Study on Multi-motor Distributed Driving System of Morphing Wing with Flexible Skin

-

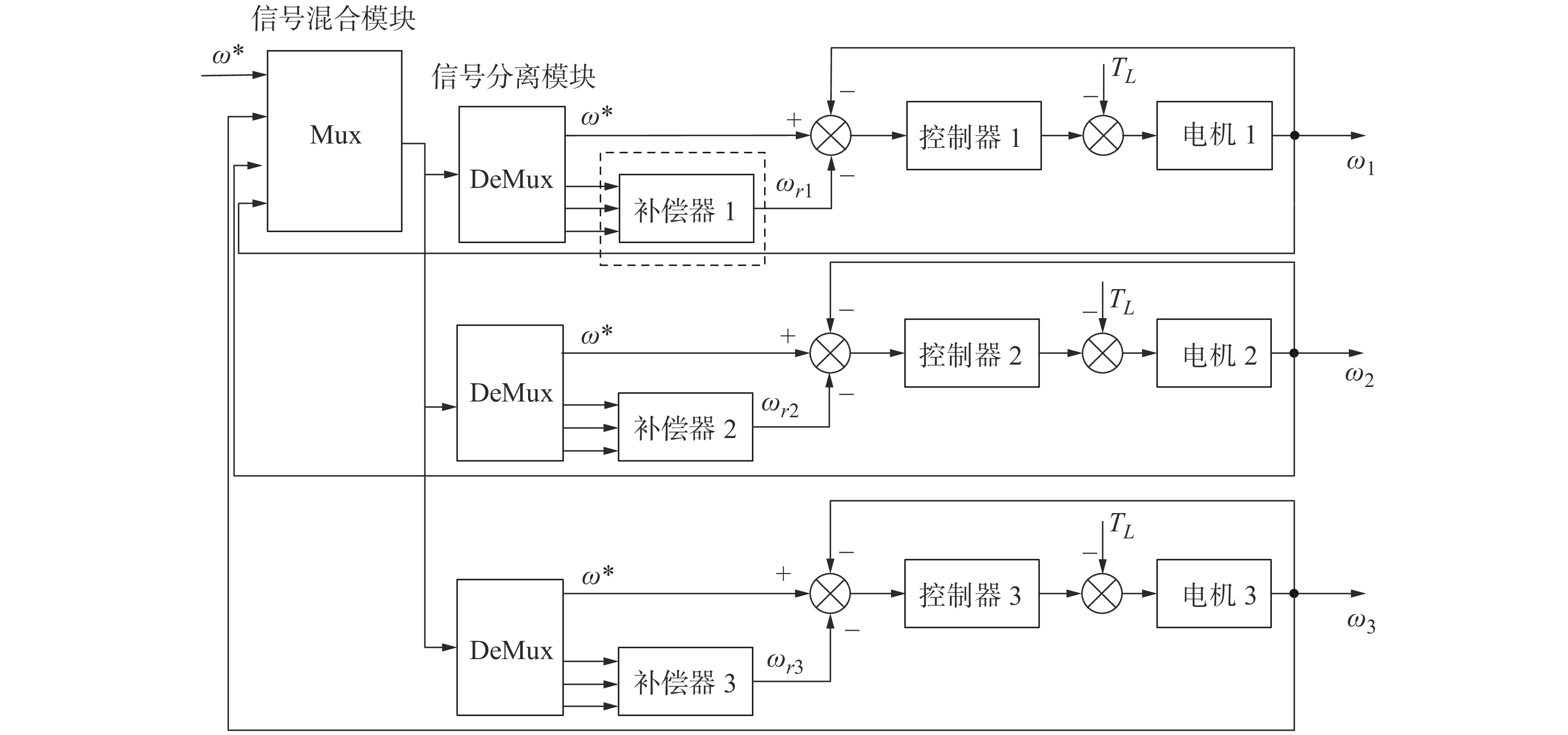

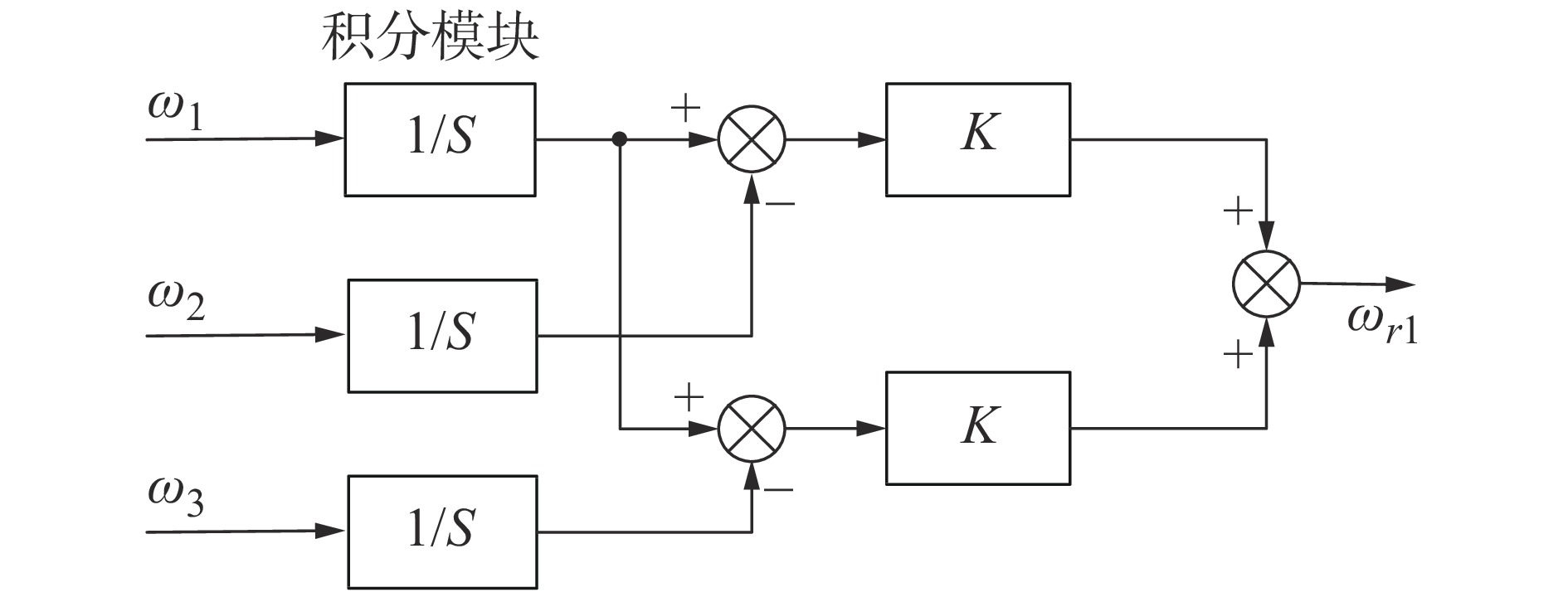

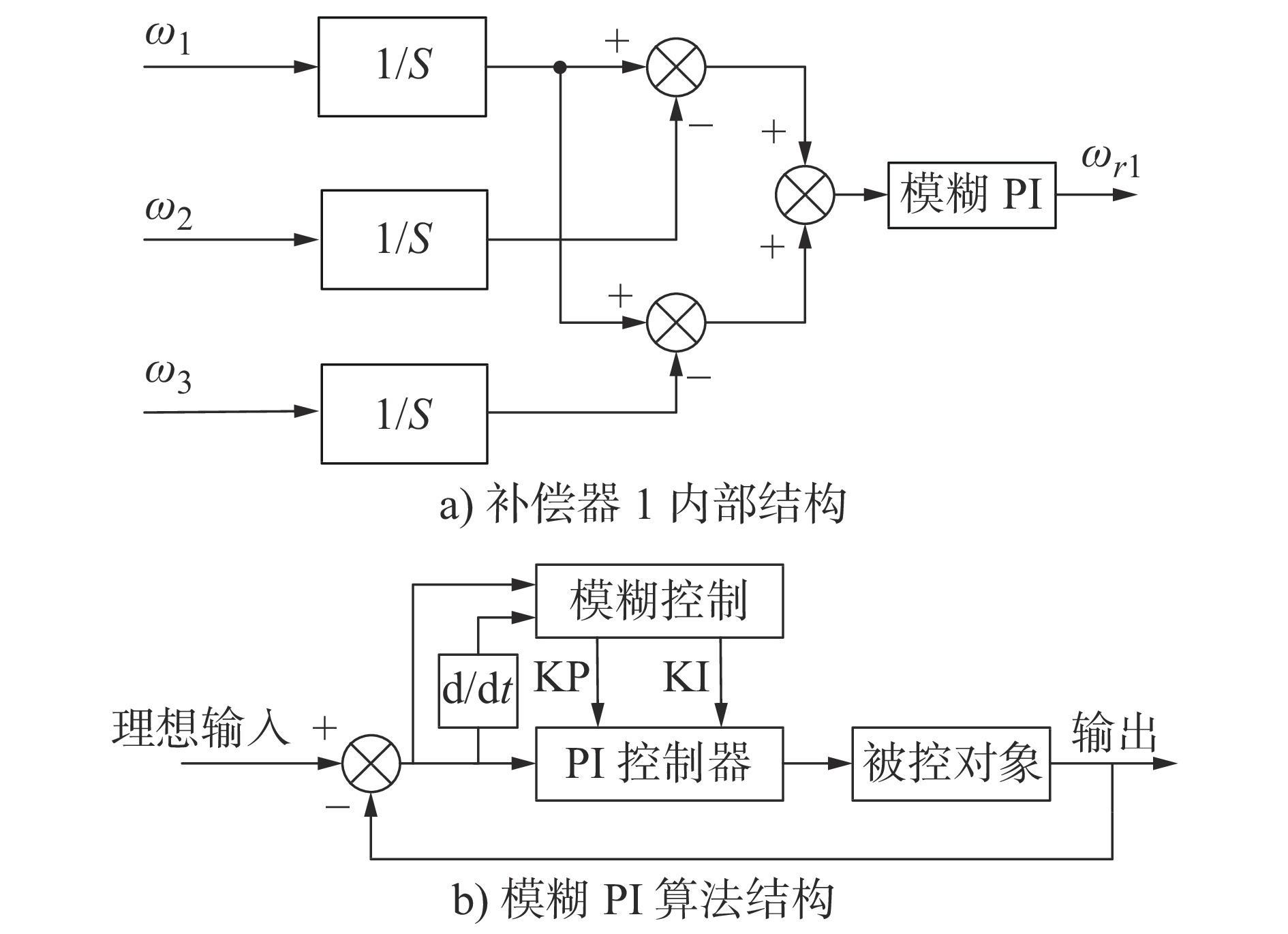

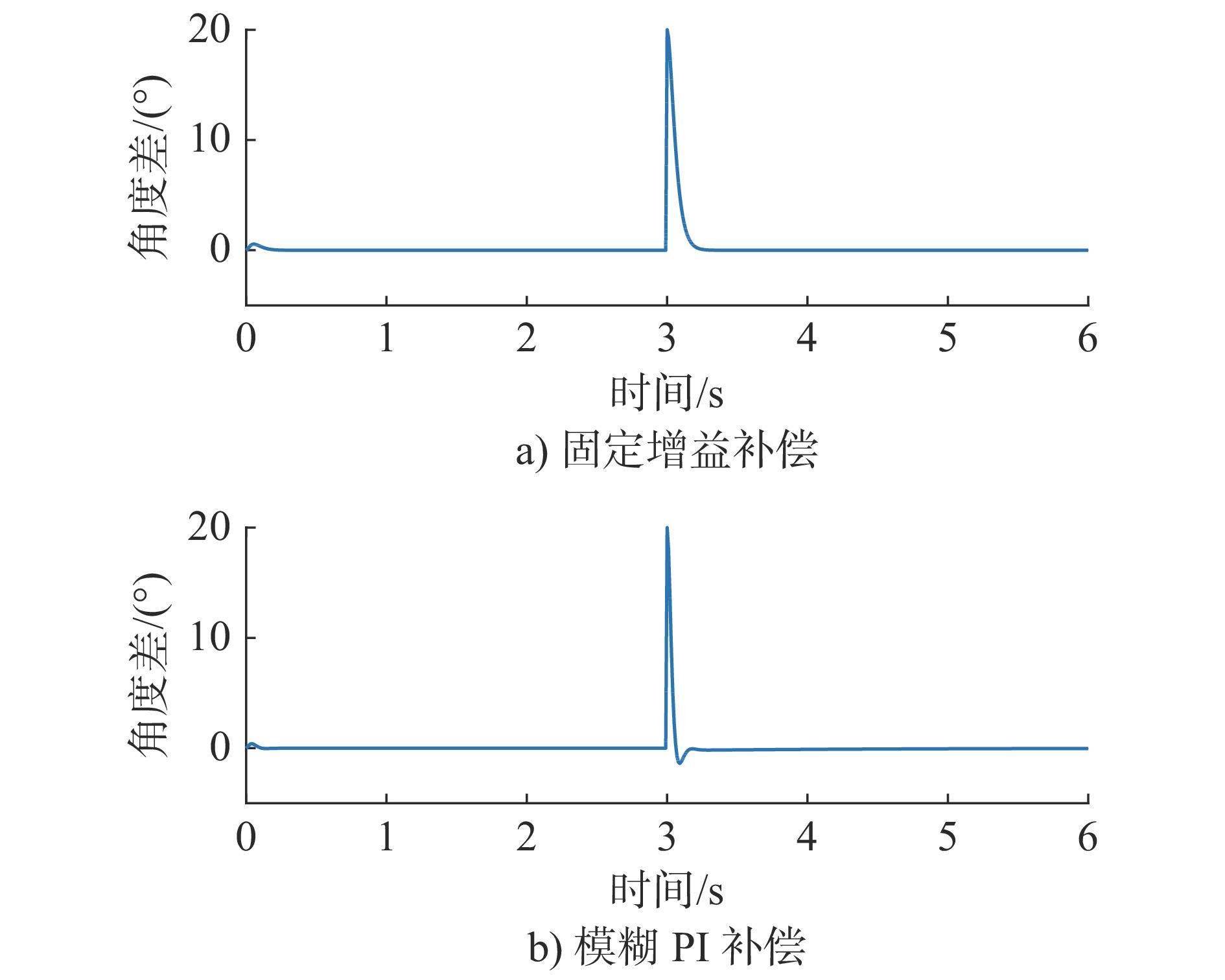

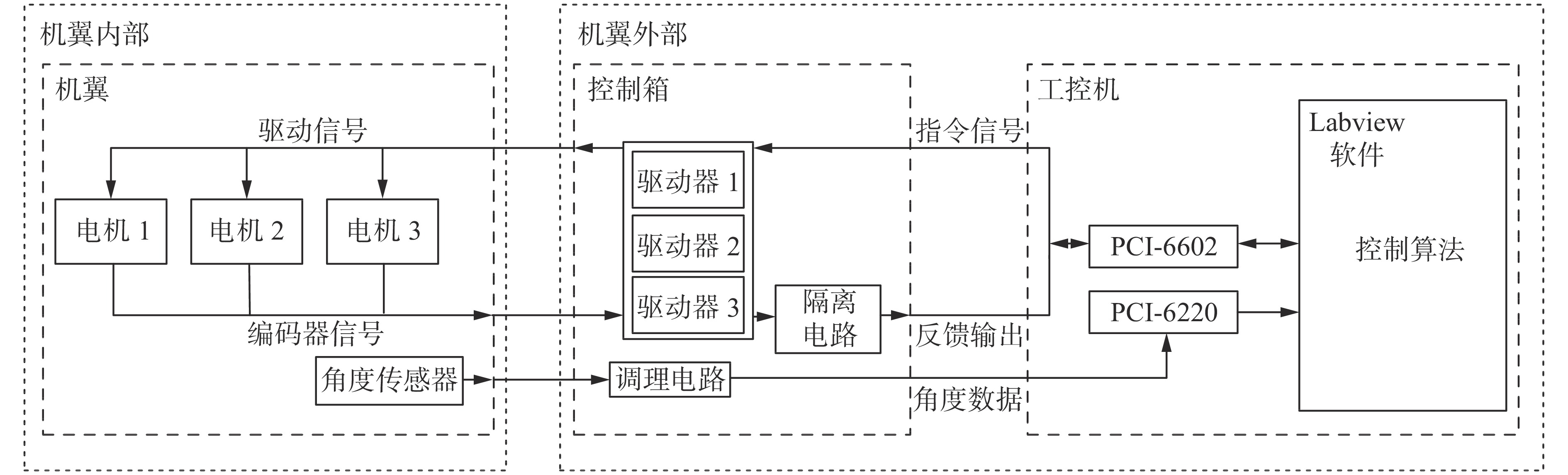

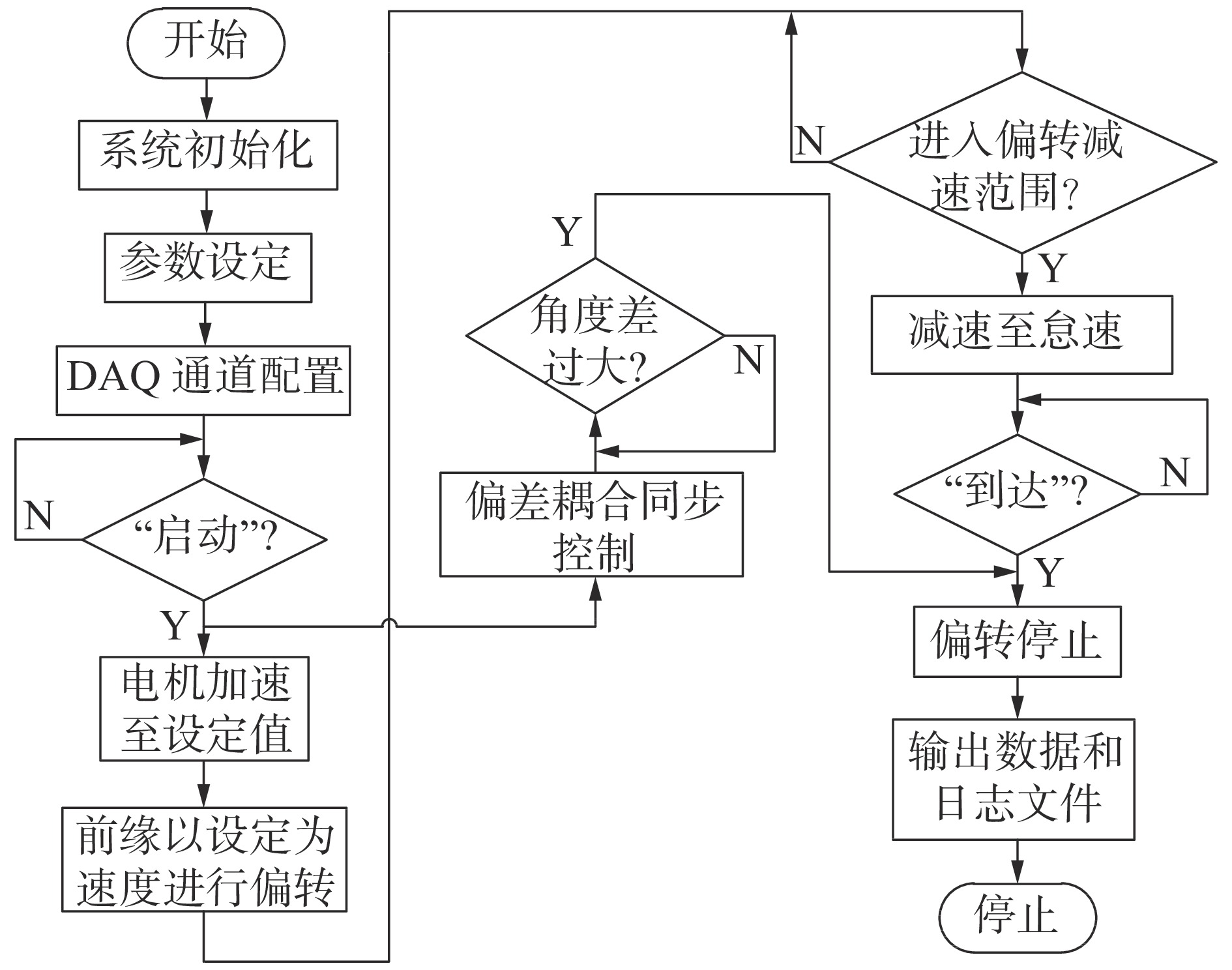

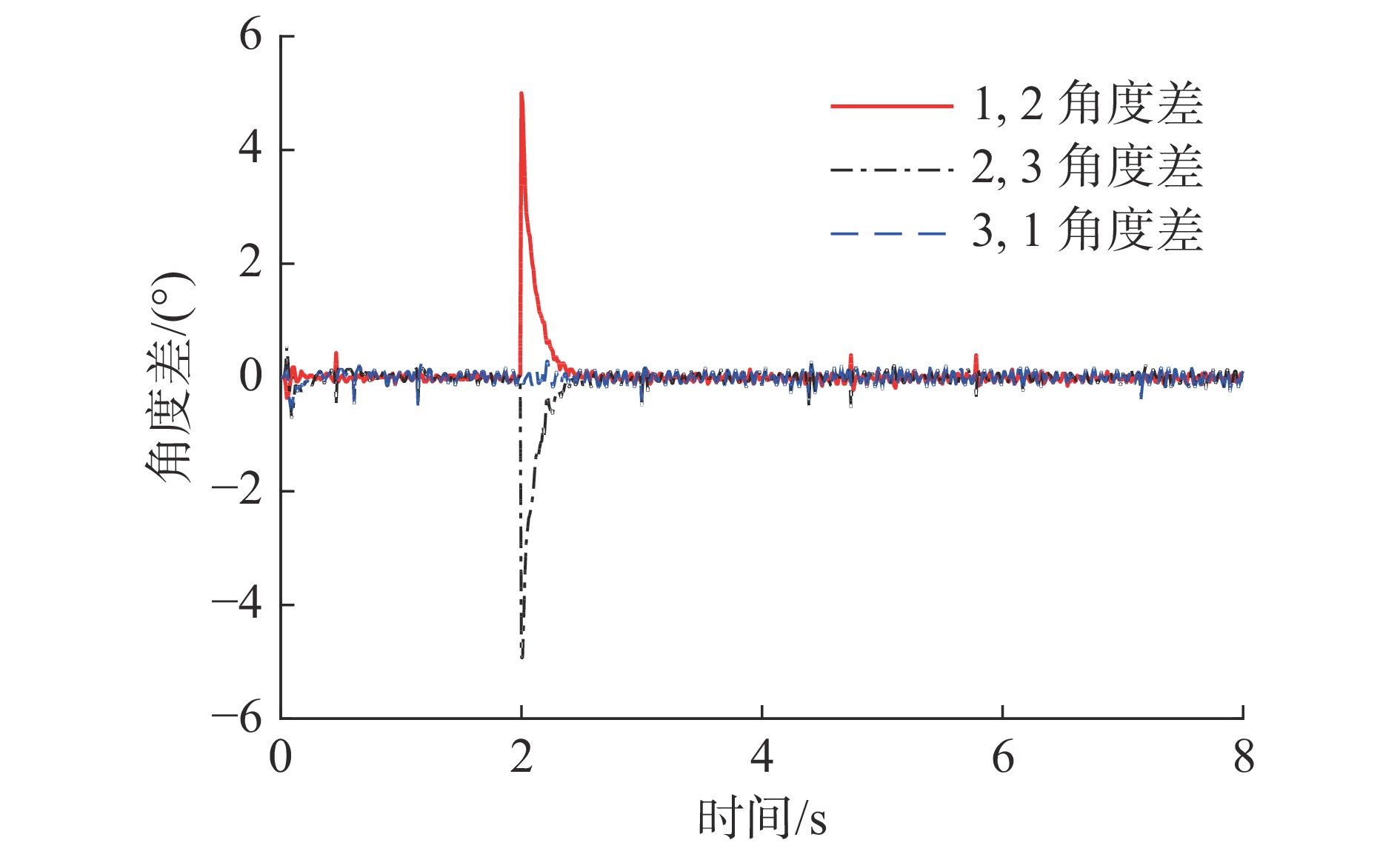

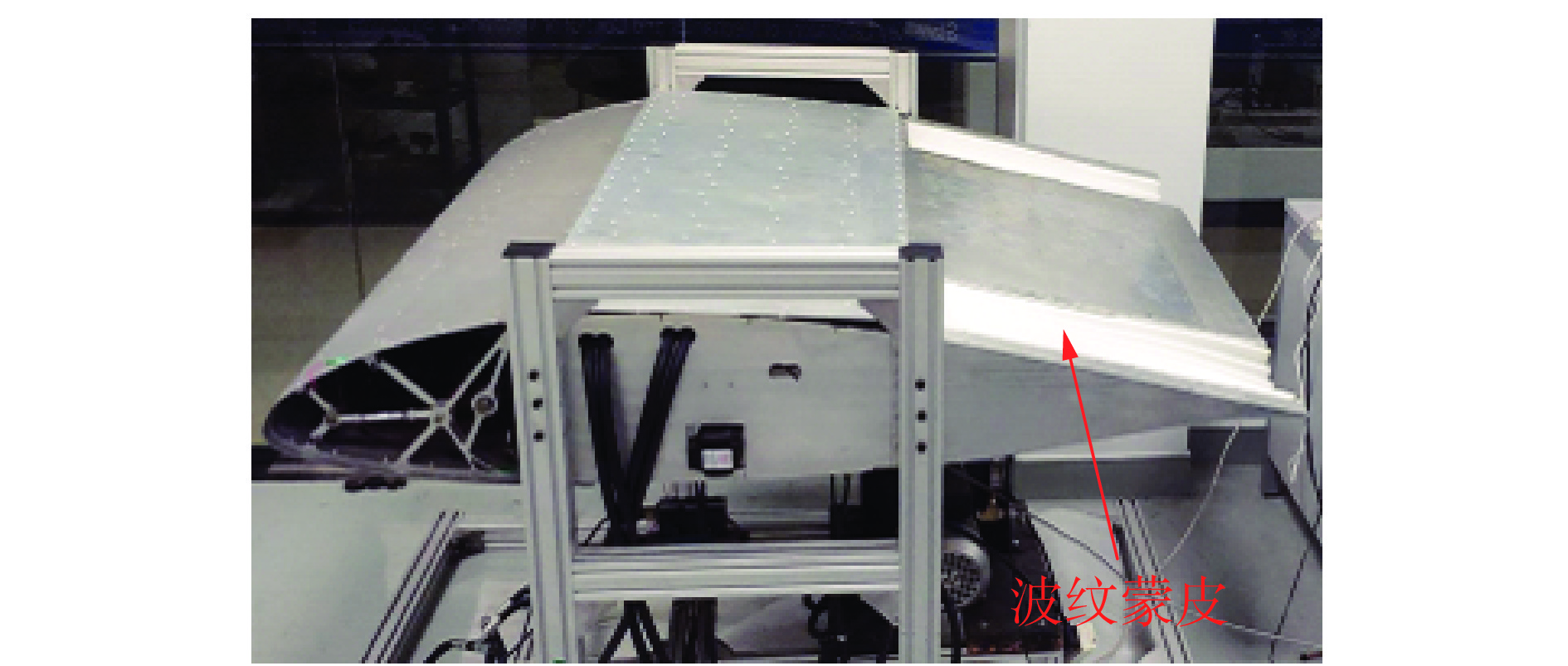

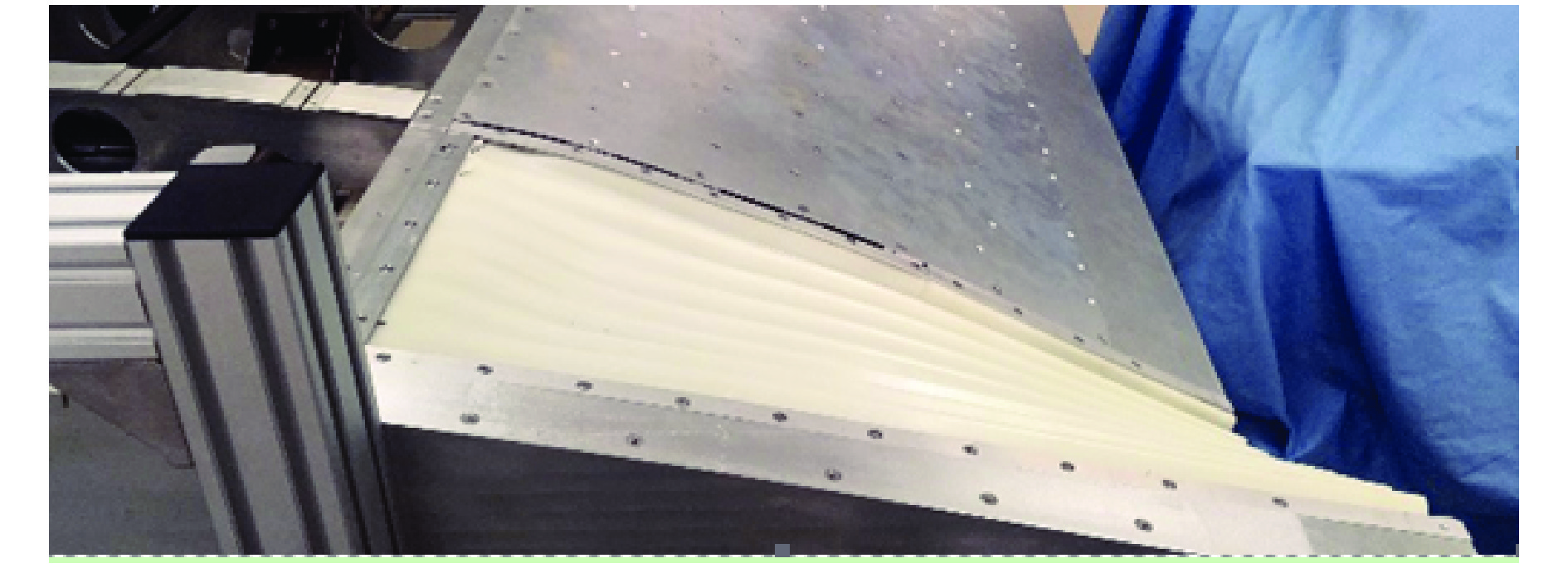

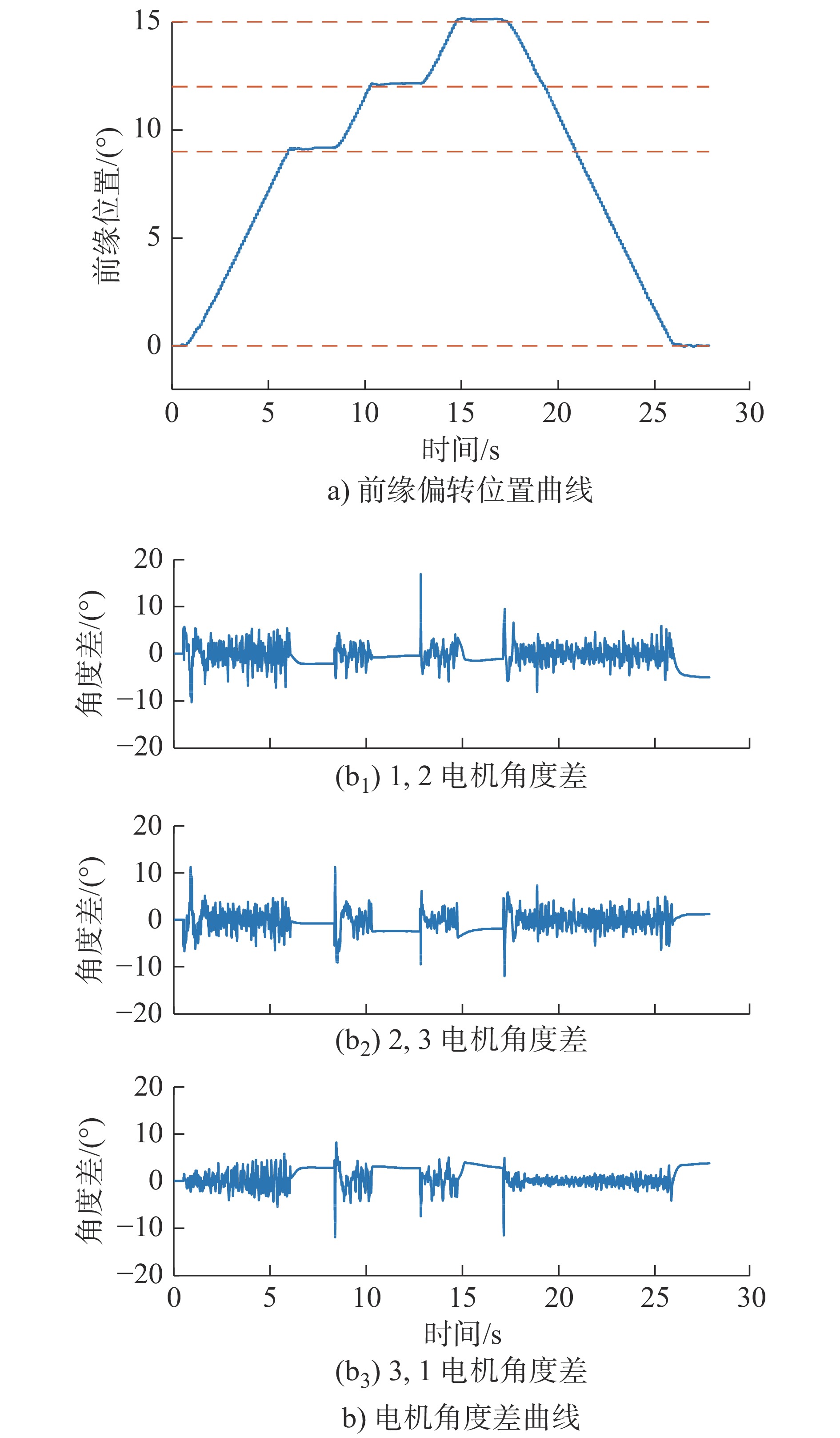

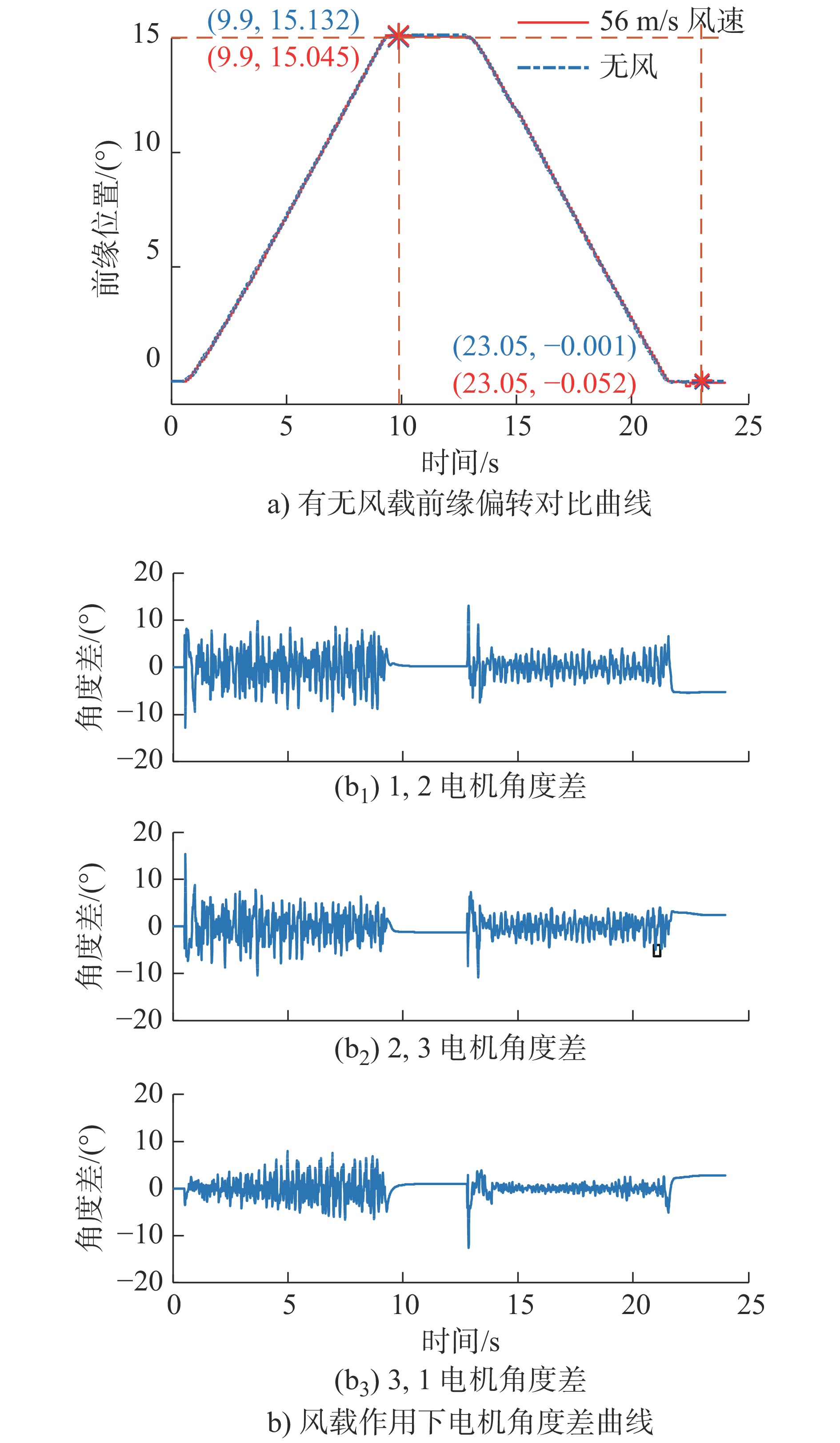

摘要: 针对可变弯度柔性波纹蒙皮后缘模型结构,采用了多电机驱动技术,设计并制备了机翼模型、驱动及测控系统;采用改进的偏差耦合算法,实现了驱动系统中3台电机的角度同步控制;完成了系统软、硬件的设计,并对后缘结构模型驱动系统进行了空载、地面加载及风洞等多组实验研究,结果表明:测控系统可以实时控制电机间的角度偏差在允许的误差范围内,在有无载荷情况下驱动系统工作无显著差异;承受风洞载荷情况下,柔性后缘结构偏转速度可达1.7 °/s,超调量小于0.3°,电机启动阶段角度差小于20°,匀速运行阶段角度差小于10°。Abstract: In this paper, a morphing trailing edge model with corrugate flexible skin is selected as an object and the multi-motor driving system is adopted to achieve the morphing operation. The model is designed, manufactured and assembled. The corresponding driving, measurement and control system are also built. Subsequently, the improved relative coupling algorithm is selected to achieve angle synchronization control of three motors in the driving system. The design of software and hardware system has been completed. The deflection experiments of trailing edge have been carried out with no-load, ground load and wind tunnel load respectively. The testing results show that the measurement and control system can keep the deflection angle error of trailing edge within an allowable error range. There is no significant difference in the operation of the driving system with or without load. In the wind tunnel test, the deflection speed of the flexible trailing edge can reach 1.7 °/s, the overshoot is below 0.3°, the deflection angle error is below 20° in the startup phase and below 10° in the constant speed stage.

-

Key words:

- morphing wing /

- trailing edge /

- multi-motor driving system /

- relative coupling control

-

表 1 数据采集卡参数

Table 1. Data acquisition card parameters

参数 PCI-6602 PCI-6220 计数器个数 8(32 bits) 2(32 bits) 时钟频率 80 MHz 80 MHz 模拟通道数 − 16(16 bits, 250 kS/s) 模拟输入范围 − ± 10 V 表 2 设定转速不同时的电机实验结果

Table 2. Experimental results for motors at different set speeds

电机设定转速/

(r·min−1)最大角度差/(°) 启动阶段 匀速阶段 500 0.7 0.5 1000 0.7 0.6 2000 1.1 0.4 3000 1.6 0.5 表 3 不同攻角后缘结构下偏测试结果

Table 3. Test results for deflection under different attack angles for the trailing edge structure

(°) 机翼攻角 后缘超调量 启动阶段

最大角度差匀速阶段

最大角度差0 0.10 7.49 6.72 6 0.09 15.41 9.82 10 0.29 15.60 6.47 12 0.05 10.94 8.03 -

[1] BARBARINO S, BILGEN O, AJAJ R M, et al. A review of morphing aircraft[J]. Journal of Intelligent Material Systems and Structures, 2011, 22(9): 823-877. doi: 10.1177/1045389X11414084 [2] BARTLEY-CHO J D, WANG D P, MARTIN C A, et al. Development of high-rate, adaptive trailing edge control surface for the smart wing phase 2 wind tunnel model[J]. Journal of Intelligent Material Systems and Structures, 2004, 15(4): 279-291. doi: 10.1177/1045389X04042798 [3] 王晓明, 周文雅, 吴志刚. 压电纤维复合材料驱动的机翼动态形状控制[J]. 航空学报, 2017, 38(1): 220313.WANG X M, ZHOU W Y, WU Z G. Dynamic shape control of wings using piezoelectric fiber composite materials[J]. Acta Aeronautica et Astronautica Sinica, 2017, 38(1): 220313. (in Chinese) [4] KUDVA J N. Overview of the DARPA smart wing project[J]. Journal of Intelligent Material Systems and Structures, 2004, 15(4): 261-267. doi: 10.1177/1045389X04042796 [5] 雷鹏轩, 王元靖, 吕彬彬, 等. 一种智能材料结构在变形体机翼气动特性研究中的应用[J]. 实验流体力学, 2017, 31(5): 74-80. doi: 10.11729/syltlx20160166LEI P X, WANG Y J, LYU B B, et al. Application of a smart material structure in the study of aerodynamic characteristics of a morphing wing[J]. Journal of Experiments in Fluid Mechanics, 2017, 31(5): 74-80. (in Chinese) doi: 10.11729/syltlx20160166 [6] 聂瑞. 变体机翼结构关键技术研究[D]. 南京: 南京航空航天大学, 2018NIE R. Research on key technologies of morphing wing structures[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2018. (in Chinese) [7] 孙江. 多电机同步协调控制系统的研究[D]. 太原: 太原科技大学, 2009SUN J. Research on multi-motor synchronous coordinated control system[D]. Taiyuan: Taiyuan University of Science & Technology, 2009. (in Chinese) [8] PEREZ-PINAL, NUNEZ C, ALVAREZ R, et al. Comparison of multi-motor synchronization techniques[C]//Proceedings of the 30th Annual Conference of IEEE Industrial Electronics Society. Busan, Korea (South): IEEE, 2004: 1670-1675 [9] 唐永聪, 刘涛, 张芳芳. 改进的双电机虚拟总轴同步控制[J]. 电子测量技术, 2017, 40(12): 1-5.TANG Y C, LIU T, ZHANG F F. Improved dual motor synchronous technology of virtual shaft quality control[J]. Electronic Measurement Technology, 2017, 40(12): 1-5. (in Chinese) [10] KOREN Y. Cross-coupled biaxial computer control for manufacturing systems[J]. Journal of Dynamic Systems, Measurement, and Control, 1980, 102(4): 265-272. doi: 10.1115/1.3149612 [11] PEREZ-PINAL F J, CALDERON G, ARAUJO-VARGAS I. Relative coupling strategy[C]//Proceedings of the IEEE International Electric Machines and Drives Conference. Madison: IEEE, 2003: 1162-1166 [12] SHIH Y T, CHEN C S, LEE A C. A novel cross-coupling control design for Bi-axis motion[J]. International Journal of Machine Tools and Manufacture, 2002, 42(14): 1539-1548. doi: 10.1016/S0890-6955(02)00109-8 [13] 张承慧, 石庆升, 程金. 一种基于相邻耦合误差的多电机同步控制策略[J]. 中国电机工程学报, 2007, 27(15): 59-63.ZHANG C H, SHI Q S, CHENG J. Synchronization control strategy in multi-motor systems based on the adjacent coupling error[J]. Proceedings of the CSEE, 2007, 27(15): 59-63. (in Chinese) [14] JERKOVIĆ ŠTIL V, VARGA T, BENŠIĆ T, et al. A survey of fuzzy algorithms used in multi-motor systems control[J]. Electronics, 2020, 9(11): 1788. doi: 10.3390/electronics9111788 [15] 耿强, 王少炜, 周湛清, 等. 改进型偏差耦合多电机转速同步控制[J]. 电工技术学报, 2019, 34(3): 474-482.GENG Q, WANG S W, ZHOU Z Q, et al. Multi-motor speed synchronous control based on improved relative coupling structure[J]. Transactions of China Electrotechnical Society, 2019, 34(3): 474-482. (in Chinese) [16] 尚小东, 刘毅力, 马龙涛, 等. 基于模糊PID的多电机系统协调控制策略的研究[J]. 自动化与仪器仪表, 2021(3): 13-17. doi: 10.14016/j.cnki.1001-9227.2021.03.013SHANG X D, LIU Y L, MA L T, et al. Research on coordinated control strategy of multi-motor system based on fuzzy PID[J]. Automation & Instrumentation, 2021(3): 13-17. (in Chinese) doi: 10.14016/j.cnki.1001-9227.2021.03.013 [17] 苗新刚, 汪苏, 韩凌攀, 等. 基于偏差耦合的多电机单神经元同步控制[J]. 微电机, 2011, 44(2): 44-47.MIAO X G, WANG S, HAN L P, et al. Single neuron PID synchronization control strategy in multi-motor systems based on the relative coupling control[J]. Micromotors, 2011, 44(2): 44-47. (in Chinese) [18] 曹玲芝, 李春文, 牛超, 等. 基于相邻交叉耦合的多感应电机滑模同步控制[J]. 电机与控制学报, 2008, 12(5): 586-592.CAO L Z, LI W C, NIU C, et al. Synchronized sliding-mode control for multi-induction motors based on adjacent cross-coupling[J]. Electric Machines and Control, 2008, 12(5): 586-592. (in Chinese) [19] 周广飞, 侯博川, 杨建华, 等. 基于动态补偿的多电机控制算法[J]. 航空学报, 2020, 41(S1): 723771.ZHOU G F, HOU B C, YANG J H, et al. Multi-motor control algorithm based on dynamic compensation[J]. Acta Aeronautica et Astronautica Sinica, 2020, 41(S1): 723771. (in Chinese) -

下载:

下载: