使用缺口应力法时,按试件的实际尺寸和国际焊接学会(International institute of welding, IIW)推荐标准,分别建立了双点和三点拉剪试件的三维实体有限元模型进行弹性应力分析,从有限元分析结果提取von Mises最大应力变化值,结合IIW推荐标准中的S-N曲线对试件进行疲劳寿命分析预测; 在使用结构应力法时则采用梁壳混合单元进行有限元应力分析,并且根据主S-N曲线进行疲劳寿命预测。结果表明,在低周疲劳范围内,缺口应力法和等效结构应力法预测的结果相对于试件的实际寿命有较好地相关性,其中等效结构应力法的结果更接近实验寿命结果。Abstract: According to the constant amplitude fatigue test results of ST12 steel double-spot and three-spot tensile shear resistance spot welded specimens, the fatigue lives were predicted by using the notch stress method and equivalent structure stress method respectively. While using notch stress method, the three-dimensional solid finite element models for double-spot and three-spot tensile shear spot weld according to the actual specimen size and the recommendation of International institute of welding(IIW), the von Mises maximum stress change regime were obtained from the finite element results, the fatigue lives were predicted according to the S-N curve in the IIW recommended standard and while using the structural stress method, a hybrid model for beam and shell stress analysis, then the fatigue lives were predicted according to the main S-N curve. The results showed that the results predicted by using the notch stress method and the equivalent structural stress method are well correlated relatively to the actual lives of the specimen within low cycle regime, where the results by using the equivalent structural stress method are closer to the experimental results.

-

表 1 点焊实验载荷水平与疲劳寿命

Table 1. Load levels and fatigue life of spot welding experiments

载荷幅/N 平均载荷/N 双点焊疲劳寿命/次 三点焊大间距疲劳寿命/次 三点焊小间距疲劳寿命/次 8 000 8 200 848 585 1 323 11 909 7 056 6 735 7 000 7 200 6 945 7 559 8 552 26 958 19 734 26 487 6 000 7 200 6 945 7 559 8 552 42 786 47 658 46 840 5 600 7 200 8 562 10 543 8 775 46 251 50 248 52 460 5 000 7 200 14 140 15 722 13 534 73 887 79 383 68 161 3 600 7 200 54 430 63 016 53 984 229 376 251 980 226 488 3 000 7 200 98 450 109 896 101 643 459 828 482 538 417 399 2 800 7 200 162 688 117 812 142 657 754 388 522 634 494 996 表 2 主S-N曲线参数表

Table 2. Main S-N curve parameter table

统计数据 Cd h 中值曲线 19 930.2 +2σ 28 626.5 -2σ 13 875.7 -0.32 +3σ 34 308.1 -3σ 11 577.9 -

[1] ASLANLAR S, OGUR A, OZSARAC U, et al. Welding time effect on mechanical properties of automotive sheets in electrical resistance spot welding[J]. Materials & Design, 2008, 29(7): 1427-1431. [2] CHO Y, RHEE S. Quality estimation of resistance spot welding by using pattern recognition with neural networks[J]. IEEE Transactions on Instrumentation and Measurement, 2004, 53(2): 330-334. doi: 10.1109/TIM.2003.822713 [3] ESMAEILI F, RAHMANI A, BARZEGAR S, et al. Prediction of fatigue life for multi-spot welded joints with different arrangements using different multiaxial fatigue criteria[J]. Materials & Design, 2015, 72: 21-30. [4] 胡鑫, 严仁军, 谌伟, 等. 基于缺口应力法的IIW多轴疲劳准则分析[J]. 焊接学报, 2019, 40(7): 77-81.HU X, YAN R J, SHEN W, et al. Research on IIW multiaxial fatigue criterion based on notch stress approach[J]. Transactions of the China Welding Institution, 2019, 40(7): 77-81. (in Chinese) [5] 刘旭, 周春平, 张开林, 等. 基于缺口应力法的转向架焊接接头疲劳性能分析[J]. 铁道学报, 2017, 39(3): 42-48.LIU X, ZHOU C P, ZHANG K L, et al. Fatigue performance analysis of bogie welded joints based on notch stress method[J]. Journal of the China Railway Society, 2017, 39(3): 42-48. (in Chinese) [6] WEI C J, KANG H T. Fatigue life prediction of spot-welded joints with a notch stress approach[J]. Theoretical and Applied Fracture Mechanics, 2020, 106: 102491. doi: 10.1016/j.tafmec.2020.102491 [7] 龚琼琼, 王成, 王效贵. 基于八节点二次壳单元的等效结构应力法[J]. 浙江工业大学学报, 2014, 42(5): 554-558. doi: 10.3969/j.issn.1006-4303.2014.05.018GONG Q Q, WANG C, WANG X G. Equivalent structural stress method based on eight-node second-order shell element[J]. Journal of Zhejiang University of Technology, 2014, 42(5): 554-558. (in Chinese) doi: 10.3969/j.issn.1006-4303.2014.05.018 [8] 李薇, 王悦东. 点焊结构疲劳寿命预测的新方法研究[J]. 农业装备与车辆工程, 2019, 57(3): 27-30.LI W, WANG Y D. New method for prediction of fatigue life of spot-welding structure[J]. Agricultural Equipment & Vehicle Engineering, 2019, 57(3): 27-30. (in Chinese) [9] FRICKE W. IIW recommendations for the fatigue assessment of welded structures by notch stress analysis: IIW-2006-09[M]. [S.L. ]: Woodhead Publishing, 2012. [10] 杨广雪, 刘志明, 李广全, 等. 基于等效结构应力法的焊接构架疲劳损伤评估[J]. 铁道学报, 2020, 42(7): 73-79.YANG G X, LIU Z M, LI G Q, et al. Fatigue damage assessment of welded frame on equivalent structural stress method[J]. Journal of the China Railway Society, 2020, 42(7): 73-79. (in Chinese) [11] 廖小伟, 王元清, 宗亮, 等. 基于有效缺口应力法的钢桥焊接细节疲劳分析[J]. 浙江大学学报(工学版), 2017, 51(1): 1-8.LIAO X W, WANG Y Q, ZONG L, et al. Fatigue analysis of typical welded joints of steel bridges using effective notch stress approach[J]. Journal of Zhejiang University (Engineering Science), 2017, 51(1): 1-8. (in Chinese) [12] SONSINO C M. A consideration of allowable equivalent stresses for fatigue design of welded joints according to the notch stress concept with the reference radii rref=1.00 and 0.05 mm[J]. Welding in the World, 2009, 53(3-4): 64-75. [13] 李向伟, 兆文忠. 基于Verity方法的焊缝疲劳评估原理及验证[J]. 焊接学报, 2010, 31(7): 9-12.LI X W, ZHAO W Z. Weld fatigue assessment and verifica-tion based on Verity method[J]. Transactions of the China Welding Institution, 2010, 31(7): 9-12. (in Chinese) [14] KYUBA H, DONG P S. Equilibrium-equivalent structural stress approach to fatigue analysis of a rectangular hollow section joint[J]. International Journal of Fatigue, 2005, 27(1): 85-94. [15] DONG P. A structural stress definition and numerical implementation for fatigue analysis of welded joints[J]. International Journal of Fatigue, 2001, 23(10): 865-876. [16] DONG P S, HONG J K, DE JESUS A M P. Analysis of recent fatigue data using the structural stress procedure in ASME Div 2 rewrite[J]. Journal of Pressure Vessel Technology, 2007, 129(3): 355-362. -

下载:

下载: