Comparative Study on Formability of Aluminum Alloy Tailor Welded Blanks using Taguchi Method

-

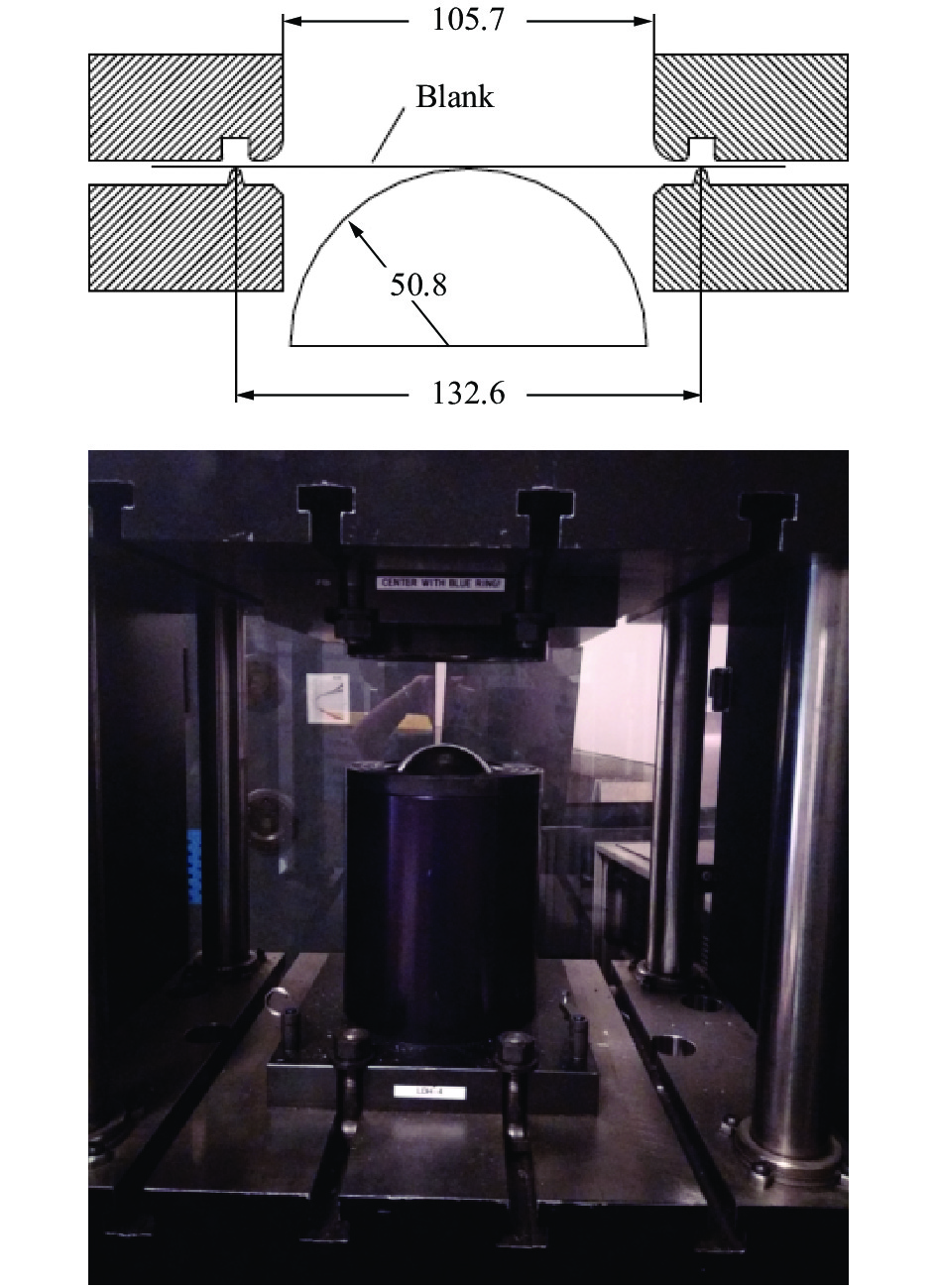

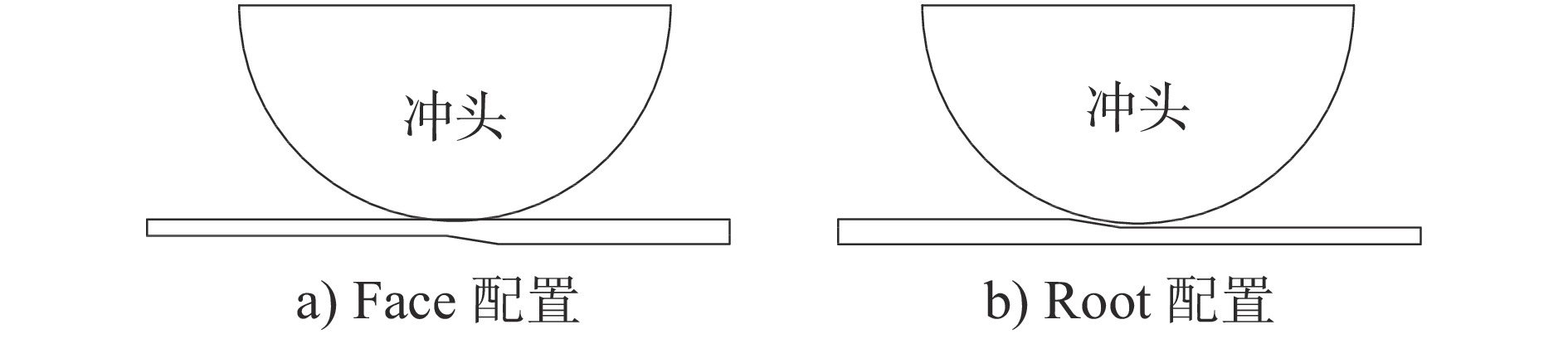

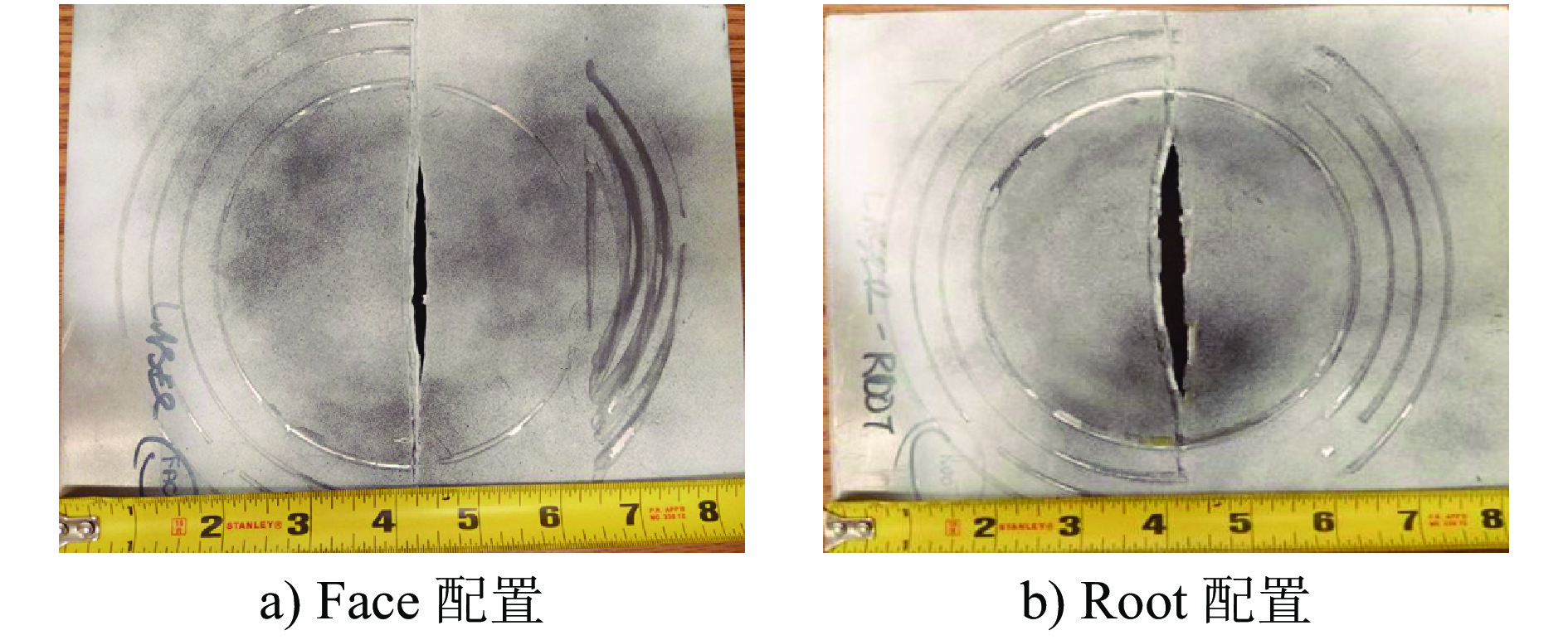

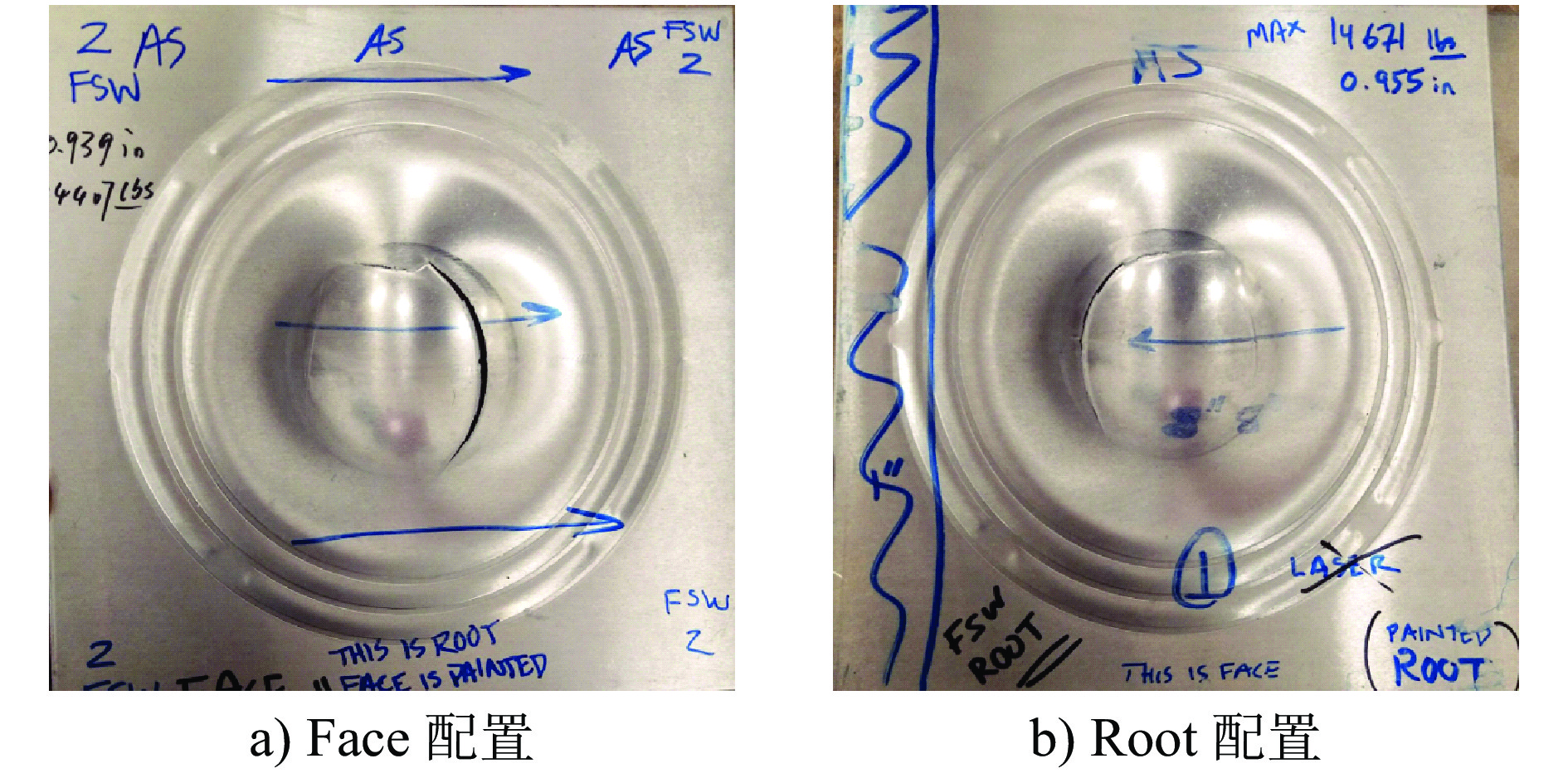

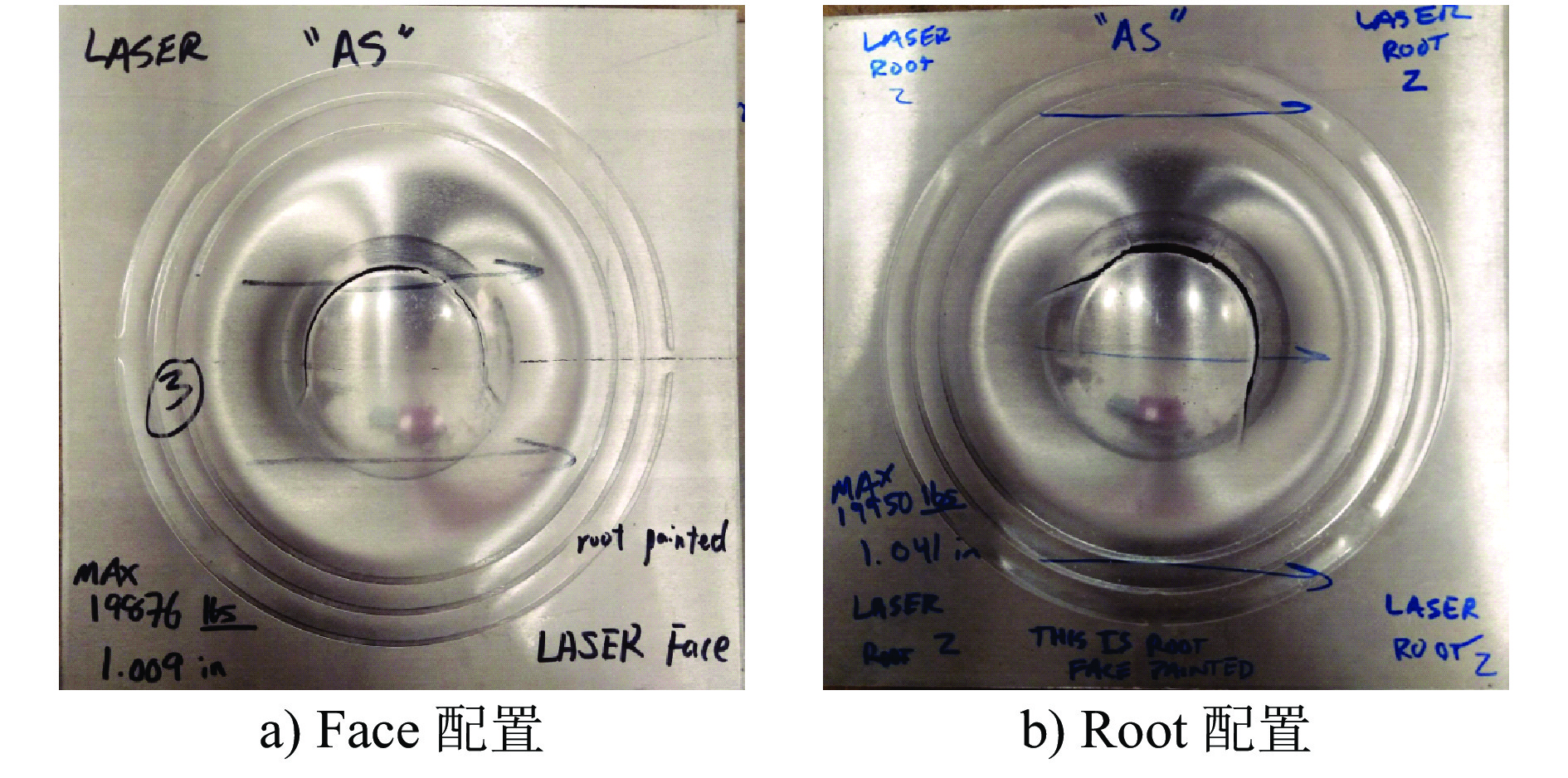

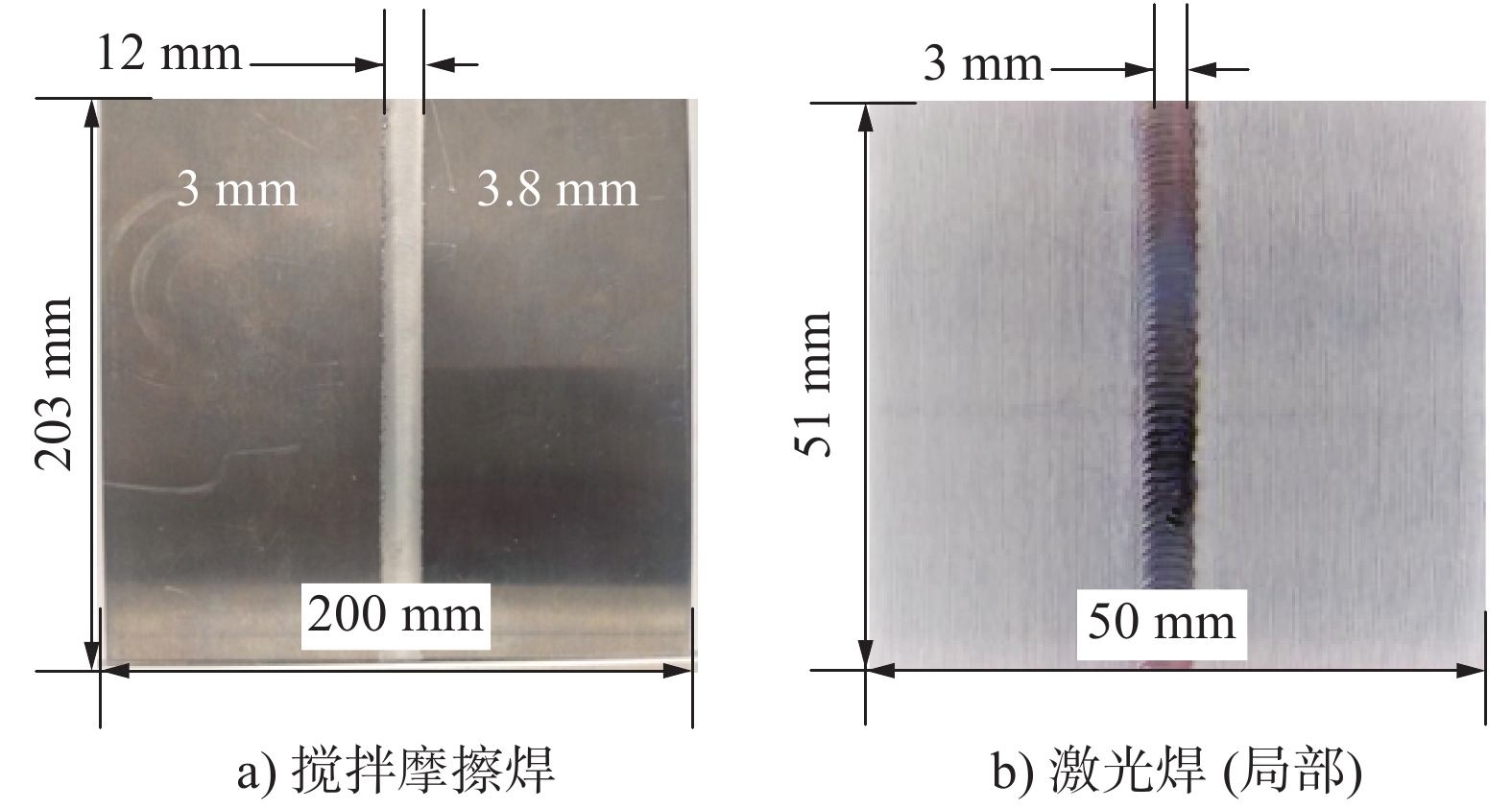

摘要: 本论文研究了不同焊接方法、接触配置和厚度差异对铝合金拼焊板成形性能极限拱顶高度(Limiting dome height,LDH)值的影响,并采用Taguchi方法对3种影响因素进行了分析。结果表明:对于异种厚度的铝合金拼焊板,Face配置时的LDH值要小于Root配置时的LDH值,与焊接方法无关;激光焊接的LDH值要小于搅拌摩擦焊接的LDH值,与配置方式无关。对于同种厚度的铝合金拼焊板,LDH值都大于异种厚度时的LDH值,与配置方式无关;且Face配置时的LDH值仍然小于Root配置时的LDH值。厚度差异是影响铝合金拼焊板LDH值最主要的因素,接触配置对LDH值的影响较小,对LDH值影响最小的是焊接方法。

-

关键词:

- 铝合金拼焊板 /

- 极限拱顶高度 /

- Taguchi 方法

Abstract: In this paper, the effects of the different welding methods, contact configuration and thickness differences on the formability (Limiting dome height, LDH) value of aluminum alloy tailor welded blanks were studied, and the three influencing factors were analyzed with Taguchi method. For the aluminum alloy tailor welded blanks with different thickness: the LDH of Face configuration is less than that of Root configuration, and has nothing to do with the welding method; the LDH of laser welding is less than that of friction stir welding and has nothing to do with the configuration. For the aluminum alloy tailor welded blanks with the same thickness: the LDH is higher than that of the different thickness, regardless of the configuration; the LDH in Face configuration is still smaller than that in Root configuration. The results show that the thickness difference is the most important factor affecting the LDH value, the contact configuration has slight influence on the LDH value, and the welding method has the least influence on the LDH value. -

表 1 AA5754铝合金各元素质量分数

% 铝 硅 锰 镁 铁 Bal. 0.4 0.5 2.6 ~ 3.2 0.4 表 2 AA5754铝合金力学性能

抗拉强度/MPa 屈服强度/MPa 伸长率/% 硬度HV 215 140 25 67.2 表 3 异厚度铝合金AA5754拼焊板LDH实验结果(3 mm vs 3.8 mm)

配置类型 最大载荷/

kNLDH /

mm断裂位置和方向 FSW face 配置 84.49 20.70 薄侧母材处,平行焊缝 FSW root 配置 90.18 21.87 薄侧母材处,平行焊缝 Laser face 配置 69.51 17.61 薄侧母材处,平行焊缝 Laser root 配置 79.90 19.81 薄侧母材处,平行焊缝 表 4 同厚度铝合金AA5754拼焊板LDH实验结果

配置类型 最大载荷/kN LDH/mm 断裂位置 FSW face 配置 64.11 23.8 位于焊缝上 FSW root 配置 65.29 24.26 位于焊缝上 Laser face 配置 88.45 25.36 位于焊缝上 Laser root配置 88.77 26.44 不位于焊缝上 表 5 L4(23)正交实验表和实验数据表

实验

编号焊接

方法配置

方法厚度 LDH/

mmS/N 1 激光焊接 Face 异厚 17.61 24.9152 2 激光焊接 Root 等厚 26.44 28.4452 3 搅拌摩擦焊接 Face 等厚 23.80 27.5315 4 搅拌摩擦焊接 Root 异厚 21.87 26.7970 表 6 基于LDH值的S/N 信噪比一览表

因子名称 效应等级 Max-Min 水准1 水准2 焊接方法 3 0.4841 26.6802 27.1643 配置方法 2 1.3977 26.2234 27.6211 厚度差异 1 2.1323 25.8561 27.9884 -

[1] SU Y, LI W Y, PATEL V, et al. Formability of an AA5083 aluminum alloy T-joint using SSFSW on both corners[J]. Materials and Manufacturing Processes, 2019, 34(15): 1737-1744 doi: 10.1080/10426914.2019.1669799 [2] PATEL V, LI W Y, WANG G Q, et al. Friction stir welding of dissimilar aluminum alloy combinations: state-of-the-art[J]. Metals, 2019, 9(3): 270 doi: 10.3390/met9030270 [3] MERKLEIN M, JOHANNES M, LECHNER M, et al. A review on tailored blanks—Production, applications and evaluation[J]. Journal of Materials Processing Technology, 2014, 214(2): 151-164 doi: 10.1016/j.jmatprotec.2013.08.015 [4] LI Y Z, ZAN Y N, WANG Q Z, et al. High-speed friction stir welding of T6-Treated B4Cp/6061Al composite[J]. Acta Metallurgica Sinica (English Letters), 2020, 33(1): 67-74 doi: 10.1007/s40195-019-00932-0 [5] LIU J, WANG A L, GAO H X, et al. Transition of failure mode in hot stamping of AA6082 tailor welded blanks[J]. Journal of Materials Processing Technology, 2018, 257: 33-44 doi: 10.1016/j.jmatprotec.2018.02.028 [6] GAUTAM V, KUMAR A. Experimental and numerical studies on formability of tailor welded blanks of high strength steel[J]. Procedia Manufacturing, 2019, 29: 472-480 doi: 10.1016/j.promfg.2019.02.164 [7] MA X D, GUAN Y P. Theoretical prediction and experimental investigation on formability of tailor-welded blanks[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(1): 228-236 doi: 10.1016/S1003-6326(16)64108-0 [8] NADIKUDI B K B, DAVIDSON M J, AKASAPU N R, et al. Formability analysis of dissimilar tailor welded blanks welded with different tool pin profiles[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(6): 1787-1793 doi: 10.1016/S1003-6326(15)63784-0 [9] SONG Y L, HUA L. Influences of thickness ratio of base sheets on formability of Tailor Welded Blanks[J]. Procedia Engineering, 2014, 81: 730-735 doi: 10.1016/j.proeng.2014.10.068 [10] BANDYOPADHYAY K, BASAK S, PANDA S K, et al. Use of stress based forming limit diagram to predict formability in two-stage forming of tailor welded blanks[J]. Materials & Design, 2015, 67: 558-570 [11] SAFDARIAN KOROUYEH R, MOSLEMI NAEINI H, TORKAMANY M J, et al. Experimental and theoretical investigation of thickness ratio effect on the formability of tailor welded blank[J]. Optics & Laser Technology, 2013, 51: 24-31 [12] SAFDARIAN R. The effects of strength ratio on the forming limit diagram of tailor-welded blanks[J]. Ironmaking & Steelmaking, 2018, 45(1): 17-24 [13] LEITAO C, ZHANG B K, PADMANABHAN R, et al. Influence of weld geometry and mismatch on formability of aluminium tailor welded blanks: numerical and experimental analysis[J]. Science and Technology of Welding and Joining, 2011, 16(8): 662-668 doi: 10.1179/1362171811Y.0000000055 [14] HOVANSKI Y, CARSLEY J, CARLSON B, et al. Comparing laser welding technologies with friction stir welding for production of Aluminum tailor-welded blanks[J]. SAE International Journal of Materials and Manufacturing, 2014, 7(3): 537-544 doi: 10.4271/2014-01-0791 [15] MILES M P, NELSON T W, DECKER B J. Formability and strength of friction-stir-welded aluminum sheets[J]. Metallurgical and Materials Transactions A, 2004, 35(11): 3461-3468 doi: 10.1007/s11661-004-0183-8 [16] SETO A, YAMAMOTO T, NIWA T. Influences of loading direction and thickness ratio on fatigue properties of tailored welded blanks[J]. International Journal of Fatigue, 2007, 29(4): 729-737 doi: 10.1016/j.ijfatigue.2006.06.008 [17] SHAKERI H R, BUSTE A, WORSWICK M J, et al. Study of damage initiation and fracture in aluminum tailor welded blanks made via different welding techniques[J]. Journal of Light Metals, 2002, 2(2): 95-110 doi: 10.1016/S1471-5317(02)00028-7 [18] 伍杰, 李理, 毛祖莉, 等. 轻量化汽车用拼焊板冲压成形性能研究现状与展望[J]. 焊接技术, 2019, 48(10): 1-5 doi: 10.13846/j.cnki.cn12-1070/tg.2019.10.001WU J, LI L, MAO Z L, et al. Research status and prospect of the stamping formability of tailor welded blanks for the application of automobile lightweight[J]. Welding Technology, 2019, 48(10): 1-5 (in Chinese) doi: 10.13846/j.cnki.cn12-1070/tg.2019.10.001 [19] 刘儒军, 周朝辉, 杜曙威. DOE在高频电流感应钎焊焊接工艺参数优化中的应用[J]. 焊接技术, 2014, 43(9): 33-36 doi: 10.13846/j.cnki.cn12-1070/tg.2014.09.010LIU R J, ZHOU Z H, DU S W. Application of DOE to the parameters optimization of the high frequency current induction brazing technology[J]. Welding Technology, 2014, 43(9): 33-36 (in Chinese) doi: 10.13846/j.cnki.cn12-1070/tg.2014.09.010 [20] 周里群, 彭宜昌, 毛昭明, 等. 基于Taguchi方法的镍涂层薄板冲压工艺参数研究[J]. 机械科学与技术, 2015, 34(7): 1054-1058 doi: 10.13433/j.cnki.1003-8728.2015.0716ZHOU L Q, PENG Y C, MAO Z M, et al. Research on process parameters in deep drawing of electroplating nickel coating sheet based on taguchi method[J]. Mechanical Science and Technology for Aerospace Engineering, 2015, 34(7): 1054-1058 (in Chinese) doi: 10.13433/j.cnki.1003-8728.2015.0716 [21] SHUNMUGASUNDARAM M, PRAVEEN KUMAR A, PONRAJ SANKAR L, et al. Optimization of process parameters of friction stir welded dissimilar AA6063 and AA5052 aluminum alloys by Taguchi technique[J]. Materials Today:Proceedings, 2020, 27: 871-876 doi: 10.1016/j.matpr.2020.01.122 -

下载:

下载: