|

[1]

|

贲玥, 张乐, 魏帅, 等. 3D打印陶瓷材料研究进展[J]. 材料导报, 2016, 30(21): 109-118.BEN Y, ZHANG L, WEI S, et al. Research progress of 3D printed ceramic materials[J]. Materials Reports, 2016, 30(21): 109-118. (in Chinese)

|

|

[2]

|

卢秉恒. 增材制造技术——现状与未来[J]. 中国机械工程, 2020, 31(1): 19-23. doi: 10.3969/j.issn.1004-132X.2020.01.003LU B C. Additive manufacturing-current situation and future[J]. China Mechanical Engineering, 2020, 31(1): 19-23. (in Chinese) doi: 10.3969/j.issn.1004-132X.2020.01.003

|

|

[3]

|

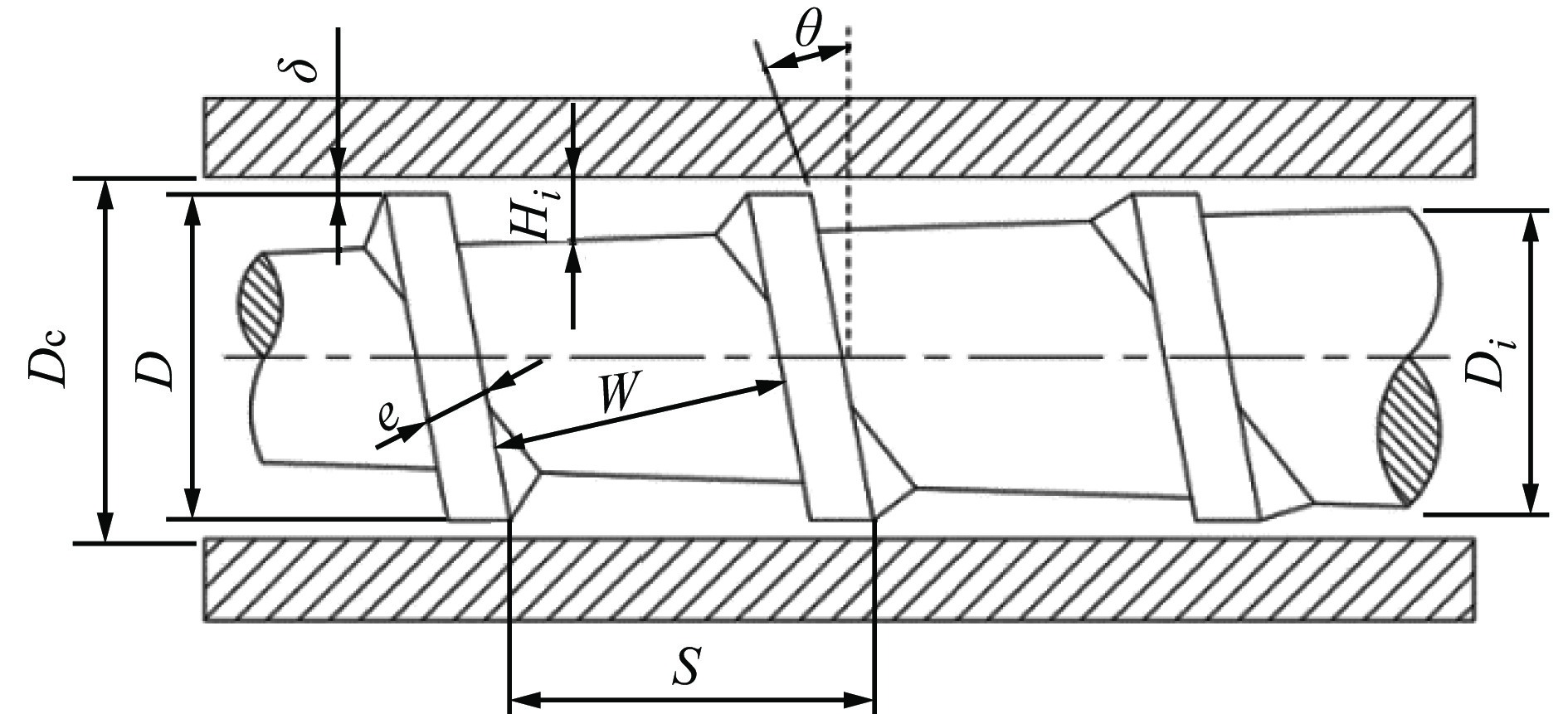

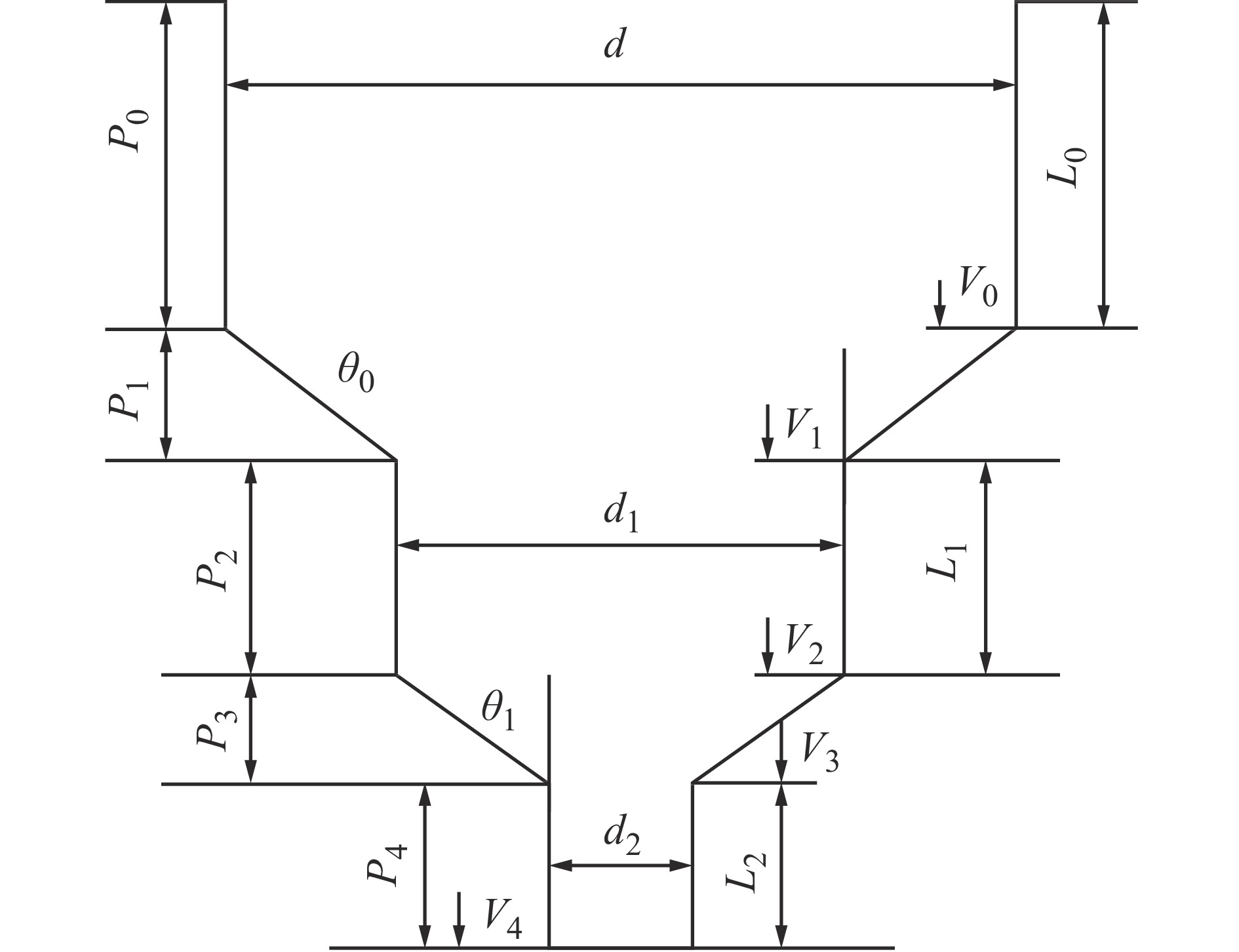

张静, 周婧, 段国林. 基于螺杆泵送料的陶瓷三维打印机挤出机理[J]. 中国机械工程, 2020, 31(10): 1252-1259. doi: 10.3969/j.issn.1004-132X.2020.10.018ZHANG J, ZHOU J, DUAN G L. Extrusion mechanism of ceramic 3D printer based on screw pump feeding[J]. China Mechanical Engineering, 2020, 31(10): 1252-1259. (in Chinese) doi: 10.3969/j.issn.1004-132X.2020.10.018

|

|

[4]

|

OBER T J, FORESTI D, LEWIS J A. Active mixing of complex fluids at the microscale[J]. Proceedings of the National Academy of Sciences of the United States of America, 2015, 112(40): 12293-12298. doi: 10.1073/pnas.1509224112

|

|

[5]

|

LEU M C, TANG L, DEUSER B, et al. Freeze-form extrusion fabrication of composite structures[R]. International Solid Freeform Fabrication Symposium.

|

|

[6]

|

DE CASTRO SILVEIRA Z, DE FREITAS M S, NETO P I, et al. Design development and functional validation of an interchangeable head based on mini screw extrusion applied in an experimental desktop 3-D printer[J]. International Journal of Rapid Manufacturing, 2014, 4(1): 49-65. doi: 10.1504/IJRAPIDM.2014.062037

|

|

[7]

|

吴明星. 微型挤出熔体流变行为分析及螺杆优化设计研究[D]. 广州: 华南理工大学, 2010.WU M X. Research of rheological behavior of melt and optimal design for screw based on micro-extrusion[D]. Guangzhou: South China University of Technology, 2010. (in Chinese)

|

|

[8]

|

王世博. FDM挤出头CFD分析与混色挤出头优化设计[D]. 哈尔滨: 哈尔滨工业大学, 2016.WANG S B. CFD analysis of fused deposition modelling nozzles and optimal design of mixing nozzles[D]. Harbin: Harbin Institute of Technology, 2016. (in Chinese)

|

|

[9]

|

程凯, 兰红波, 邹淑亭, 等. 多材料多尺度3D打印主动混合喷头的研究[J]. 中国科学: 技术科学, 2017, 47(2): 149-162.CHENG K, LAN H B, ZOU S T, et al. Research on active mixing printhead for multi-material and multi-scale 3D printing[J]. Scientia Sinica (Technologica) 2017, 47(2): 149-162. (in Chinese)

|

|

[10]

|

李亚运. 陶瓷无模直写成型技术的研究[D]. 北京: 清华大学, 2015.LI Y Y. Research on the freeform direct writing technique based on ceramic ink[D]. Beijing: Tsinghua University, 2015. (in Chinese)

|

|

[11]

|

HOHMANN J K, RENNER M, WALLER E H, et al. Three-dimensional μ-printing: an enabling technology[J]. Advanced Optical Materials, 2015, 3(11): 1488-1507. doi: 10.1002/adom.201500328

|

|

[12]

|

贾明印, 薛平, 朱复华. 新型螺杆挤出机熔体输送理论的研究[J]. 中国塑料, 2006, 20(3): 103-107. doi: 10.3321/j.issn:1001-9278.2006.03.023JIA M Y, XUE P, ZHU F H. Study on the theory of melt conveying for the novel screw extruder[J]. China Plastics, 2006, 20(3): 103-107. (in Chinese) doi: 10.3321/j.issn:1001-9278.2006.03.023

|

|

[13]

|

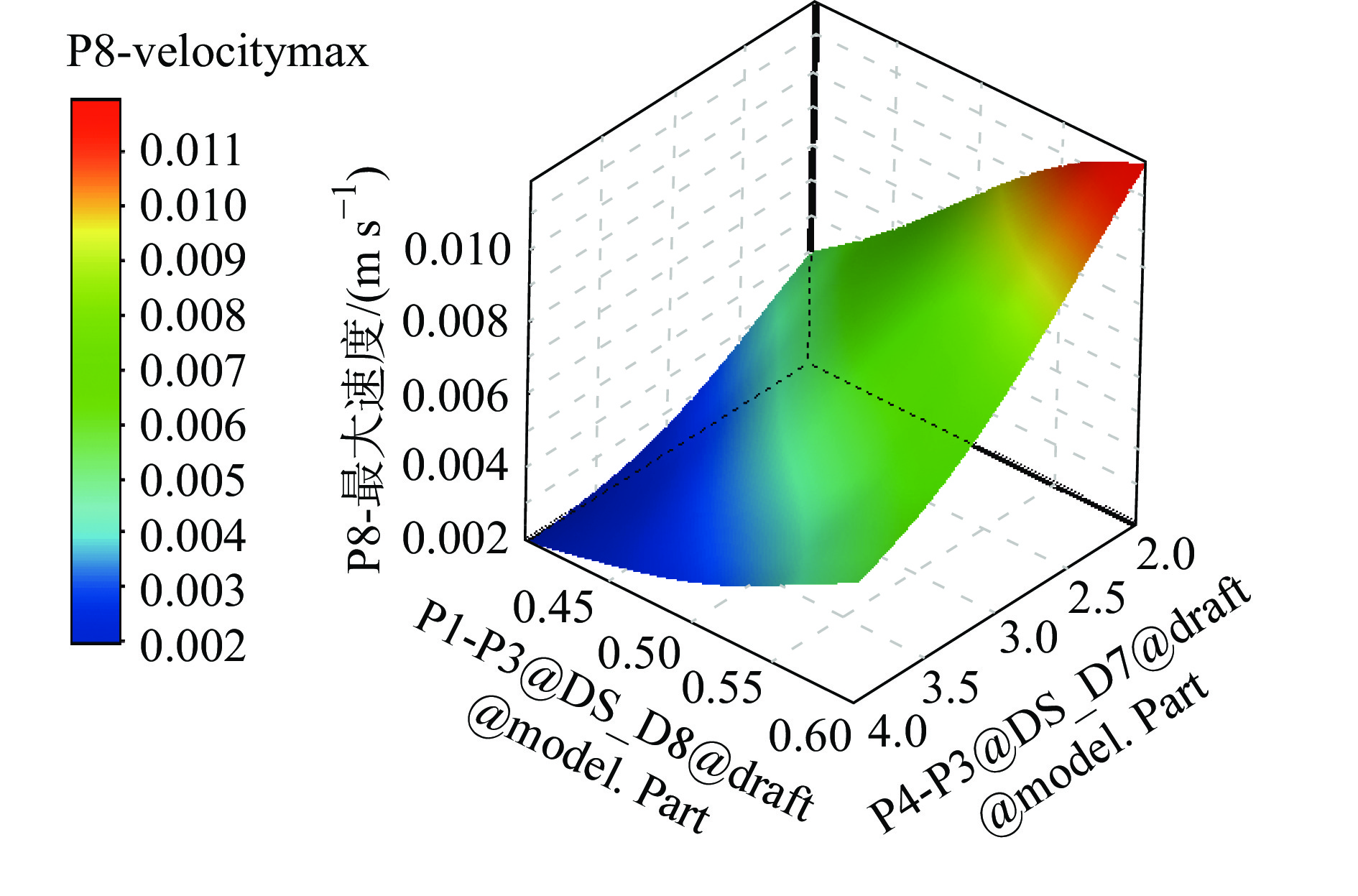

丛日原, 杜云刚, 鲁玥, 等. 陶瓷3D打印机挤出机的设计与仿真分析[J]. 中国陶瓷工业, 2019, 26(4): 13-17.CONG R Y, DU Y G, LU Y, et al. Design and simulation analysis of ceramic 3D printer extruder[J]. China Ceramic Industry, 2019, 26(4): 13-17. (in Chinese)

|

|

[14]

|

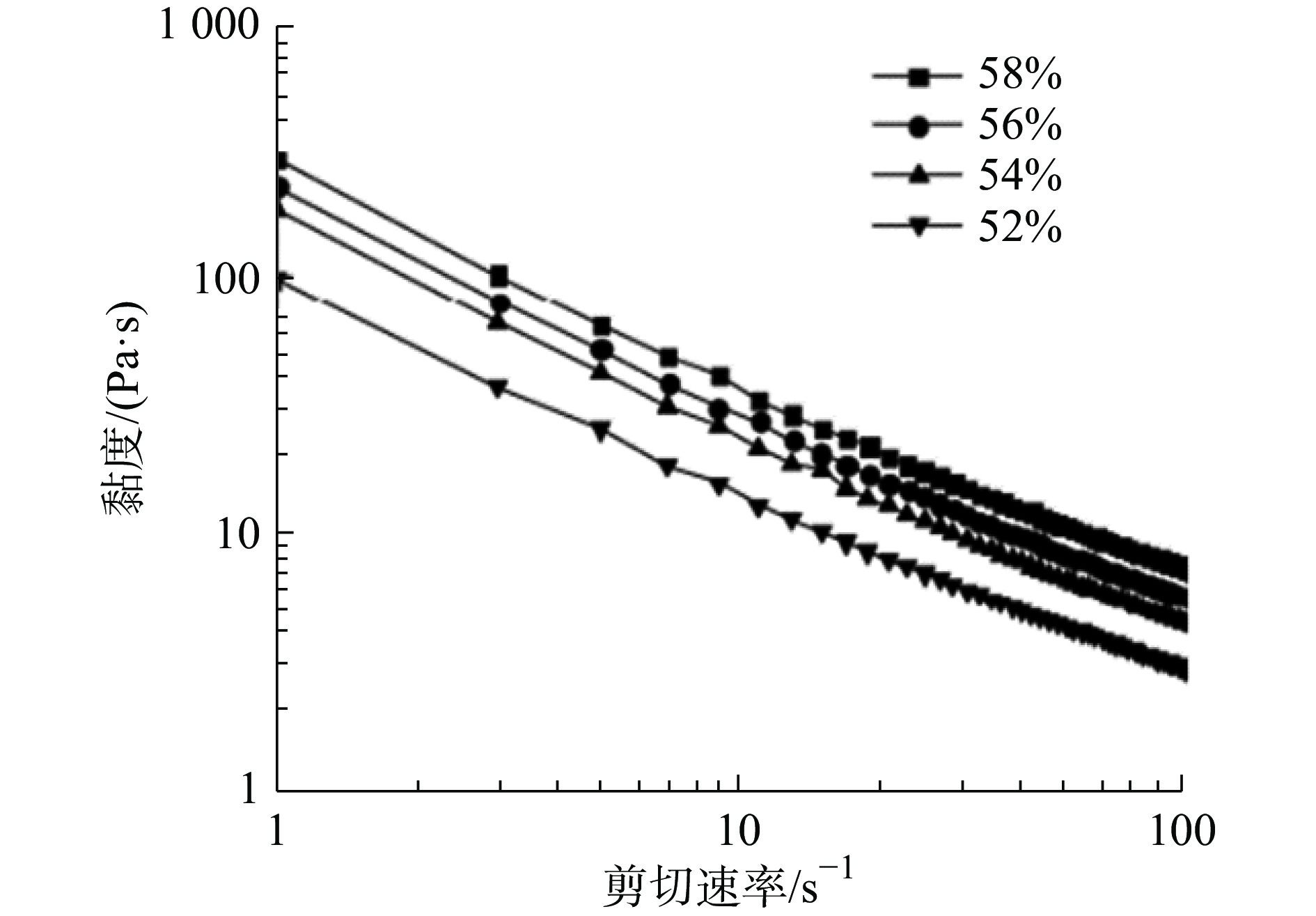

夏晓光, 段国林. 基于溶剂挥发的陶瓷直写成型工艺[J]. 硅酸盐学报, 2020, 48(12): 1880-1885.XIA X G, DUAN G L. Ceramic direct ink writing process based on solvent evaporation[J]. Journal of the Chinese Ceramic Society, 2020, 48(12): 1880-1885. (in Chinese)

|

|

[15]

|

李烁, 徐元铭, 张俊. 复合材料加筋结构的神经网络响应面优化设计[J]. 机械工程学报, 2006, 42(11): 115-119. doi: 10.3321/j.issn:0577-6686.2006.11.018LI S, XU Y M, ZHANG J. Neural network response surface optimization design for composite stiffened structures[J]. Journal of Mechanical Engineering, 2006, 42(11): 115-119. (in Chinese) doi: 10.3321/j.issn:0577-6686.2006.11.018

|

下载:

下载: