Damage Analysis of Composites by Coupling Multiple Failure Mode

-

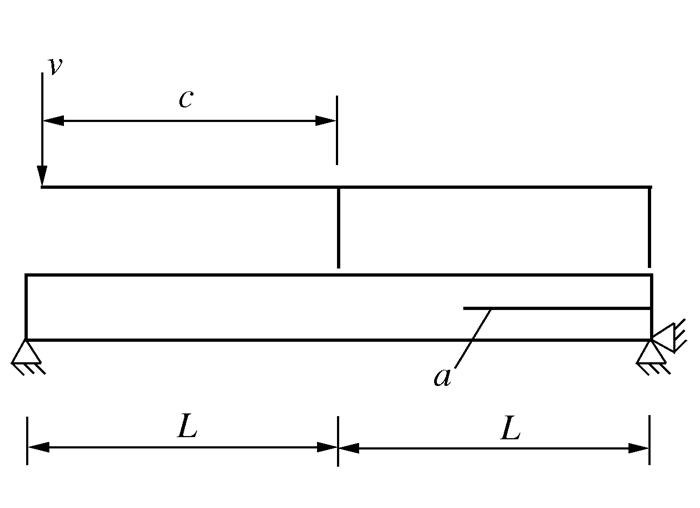

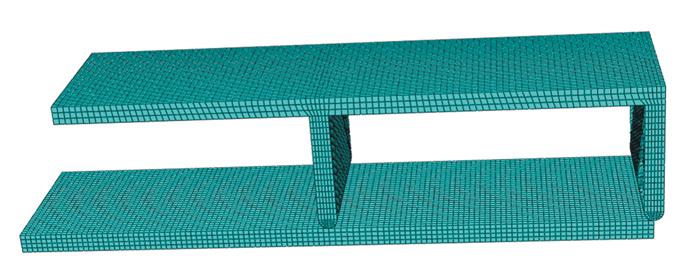

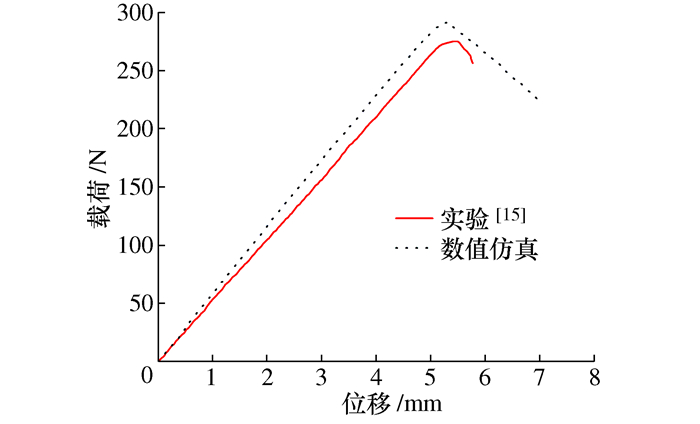

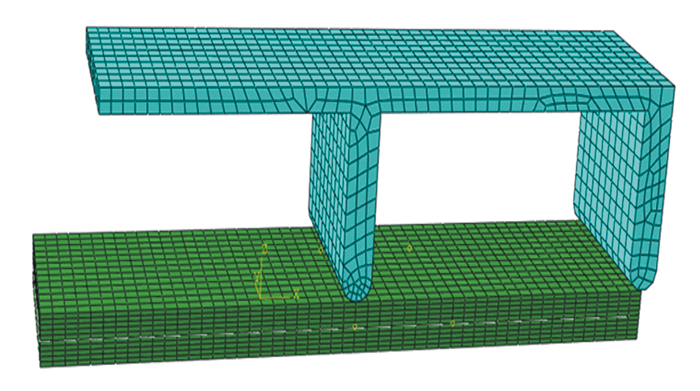

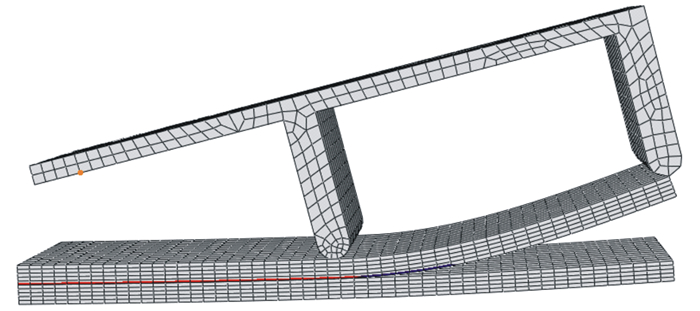

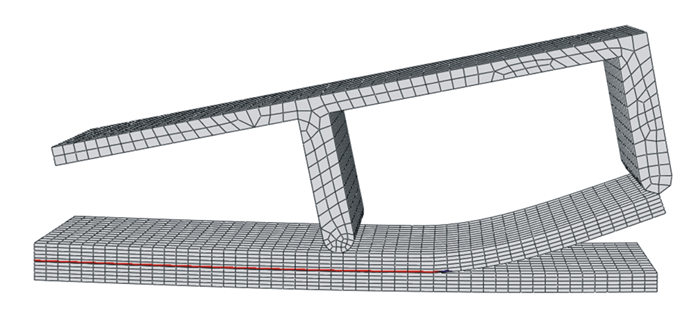

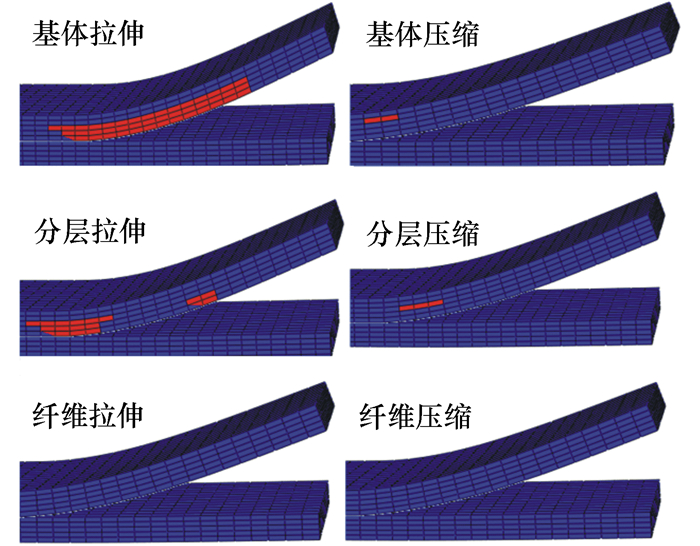

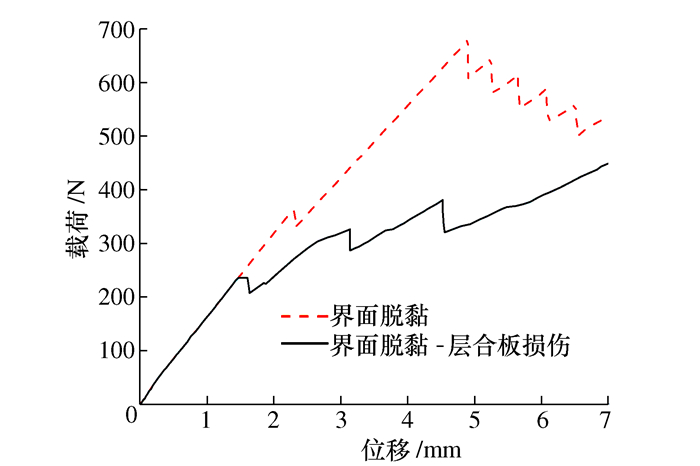

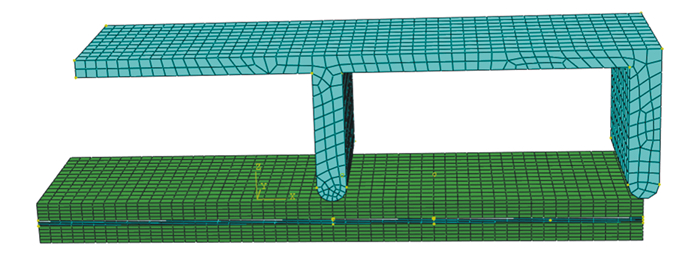

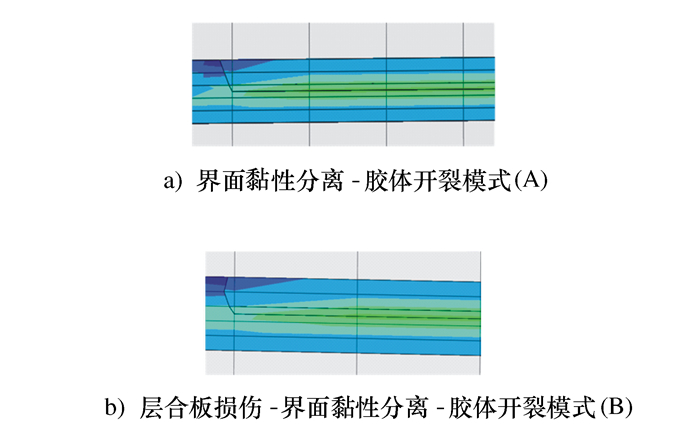

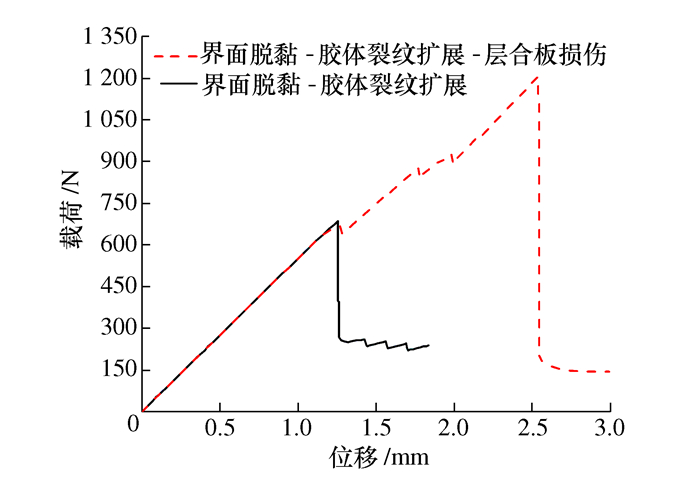

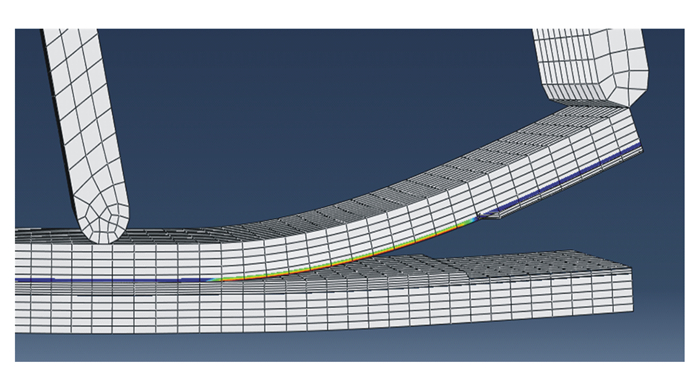

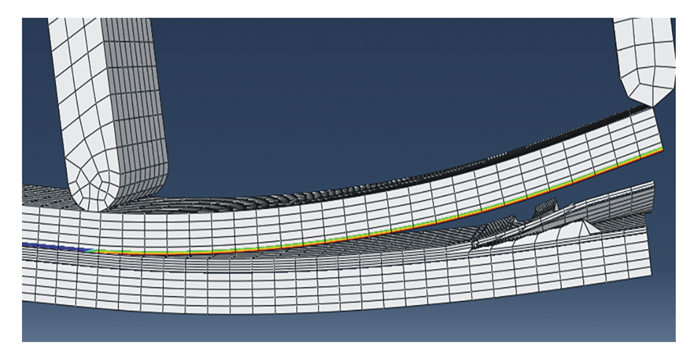

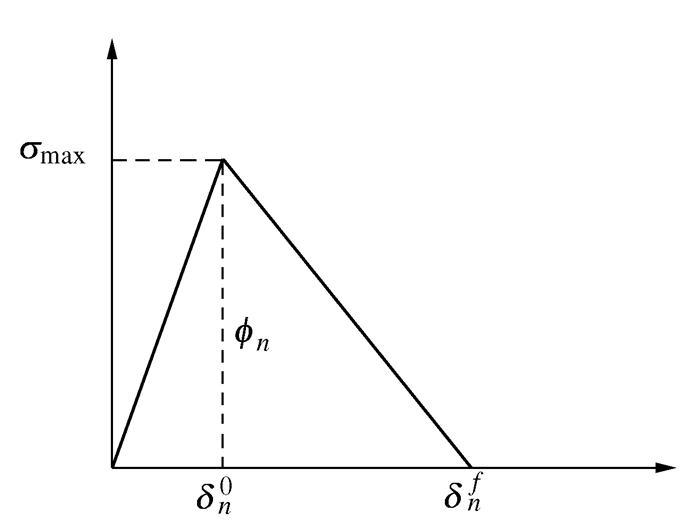

摘要: 复合材料的损伤失效形式是多样的, 其损伤失效形式包括层合板损伤、胶体裂纹扩展和界面脱黏。为了探讨层合板损伤、胶体裂纹扩展、界面脱黏3种损伤失效之间的内在联系, 先利用ABAQUS/Explicit软件建立混合型弯曲(MMB)断裂有限元模型, 通过数值仿真结果与实验结果的比较, 从而证明MMB模型的准确性。然后结合Hashin失效准则、扩展有限元法(XFEM)和内聚力模型(CZM)来研究3种失效模式的内在联系。结果表明: 层合板损伤不仅可以影响界面脱黏失效发生时间, 同时也能影响胶体中裂纹扩展路径, 为复合材料损伤问题数值分析提供了一定的参考。Abstract: Composite damage failure form is various, the damage failure forms including laminated plate damage, colloid crack extension and interface debonding. To investigate damage of laminates, colloid crack propagation, interface delamination inherent relations among the three kinds of damage failure, the hybrid bending (MMB) fracture finite element model is firstly established by using ABAQUS/Explicit software, by comparing the simulation and experimental results, which proves the accuracy of MMB model. Then, the internal relationship among the three failure modes was studied by combining the Hashin failure criterion, extended finite Element method (XFEM) and cohesive force model (CZM). The results show that the damage of laminates can not only affect the time of interface viscous separation failure, but also affect the crack propagation path in colloid, which provides a certain reference for numerical analysis of the damage problem of composites.

-

Key words:

- damage of laminates /

- colloid crack propagation /

- interface delamination /

- Hashin failure criterion /

- XFEM /

- CZM

-

表 1 AS4/PEEK材料属性

Table 1. AS4/PEEK material properties

参数 数值 层内 E11 122.7 GPa E22=E33 10.1 GPa G12=G13 5.5 GPa G23 3.7 GPa v12=v13 0.25 v23 0.45 层间 K 106 N/mm3 σn0 80 MPa σs0 100 MPa GⅠC 0.969 mJ/mm2 GⅡC 1.719 mJ/mm2 ηBK 2.73 表 2 T300/1034-C材料属性

Table 2. Material properties of T300/1034-C

参数 数值 参数 数值 E11 146.757 GPa G23 3.790 GPa E22=E33 11.369 GPa v12=v13 0.3 G12=G13 6.180 GPa v23 0.5 XC 1 378 MPa XT 1 729 MPa YC 268 MPa YT 67 MPa ZT 67 MPa ZC 268 MPa Sxy 134 MPa Sxz 100 MPa Syz 100 MPa 表 3 AV138材料属性

Table 3. Material properties

参数 数值 参数 数值 E 4 890 MPa GIC 0.2 mJ/mm2 σn0 39.45 MPa GⅡC=GⅢC 0.38 mJ/mm2 σs0=σt0 30.2 MPa α 1 v 0.35 K 106 N/mm3 -

[1] NAGARAJ M H, CARRERA E, PETROLO M. Progressive damage analysis of composite laminates subjected to low-velocity impact using 2D layer-wise structural models[J]. International Journal of Non-Linear Mechanics, 2020, 127: 103591. doi: 10.1016/j.ijnonlinmec.2020.103591 [2] 郑亦媚, 程吉, 王轩, 等. 褶皱层数对玻璃纤维层合板拉伸性能的影响[J]. 兵器材料科学与工程, 2021, 44(1): 104-110.ZHENG Y M, CHENG J, WANG X, et al. Effect of different wrinkled layers on tensile properties of glass fiber reinforced laminates[J]. Ordnance Material Science and Engineering, 2021, 44(1): 104-110. (in Chinese) [3] 张军, 贾宏. 内聚力模型的形状对胶接结构断裂过程的影响[J]. 力学学报, 2016, 48(5): 1088-1095.ZHANG J, JIA H. Influence of cohesive zone models shape on adhesively bonded joints[J]. Chinese Journal of Theoretical and Applied Mechanics, 2016, 48(5): 1088-1095. (in Chinese) [4] RAFIEE R, HASHEMI-TAHERI M R. Failure analysis of a composite wind turbine blade at the adhesive joint of the trailing edge[J]. Engineering Failure Analysis, 2021, 121: 105148. doi: 10.1016/j.engfailanal.2020.105148 [5] 龙文元, 季松, 汪正飞. 基于XFEM法的Ti/TiC叠层复合材料裂纹扩展有限元分析[J]. 特种铸造及有色合金, 2019, 39(9): 929-932.LONG W Y, JI S, WANG Z F. Finite element analysis of crack propagation of Ti/Tic laminated composites based on XFEM method[J]. Special Casting & Nonferrous Alloys, 2019, 39(9): 929-932. (in Chinese) [6] SANTOS T F, CAMPILHO R D S G. Numerical modelling of adhesively-bonded double-lap joints by the eXtended Finite Element Method[J]. Finite Elements in Analysis and Design, 2017, 133: 1-9. doi: 10.1016/j.finel.2017.05.005 [7] 冯威, 徐绯, 由昊, 等. 扩展有限元方法与内聚力模型耦合下斜接修补复合材料的胶层损伤和缺陷[J]. 复合材料学报, 2018, 35(5): 1354-1360.FENG W, XU F, YOU H, et al. Adhesive damage and defect analysis of scarf-repaired composite by combining extended finite element method and cohesive zone model[J]. Acta Materiae Compositae Sinica, 2018, 35(5): 1354-1360. (in Chinese) [8] 周伟, 张超, 甘淑媛. 基于XFEM-CZM耦合法的胶接接头裂纹扩展分析及强度预测[J]. 北京航空航天大学学报, 2020, 46(11): 2121-2130.ZHOU W, ZHANG C, GAN S Y. Crack propagation analysis and strength prediction of bonded joints based on XFEM-CZM coupling method[J]. Journal of Beijing University of Aeronautics and Astronautics, 2020, 46(11): 2121-2130. (in Chinese) [9] 赵文滔, 杨颜志, 王长焕, 等. 基于贝叶斯推断的复合材料层间内聚力模型参数反演[J]. 机械工程学报, 2022, 58(6): 110-118.ZHAO W T, YANG Y Z, WANG C H, et al. Parameter inversion for composite interlayer cohesive zone model based on Bayesian inference[J]. Journal of Mechanical Engineering, 2022, 58(6): 110-118. (in Chinese) [10] 底月兰, 王海斗, 董丽虹, 等. 扩展有限元法在裂纹扩展问题中的应用[J]. 材料导报A: 综述篇, 2017, 31(3): 70-74.DI Y L, WANG H D, DONG L H, et al. Application of the extended finite element method in crack propagation[J]. Materials Reports, 2017, 31(3): 70-74. (in Chinese) [11] 朱敏. 耐高温聚酰亚胺复合材料层合板连接力学性能分析[D]. 哈尔滨: 哈尔滨工程大学, 2015.ZHU M. Analysis of mechanics properties of bolted high temperature resistant polyimide composite laminates[D]. Harbin: Harbin Institute of Technology, 2015. (in Chinese) [12] CHANG F K, LESSARD L B. Damage tolerance of laminated composites containing an open hole and subjected to compressive loadings: Part Ⅰ-analysis[J]. Journal of Composite Materials, 1991, 25(1): 2-43. doi: 10.1177/002199839102500101 [13] CAMANHO P P, MATTHEWS F L. A progressive damage model for mechanically fastened joints in composite laminates[J]. Journal of Composite Materials, 1999, 33(24): 2248-2280. doi: 10.1177/002199839903302402 [14] TAN S C. A progressive failure model for composite laminates containing openings[J]. Journal of Composite Materials, 1991, 25(5): 556-577. [15] CAMANHO P P, DAVILA C G. Mixed-mode decohesion finite elements for the simulation of delamination in composite materials[R]. Hampton: NASA Langley Research Center; 2002. -

下载:

下载: