Ultrasonic Testing Simulation Research of Honeycomb Core Defects in Composite Sandwich Structure

-

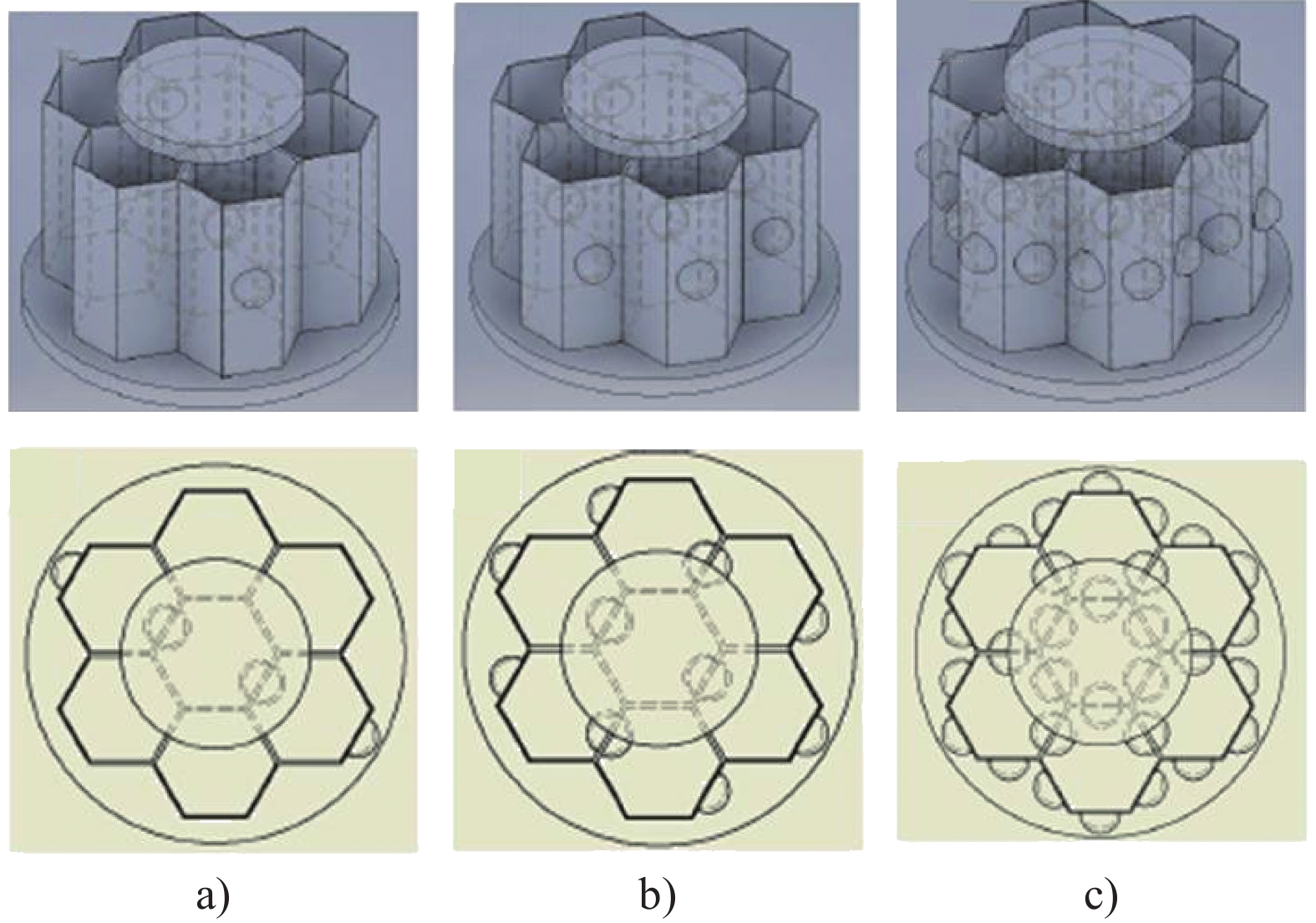

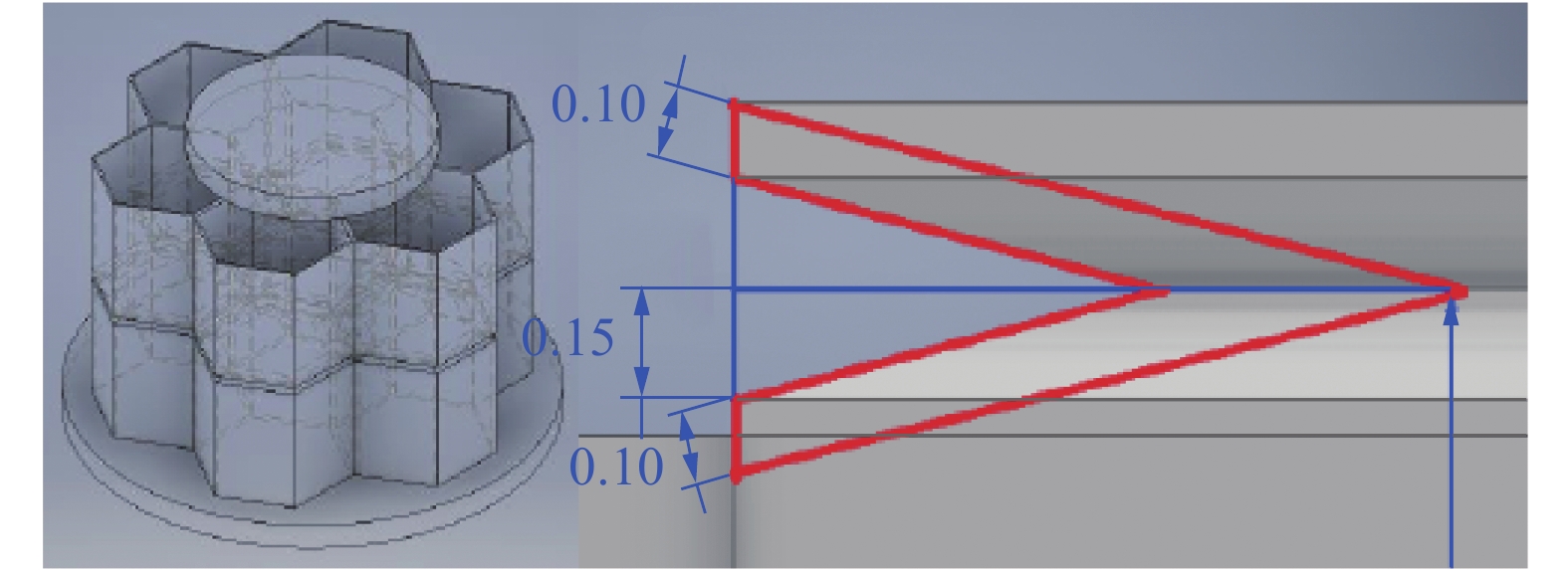

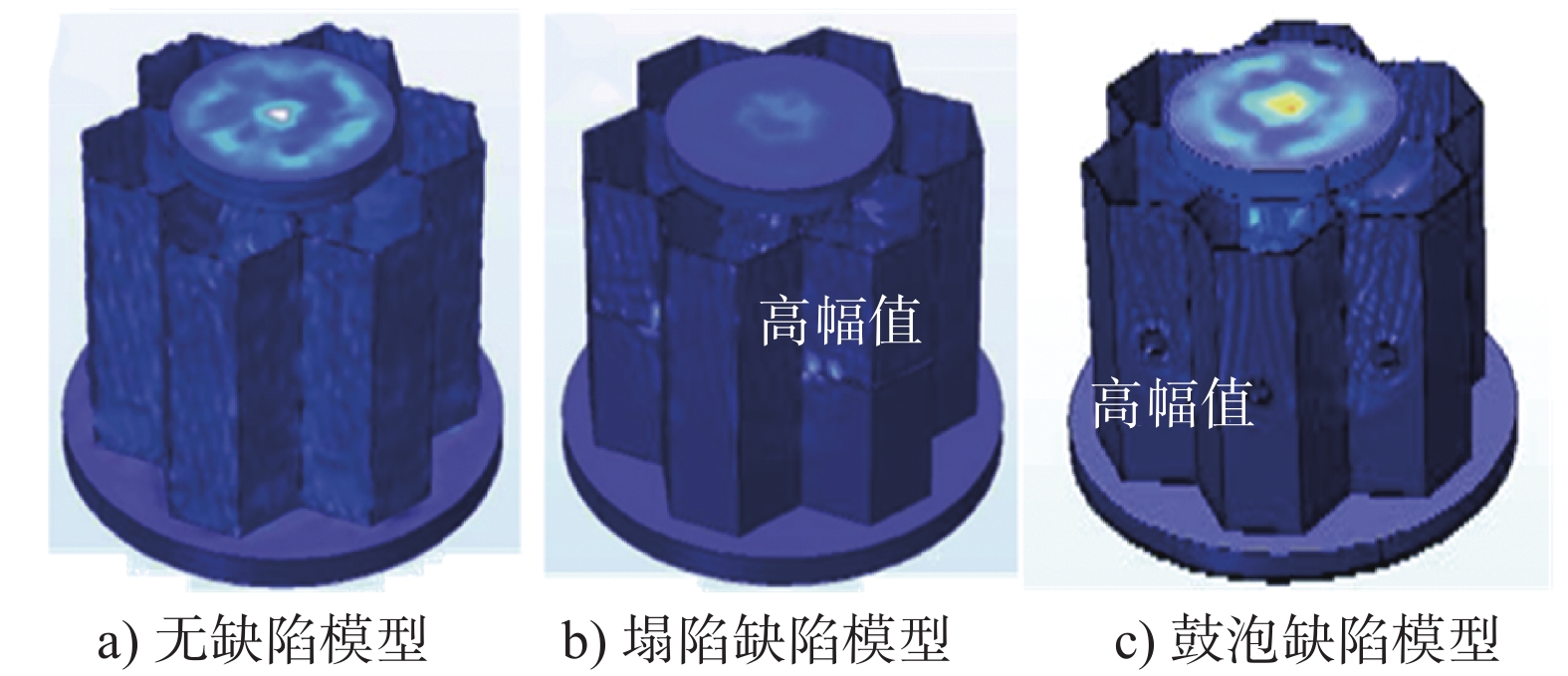

摘要: 实际检测中发现,复合材料蜂窝夹层结构中的芯格塌陷和胞壁鼓泡缺陷能够引起喷水超声穿透法C扫描检测中超声大幅度衰减。为了从理论上分析并验证蜂窝夹芯缺陷对穿透法超声传播的影响,本文采用3D有限元建模仿真方法,分别模拟了超声波在蜂窝壁完好、芯格塌陷、胞壁鼓泡这3种模型中的传播方式,研究了不同缺陷种类的尺寸和数量对、超声透射波幅值的影响,讨论了复合材料蜂窝芯格塌陷和胞壁鼓泡缺陷引起零件检测中超声波大幅度衰减的原因,与实际超声C扫描检测结果具有较好的一致性。Abstract: A large ultrasonic attenuation is found in water-squirting through-transmission ultrasonic C-scan detection of composite aramid paper honeycomb sandwich structure, which is caused by the defects of honeycomb collapse and cell bubbling. 3D finite element modeling simulation method is used to analyze and verify the influence of the honeycomb sandwich defects on the ultrasonic propagation in penetrating method. The propagation modes of ultrasonic wave in the integrity honeycomb, honeycomb with collapse and cell bubbling defects are simulated. The influences of the size and number of different defects on the amplitude of ultrasonic transmission wave are analyzed. The causes of the ultrasonic wave attenuation are discussed. The results of finite element simulation are consistent with those of the ultrasonic C scan test.

-

表 1 复合材料蜂窝夹层结构基本参数

Table 1. Basic parameters of composite honeycomb sandwich structure

部位 密度/

(g·cm–3)纵波声速/

(m·s–1)弹性模量/

GPa声阻抗/

MRayl上蒙皮 1.87 3194 12.718 5.973 下蒙皮 1.78 2680 8.514 4.675 蜂窝 0.8 2217 2.619 1.774 表 2 鼓泡缺陷对透射幅值变化的影响

Table 2. Effect of lattices bubbling defects on transmission amplitude changes

缺陷直径/mm 缺陷数量/排 透射波幅值分贝变化/dB 完好 0 0 2.0 1 −1.8 2.0 2 −2.5 2.0 3 −11.8 2.2 3 −16.1 2.4 3 −21.1 2.8 3 −26.1 表 3 塌陷缺陷对透射幅值变化的影响

Table 3. Effect of lattices collapse defects on transmission amplitude changes

缺陷内伸长度/mm 缺陷数量/个 透射波幅值分贝变化/dB 完好 0 0 0.5 1 −1.0 0.5 4 −6.5 0.5 7 −13.3 0.7 7 −14.0 1.0 7 −18.1 1.2 7 −23.6 1.6 7 −32.2 -

[1] 沈建中, 林俊明. 现代复合材料的无损检测技术[M]. 北京: 国防工业出版社, 2016SHEN J Z, LIN J M. Nondestructive testing technology of modern composite materials[M]. Beijing: National Defense Industry Press, 2016. (in Chinese) [2] 窦明月, 王显峰, 张冬梅, 等. Nomex蜂窝芯静态压缩屈曲与后屈曲分析[J]. 南京航空航天大学学报, 2019, 51(1): 69-74.DOU M Y, WANG X F, ZHANG D M, et al. Buckling and Post-buckling of Nomex honeycomb cores under compression[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2019, 51(1): 69-74. (in Chinese) [3] TOWSYFYAN H, BIGURI A, BOARDMAN R, et al. Successes and challenges in non-destructive testing of aircraft composite structures[J]. Chinese Journal of Aeronautics, 2020, 33(3): 771-791. doi: 10.1016/j.cja.2019.09.017 [4] 刘松平, 刘菲菲. 先进复合材料无损检测技术[M]. 北京: 航空工业出版社, 2017LIU S P, LIU F F. Advanced NDT&E techniques for composites[M]. Beijing: Aviation Industry Press, 2017. (in Chinese) [5] 卢鹏, 危荃, 敖波, 等. 铝蜂窝夹芯结构的数字成像检测研究[J]. 失效分析与预防, 2014, 9(6): 340-346.LU P, WEI Q, AO B, et al. Digital imaging detection of aluminum-honeycomb sandwich structure[J]. Failure Analysis and Prevention, 2014, 9(6): 340-346. (in Chinese) [6] 郝威,李明,徐莹.一种用于检测蜂窝内部缺陷的新方法:中国, 108844978B[P]. 2020-11-13HAO W, LI M, XU Y. Novel method for detecting internal defects of honeycomb: CN, 108844978B[P]. 2020-11-13. (in Chinese) [7] HU C Q, DUAN Y X, LIU S C, et al. LSTM-RNN-based defect classification in honeycomb structures using infrared thermography[J]. Infrared Physics & Technology, 2019, 102: 103032. [8] SCHAAL C, MAL A. Core-skin disbond detection in a composite sandwich panel using guided ultrasonic waves[J]. Journal of Nondestructive Evaluation, Diagnostics and Prognostics of Engineering Systems, 2018, 1(1): 011006. doi: 10.1115/1.4037544 [9] DIAMANTI K, SOUTIS C. Structural health monitoring techniques for aircraft composite structures[J]. Progress in Aerospace Sciences, 2010, 46(8): 342-352. doi: 10.1016/j.paerosci.2010.05.001 [10] 郝威, 李明, 王珏, 等. 复合材料芳纶蜂窝夹层结构件特殊缺陷检测[J]. 航空学报, 2022, 43(7): 425426.HAO W, LI M, WANG J, et al. Special defect inspection of composite aramid paper honeycomb sandwich structure[J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(7): 425426. (in Chinese) [11] 王志伟, 姚著. 蜂窝纸板冲击压缩的试验研究和有限元分析[J]. 机械工程学报, 2012, 48(12): 49-55. doi: 10.3901/JME.2012.12.049WANG Z W, YAO Z. Experimental investigation and finite element analysis for impact compression of honeycomb paperboards[J]. Journal of Mechanical Engineering, 2012, 48(12): 49-55. (in Chinese) doi: 10.3901/JME.2012.12.049 [12] 张杰, 周进, 罗宏建. 基于AutoCAD的超声场模拟在超声检测中的应用[J]. 无损检测, 2011, 33(2): 72-74.ZHANG J, ZHOU J, LUO H J. The application of virtual ultrasonic field based on AutoCAD software in ultrasonic testing[J]. Nondestructive Testing, 2011, 33(2): 72-74. (in Chinese) [13] 邬冠华, 王丹, 贺小玉, 等. 碳纤维复合材料板冲击损伤计算及超声检测[J]. 无损检测, 2011, 33(11): 42-45.WU G H, WANG D, HE X Y, et al. The calculation and detection of impact damage in carbon fiber reinforced composites[J]. Nondestructive Testing, 2011, 33(11): 42-45. (in Chinese) [14] GHOSE B, BALASUBRAMANIAM K, KRISHNAMURTHY C V, et al. Two-dimensional FEM simulation of ultrasonic wave propagation in isotropic solid media using COMSOL[C]//COMSOL Conference. India, 2011. [15] 张继敏, 周晖, 刘奎. 航空复合材料多层蜂窝夹芯结构的空气耦合式超声检测技术研究[J]. 复合材料科学与工程, 2020(9): 74-78.ZHANG J M, ZHOU H, LIU K. Study on multi-layer honeycomb sandwich structure of aeronautical composite by air-coupled ultrasonic inspection technique[J]. Composites Science and Engineering, 2020(9): 74-78. (in Chinese) -

下载:

下载: