Experimental Study on Windage Power Loss of Fan Drive Gearbox System in GTF Engine

-

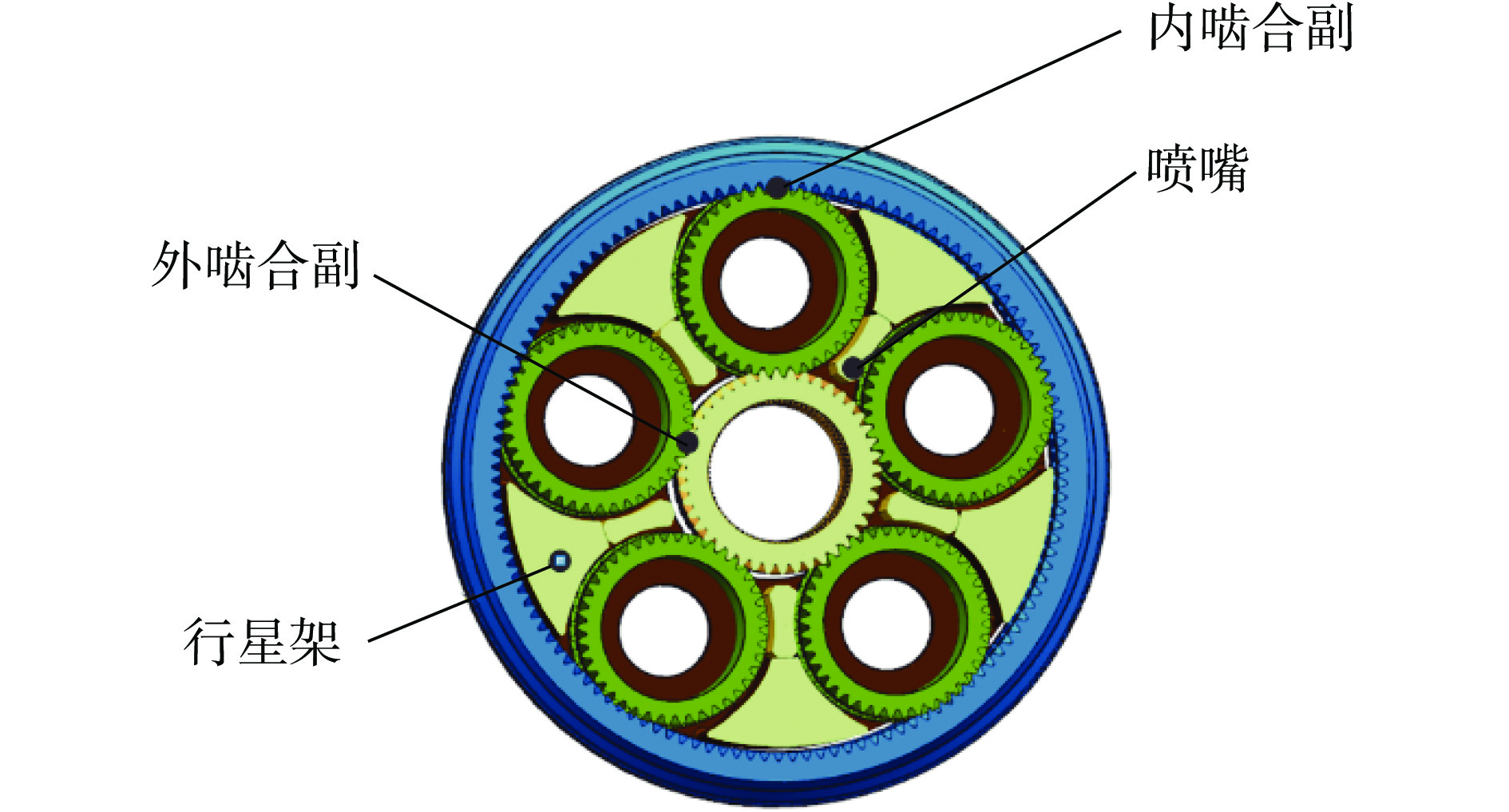

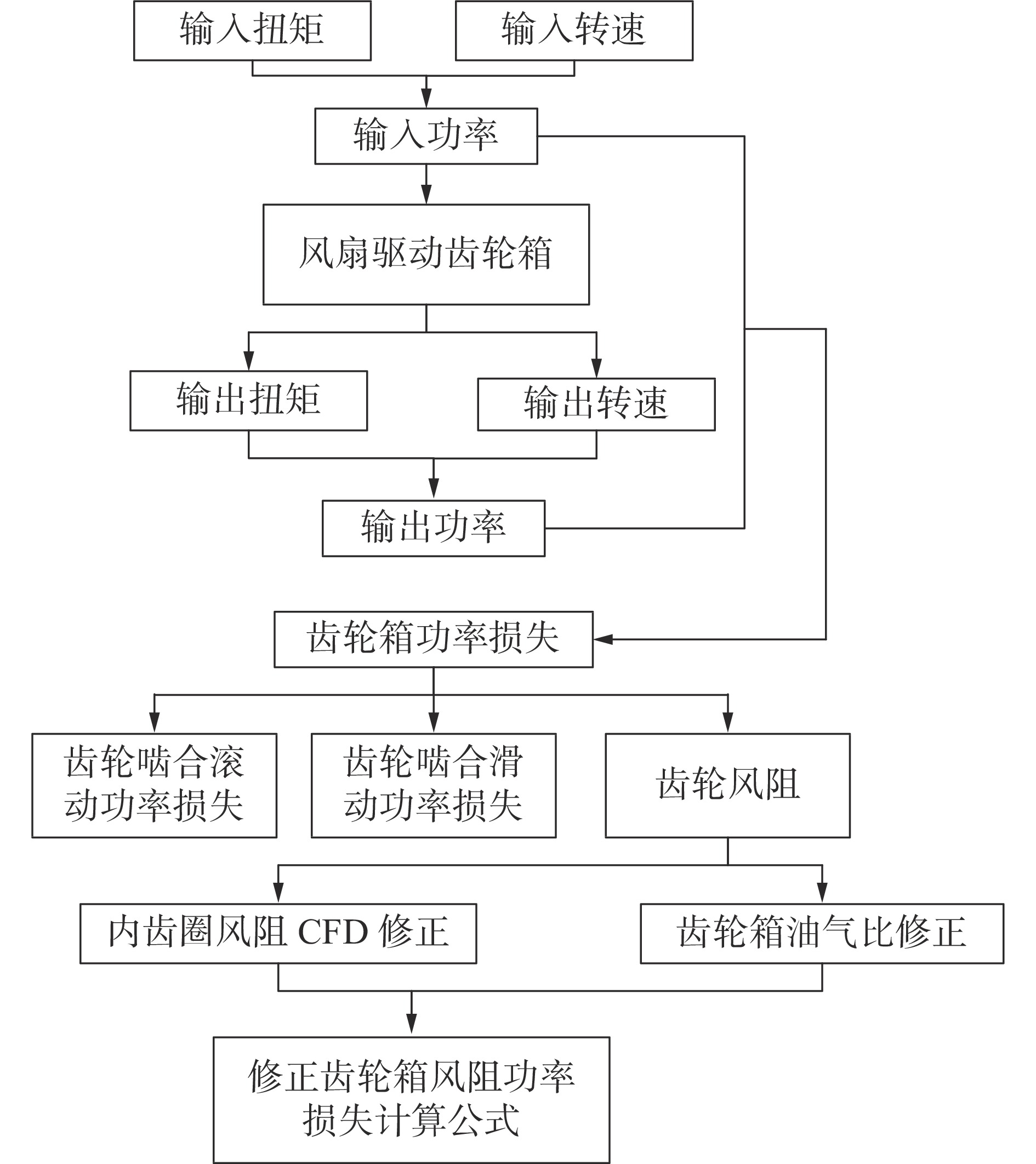

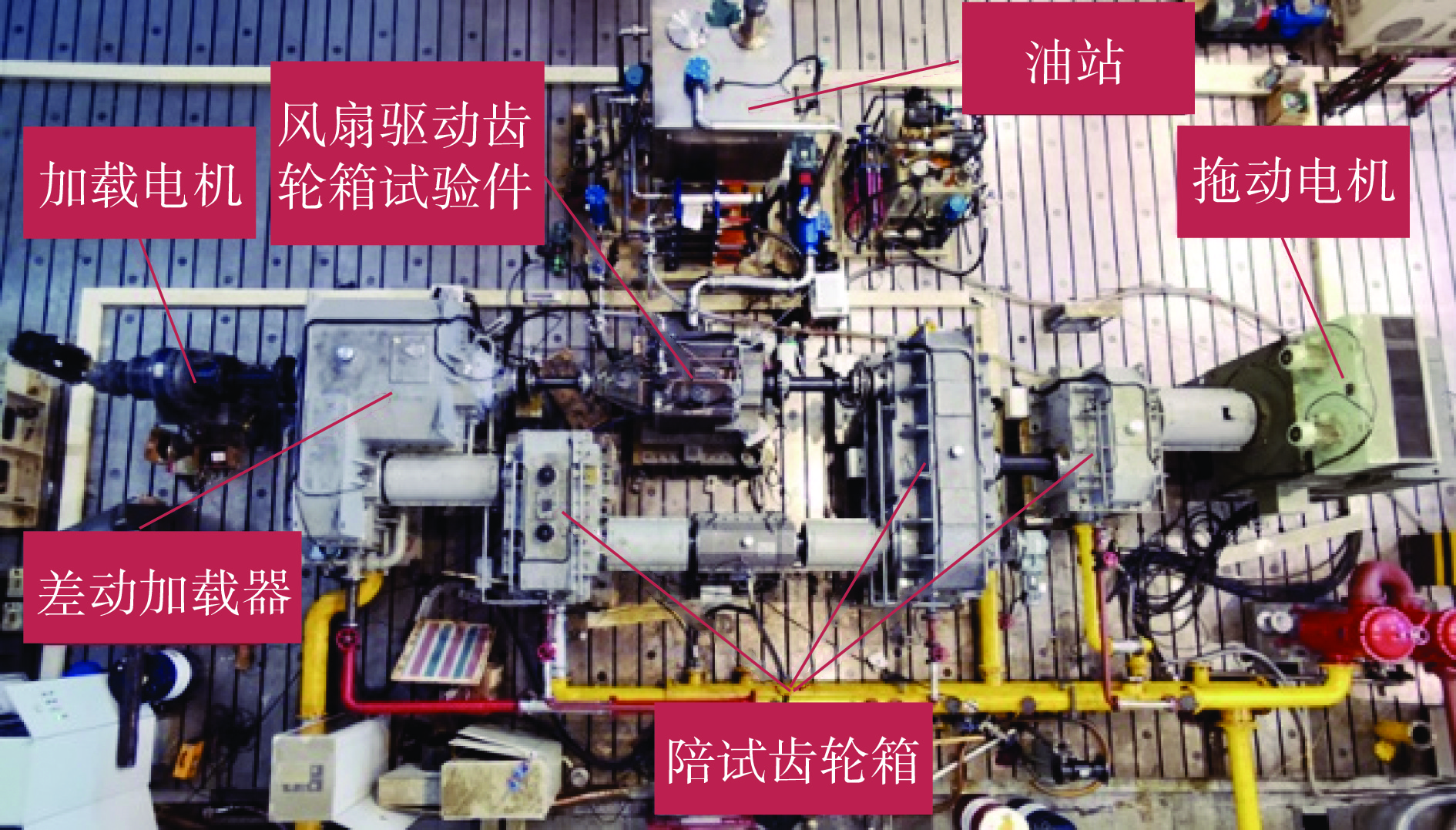

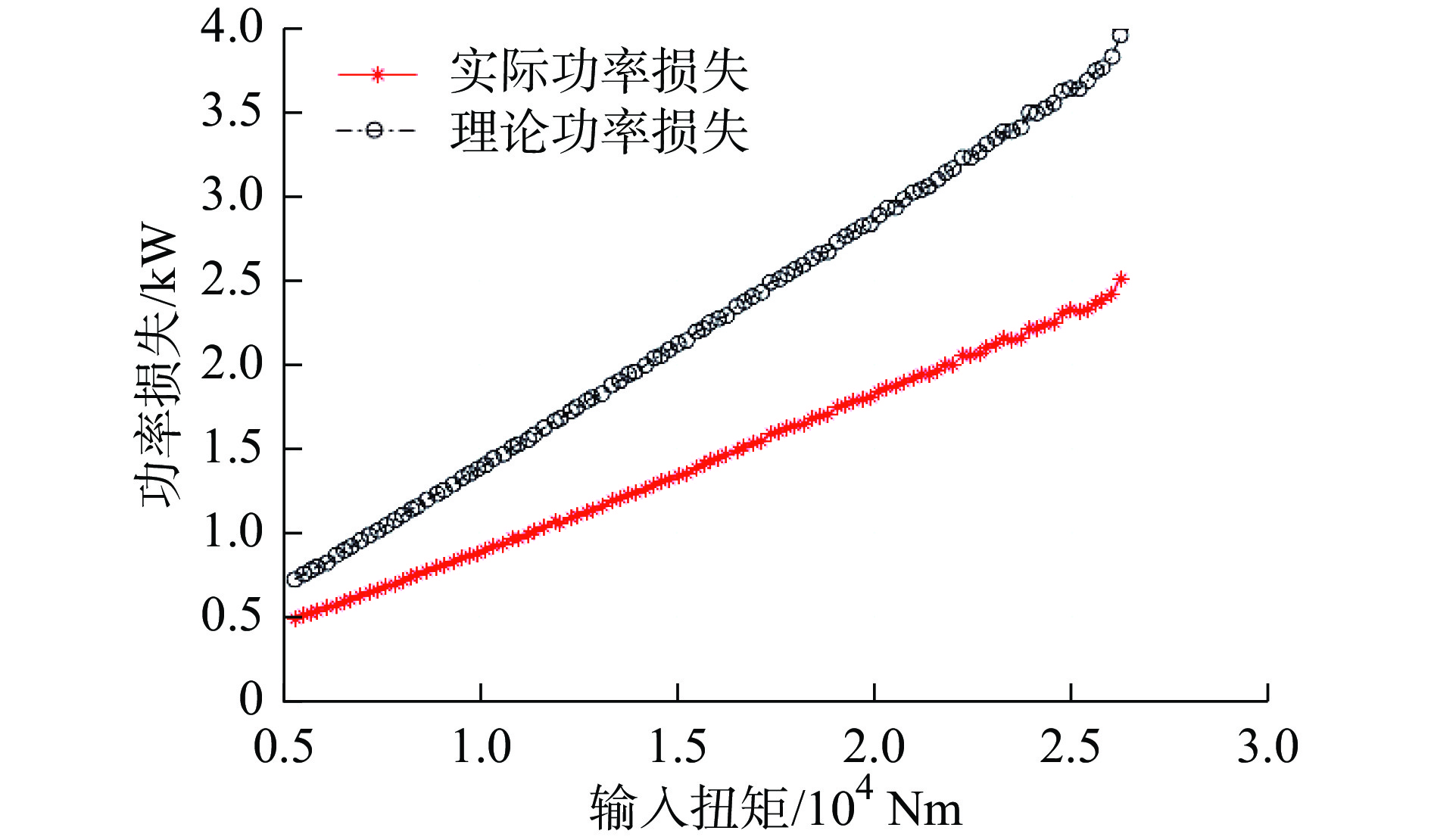

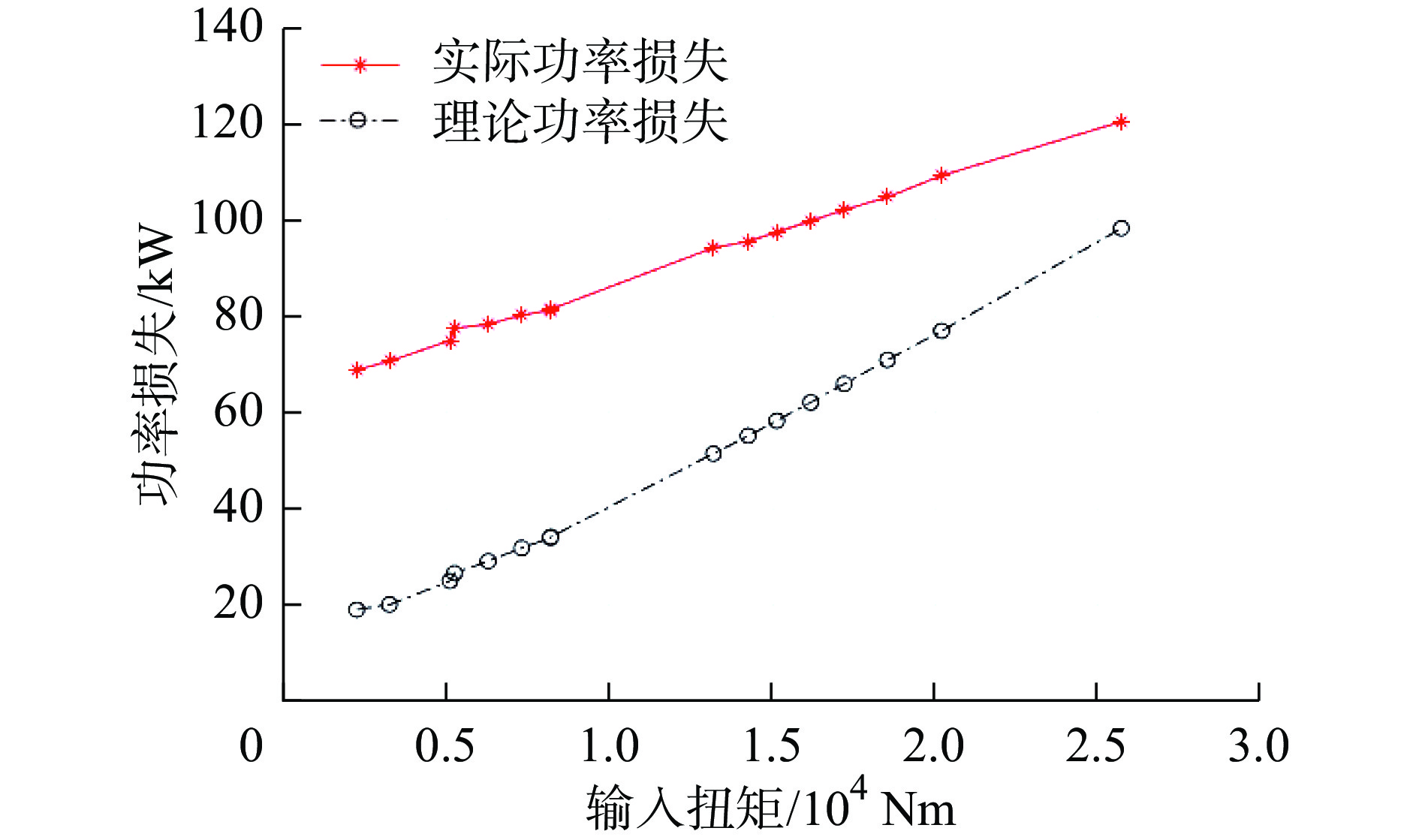

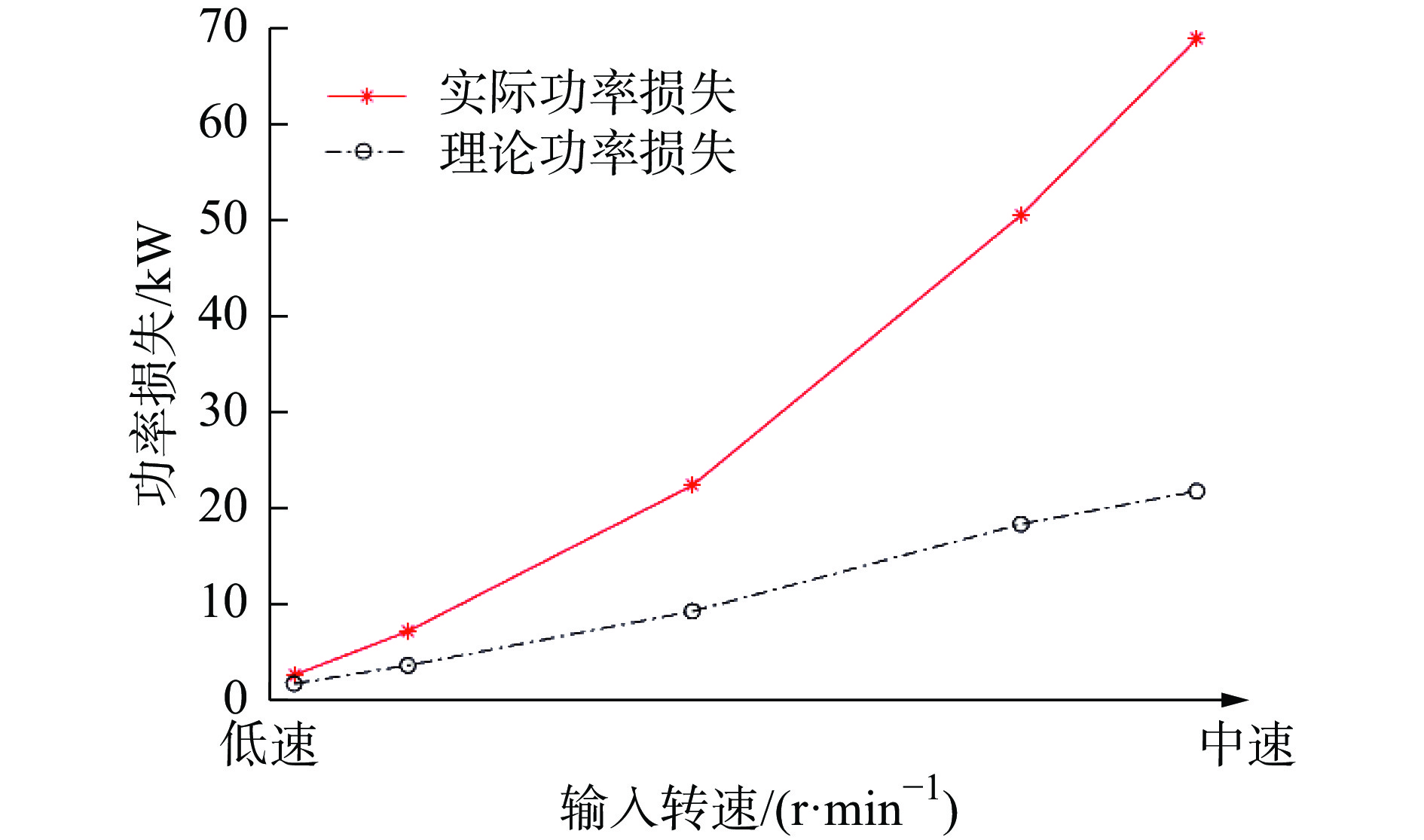

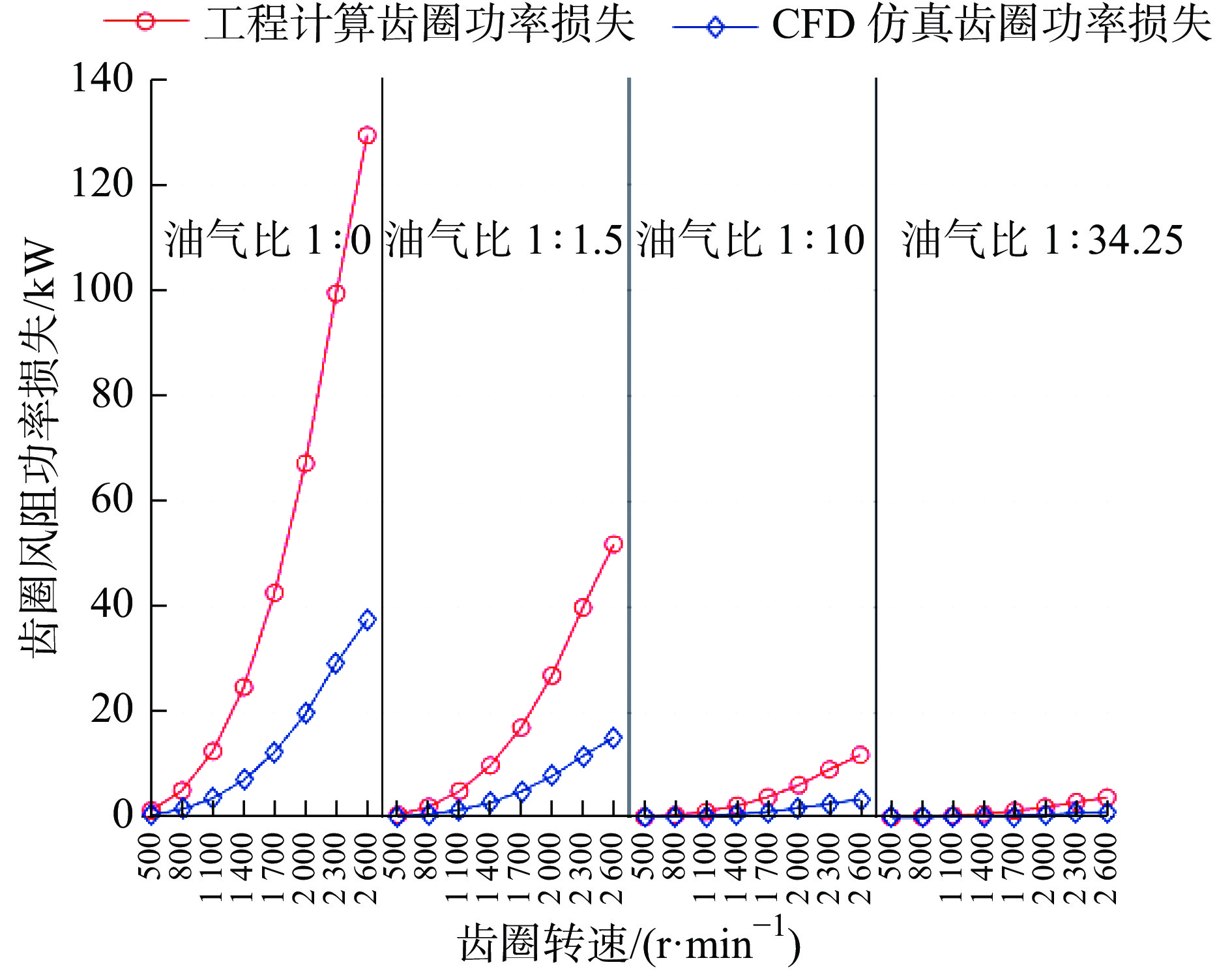

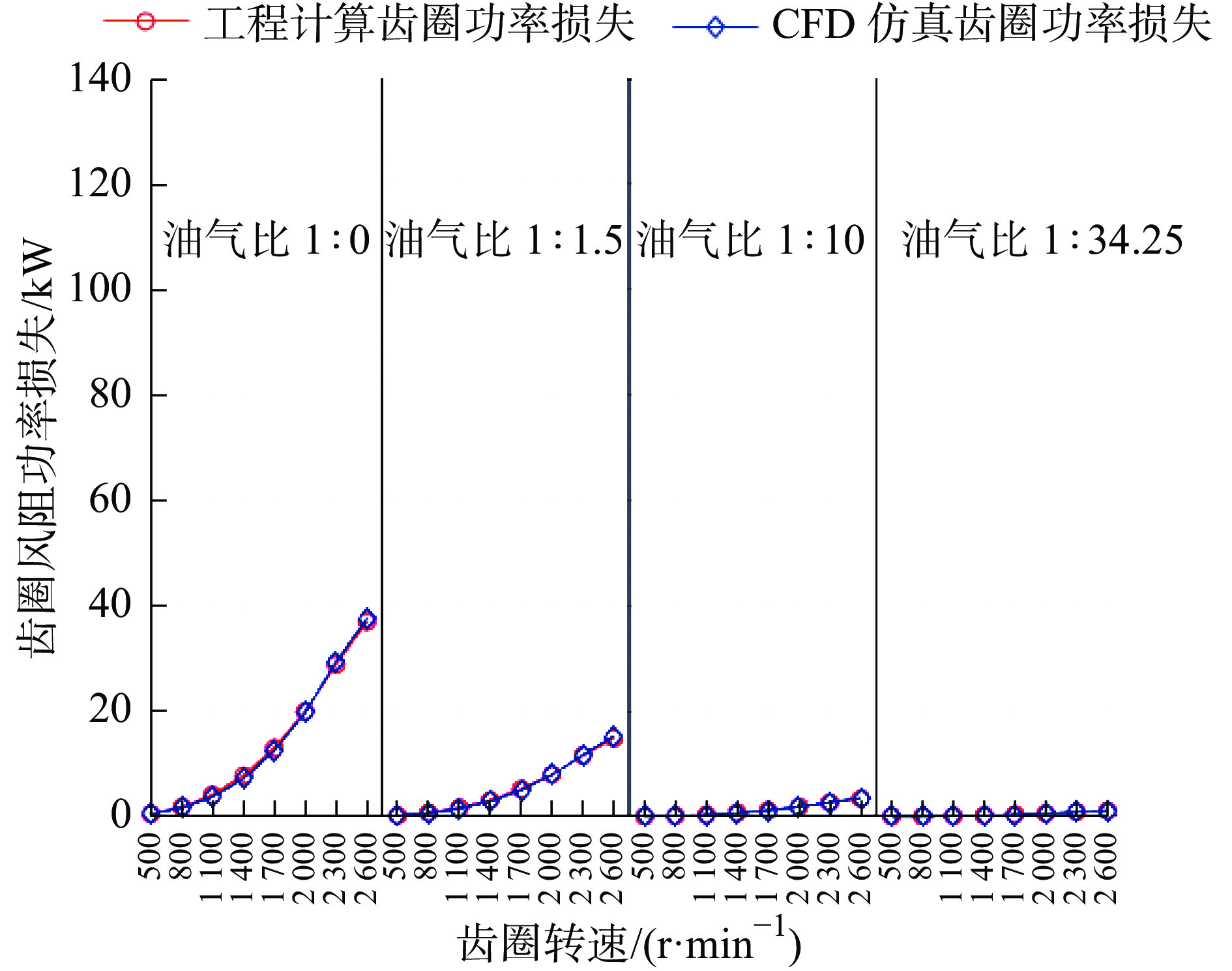

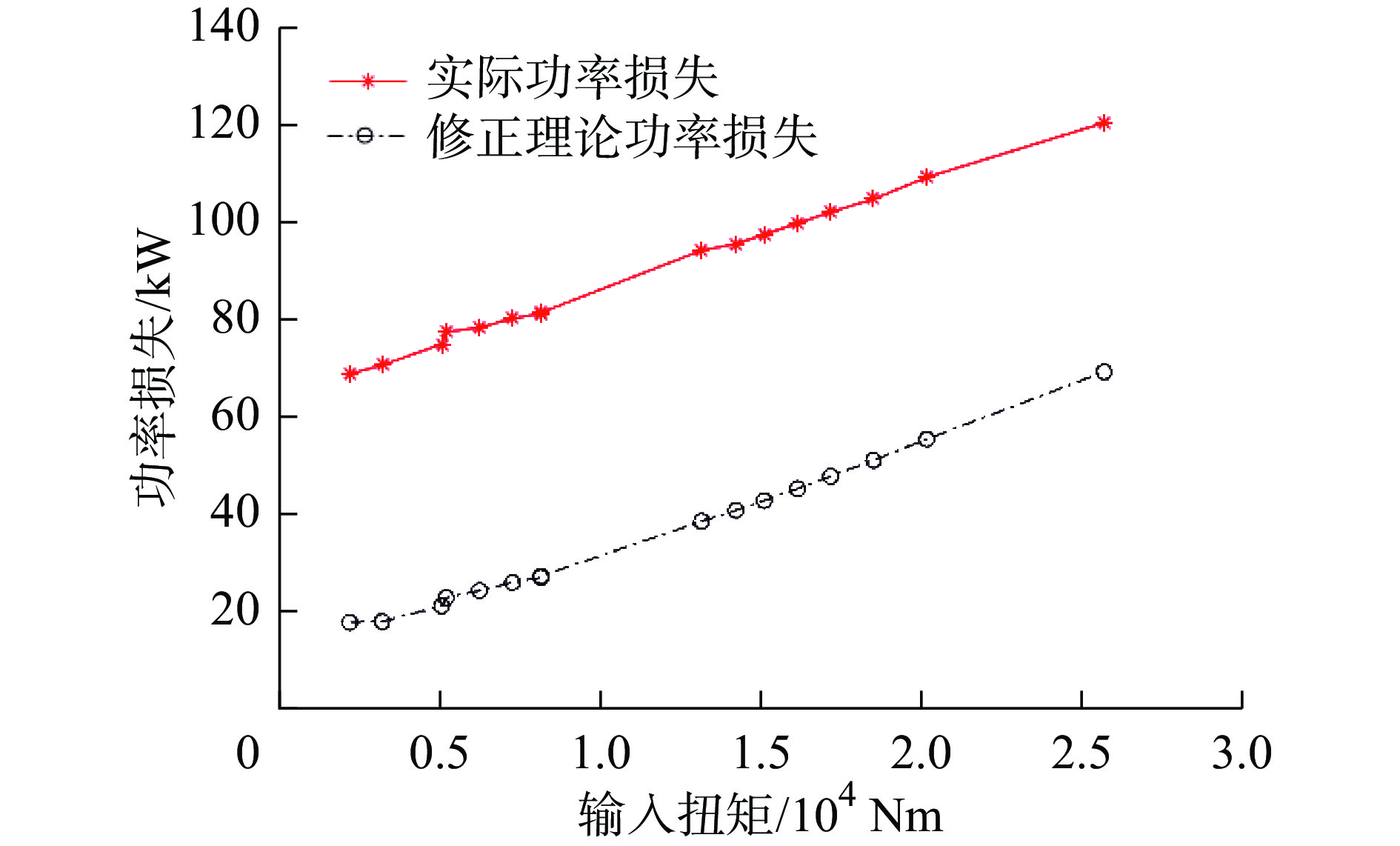

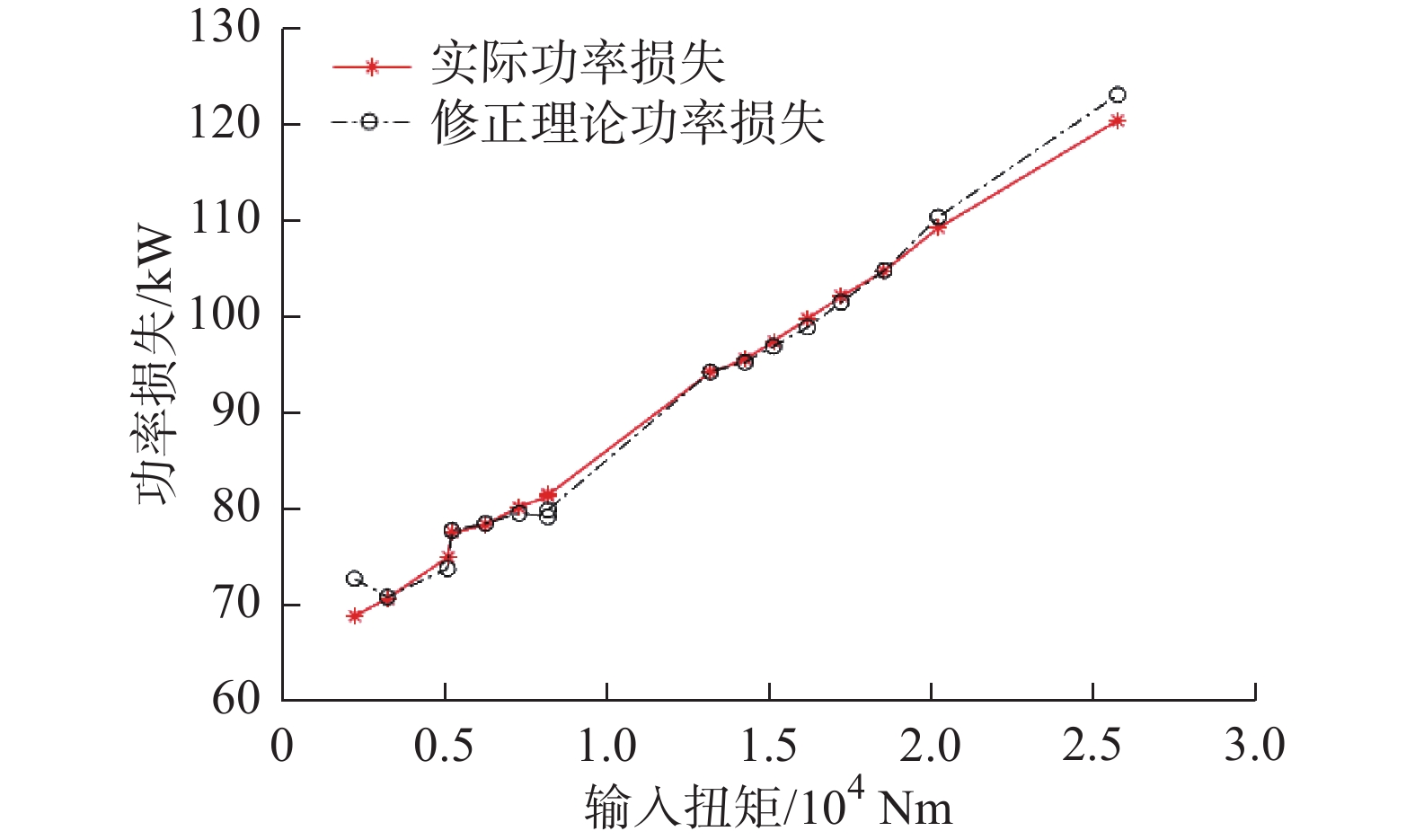

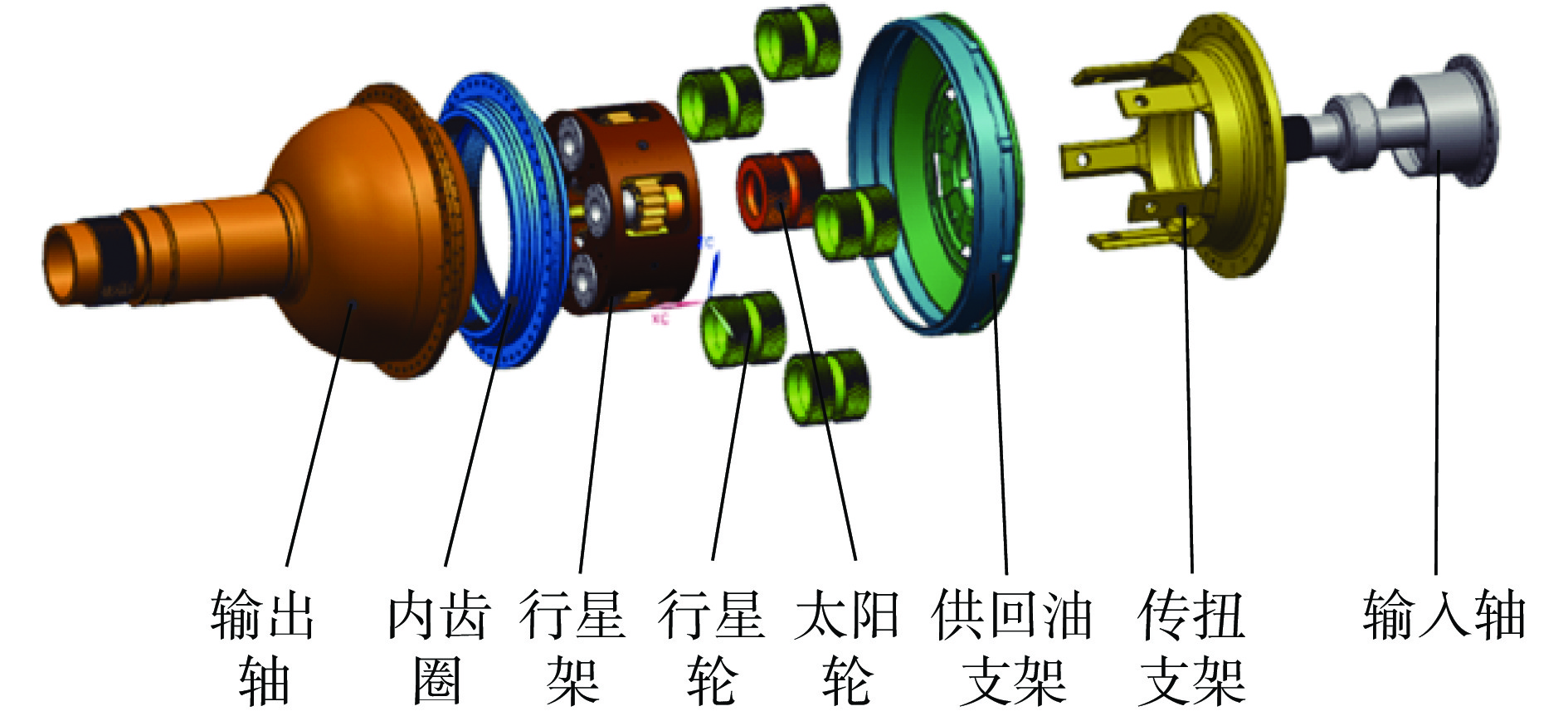

摘要: 为研究风扇驱动齿轮箱风阻功率损失,基于齿轮风阻原始公式,阐明了油气比1∶34.25的通用风阻公式在风扇驱动齿轮箱中应用的局限性,除油气比外,内齿圈风阻计算公式需通过CFD仿真进行了修正;通过直接法测量GTF风扇驱动齿轮箱不同工况下的功率损失,结果表明:在轻载状态下齿轮箱总功率损失与转速成明显的指数关系,风阻损失占主导,理论值与实测值相差50 kW;不同转速相同扭矩状态下,修正理论功率损失和实测功率损失之间的差值由齿轮风阻引起,风扇驱动齿轮箱中拟合油气比约为1∶1.37;并给出齿轮箱风阻功率损失计算公式修正系数。Abstract: In order to study the windage power loss of Fan Drive Gearbox(FDGS), the limitation of the application of the general wind resistance formula with an oil air ratio of 1∶34.25 in the fan drive gearbox are clarified based on the original formula of gear windage power loss. Besides the oil-gas rate, the wind resistance formula of the inner gear ring windage power loss needed to be modified by using the CFD simulation. The power loss of FDGS under different working conditions was measured by using the direct method. The result show that the total power loss of the gearbox under light load has an exponential relationship with the rotational speed, and the windage power loss is dominant. The difference between the theoretical and the measured value is 50kW. Under the different rotational speeds and the same torque, the difference between the theoretical and the measured power loss is caused by the gear windage power loss, and the fitted oil-gas ratio in the FDGS is about 1∶1.37, in which the modified coefficient in the calculation formula of windage power loss is given.

-

Key words:

- fan drive gearbox /

- windage power loss /

- oil-gas ratio

-

表 1 工况说明

Table 1. Description of operating conditions

工况 参数名称 转速/(r·min−1) 扭矩/Nm 1 低速变载 20 2000 ~ 26000 2 中速变载 5000 2000 ~ 26000 3 低载变速 500 ~ 5000 2000 表 2 工况1最大扭矩状态点各项功率损失对比

Table 2. Comparison of various power losses at the maximum torque state for operating condition 1

kW 参数 数值 参数 数值 $ {P_{\rm S12}} $ 2.65 $ {P_{\rm S23}} $ 1.0038 $ {P_{\rm R12}} $ 0.007 $ {P_{\rm R23}} $ 0.008 $ {P_{\rm{W}}} $ 0.000062 $ {P_{{\text{ bear}}}} $ 0.28 表 3 工况2最大扭矩状态点各项功率损失对比

Table 3. Comparison of various power losses at the maximum torque state for operating Condition 2

kW 参数 数值 参数 数值 $ {P_{\rm S12}} $ 50.84 $ {P_{\rm S23}} $ 21.71 $ {P_{\rm R12}} $ 2.41 $ {P_{\rm R23}} $ 2.763 $ {P_{\rm{W}}} $ 5 $ {P_{{\text{bear}}}} $ 19.5 表 4 齿圈转速

Table 4. Ring gear speed

计算点 转速/(r·min−1) 计算点 转速/(r·min−1) 1 500 5 1700 2 800 6 2000 3 1100 7 2300 4 1400 8 2600 表 5 工况2修正理论功率损失与实际功率损失

Table 5. Comparison of modified theoretical and actual power losses for operating condition 2

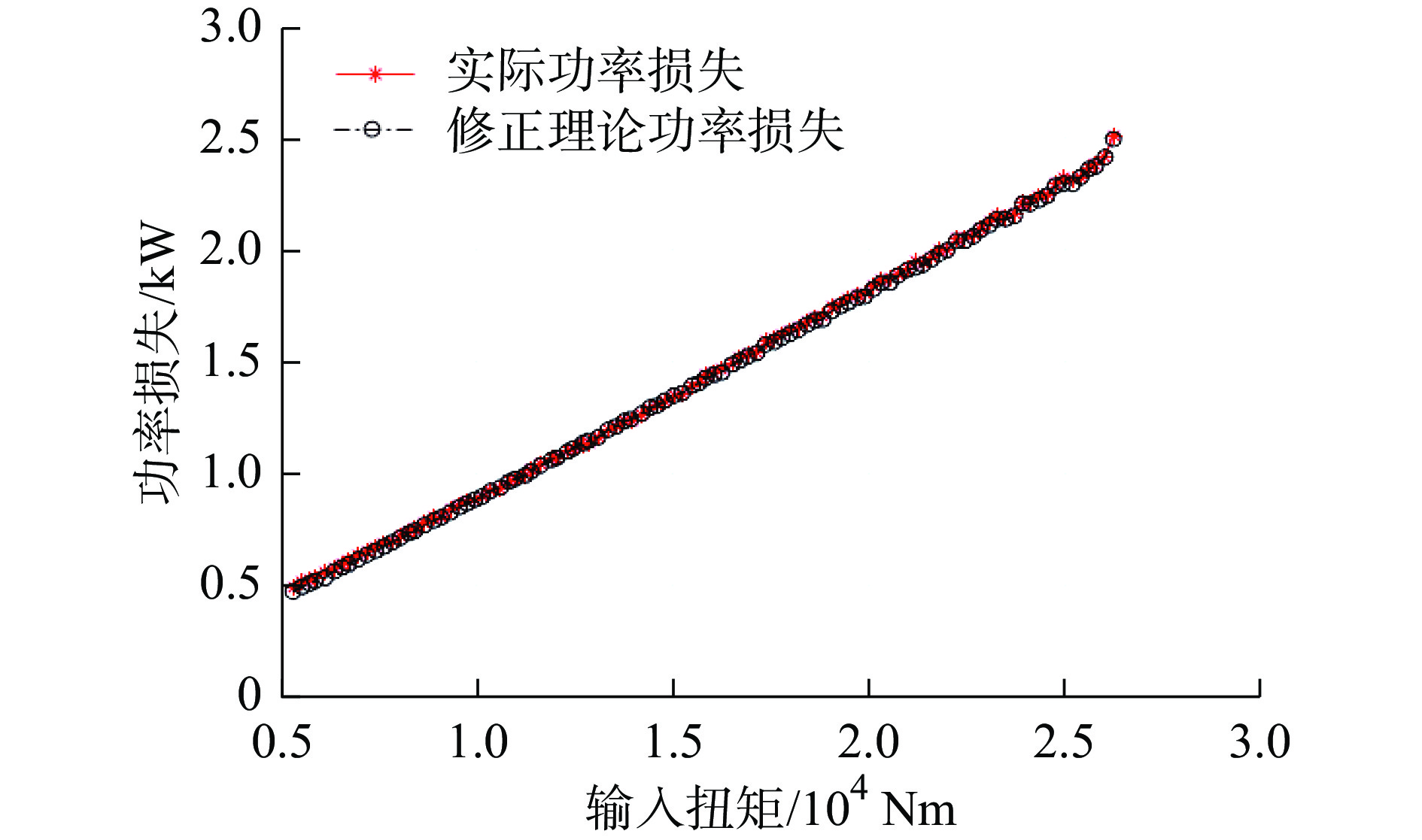

状态点 理论功率损失/kW 实际功率损失/kW 误差/% 状态点 理论功率损失/kW 实际功率损失/kW 误差/% 1 72.72 68.82 −5.37 9 94.23 94.21 −0.03 2 70.80 70.66 −0.21 10 95.23 95.52 0.30 3 73.76 74.92 1.57 11 96.90 97.45 0.56 4 77.74 77.46 −0.37 12 98.88 99.76 0.88 5 78.47 78.34 −0.18 13 101.48 102.08 0.58 6 79.53 80.20 0.84 14 104.79 104.74 −0.05 7 79.14 81.26 2.67 15 110.36 109.21 −1.04 8 79.86 81.42 1.95 16 123.07 120.41 −2.17 表 6 风阻功率损失计算公式修正系数

Table 6. Wind resistance power loss calculation formula correction factors

名称 修正前 修正后 油气比1∶k 1∶34.25 1∶1.37 内齿圈风阻转速系数 2.80 2.64 -

[1] 陈聪慧, 信琦. 风扇齿轮驱动系统的概念设计[J]. 航空科学技术, 2011(4): 8-11. doi: 10.3969/j.issn.1007-5453.2011.04.003CHEN C H, XIN Q. Conceptual design of fan gear drive system[J]. Aeronautical Science & Technology, 2011(4): 8-11. (in Chinese) doi: 10.3969/j.issn.1007-5453.2011.04.003 [2] 冯金, 覃坤, 王丹. 星型风扇驱动齿轮箱概念设计探讨[J]. 航空工程进展, 2015, 6(4): 490-494. doi: 10.16615/j.cnki.1674-8190.2015.04.015FENG J, QIN K, WANG D. Discussion on conceptual design of fan drive gear system with star gears[J]. Advances in Aeronautical Science and Engineering, 2015, 6(4): 490-494. (in Chinese) doi: 10.16615/j.cnki.1674-8190.2015.04.015 [3] 冯金, 刘晓凡, 覃琨. 风扇驱动齿轮箱行星轮偏心相位同步方法研究[J]. 机械传动, 2021, 45(7): 166-171. doi: 10.16578/j.issn.1004.2539.2021.07.025FENG J, LIU X F, QIN K. Research on offset phase synchronization method of fan drive gearbox planetary gear[J]. Journal of Mechanical Transmission, 2021, 45(7): 166-171. (in Chinese) doi: 10.16578/j.issn.1004.2539.2021.07.025 [4] ANDERSON N E, LOEWENTHAL S H. Spur-gear-system efficiency at part and full load[R]. NASA Technical Paper 1622, 1980: 10-11. [5] PETRY-JOHNSON T T, KAHRAMAN A, ANDERSON N E, et al. An experimental investigation of spur gear efficiency[J]. Journal of Mechanical Design, 2008, 130(6): 062601. doi: 10.1115/1.2898876 [6] VIDYANATHAN A. An experimental investigation of helical gear efficiency[D]. Ohio: Ohio State University, 2009: 36-97 [7] DAWSON P H. Windage loss in larger high-speed gears[J]. Proceedings of the Institution of Mechanical Engineers, Part A:Journal of Power and Energy, 1984, 198(1): 51-59. [8] RUZEK M, VILLE F, VELEX P, et al. On windage losses in high-speed pinion-gear pairs[J]. Mechanism and Machine Theory, 2019, 132: 123-132. doi: 10.1016/j.mechmachtheory.2018.10.018 [9] 陈士煊. 航空齿轮传动系统的“风阻”问题[J]. 航空动力学报, 1993, 8(3): 303-304. doi: 10.13224/j.cnki.jasp.1993.03.023CHEN S X. "Windage" for high gear systems in aviation[J]. Journal of Aerospace Power, 1993, 8(3): 303-304. (in Chinese) doi: 10.13224/j.cnki.jasp.1993.03.023 [10] 贾清健, 赵宁. 高速圆柱直齿轮风阻功率损失参数研究[J]. 机械传动, 2012, 36(10): 24-28. doi: 10.16578/j.issn.1004.2539.2012.10.013JIA Q J, ZHAO N. Research on windage power loss in high speed spur gear[J]. Journal of Mechanical Transmission, 2012, 36(10): 24-28. (in Chinese) doi: 10.16578/j.issn.1004.2539.2012.10.013 [11] 梁作斌, 杜佳佳, 郭梅. 齿轮风阻损失仿真及其实际应用[J]. 航空动力学报, 2017, 32(6): 1419-1424. doi: 10.13224/j.cnki.jasp.2017.06.019LIANG Z B, DU J J, GUO M. Simulation of gear windage losses and its application[J]. Journal of Aerospace Power, 2017, 32(6): 1419-1424. (in Chinese) doi: 10.13224/j.cnki.jasp.2017.06.019 [12] 鲍和云, 王春雷, 陆凤霞, 等. 基于CFD的GTF发动机风扇驱动齿轮箱行星齿轮风阻损失分析[J]. 中南大学学报(自然科学版), 2020, 51(4): 971-978.BAO H Y, WANG C L, LU F X, et al. Windage losses analysis of GTF engine fan drive gearbox planetary gear based on CFD[J]. Journal of Central South University (Science and Technology), 2020, 51(4): 971-978. (in Chinese) [13] 林腾蛟, 刘瑞锐. 高速人字齿轮副风阻损失及其影响因素分析[J]. 航空动力学报, 2021, 36(7): 1533-1544. doi: 10.13224/j.cnki.jasp.20200436LIN T J, LIU R R. Analysis of windage power loss and influencing factors of high speed double helical gear pair[J]. Journal of Aerospace Power, 2021, 36(7): 1533-1544. (in Chinese) doi: 10.13224/j.cnki.jasp.20200436 [14] 王成, 方宗德, 贾海涛. 斜齿轮滑动摩擦功率损失的计算[J]. 燕山大学学报, 2009, 33(2): 99-102. doi: 10.3969/j.issn.1007-791X.2009.02.002WANG C, FANG Z D, JIA H T. Calculation of sliding friction power losses on helical gears[J]. Journal of Yanshan University, 2009, 33(2): 99-102. (in Chinese) doi: 10.3969/j.issn.1007-791X.2009.02.002 [15] 姚建初, 陈义保, 周济, 等. 齿轮传动啮合效率计算方法的研究[J]. 机械工程学报, 2001, 37(11): 18-21. doi: 10.3321/j.issn:0577-6686.2001.11.004YAO J C, CHEN Y B, ZHOU J, et al. Study on a method for calculating gearing meshing efficiency[J]. Journal of Mechanical Engineering, 2001, 37(11): 18-21. (in Chinese) doi: 10.3321/j.issn:0577-6686.2001.11.004 [16] 航空发动机设计手册总编委会. 航空发动机设计手册第13册[M]. 北京: 航空工业出版社, 2001General Editorial Board of Aeroengine Design Manual. Aeroengine Design Manual Volume 13[M]. Beijing: Aviation Industry Press, 2001. (in Chinese) -

下载:

下载: