Strength Prediction Model of Aluminum Alloy Clinched Joints Formed With Segmental Mandrel

-

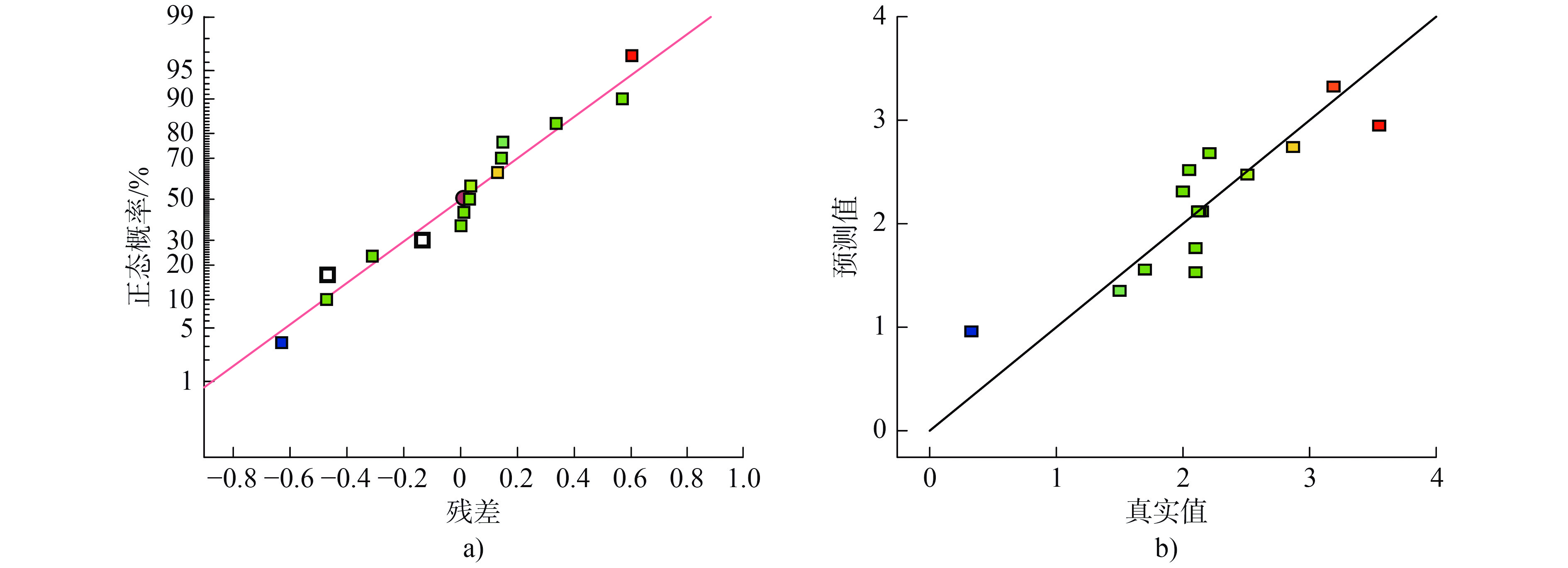

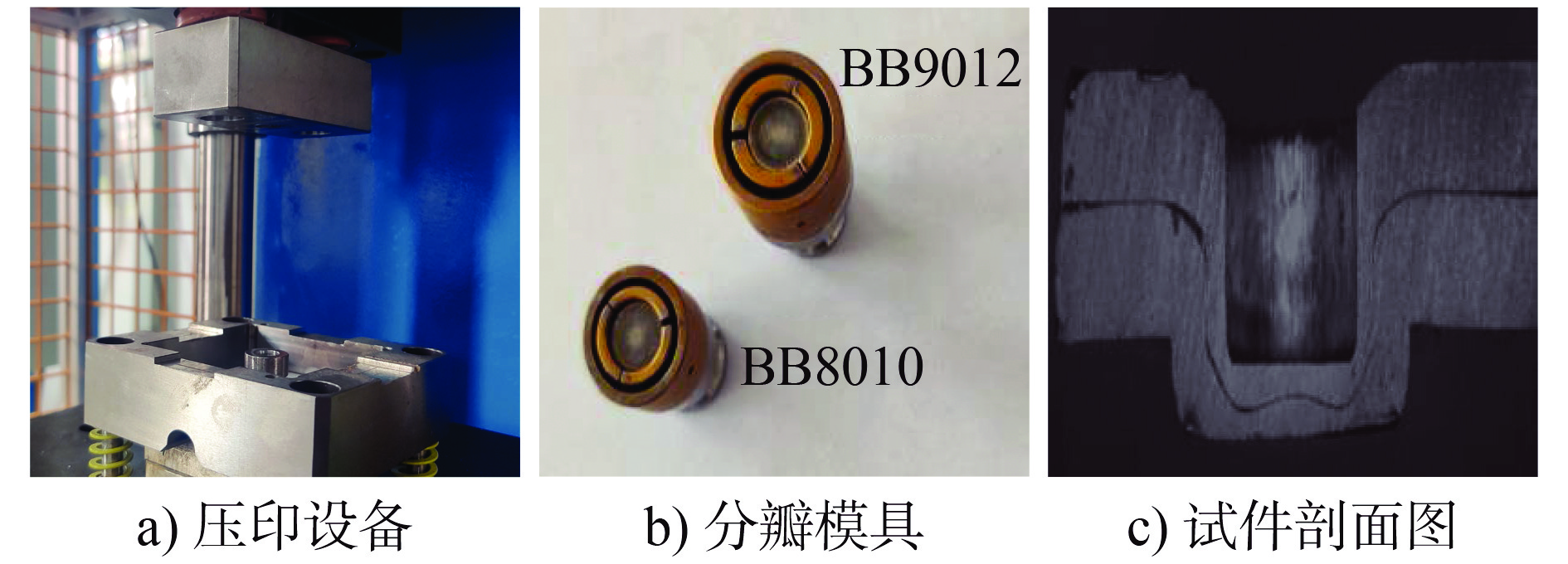

摘要: 采用Box-behnken design(BBD)实验设计法,开展铝合金压印接头的工艺试验研究。试验过程选用了5182、5052和6061这3种铝合金薄板,建立了以冲压力、板材厚度、板材硬度为影响因素,以失效载荷为响应值的多元回归模型,并进行了试验验证。结果表明:建立的多元回归模型可以预测铝合金压印接头的拉剪失效载荷,最大误差为17.7%,其误差在工程应用范围内较小;且方差分析表明,各因素对失效载荷影响程度大小的顺序为冲压力、板材硬度、板材厚度;压印接头的失效载荷随冲压力的增大呈先增大后减小的趋势,随板材厚度的增大呈先减小后增大的趋势,板材硬度对接头失效载荷的影响呈正线性相关性。Abstract: Based on the Box-behnken design (BBD) test design method, the mechanical properties analysis of aluminum alloy clinched joints was carried out. Three kinds of aluminum alloy sheets 5182、5052 and 6061 were used in the test. A multivariate regression model with punching pressure, sheet thickness and sheet hardness as the influence factors and failure load as response value was established, and the model was verified via experiments. The results show that the multivariate regression model can accurately predict the tension-shear failure load of aluminum alloy clinched joints in a certain range of processing parameters, the maximum error is 17.7%, and the error is small in application. Variance analysis shows that the impact on the failure load is the largest in the order of punching pressure, followed by the sheet hardness and the sheet thickness. The failure load of the clinched joint firstly increases and then decreases with the increasing of punching pressure, and firstly decreases and then increases with the increasing of sheet thickness. The influence of the sheet hardness on the failure load of joint is positively linear correlation.

-

Key words:

- clinching /

- response surface method /

- regression model /

- prediction mode

-

表 1 试验因素及水平设计

Table 1. Experimental factors and level design

因素编码值 冲压力

X1/kN板材硬度

X2/HBR板材厚度

X2/mm−1 32.2 18.6 1 0 38.4 31.0 1.5 1 48.7 55.3 2 表 2 实验方案及结果

Table 2. Experimental program and results

组号 冲压力

X1/kN板材硬度

X2/HRB板材厚度

X3/mm失效载荷

Y/kN1 32.2 18.6 1.5 1.5 2 48.7 18.6 1.5 2.1 3 32.2 55.3 1.5 0.33 4 48.7 55.3 1.5 3.19 5 32.2 31 1 1.7 6 48.7 31 1 2.51 7 32.2 31 2 2.1 8 48.7 31 2 2.21 9 38.4 18.6 1 2 10 38.4 55.3 1 2.87 11 38.4 18.6 2 2.05 12 38.4 55.3 2 3.55 13 38.4 31 1.5 2.15 14 38.4 31 1.5 2.13 15 38.4 31 1.5 2.12 表 3 失效载荷响应面回归模型的方差分析

Table 3. ANOVA of the response surface regression model for failure loads

因素 平方和 自由度 均方差 F值 Prob>F 模型 5.85 6 0.98 4.30 0.0310 X1 3.09 1 3.09 13.61 0.0061 X2 1.00 1 1.00 4.41 0.0689 X3 0.086 1 0.086 0.38 0.5549 X1X2 1.29 1 1.29 5.70 0.0440 X1 2 1.11 1 1.11 4.89 0.0579 X3 2 0.72 1 0.72 3.18 0.1124 失拟项 1.81 6 0.30 1295.78 0.0008 表 4 验证实验结果

Table 4. Results of validation experiments

组号 基板材料 冲压力/kN 板材硬度/HRB 板材厚度/mm 预测值/kN 试验均值/kN 相对误差/% 1 5182 44.3 18.6 2.0 2.499 2.141 16.7 2 1420 56.1 62.0 1.5 3.374 2.867 17.7 -

[1] HE X C, ZHANG Y, XING B Y, et al. Mechanical properties of extensible die clinched joints in titanium sheet materials[J]. Materials & Design, 2015, 71: 26-35. [2] HE X C. Recent development in finite element analysis of clinched joints[J]. The International Journal of Advanced Manufacturing Technology, 2010, 48(5-8): 607-612. doi: 10.1007/s00170-009-2306-2 [3] HE X C, LEI L, ZHANG Y, et al. Mechanical properties and fracture analysis of clinched joints in titanium sheet materials[J]. Acta Physica Polonica A, 2017, 131(1): 16-19. doi: 10.12693/APhysPolA.131.16 [4] KARIM M A, PARK Y D. A review on welding of dissimilar metals in car body manufacturing[J]. Journal of Welding and Joining, 2020, 38(1): 8-23. doi: 10.5781/JWJ.2020.38.1.1 [5] CISCHINO E, DI PAOLO F, MANGINO E, et al. An advanced technological lightweighted solution for a body in white[J]. Transportation Research Procedia, 2016, 14: 1021-1030. doi: 10.1016/j.trpro.2016.05.082 [6] DEEPATI A K, ALHAZMI W, BENJEER I. Mechanical characterization of AA5083 aluminum alloy welded using resistance spot welding for the lightweight automobile body fabrication[J]. Materials Today:Proceedings, 2021, 45: 5139-5148. doi: 10.1016/j.matpr.2021.01.646 [7] CHEN C, ZHANG H Y, ZHAO S D, et al. Effects of sheet thickness and material on the mechanical properties of flat clinched joint[J]. Frontiers of Mechanical Engineering, 2021, 16(2): 410-419. doi: 10.1007/s11465-020-0618-y [8] CHEN C, ZHAO S D, CUI M C, et al. Effects of geometrical parameters on the strength and energy absorption of the height-reduced joint[J]. The International Journal of Advanced Manufacturing Technology, 2017, 90(9-12): 3533-3541. doi: 10.1007/s00170-016-9619-8 [9] LONG J L, LAN F C, CHEN J Q, et al. Mechanical properties prediction of the mechanical clinching joints based on genetic algorithm and BP neural network[J]. Chinese Journal of Mechanical Engineering, 2009, 22(1): 36-41. doi: 10.3901/CJME.2009.01.036 [10] OUDJENE M, BEN-AYED L, DELAMÉZIÈRE A, et al. Shape optimization of clinching tools using the response surface methodology with moving least-square approximation[J]. Journal of Materials Processing Technology, 2009, 209(1): 289-296. doi: 10.1016/j.jmatprotec.2008.02.030 [11] 杨露露, 宋燕利, 辜志强, 等. 钢铝压-胶复合连接接头力学行为与失效机理研究[J]. 机械科学与技术, 2021, 40(7): 1120-1127. doi: 10.13433/j.cnki.1003-8728.20200167YANG L L, SONG Y L, GU Z Q, et al. Study on mechanical behavior and failure mechanism of steel-aluminum clinch-bonded hybrid joints[J]. Mechanical Science and Technology for Aerospace Engineering, 2021, 40(7): 1120-1127. (in Chinese) doi: 10.13433/j.cnki.1003-8728.20200167 [12] 杨慧艳, 何晓聪, 丁燕芳, 等. 铝合金压印接头的强度研究[J]. 应用力学学报, 2014, 31(2): 299-304. doi: 10.11776/cjam.31.02.B038YANG H Y, HE X C, DING Y F, et al. Analytical models and experimental studies on clinched joints in aluminium alloy[J]. Chinese Journal of Applied Mechanics, 2014, 31(2): 299-304. (in Chinese) doi: 10.11776/cjam.31.02.B038 [13] 杨慧艳, 何晓聪, 周森. 压印接头强度的有限元模型及理论计算方法[J]. 吉林大学学报(工学版), 2015, 45(3): 864-871. doi: 10.13229/j.cnki.jdxbgxb201503026YANG H Y, HE X C, ZHOU S. Simulation and calculation methods for clinched joint strength[J]. Journal of Jilin University (Engineering and Technology Edition), 2015, 45(3): 864-871. (in Chinese) doi: 10.13229/j.cnki.jdxbgxb201503026 [14] 韩晓兰, 陈超, 刘辰, 等. 双层板材平底无铆塑性连接的抗拉强度预测模型[J]. 机械工程学报, 2018, 54(24): 61-68. doi: 10.3901/JME.2018.24.061HAN X L, CHEN C, LIU C, et al. Predictive model of tensile strength in flat clinching[J]. Journal of Mechanical Engineering, 2018, 54(24): 61-68. (in Chinese) doi: 10.3901/JME.2018.24.061 [15] 曾凯, 孙晓婷, 邢保英, 等. DP780高强钢胶接点焊的工艺优化及断裂特征分析[J]. 焊接学报, 2020, 41(4): 77-83. doi: 10.12073/j.hjxb.20191017001ZENG K, SUN X T, XING B Y, et al. Process optimization and fracture characteristic analysis of DP780 high strength steel weld-bonding[J]. Transactions of the China Welding Institution, 2020, 41(4): 77-83. (in Chinese) doi: 10.12073/j.hjxb.20191017001 -

下载:

下载: