Analysis of AE Characteristic Signal of CFRP-reinforced Tubular Columns Under Static Loading

-

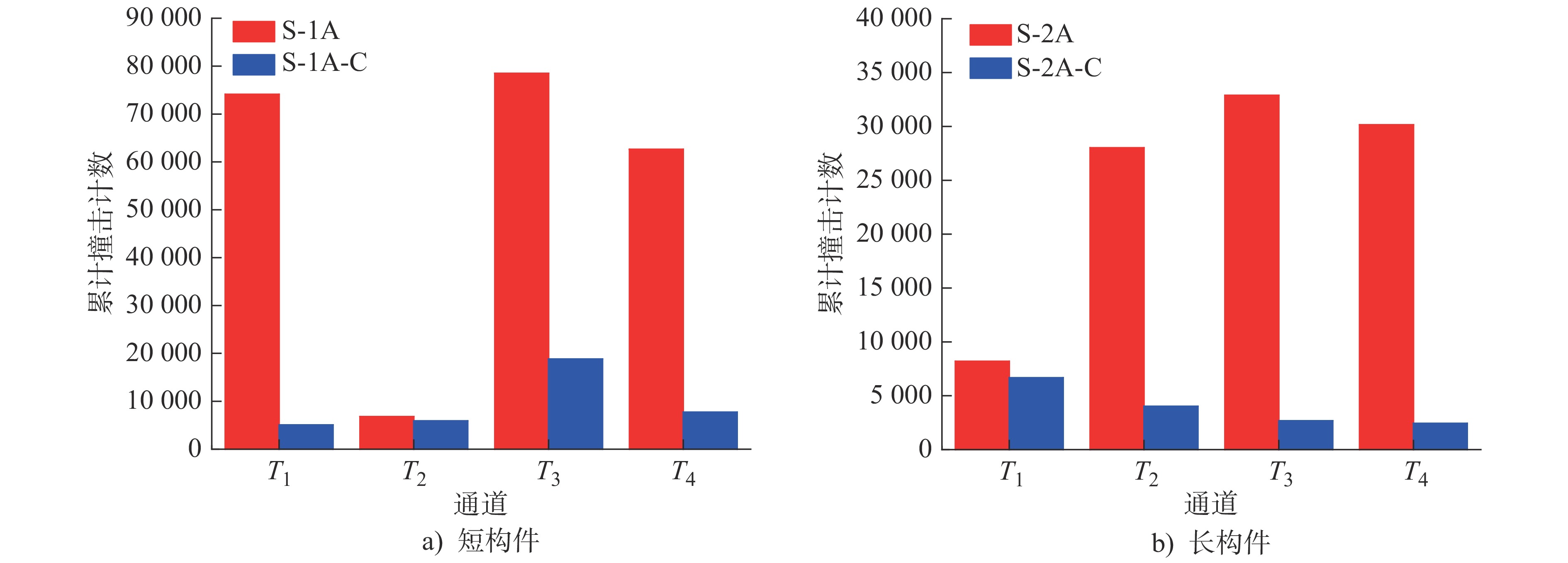

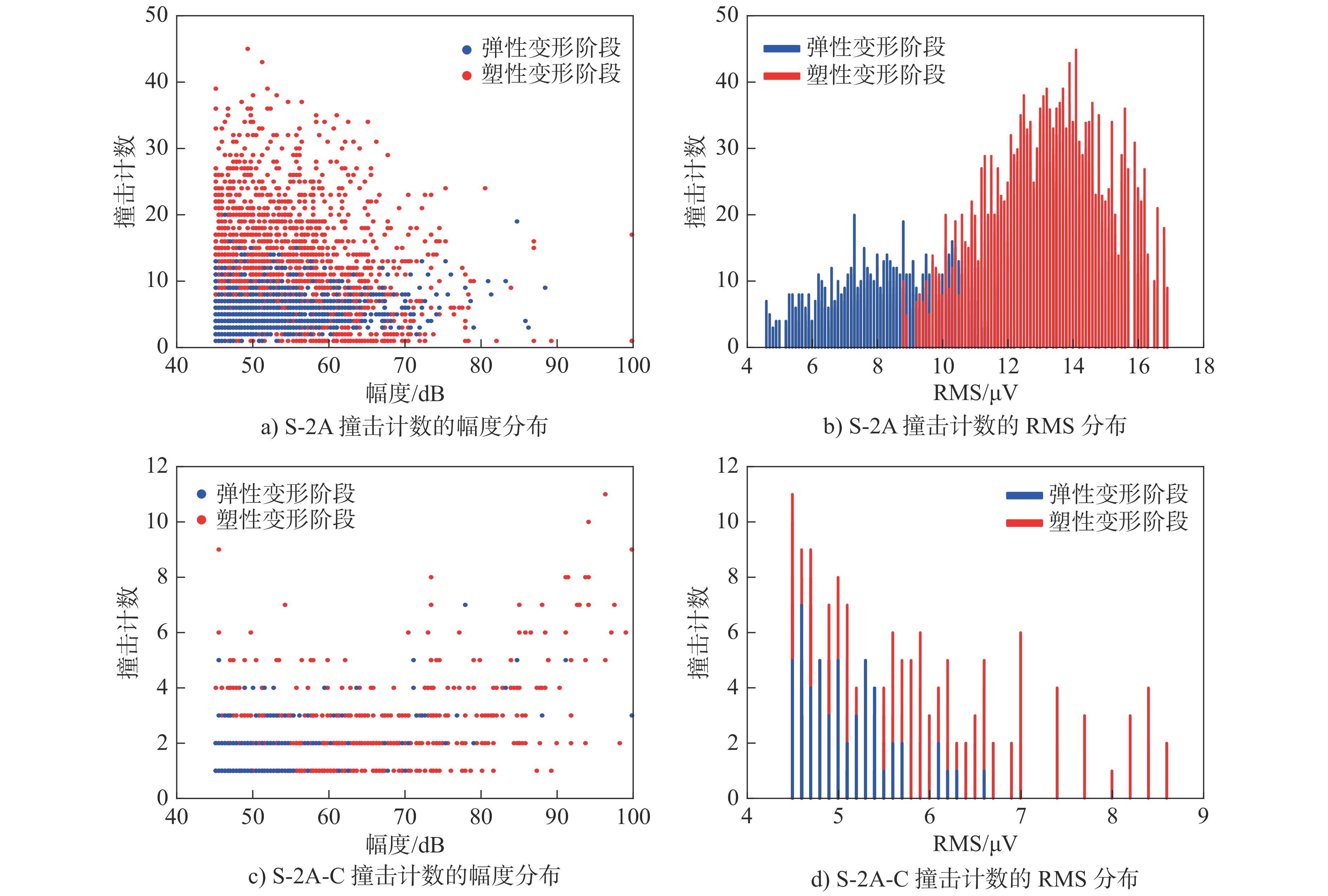

摘要: 为研究腐蚀管柱加固前后的承载力变化,使用声发射仪采集了准静态压缩过程中有腐蚀缺陷和经碳纤维增强复合材料(CFRP)加固的管柱构件的声发射参数。通过比较声发射的撞击数、幅度、均方根植(RMS)、振铃计数率和累积能量计数等参数,对构件的承载力进行了研究。结果表明:声发射特征参数能够较好的体现构件材料的弹性阶段、屈服阶段、强化阶段、颈缩和断裂过程;幅度和RMS可以反映试验过程中试件内部损伤破坏进程;振铃计数和累积能量的变化趋势能够体现管柱构件的压缩变形过程;CFRP加固后的管柱变形小,承载力提高,声发射振铃计数降低,累积能量计数增大。Abstract: To study the changes in the bearing capacity of the corroded pipe string before and after reinforcement, the acoustic emission instrument was used to collect the acoustic emission parameters of the tubular column members with corrosion defects and carbon fiber-reinforced polymer(CFRP) reinforcement during the quasi-static compression process. By comparing the number of hits, amplitude, root of mean square(RMS), counts rate, and cumulative energy count of acoustic emission parameters, the bearing capacity of the components was studied. The result shows that the acoustic emission characteristic parameters can better reflect the elastic phase, yielding phase, strengthened phase, necking, and fracture process of component materials. Amplitude and RMS can reflect the internal damage and destruction process of the specimen during the test. The changing trend of acoustic emission counts and acoustic emission accumulated energy can reflect the compression process of tubular columns. The deformation of the tubular columns with CFRP-reinforced is small, the bearing capacity is improved, the acoustic emission count is reduced, and the acoustic emission accumulated energy is increased.

-

Key words:

- acoustic emission /

- corrosion defect /

- tubular column /

- static compression /

- bearing capacity

-

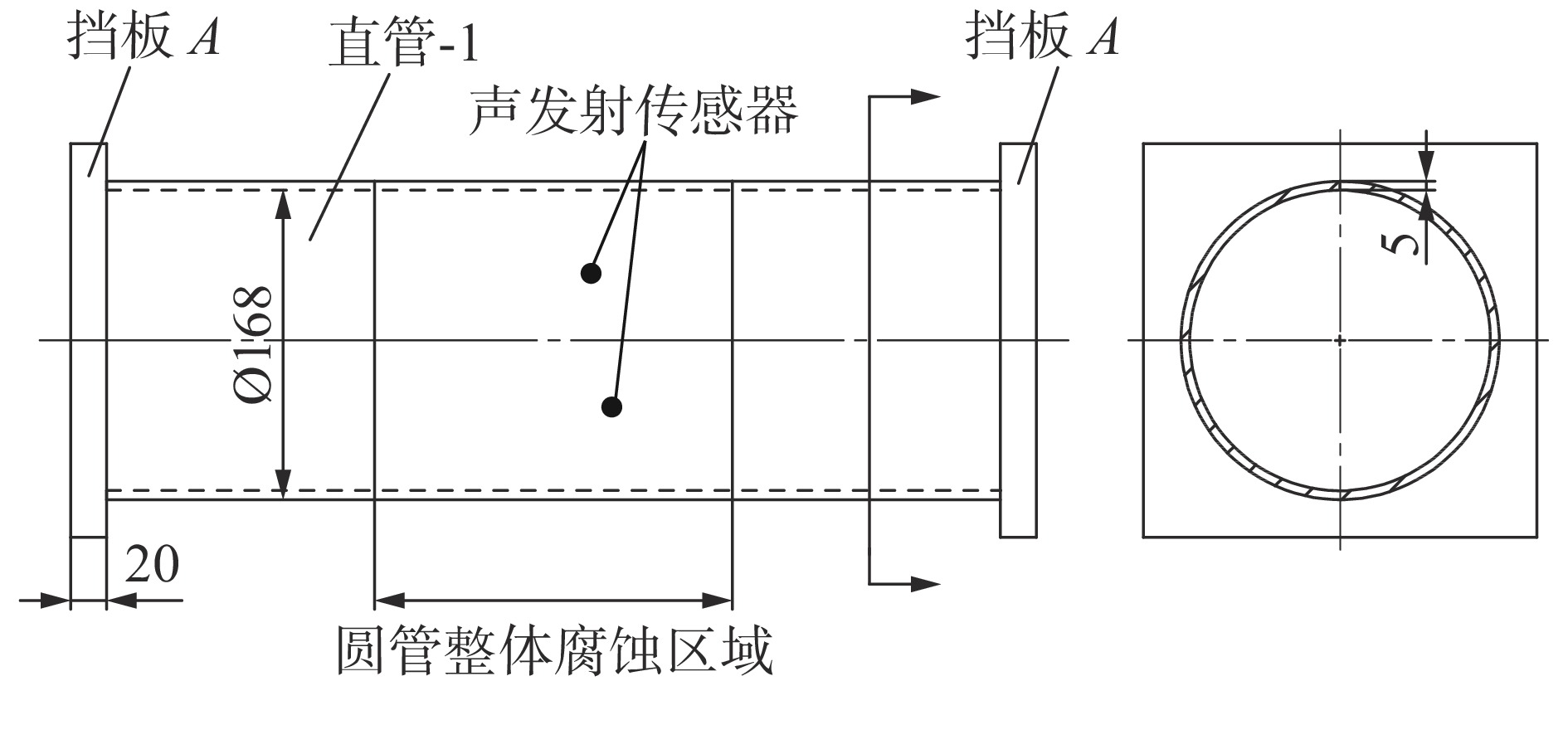

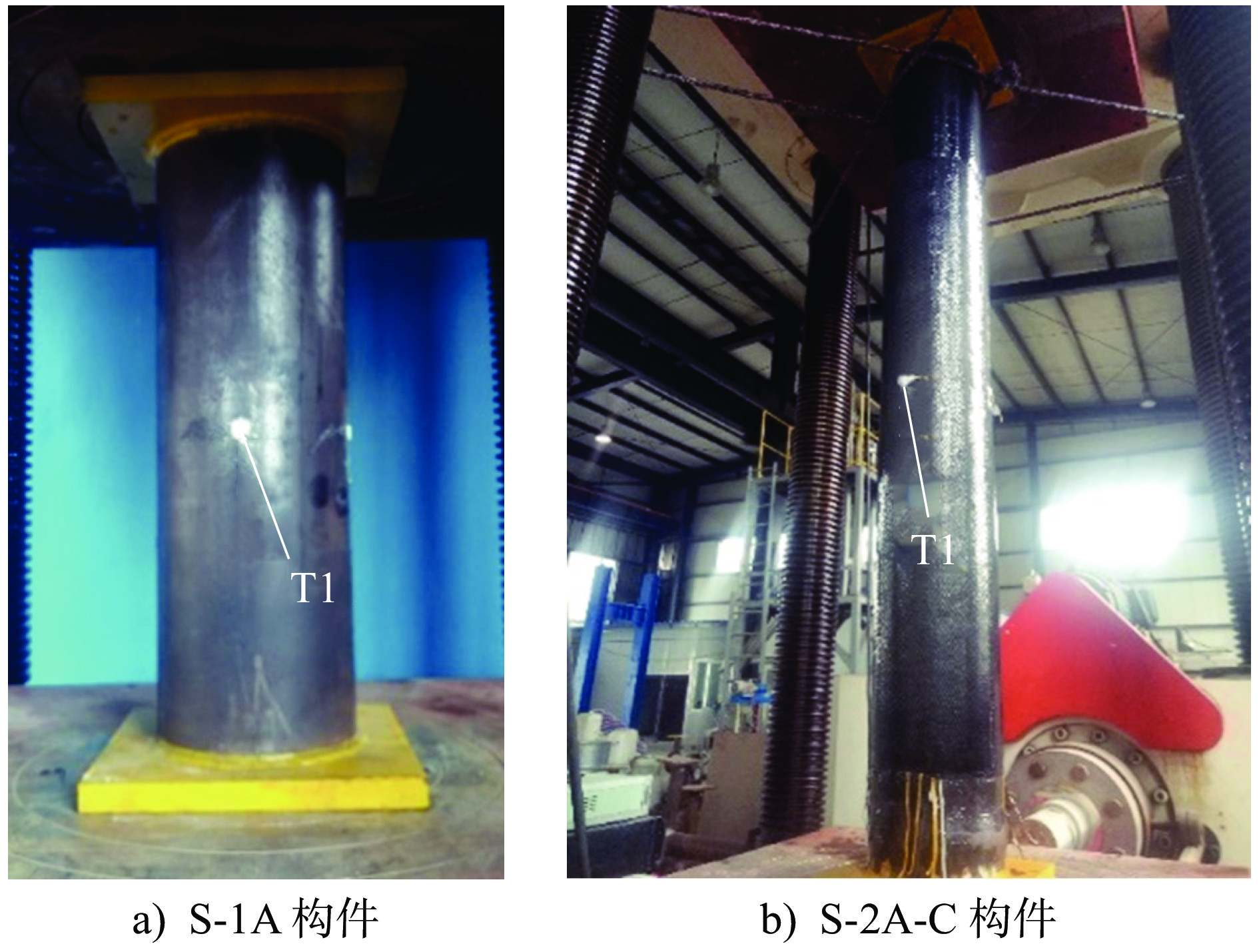

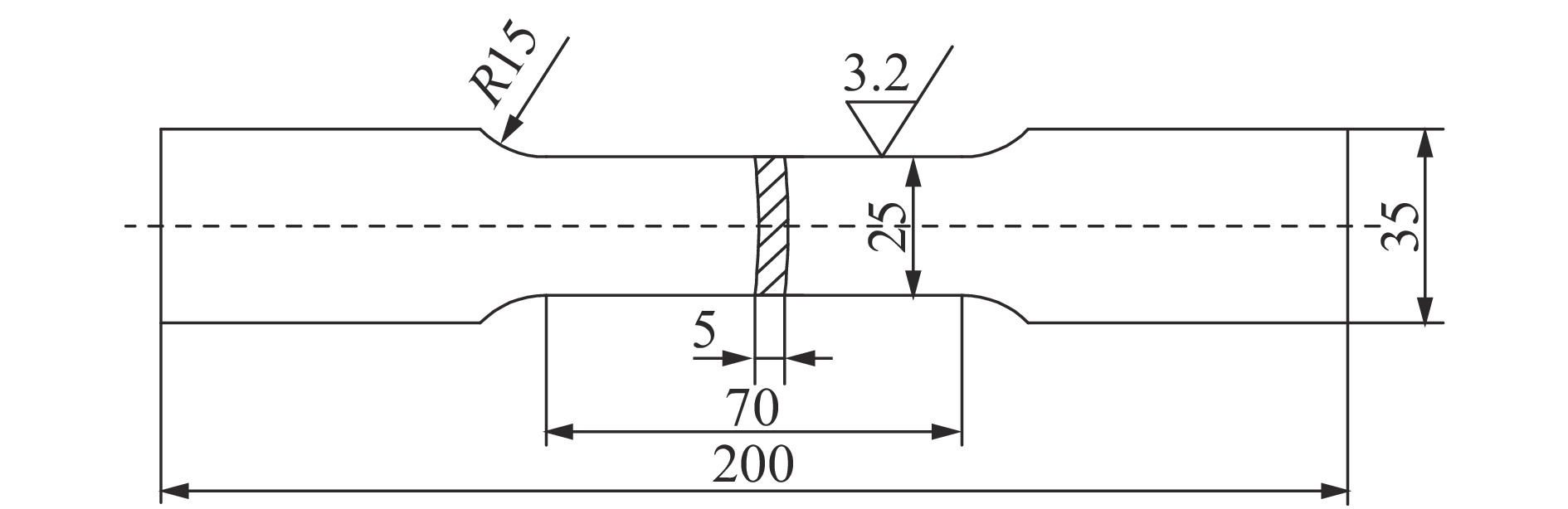

表 1 管柱构件尺寸参数

Table 1. Dimension parameters of tubular column members

组号 试件编号 尺寸/mm 长度/mm 腐蚀深度/mm 腐蚀长度/mm CFRP加固 加固方式 1 S-1A Ø168 × 5 500 0.3 200 无 2 S-1A-C Ø168 × 5 500 0.3 200 有 HLHLHL 3 S-2A Ø180 × 5 1500 0.5 500 无 4 S-2A-C Ø180 × 5 1500 0.5 500 有 HLHLHL 表 2 管柱构件承载力对比

Table 2. Comparison of bearing capacities of tubular column members

试件编号 承载力/kN 提升/% S-1A 961.75 S-1A-C 1273.34 32.4 S-2A 779.53 S-2A-C 990.38 27.0 -

[1] CHEN Y F, ZHANG H, ZHANG J, et al. Residual bending capacity for pipelines with corrosion defects[J]. Journal of Loss Prevention in the Process Industries, 2014, 32: 70-77. doi: 10.1016/j.jlp.2014.07.011 [2] 张小勇. 腐蚀海底管道极限承载力和失效机理研究[D]. 杭州: 浙江大学, 2013.ZHANG X Y. Investigation on ultimate load capacity and failure mechanism of corroded submarine pipeline[D]. Hangzhou: Zhejiang University, 2013. (in Chinese) [3] 刘维洋, 马廷霞, 邹海翔, 等. 含腐蚀凹陷压力管道极限载荷数值分析[J]. 中国安全科学学报, 2016, 26(6): 92-97.LIU W Y, MA T X, ZOU H X, et al. Numerical analysis of limit load on pressure pipeline with corrosion defect and dent[J]. China Safety Science Journal, 2016, 26(6): 92-97. (in Chinese) [4] 臧雪瑞, 顾晓婷, 王秋妍. 含腐蚀缺陷X100输气管道的剩余强度研究[J]. 材料保护, 2019, 52(9): 125-131.ZANG X R, GU X T, WANG Q Y. Research on residual strength of X100 pipeline with corrosion defects[J]. Materials Protection, 2019, 52(9): 125-131. (in Chinese) [5] 李非飞, 黄坤, 吴佳丽, 等. X80管道单腐蚀缺陷失效研究[J]. 应用力学学报, 2020, 37(1): 330-337.LI F F, HUANG K, WU J L, et al. Research on failure of single corrosion defect in X80 pipeline[J]. Chinese Journal of Applied Mechanics, 2020, 37(1): 330-337. (in Chinese) [6] 周利剑, 曹武朋, 卢召红, 等. 腐蚀长度、宽度、深度对带大面积腐蚀缺陷管道应力的影响分析[J]. 材料保护, 2021, 54(3): 153-157.ZHOU L J, CAO W P, LU Z H, et al. Analysis on effects of corrosion length, width and depth on stress state of large-area corrosion defects pipes[J]. Materials Protection, 2021, 54(3): 153-157. (in Chinese) [7] ALANG N A, RAZAK N A, SULAIMAN A S. Determination of burst pressure of API steel pipes using stress modified critical strain model[J]. IOP Conference Series:Materials Science and Engineering, 2012, 36: 012025. doi: 10.1088/1757-899X/36/1/012025 [8] ZHANG S, ZHOU W. Assessment of effects of idealized defect shape and width on the burst capacity of corroded pipelines[J]. Thin-Walled Structures, 2020, 154: 106806. doi: 10.1016/j.tws.2020.106806 [9] TEE K F, WORDU A H. Burst strength analysis of pressurized steel pipelines with corrosion and gouge defects[J]. Engineering Failure Analysis, 2020, 108: 104347. doi: 10.1016/j.engfailanal.2019.104347 [10] ZHANG X H, CHEN B Q, SOARES C G. Effect of non-symmetrical corrosion imperfection on the collapse pressure of subsea pipelines[J]. Marine Structures, 2020, 73: 102806. doi: 10.1016/j.marstruc.2020.102806 [11] GU W, LI H N. Research on the properties of the concrete filled steel tube columns with CFRP composite materials[J]. Advanced Materials Research, 2010, 163-167: 3555-3559. doi: 10.4028/www.scientific.net/AMR.163-167.3555 [12] 吴健, 张彤彤, 李泓运, 等. CFRP加固损伤钢板的双轴拉伸性能研究[J]. 玻璃钢/复合材料, 2015(12): 23-27.WU J, ZHANG T T, LI H Y, et al. Study on biaxial tension of cracked steel plates reinforced by CFRP plates[J]. Fiber Reinforced Plastics/Composites, 2015(12): 23-27. (in Chinese) [13] 邵永波, 朱红梅, 杨冬平. 轴压作用下CFRP加固圆钢管短柱的静力承载力分析[J]. 西南交通大学学报, 2020, 55(1): 167-174.SHAO Y B, ZHU H M, YANG D P. Static bearing capacity analysis of CFRP-reinforced short CHS steel tubular columns under axial compression[J]. Journal of Southwest Jiaotong University, 2020, 55(1): 167-174. (in Chinese) [14] 史曼瑜, 邵永波, 杨冬平. 碳纤维复合材料(CFRP)加固含腐蚀缺陷的TT型管节点静力性能研究[J]. 应用力学学报, 2020, 37(3): 959-968.SHI M Y, SHAO Y B, YANG D P. Static performance of CFRP-strengthened tubular TT-joints with corrosion defects[J]. Chinese Journal of Applied Mechanics, 2020, 37(3): 959-968. (in Chinese) [15] 李光海. 声发射源识别技术的研究[D]. 广州: 华南理工大学, 2002.LI G H. A study on recognition of acoustic emission source[D]. Guangzhou: South China University of Technology, 2002. (in Chinese) [16] XU J, SUN T, XU Y T, et al. Fracture toughness research of G20Mn5QT cast steel based on the acoustic emission technique[J]. Construction and Building Materials, 2020, 230: 116904. doi: 10.1016/j.conbuildmat.2019.116904 [17] CHULUUNBAT T, KOSTRYZHEV A G, MARENYCH O. Investigation of X80 line pipe steel fracture during tensile testing using acoustic emission monitoring[J]. Key Engineering Materials, 2019, 794: 21-27. doi: 10.4028/www.scientific.net/KEM.794.21 [18] GOLDARAN R, TURER A, KOUHDARAGH M, et al. Identification of corrosion in a prestressed concrete pipe utilizing acoustic emission technique[J]. Construction and Building Materials, 2020, 242: 118053. doi: 10.1016/j.conbuildmat.2020.118053 [19] XU J, WANG W X, HAN Q H, et al. Damage pattern recognition and damage evolution analysis of unidirectional CFRP tendons under tensile loading using acoustic emission technology[J]. Composite Structures, 2020, 238: 111948. doi: 10.1016/j.compstruct.2020.111948 [20] 何攀, 蒋天植, 刘才学, 等. 基于声发射的压力管道LBB监测系统研制[J]. 核动力工程, 2019, 40(S1): 59-62.HE P, JIANG T Z, LIU C X, et al. Development of pressure pipeline LBB monitoring system based on acoustic emission[J]. Nuclear Power Engineering, 2019, 40(S1): 59-62. (in Chinese) [21] SHRESTHA S, KANNAN M, MORSCHER G N, et al. In-situ fatigue life analysis by modal acoustic emission, direct current potential drop and digital image correlation for steel[J]. International Journal of Fatigue, 2021, 142: 105924. doi: 10.1016/j.ijfatigue.2020.105924 [22] 李兆南, 龚斌, 林木, 等. 压力管道泄漏声发射信号频谱特性实验研究[J]. 声学技术, 2007, 26(3): 422-426.LI Z N, GONG B, LIN M, et al. Experimental study on spectral characteristics of acoustic emission from pressure pipe leakage[J]. Technical Acoustics, 2007, 26(3): 422-426. (in Chinese) [23] 艾琼, 刘才学, 王瑶, 等. 液压下压力管线活动缺陷声发射信号研究[J]. 核动力工程, 2009, 30(4): 13-16.AI Q, LIU C X, WANG Y, et al. Study on acoustic emission signals of active defect in pressure piping under hydraulic pressure[J]. Nuclear Power Engineering, 2009, 30(4): 13-16. (in Chinese) [24] 李倩倩, 张加顺, 脱晓庆, 等. 基于AE的碳纤维复合材料圆管轴向压缩性能研究[J]. 复合材料科学与工程, 2021(7): 76-83.LI Q Q, ZHANG J S, TUO X Q, et al. Research on axial compression performance of carbon fiber composite tube based on AE[J]. Composites Science and Engineering, 2021(7): 76-83. (in Chinese) [25] AKDAG S, KARAKUS M, TAHERI A, et al. Effects of thermal damage on strain burst mechanism for brittle rocks under true-triaxial loading conditions[J]. Rock Mechanics and Rock Engineering, 2018, 51(6): 1657-1682. doi: 10.1007/s00603-018-1415-3 [26] 沈功田. 声发射检测技术及应用[M]. 北京: 科学出版社, 2015.SHEN G T. Acoustic emission technology and application[M]. Beijing: Science Press, 2015. (in Chinese) [27] 张一辉, 张文斌, 许飞云, 等. Q235B钢板拉伸损伤试验的声发射特性[J]. 振动与冲击, 2015, 34(15): 156-161.ZHANG Y H, ZHANG W B, XU F Y, et al. Acoustic emission characteristics of Q235B steel plates′ tensile damage tests[J]. Journal of Vibration and Shock, 2015, 34(15): 156-161. (in Chinese) [28] 邱枫, 白永忠, 单广斌, 等. 基于时频熵特征的2.25Cr-1Mo损伤开裂声发射识别方法研究[J]. 安全、健康和环境, 2020, 20(11): 1-5.QIU F, BAI Y Z, SHAN G B, et al. Acoustic emission identification of 2.25Cr-1Mo crack based on time-frequency entropy[J]. Safety Health & Environment, 2020, 20(11): 1-5. (in Chinese) -

下载:

下载: