Analysis of Thermal Post-buckling Behavior of Graded Porous Circular Plate with Variable Thickness

-

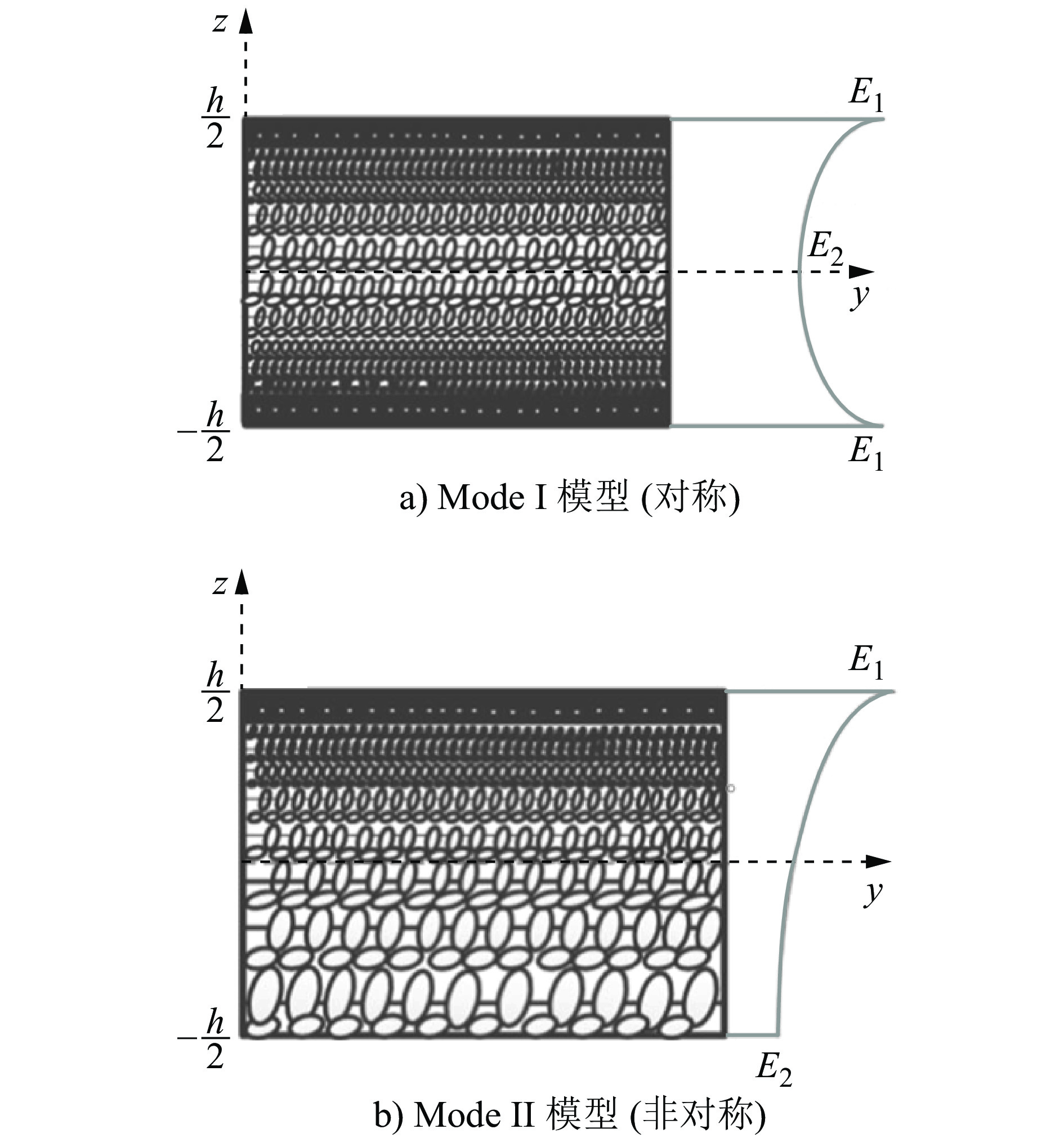

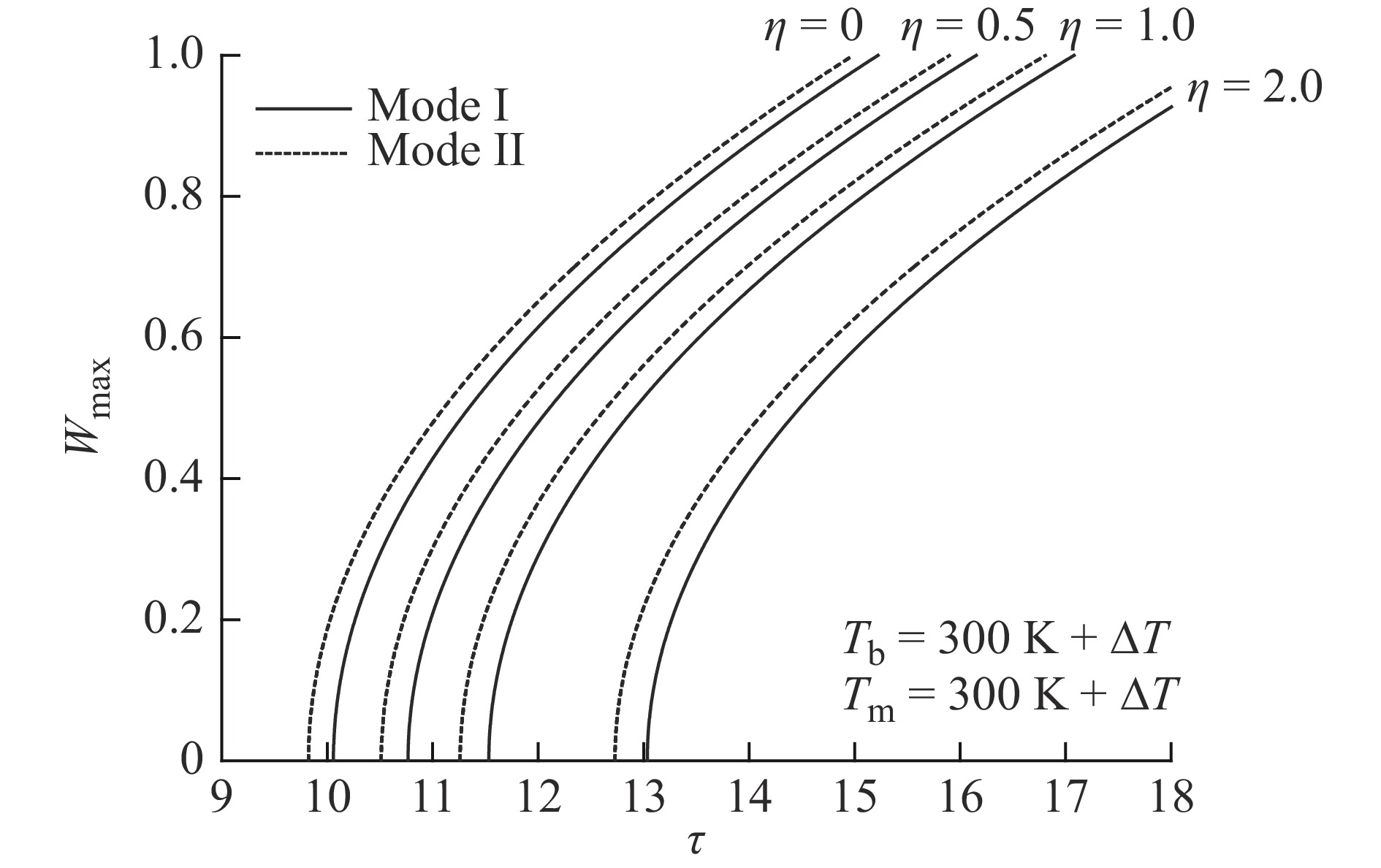

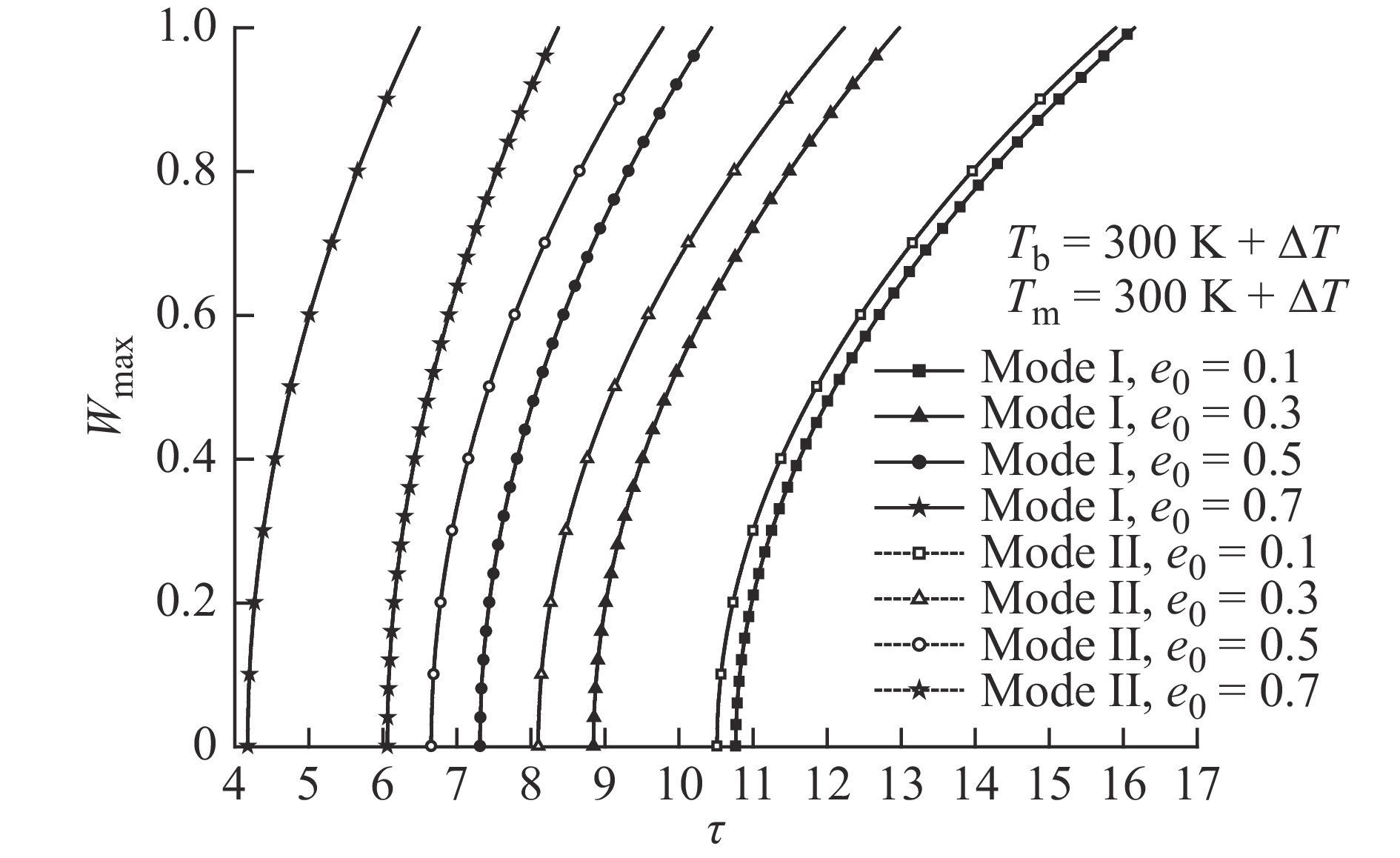

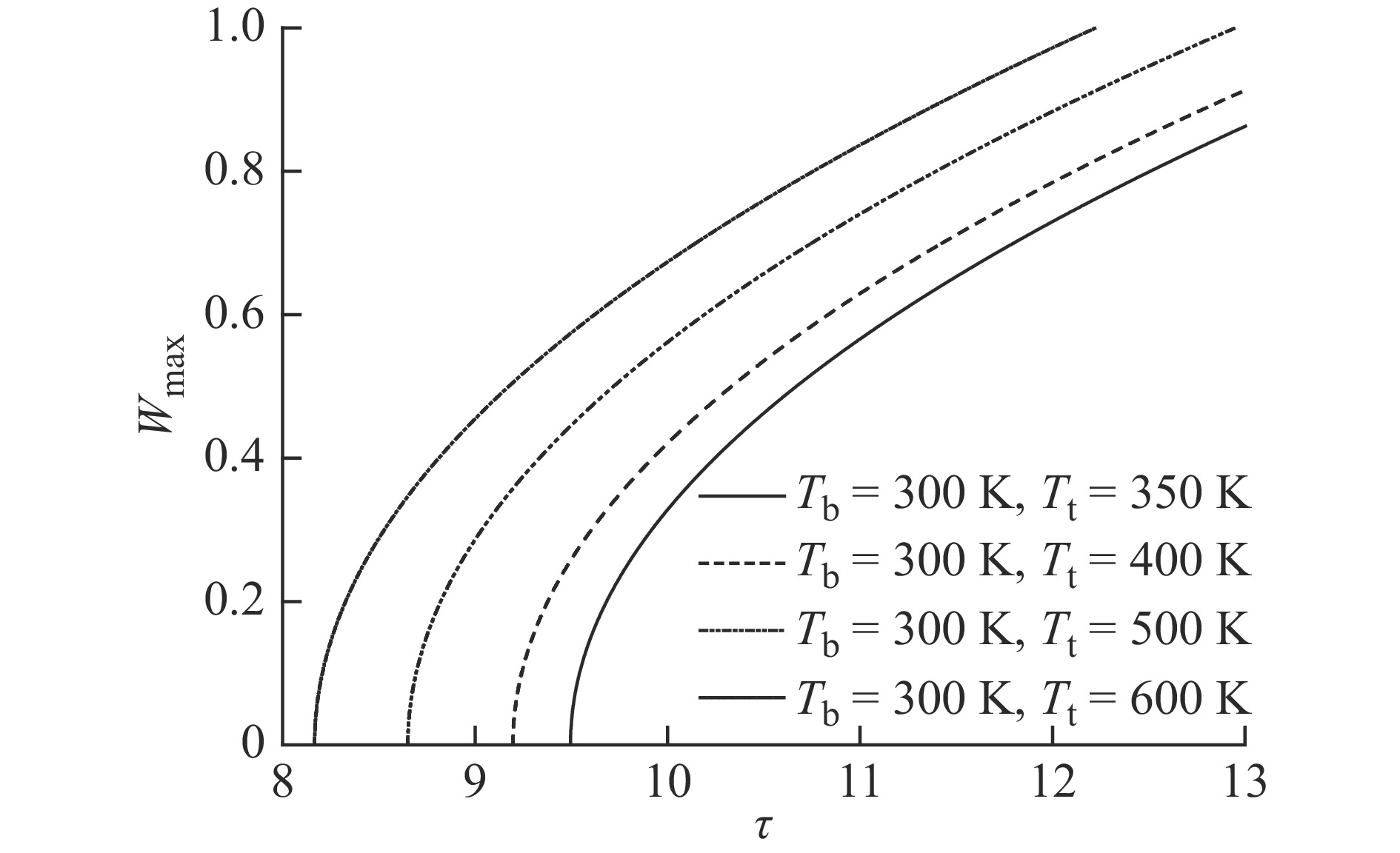

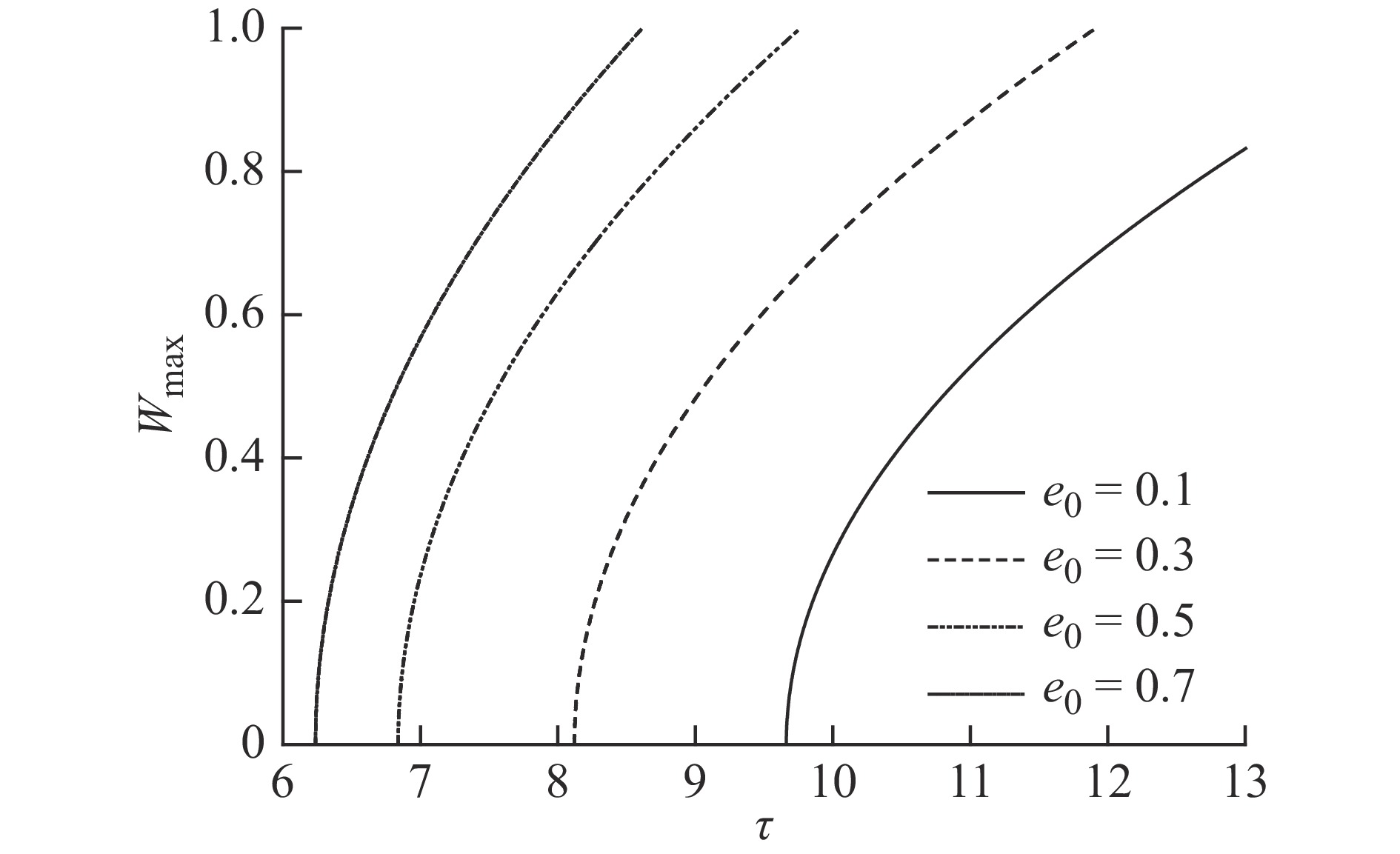

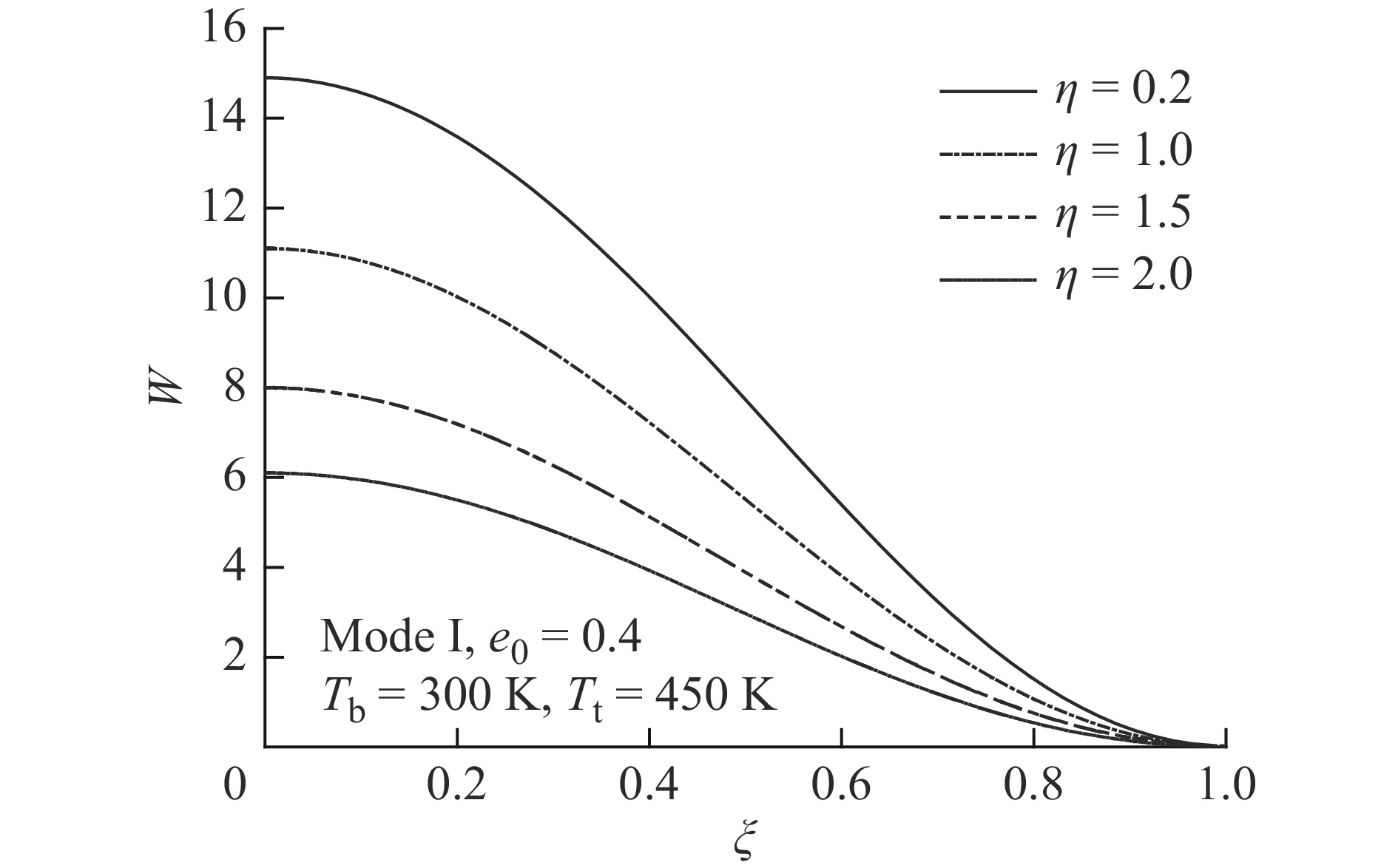

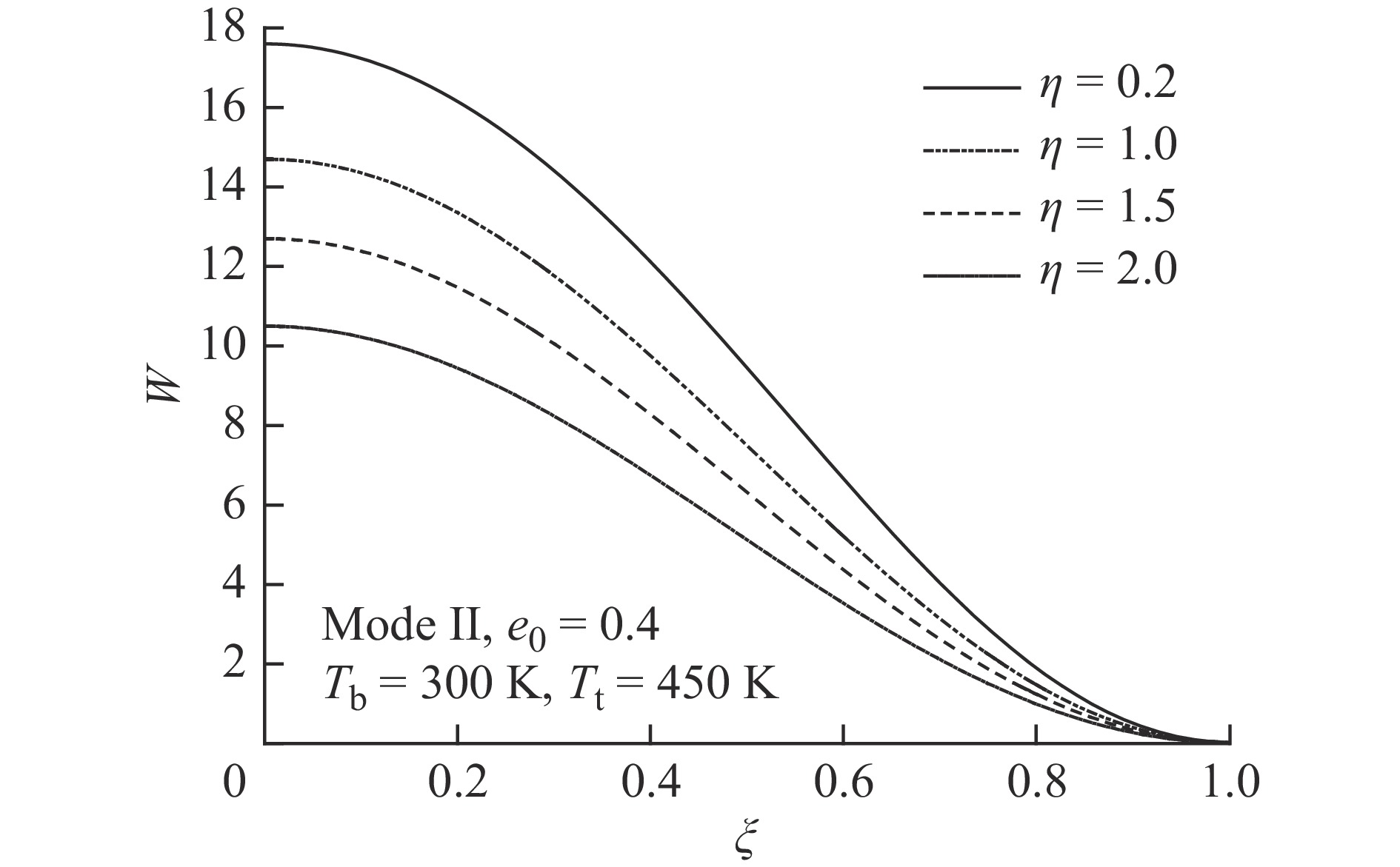

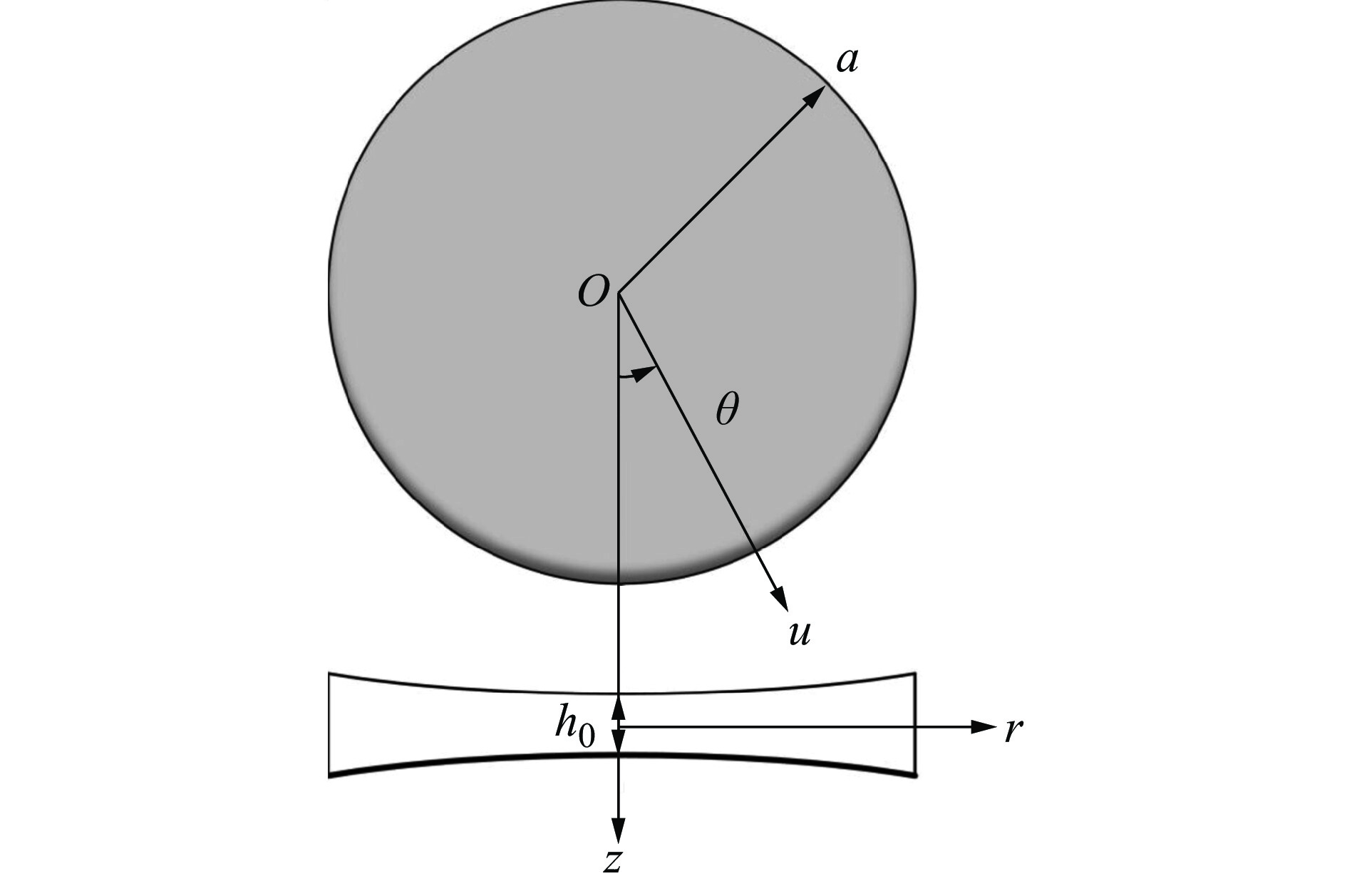

摘要: 为分析多孔梯度材料圆板在非均匀温度场中的热后屈曲响应,基于经典板理论和物理中面概念建立了梯度多孔材料圆板在热载荷作用下的控制微分方程,其中假设厚度变化沿半径为二次抛物线型且板在其厚度上具有对称和非对称的非均匀孔隙率分布。采用打靶法数值求解了问题的屈曲和后屈曲响应,给出了均匀升温和热传导下的梯度多孔非线性变厚度圆板后屈曲平衡路径。结果显示:变厚度系数、孔隙率系数、孔隙分布方式以及温度场对板的临界载荷和后屈曲平衡路径均有影响;在不同温度场中孔隙率系数越大,屈曲时的临界载荷越小;孔隙率对称分布下的临界载荷大于非对称情况下的。Abstract: In order to analyze the thermal post-buckling response of the graded porous material circular plate in the non-uniform temperature field, the governing differential equation of the graded porous material circular plate under thermal load was established on the basis of classical plate theory and the concept of physical neutral plane. It is assumed that the thickness change is quadratic parabolic along the radius and the plate has symmetric and asymmetric non-uniform porosity distribution across their thickness. Using shooting method technique, the buckling and post-buckling responses of the problem was numerically solved, and the post-buckling equilibrium paths of the graded porous nonlinear variable thickness circular plate under different types of thermal loads as heat conduction and uniform temperature rise were obtained. The results show that the variable thickness coefficient, porosity coefficient, pore distribution and temperature field have the effects on the critical load and post buckling equilibrium path of the plate; under different temperature fields, the larger the porosity coefficient, the smaller the critical load during buckling; the critical load under symmetrical porosity distribution is greater than that under asymmetric porosity distribution.

-

Key words:

- graded porous materials /

- physical neutral plane /

- circular plate /

- post-buckling /

- numerical solution

-

表 1 梯度多孔圆板的临界温度(

$\eta = 0.{\text{1}}$ )Table 1. The critical temperature of

$\Delta T_{\rm{cr}} $ porous plate (η=0.1)孔隙率系数

$ {e_0} $均匀升温/K 非均匀升温/K Mode I Mode II Mode I Mode II 0.1 162.59 157.42 132.35 111.42 0.2 140.15 128.35 122.48 101.36 0.3 133.57 122.30 113.35 92.35 0.4 121.38 107.54 104.87 84.24 0.5 110.41 100.46 97.28 76.90 表 2 不同变厚度系数下多孔圆板的临界温度(

${e_0} = 0.{\text{3}}$ )Table 2. Critical temperature of porous circular plate with variable thickness coefficient(e0=0.3)

变厚度系数

$ \eta $均匀升温/K 非均匀升温/K Mode I Mode II Mode I Mode II 0.0 127.14 116.41 107.89 80.486 0.2 147.53 139.66 118.93 88.721 0.5 160.45 145.53 136.16 101.57 1.0 195.63 179.12 166.01 123.84 2.0 269.64 246.89 228.81 170.69 -

[1] KOIZUMI M. The concept of FGM, ceramic transactions[J]. Functionally Gradient Materials, 1993, 34: 3-10. [2] CHEN Y, LI Q L. Thermal vibration analysis of functionally graded circular plates based on Levinson's third-order shear deformation theory[J]. Mechanics Based Design of Structures and Machines, 2021: 1-18,doi: 10.1080/15397734.2021.1991808. [3] 刘培生. 多孔材料引论[M]. 2版. 北京: 清华大学出版社, 2012.LIU P S. Introduction to porous materials[M]. 2nd ed. Beijing: Tsinghua University Press, 2012. (in Chinese) [4] YÜSUF Y Z, AKBAŞ Ş D. Buckling analysis of a fiber reinforced laminated composite plate with porosity[J]. Journal of Computational Applied Mechanics, 2019, 50(2): 375-380. [5] 周攀, 李淑娟, 杨磊鹏. 单液滴冲击多孔介质过程的数值模拟与试验[J]. 机械科学与技术, 2017, 36(6): 965-970.ZHOU P, LI S J, YANG L P. Process simulation and experiments of single droplet impactingon porous materials[J]. Mechanical Science and Technology for Aerospace Engineering, 2017, 36(6): 965-970. (in Chinese) [6] ZHAO C Y. Review on thermal transport in high porosity cellular metal foams with open cells[J]. International Journal of Heat and Mass Transfer, 2012, 55(13-14): 3618-3632. doi: 10.1016/j.ijheatmasstransfer.2012.03.017 [7] WATTANASAKULPONG N, CHAIKITTIRATANA A, PORNPEERAKEAT S. Chebyshev collocation approach for vibration analysis of functionally graded porous beams based on third-order shear deformation theory[J]. Acta Mechanica Sinica, 2018, 34(6): 1124-1135. doi: 10.1007/s10409-018-0770-3 [8] XUE Y Q, JIN G Y, MA X L, et al. Free vibration analysis of porous plates with porosity distributions in the thickness and in-plane directions using isogeometric approach[J]. International Journal of Mechanical Sciences, 2019, 152: 346-362. doi: 10.1016/j.ijmecsci.2019.01.004 [9] SHE G L, LIU H B, KARAMI B. On resonance behavior of porous FG curved nanobeams[J]. Steel and Composite Structures, 2020, 36(2): 179-186. [10] 卢子兴, 郭宇. 金属泡沫材料力学行为的研究概述[J]. 北京航空航天大学学报, 2003, 29(11): 978-983.LU Z X, GUO Y. Brief review of studies on the mechanical behavior of metallic foams[J]. Journal of Beijing University of Aeronautics and Astronautics, 2003, 29(11): 978-983. (in Chinese) [11] 梁永仁, 杨志懋, 丁秉钧. 金属多孔材料应用及制备的研究进展[J]. 稀有金属材料与工程, 2006, 35(S2): 30-34.LIANG Y R, YANG Z M, DING B J. Progress in the applications and preparations of porous Metals[J]. Rare Metal Materials and Engineering, 2006, 35(S2): 30-34. (in Chinese) [12] 杨保军, 奚正平, 汤慧萍, 等. 梯度多孔金属材料制备及应用的研究进展[J]. 粉末冶金工业, 2008, 18(2): 28-32.YANG B J, XI Z P, TANG H P, et al. Research progress in preparation and application of gradient-porous metal[J]. Powder Metallurgy Industry, 2008, 18(2): 28-32. (in Chinese) [13] 刘培生, 周茂奇. 多孔金属材料失效模式的数理分析[J]. 中国有色金属学报, 2021, 31(2): 384-400. doi: 10.11817/j.ysxb.1004.0609.2021-35920LIU P S, ZHOU M Q. Mathematical analysis of failure mode for porous metallic materials[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(2): 384-400. (in Chinese) doi: 10.11817/j.ysxb.1004.0609.2021-35920 [14] 张海鸿, 王启, 王金海, 等. HF原位催化高气孔率晶须框架多孔莫来石的制备及强化机制研究[J]. 西北工业大学学报, 2021, 39(1): 208-215. doi: 10.3969/j.issn.1000-2758.2021.01.026ZHANG H H, WANG Q, WANG J H, et al. Preparation and strengthening mechanisms of in-situ HF catalyzed highly porous mullite with whisker frame structure[J]. Journal of Northwestern Polytechnical University, 2021, 39(1): 208-215. (in Chinese) doi: 10.3969/j.issn.1000-2758.2021.01.026 [15] MAGNUCKI K, STASIEWICZ P. Elastic buckling of a porous beam[J]. Journal of Theoretical and Applied Mechanics, 2004, 42(4): 859-868. [16] SHAFIEI N, KAZEMI M. Buckling analysis on the bi-dimensional functionally graded porous tapered nano-/micro-scale beams[J]. Aerospace Science and Technology, 2017, 66: 1-11. doi: 10.1016/j.ast.2017.02.019 [17] MAGNUCKA-BLANDZI E. Axi-symmetrical deflection and buckling of circular porous-cellular plate[J]. Thin-Walled Structures, 2008, 46(3): 333-337. doi: 10.1016/j.tws.2007.06.006 [18] REZAIEE-PAJAND M, KAMALI F. Exact solution for thermal−mechanical post-buckling of functionally graded micro-beams[J]. CEAS Aeronautical Journal, 2021, 12(1): 85-100. doi: 10.1007/s13272-020-00480-9 [19] MA L S, WANG T J. Nonlinear bending and post-buckling of a functionally graded circular plate under mechanical and thermal loadings[J]. International Journal of Solids and Structures, 2003, 40(13-14): 3311-3330. doi: 10.1016/S0020-7683(03)00118-5 [20] 佘银柱, 吕明, 王时英. 阶梯变厚度齿轮的横向弯曲振动[J]. 机械科学与技术, 2013, 32(1): 116-119.SHE Y Z, LYU M, WANG S Y. Transverse bending vibration of gear with stepped variable thickness[J]. Mechanical Science and Technology for Aerospace Engineering, 2013, 32(1): 116-119. (in Chinese) [21] 李清禄, 段鹏飞, 张靖华. 陶瓷基FGM材料线形变厚度圆板的热后屈曲[J]. 航空材料学报, 2019, 39(1): 102-107.LI Q L, DUAN P F, ZHANG J H. Thermal post-buckling behavior of ceramic-based FGM circular plates with linear variable thickness[J]. Journal of Aeronautical Materials, 2019, 39(1): 102-107. (in Chinese) [22] LI Q L, YAN X, ZHANG J H. Axisymmetric vibration analysis of graded porous Mindlin circular plates subjected to thermal environment[J]. Journal of Mechanics of Materials and Structures, 2021, 16(3): 371-388. doi: 10.2140/jomms.2021.16.371 [23] 刘繁茂, 蒋彭, 刘永祥. 非局域热平衡理论下斯特林热机回热器温度场分布数值分析[J]. 机械科学与技术, 2019, 38(6): 863-869.LIU F M, JIANG P, LIU Y X. Numerical analysis of temperature distribution of stirling engine regenerator under non-local thermodynamics equilibrium theory[J]. Mechanical Science and Technology for Aerospace Engineering, 2019, 38(6): 863-869. (in Chinese) [24] EBRAHIMI F, JAFARI A, BARATI M R. Free vibration analysis of smart porous plates subjected to various physical fields considering neutral surface position[J]. Arabian Journal for Science and Engineering, 2017, 42(5): 1865-1881. doi: 10.1007/s13369-016-2348-3 -

下载:

下载: