Study on Stress Intensity Factors of EMU Hollow Axles

-

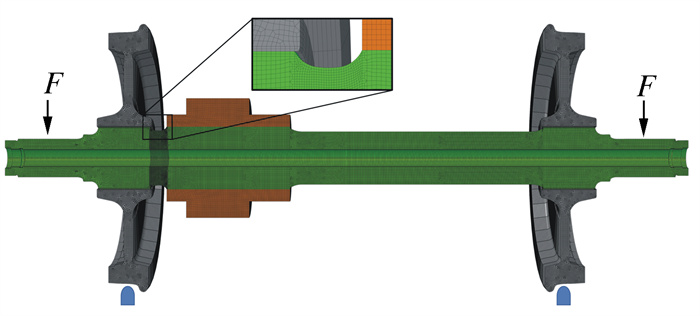

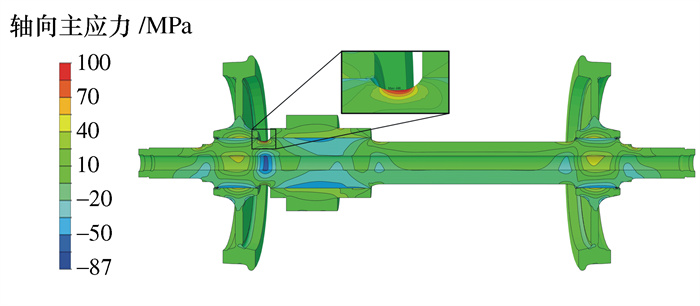

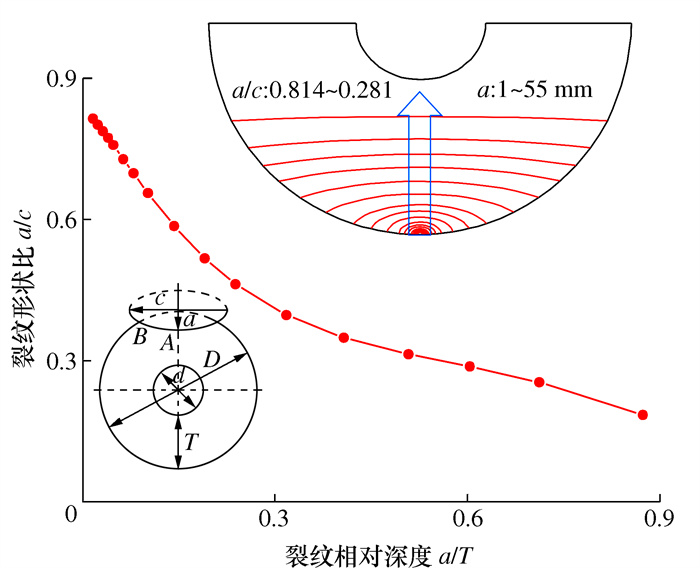

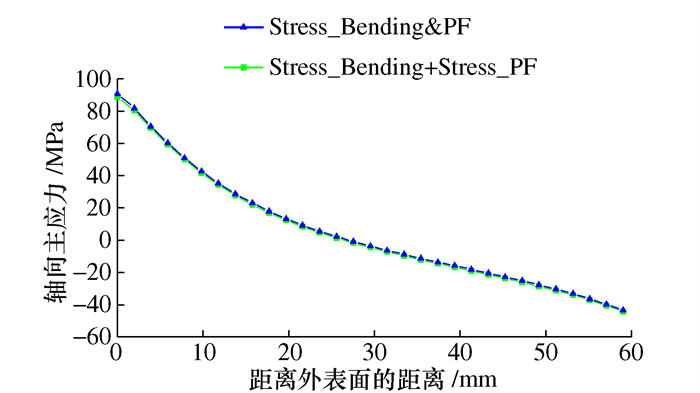

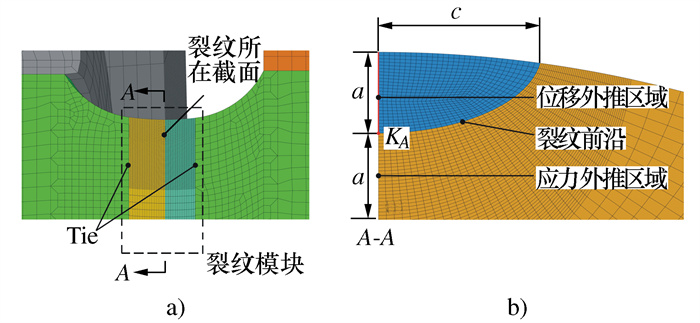

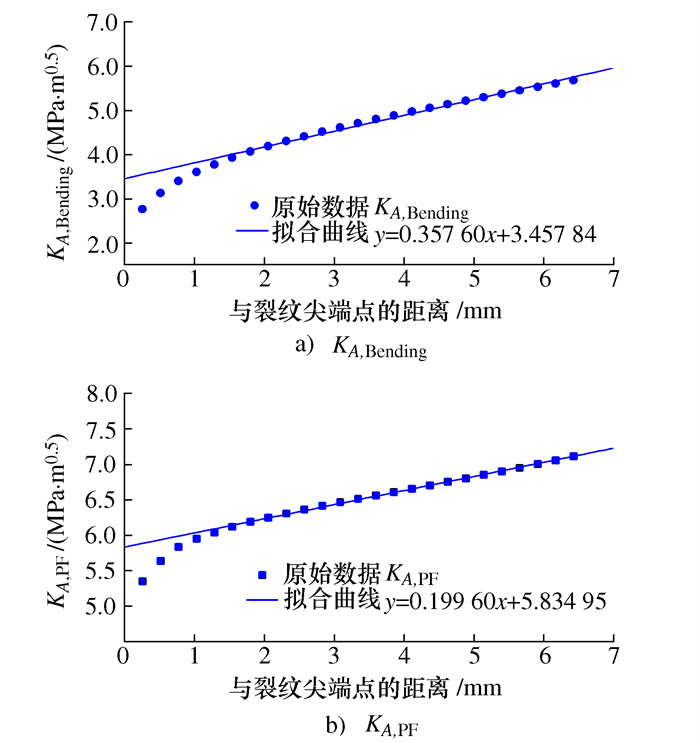

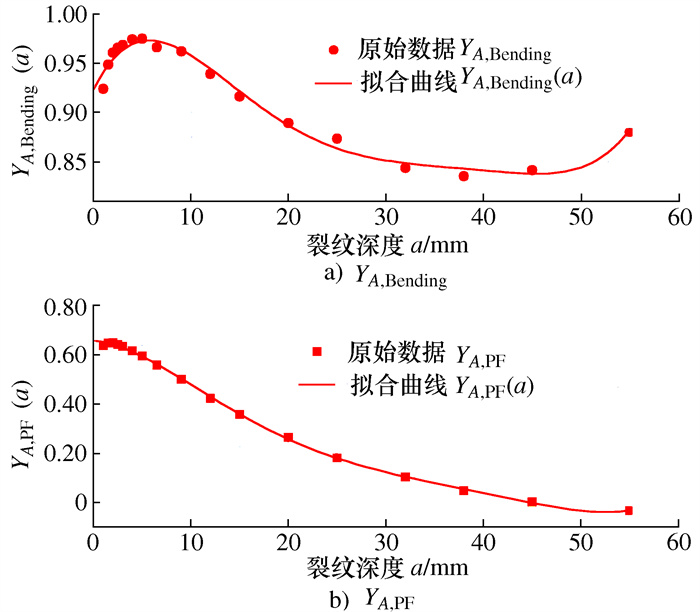

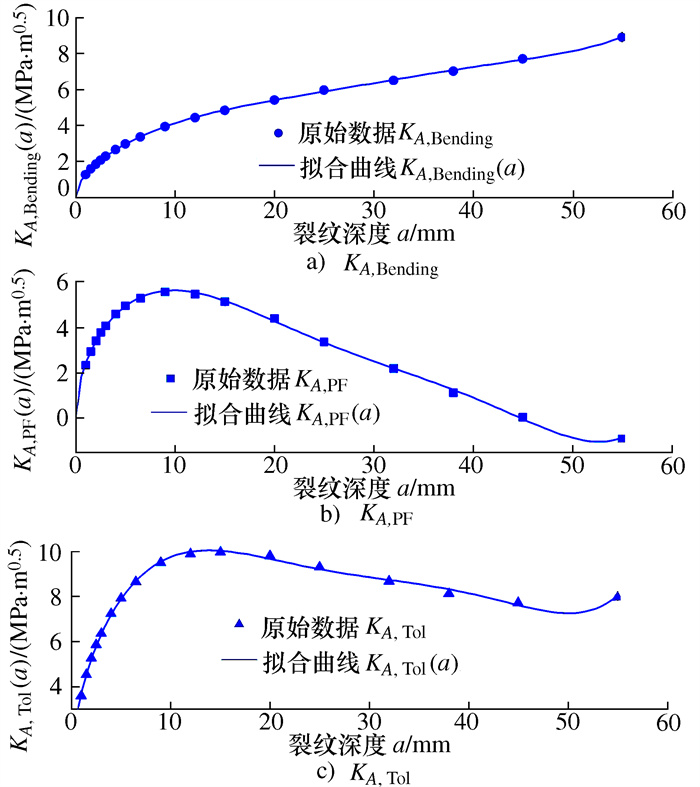

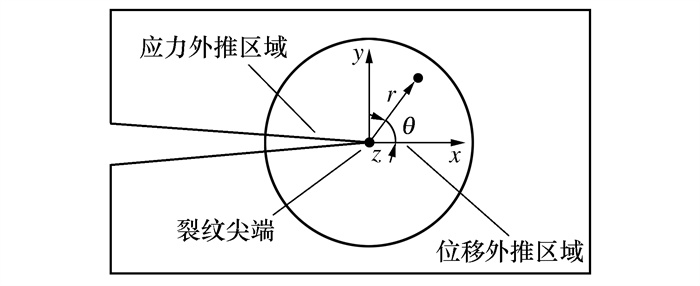

摘要: 为研究动车组空心车轴应力强度因子,首先分析了车轴应力强度因子的影响因素,建立了含裂纹车轴有限元模型,并使用叠加法求解不同载荷下的应力强度因子。然后采用应力外推法和位移外推法计算了应力强度因子,并将计算结果与文献形状因子公式法进行对比。最后根据应力强度因子的一般解析式和位移外推法的计算结果,使用五次多项式对形状因子函数进行拟合,通过设置不同的裂纹深度和载荷验证了形状因子函数和解析式的适用性。结果表明该方法对于求解同一载荷模式下的车轴应力强度因子具有一定的参考价值。Abstract: In order to study the stress intensity factors (SIFs) for hollow axle of EMU, the influencing factors of the axle SIFs were firstly analyzed. The finite element model for axle with crack was established, and the superposition method was used to evaluate SIFs under different loads. Then, the SIFs were calculated by using the stress extrapolation method (SEM) and displacement extrapolation method (DEM), and the calculation results were compared with that by using the shape factor formula method. Finally, a fifth-order polynomial was used to fit the shape factor function according to the general analytical formula of SIFs and calculation results via DEM. The applicability of the shape factor function and the analytical formula was verified by setting the different crack depths and loads. The results indicated the present method had certain reference value for calculating SIFs of axle under the same load mode.

-

表 1 应力强度因子计算结果

Table 1. Calculation results of stress intensity factors

计算方法 位移外推法 应力外推法 KA, Bending/(MPa·m0.5) 3.457 84 2.401 66 KA, PF/(MPa·m0.5) 5.834 95 6.062 21 KA, Tol/(MPa·m0.5) 9.292 79 8.463 87 表 2 形状因子函数拟合常数

Table 2. Constants for fitting the shape factor function

i pi qi 0 9.228×10-1 6.580×10-1 1 2.024×10-2 -3.673×10-3 2 -2.545×10-3 -2.373×10-3 3 1.045×10-4 1.151×10-4 4 -1.864×10-6 -2.155×10-6 5 1.235×10-8 1.446×10-8 -

[1] 赵大华, 李华锋. 用光弹性法测定复合应力强度因子[J]. 实验力学, 2006, 21(4): 513-518.ZHAO D H, LI H F. Photoelastic method for determination of mixed-mode stress-intensity factors[J]. Journal of Experimental Mechanics, 2006, 21(4): 513-518. (in Chinese) [2] 李相麟, 朱翔华, 谢立新. 光弹性法测定圆轴弯扭组合变形复合应力强度因子[J]. 南昌大学学报(工科版), 2005, 27(1): 33-39.LI X L, ZHU X H, XIE L X. Photoelastic determination of mixed-mode stress-intensity factors in a cylindrical bar subjected to bending and torsion simultaneously[J]. Journal of Nanchang University (Engineering & Technology), 2005, 27(1): 33-39. (in Chinese) [3] WANG X, LAMBERT S B. Stress intensity factors for low aspect ratio semi-elliptical surface cracks in finite-thickness plates subjected to nonuniform stresses[J]. Engineering Fracture Mechanics, 1995, 51(4): 517-532. doi: 10.1016/0013-7944(94)00311-5 [4] JIN Z, WANG X. Weight functions for the determination of stress intensity factor and T-stress for semi-elliptical cracks in finite thickness plate[J]. Fatigue & Fracture of Engineering Materials & Structures, 2013, 36(10): 1051-1066. [5] 周素霞, 卢术娟, 赵兴晗, 等. 高速列车空心轴表面裂纹前缘应力强度因子解析模型[J]. 铁道学报, 2019, 41(2): 64-69.ZHOU S X, LU S J, ZHAO X H, et al. Analytical model of stress intensity factor on front edge of surface crack of hollow shaft of high speed train[J]. Journal of the China Railway Society, 2019, 41(2): 64-69. (in Chinese) [6] 周素霞. 高速列车空心车轴损伤容限理论与方法研究[D]. 北京: 北京交通大学, 2009.ZHOU S X. Theory and method research on damage tolerance of the hollow axles of high speed trains[D]. Beijing: Beijing Jiaotong University, 2009. (in Chinese) [7] ANDERSSON R, LARSSON F, KABO E. Evaluation of stress intensity factors under multiaxial and compressive conditions using low order displacement or stress field fitting[J]. Engineering Fracture Mechanics, 2018, 189: 204-220. doi: 10.1016/j.engfracmech.2017.11.015 [8] HAN Q H, WANG Y R, YIN Y, et al. Determination of stress intensity factor for mode I fatigue crack based on finite element analysis[J]. Engineering Fracture Mechanics, 2015, 138: 118-126. doi: 10.1016/j.engfracmech.2015.02.019 [9] WU S C, LIU Y X, LI C H, et al. On the fatigue performance and residual life of intercity railway axles with inside axle boxes[J]. Engineering Fracture Mechanics, 2018, 197: 176-191. doi: 10.1016/j.engfracmech.2018.04.046 [10] FU G Y, YANG W, LI C Q. Elastic and fully plastic J-integrals for mixed mode fracture induced by inclined surface cracks in plates under biaxial loading[J]. Engineering fracture mechanics, 2017, 186: 483-495. doi: 10.1016/j.engfracmech.2017.10.032 [11] FATIMA N S, ROWLANDS R E. SIF determination in finite double-edge cracked orthotropic composite using J-integral and digital image correlation[J]. Engineering Fracture Mechanics, 2020, 235: 107099. doi: 10.1016/j.engfracmech.2020.107099 [12] YU H J, KUNA M. Interaction integral method for computation of crack parameters K-T-a review[J]. Engineering Fracture Mechanics, 2021, 249: 107722. doi: 10.1016/j.engfracmech.2021.107722 [13] MADIA M, BERETTA S, ZERBST U. An investigation on the influence of rotary bending and press fitting on stress intensity factors and fatigue crack growth in railway axles[J]. Engineering Fracture Mechanics, 2008, 75(8): 1906-1920. doi: 10.1016/j.engfracmech.2007.08.015 [14] MADIA M, BERETTA S, SCHÖDEL M, et al. Stress intensity factor solutions for cracks in railway axles[J]. Engineering Fracture Mechanics, 2011, 78(5): 764-779. doi: 10.1016/j.engfracmech.2010.03.019 [15] POKORNY P, HUTAR P, NÁHLÌK L. Residual fatigue lifetime estimation of railway axles for various loading spectra[J]. Theoretical and Applied Fracture Mechanics, 2016, 82: 25-32. [16] 徐忠伟, 吴圣川, 段浩, 等. 考虑压装和实测动应力的含缺陷空心车轴剩余寿命评估[J]. 中国科学: 技术科学, 2017, 47(6): 656-665.XU Z W, WU S C, DUAN H, et al. Fatigue crack growth life prediction of railway hollow axis with flaws under press fitting and measured dynamic stress spectrum[J]. Scientia Sinica Technologica, 2017, 47(6): 656-665. (in Chinese) [17] 周素霞, 张俊清, 谢基龙. 空心车轴不同深度表面裂纹应力强度因子研究[J]. 计算力学学报, 2010, 27(4): 704-710.ZHOU S X, ZHANG J Q, XIE J L. Research on stress intensity factors of surface crack of hollow axles at different depth[J]. Chinese Journal of Computational Mechanics, 2010, 27(4): 704-710. (in Chinese) [18] 周素霞, 谢基龙, 郑红霞. 空心车轴不同形状比裂纹应力强度因子的仿真研究[J]. 铁道学报, 2008, 30(5): 114-118.ZHOU S X, XIE J L, ZHENG H X. The finite element research of stress intensity factors at surface crack front of hollow axles[J]. Journal of the China Railway Society, 2008, 30(5): 114-118. (in Chinese) [19] 刘宇轩, 吴圣川, 李存海, 等. 轴箱内置型铁路车轴疲劳性能与寿命评估[J]. 交通运输工程学报, 2019, 19(3): 100-108.LIU Y X, WU S C, LI C H, et al. Fatigue performance and life assessment of railway axle with inside axle box[J]. Journal of Traffic and Transportation Engineering, 2019, 19(3): 100-108. (in Chinese) [20] ZERBST U, VORMWALD M, ANDERSCH C, et al. The development of a damage tolerance concept for railway components and its demonstration for a railway axle[J]. Engineering Fracture Mechanics, 2005, 72(2): 209-239. [21] NÁHLÌK L, POKORNY P, ŠEVĈÌK M, et al. Fatigue lifetime estimation of railway axles[J]. Engineering Failure Analysis, 2017, 73: 139-157. -

下载:

下载: