Optimizing Residential Cabin Layout of Naval Ship with Energy Method and NSGA-II Algorithm

-

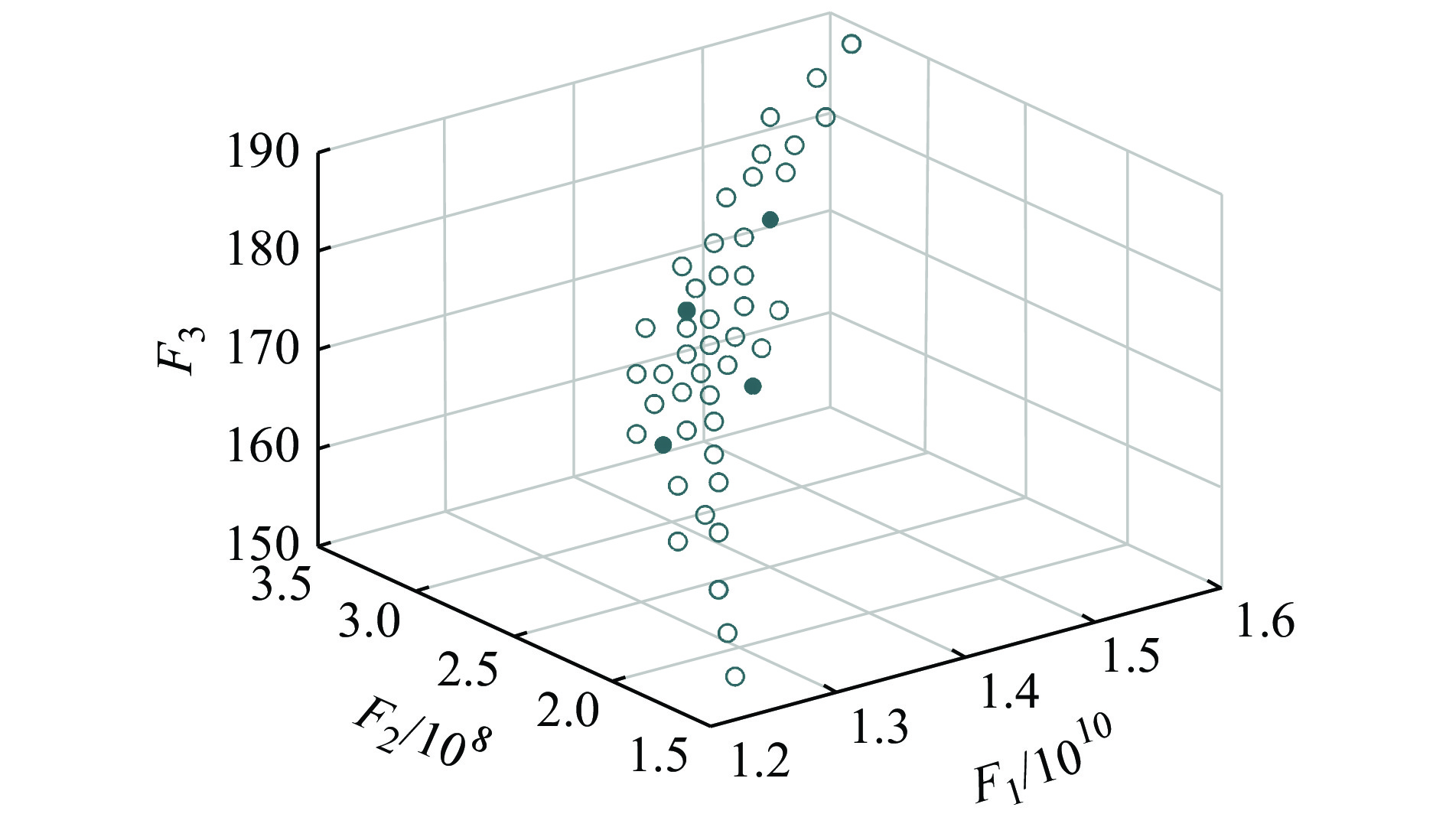

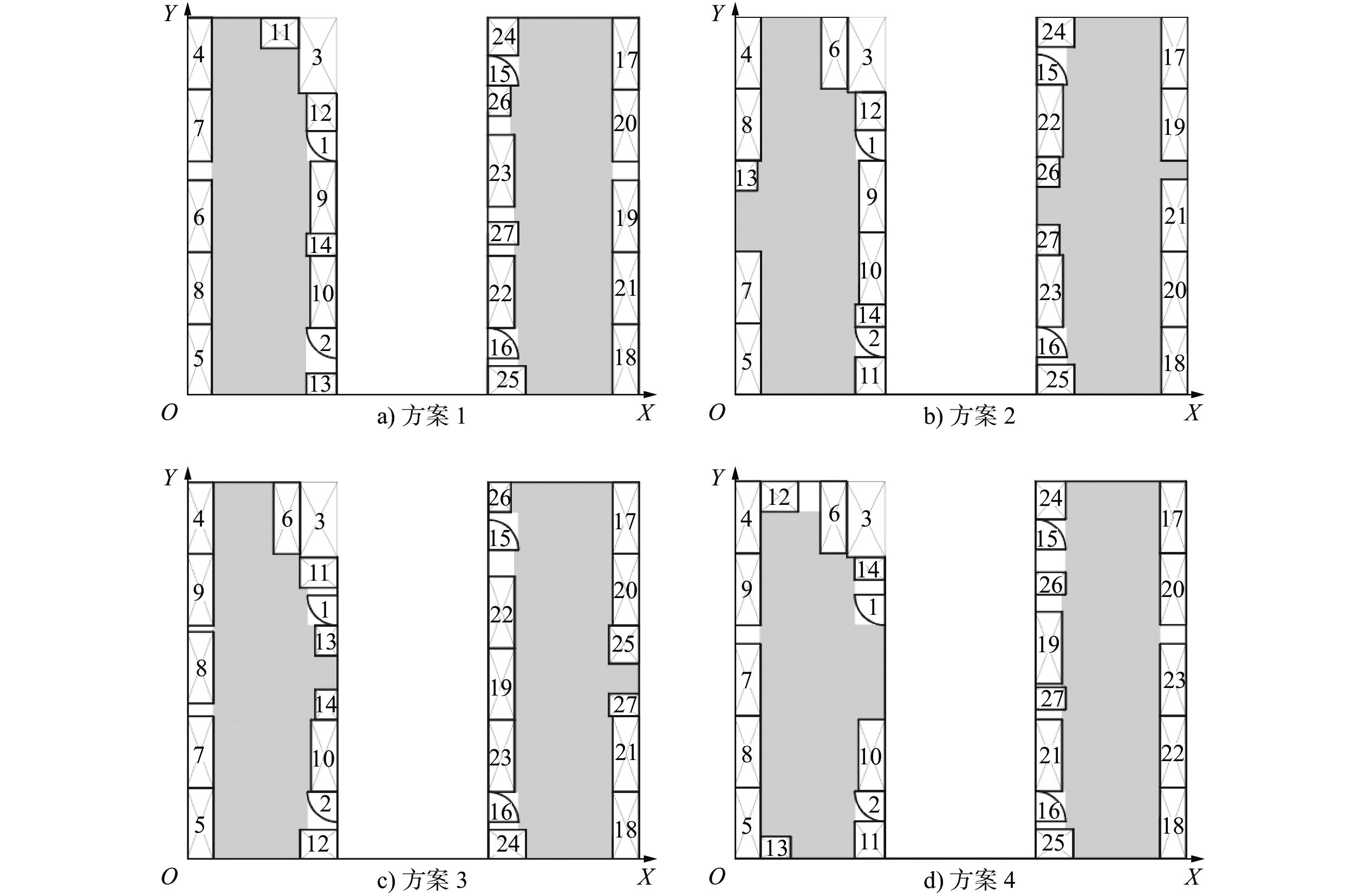

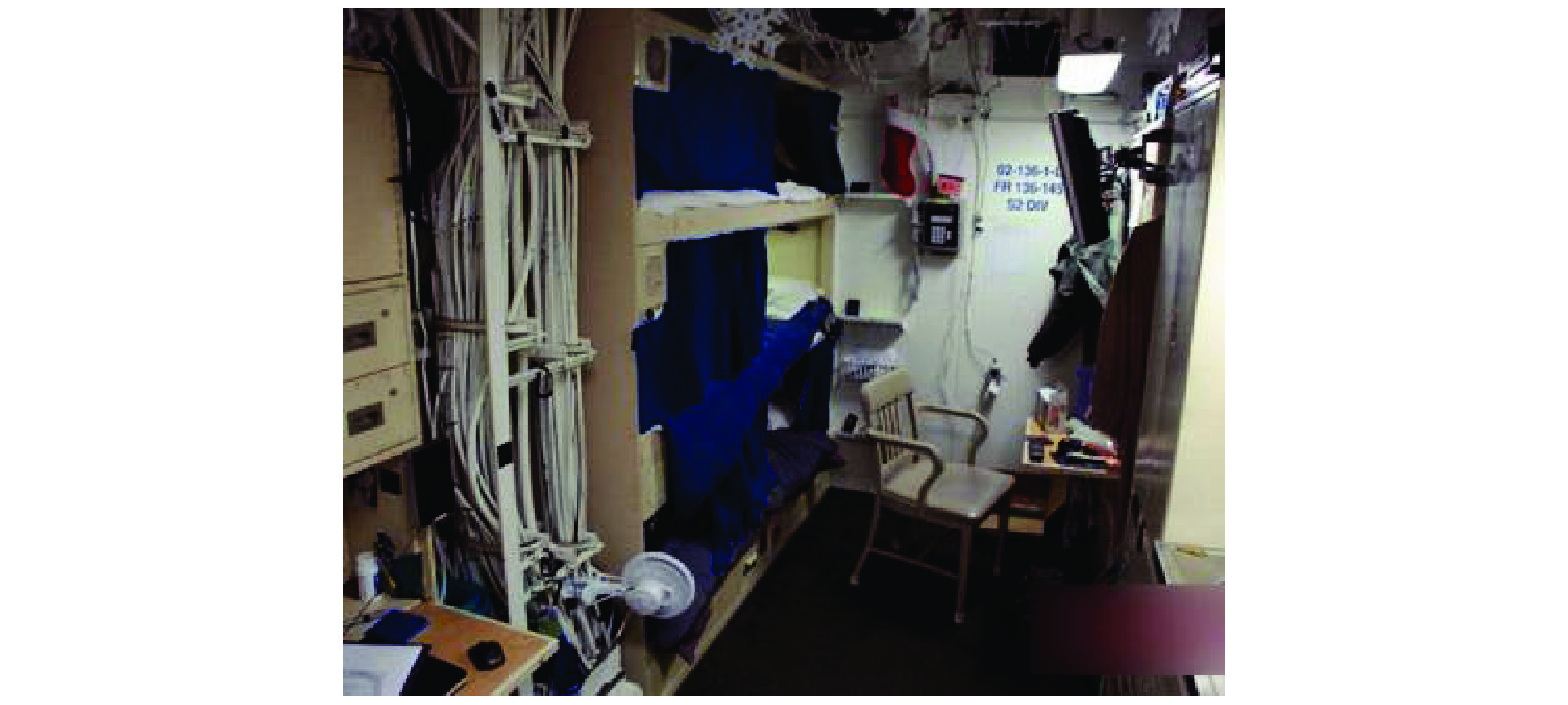

摘要: 为了提高舰艇居住舱室布局优化求解速度,将能量法引入NSGA-Ⅱ算法。借鉴能量法的思想建立待布舱室数学模型,量化舱室内属具摆放的具体要求,并以此形成目标函数进行方案筛选。利用MATLAB在二维平面内实现舱室布局优化方案的自动化输出。最后,以某舰艇20人居住舱室为例对方法进行了验证。实验结果表明,采用该方法的布局设计速度明显提升,布局方案满足需求且提高了舱室的空间利用率。Abstract: To optimize a naval ship's residential cabin layout and improve its design speed, the energy method is introduced into the NSGA-Ⅱgenetic algorithm and used to establish the mathematical model of the residential cabin layout, quantify specific requirements for the placement of accessories in the cabin and form the objective function for program selection. The MATLAB program is used to realize the algorithm's iterative calculation and automatic output of the layout scheme. Finally, a naval ship′s 20-person living cabin is taken as an example to verify the optimization. The experimental results show that the layout design speed is obviously improved, the layout scheme meets the requirements and improves the cabin layout utilization rate.

-

Key words:

- layout optimization /

- NSGA-Ⅱ algorithm /

- energy method /

- naval ship residential cabin

-

表 1 舱室单元能量值求解

Table 1. The energy value of the cabin unit is solved

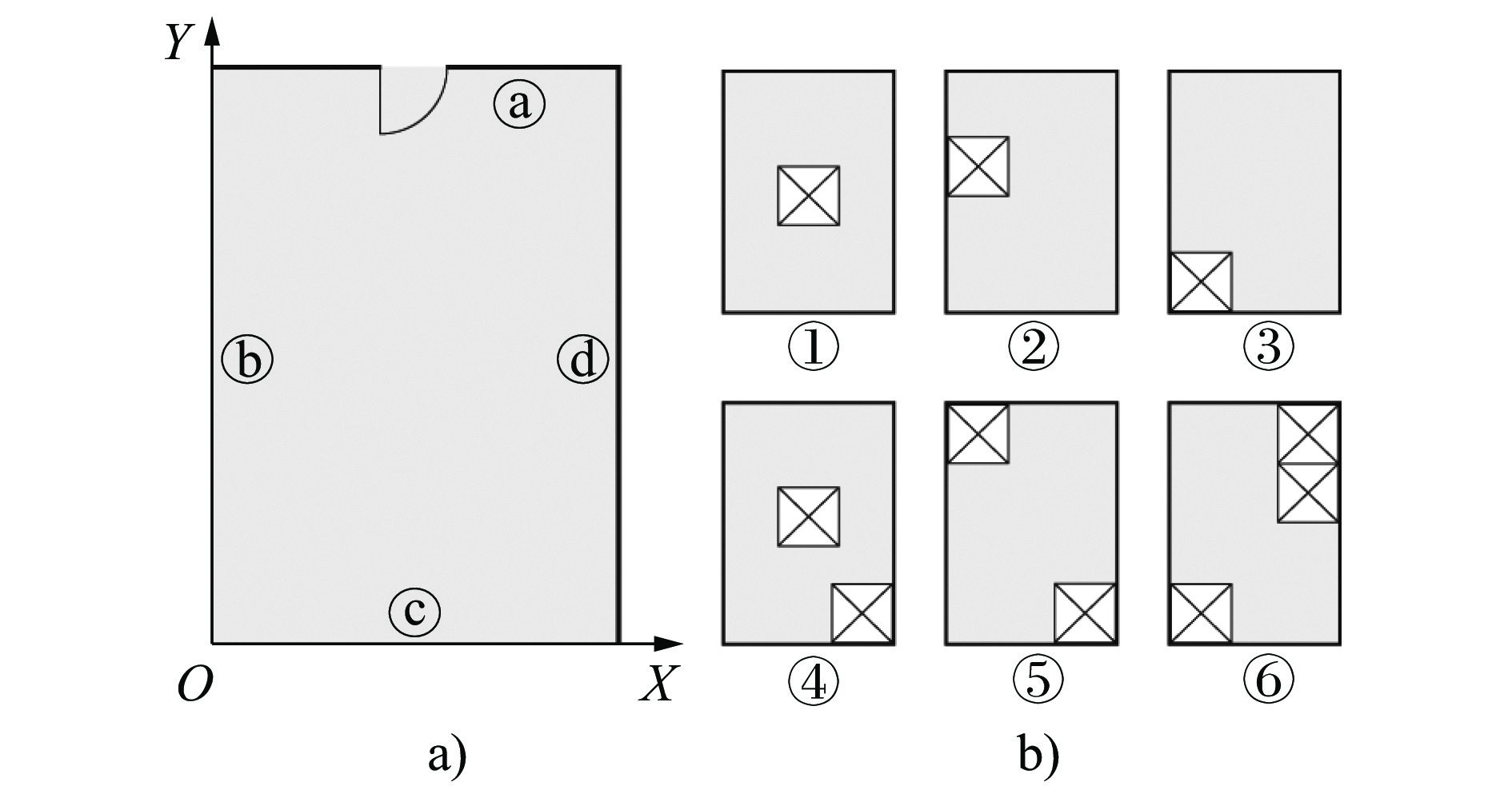

方案序号 属具数量 能量值 ① 1 0 ② 1 $ b $ ③ 1 $ b + c $ ④ 2 $ c + d $ ⑤ 2 $ a + b + c + d $ ⑥ 3 $ a + b + c + d + d $ 表 2 待布舱室及待布单元数据

Table 2. Data of waiting room and waiting unit

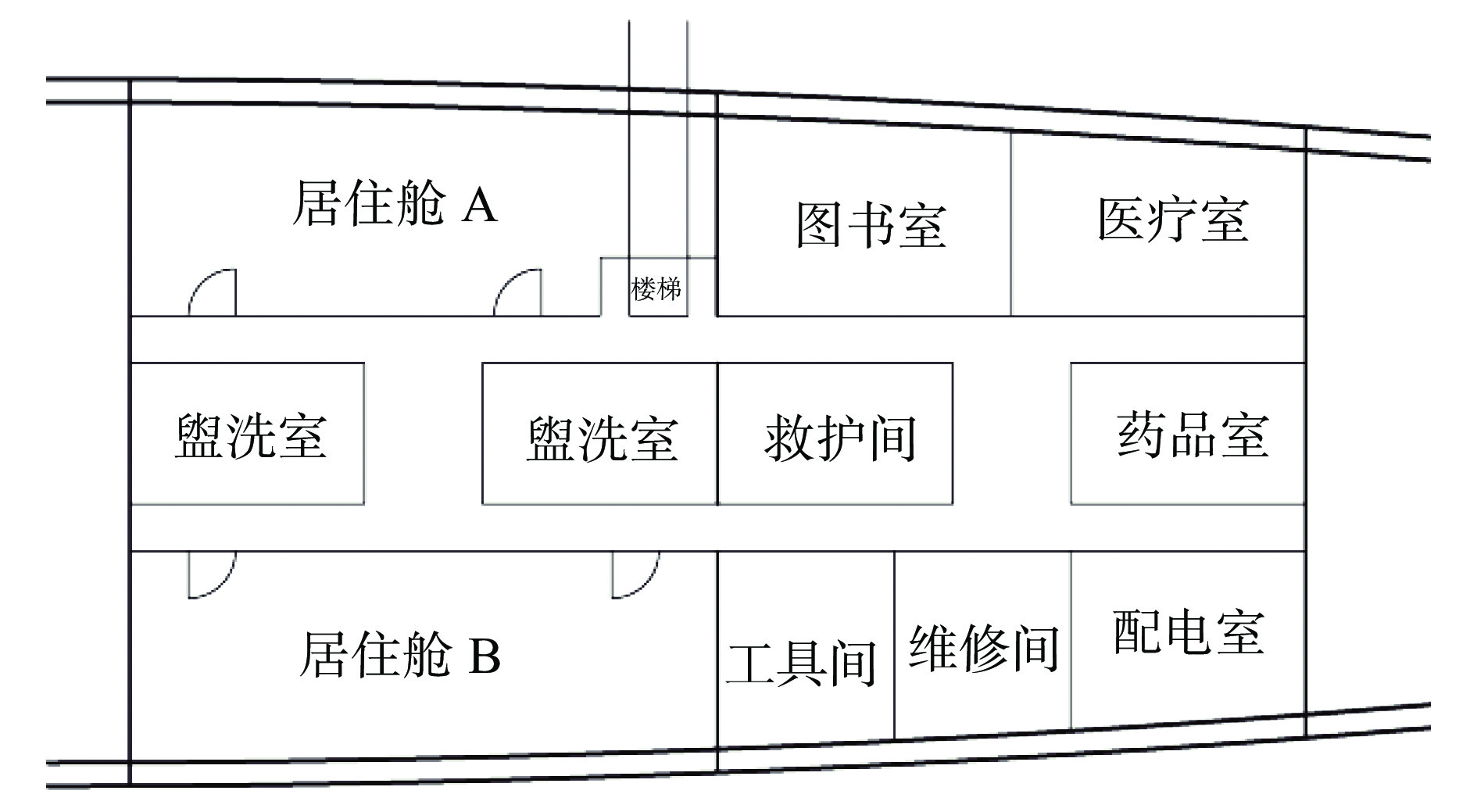

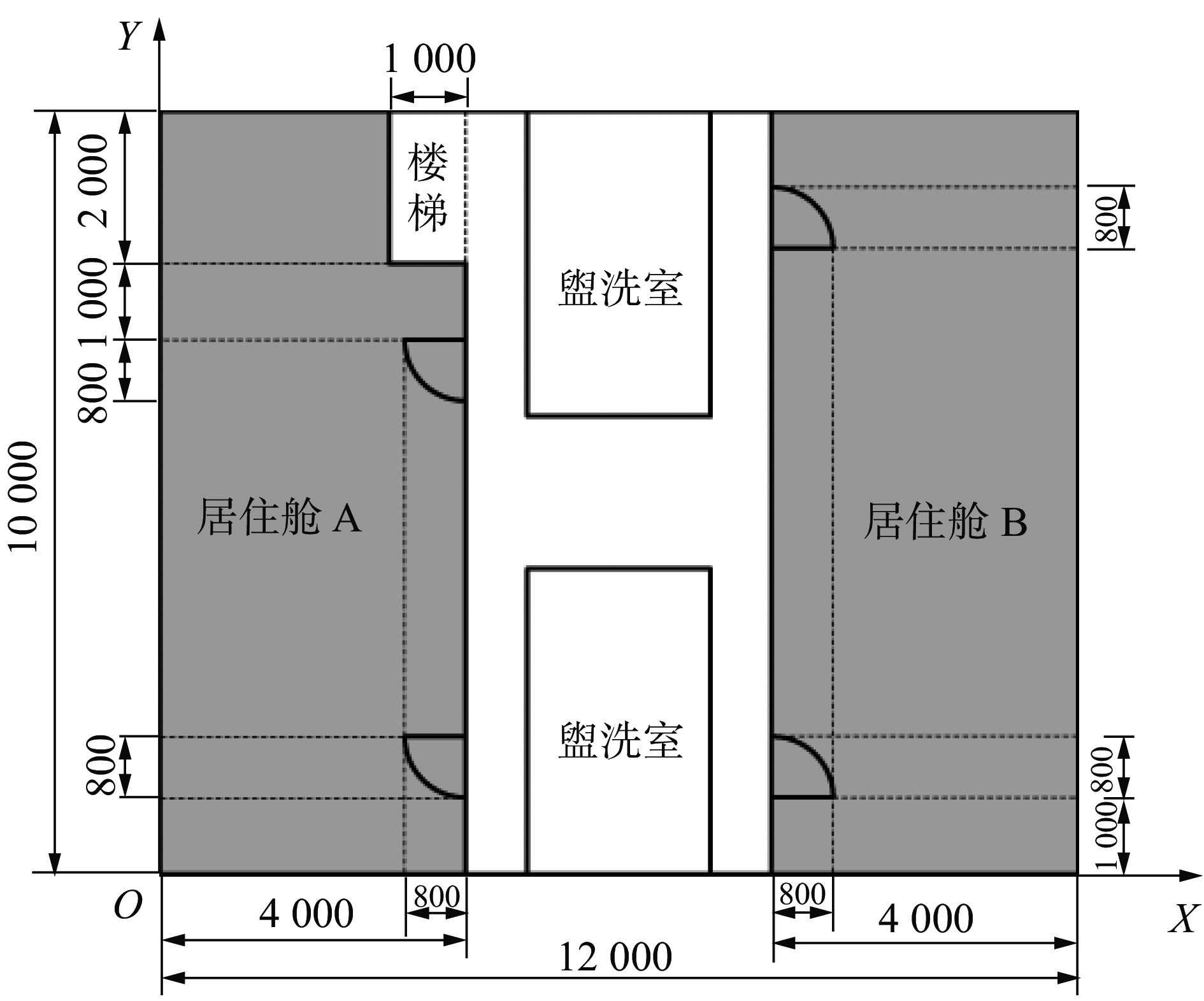

舱室编号 单元类型 单元名称 个数 编号 长

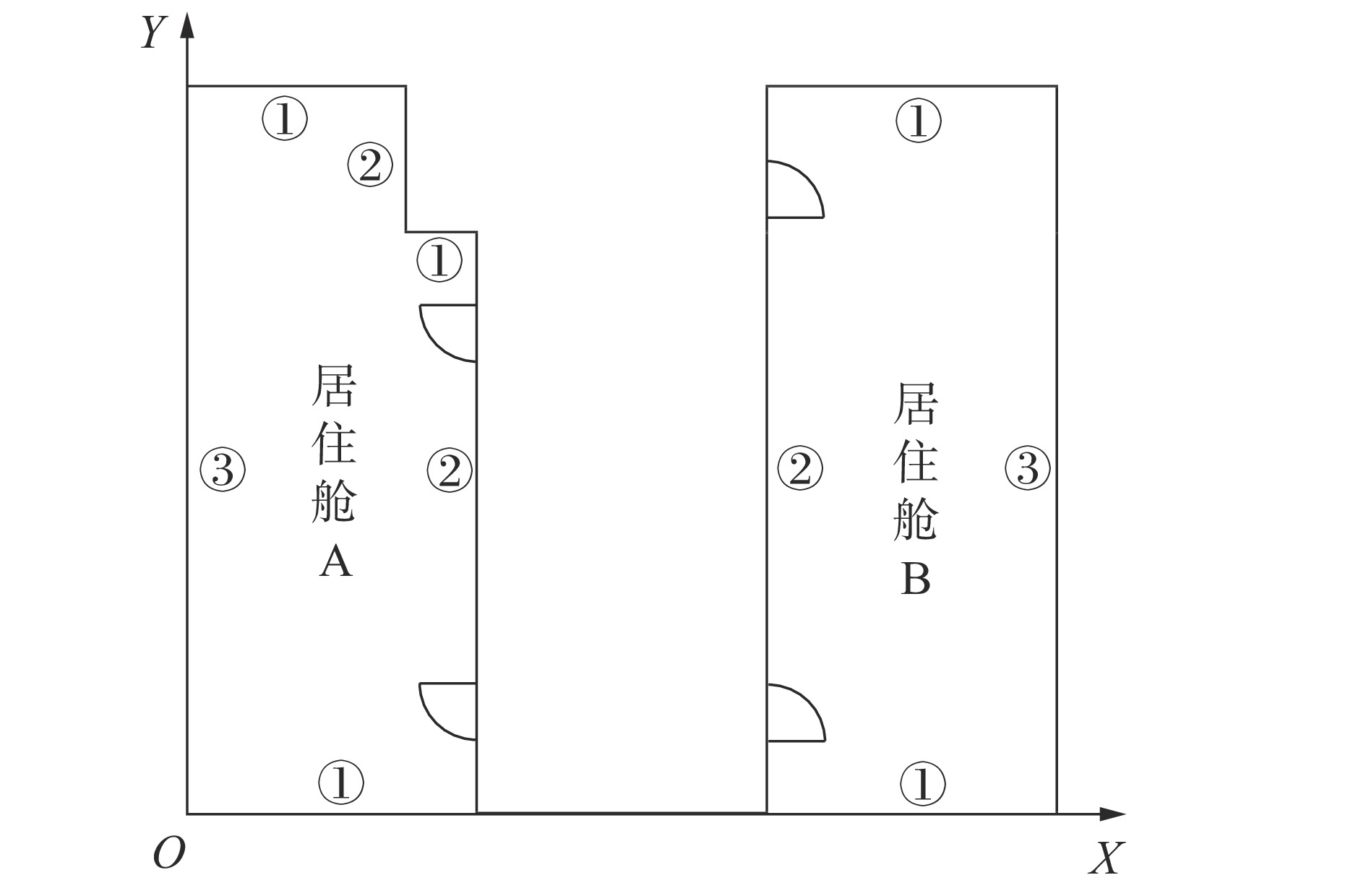

/mm宽/mm 中心点坐标 X Y 居住舱A 固定单元 门(位置固定) 2 1 800 800 3600 6600 2 800 800 3600 1400 楼梯(位置固定) 1 3 2000 1000 3500 9500 待布单元 床单元 6 4~10 1900 700 待布 书桌单元 2 11~12 800 600 储物单元 2 13~14 1000 800 居住舱B 固定单元 门(位置固定) 2 15 800 800 8400 8600 16 800 800 8400 1400 待布单元 床单元 6 17~23 1900 700 待布 书桌单元 2 24~25 800 600 储物单元 2 26~27 1000 800 表 3 方案1布局优化结果

Table 3. Scheme 1 Layout optimization results

舱室 属具单元 编号 X/mm Y/mm si/mm qi/mm 居住舱A 床单元 4 350 9050 700 1900 5 350 950 6 350 4750 7 350 7150 8 350 2850 9 3650 4950 10 3650 2750 储物单元 11 2500 9600 1000 800 12 3600 7500 800 1000 书桌单元 13 3600 300 800 600 14 3600 4000 800 600 居住舱B 床单元 17 11650 9050 700 1900 18 11650 950 19 11650 4750 20 11650 7150 21 11650 2850 22 8350 2750 23 8350 5600 储物单元 24 8400 9600 800 1000 25 8500 400 1000 800 书桌单元 26 8300 7800 800 600 27 8400 4350 600 800 表 4 方案有效活动空间计算

Table 4. Scheme active space calculation

方案 有效空间面积/m2 方案 有效空间面积/m2 1 50.35 3 50.40 2 51.69 4 49.06 -

[1] 蔡薇, 陈湛, 陈琪. 一种大型邮轮乘客舱室智能布局设计方法[J]. 中国造船, 2019, 60(2): 186-195. doi: 10.3969/j.issn.1000-4882.2019.02.019CAI W, CHEN Z, CHEN Q. A new intelligent layout design method for passenger cabins in large cruise ship[J]. Shipbuilding of China, 2019, 60(2): 186-195. (in Chinese) doi: 10.3969/j.issn.1000-4882.2019.02.019 [2] 陈永林, 于雁云, 林焰, 等. 一种船用LNG管路管夹布局优化方法[J]. 船舶工程, 2015, 37(5): 74-77. doi: 10.13788/j.cnki.cbgc.2015.05.074CHEN Y L, YU Y Y, LIN Y, et al. A layout optimization method for marine LNG pipe support design[J]. Ship Engineering, 2015, 37(5): 74-77. (in Chinese) doi: 10.13788/j.cnki.cbgc.2015.05.074 [3] 宗立成, 叶聪, 余隋怀, 等. 载人潜水器舱室设备智能布局设计方法研究[J]. 中国造船, 2013, 54(3): 147-154. doi: 10.3969/j.issn.1000-4882.2013.03.018ZONG L C, YE C, YU S H, et al. Research and application of intelligent layout method in DSV cabin equipment[J]. Shipbuilding of China, 2013, 54(3): 147-154. (in Chinese) doi: 10.3969/j.issn.1000-4882.2013.03.018 [4] KIA R, KHAKSAR-HAGHANI F, JAVADIAN N, et al. Solving a multi-floor layout design model of a dynamic cellular Manufacturing system by an efficient genetic algorithm[J]. Journal of Manufacturing Systems, 2014, 33(1): 218-232. doi: 10.1016/j.jmsy.2013.12.005 [5] LEE C J. Optimal multi-floor plant layout based on the mathematical programming and particle swarm optimization[J]. Industrial Health, 2015, 53(6): 491-497. doi: 10.2486/indhealth.2014-0234 [6] IZADINIA N, ESHGHI K. A robust mathematical model and ACO solution for multi-floor discrete layout problem with uncertain locations and demands[J]. Computers & Industrial Engineering, 2016, 96: 237-248. [7] 王运龙, 王晨, 纪卓尚, 等. 船舶居住舱室智能布局优化设计方法研究[J]. 中国造船, 2013, 54(3): 139-146. doi: 10.3969/j.issn.1000-4882.2013.03.017WANG Y L, WANG C, JI Z S, et al. A study on intelligent layout design of ship cabin[J]. Shipbuilding of China, 2013, 54(3): 139-146. (in Chinese) doi: 10.3969/j.issn.1000-4882.2013.03.017 [8] 熊炳旭. 豪华邮轮室内布局优化系统开发研究[D]. 大连: 大连理工大学, 2019XIONG B X. Research on the development of the interior layout optimization system of luxury cruise ships[D]. Dalian: Dalian University of Technology, 2019. (in Chinese) [9] 宗立成. 潜水器舱室空间布局的多学科设计方法研究[J]. 计算机工程与应用, 2017, 53(22): 212-216. doi: 10.3778/j.issn.1002-8331.1605-0177ZONG L C. Study of multidisciplinary design optimization method on DSV cabin space layout[J]. Computer Engineering and Applications, 2017, 53(22): 212-216. (in Chinese) doi: 10.3778/j.issn.1002-8331.1605-0177 [10] 王文中, 张树生, 余隋怀, 等. 基于解构·重构思维的潜水器舱室布局优化[J]. 计算机集成制造系统, 2021, 27(7): 2045-2052.WANG W Z, ZHANG S S, YU S H, et al. Optimization of submarine cabin layout based on deconstruction and reconstruction[J]. Computer Integrated Manufacturing Systems, 2021, 27(7): 2045-2052. (in Chinese) [11] 刘苗苗, 查振元, 王云彤, 等. 港口重载纯电动牵引车车架总成布局优化设计[J]. 机械设计, 2019, 36(S1): 183-187. doi: 10.13841/j.cnki.jxsj.2019.s1.042LIU M M, ZHA Z Z, WANG Y T, et al. Optimal design of frame assembly layout of port heavy-duty electric tractor[J]. Journal of Machine Design, 2019, 36(S1): 183-187. (in Chinese) doi: 10.13841/j.cnki.jxsj.2019.s1.042 [12] 朱敬燕, 黄志平, 杨春. 船舶居住舱室整体设计方案的研究与分析[J]. 中国水运, 2017, 17(3): 5-6.ZHU J Y, HUANG Z P, YANG C. Research and analysis of the overall design scheme of the ship's accommodation[J]. China Water Transport, 2017, 17(3): 5-6. (in Chinese) [13] WANG Y L, WANG C, LIN Y. Ship cabin layout optimization design based on the improved genetic algorithm method[J]. Applied Mechanics and Materials, 2013, 300-301: 146-149. doi: 10.4028/www.scientific.net/AMM.300-301.146 [14] 杨海元. 固体力学的数值方法[M]. 天津: 天津大学出版社, 1991YANG H Y. Numerical methods for solid mechanics[M]. Tianjin: Tianjin University Press, 1991. (in Chinese) [15] ERIKSEN B O H, BREIVIK M, WILTHIL E F, et al. The branching-course model predictive control algorithm for maritime collision avoidance[J]. Journal of Field Robotics, 2019, 36(7): 1222-1249. doi: 10.1002/rob.21900 [16] HOPPER E, TURTON B C H. An empirical investigation of meta-heuristic and heuristic algorithms for a 2D packing problem[J]. European Journal of Operational Research, 2011, 128(1): 34-57. [17] 李辉, 张淑红, 陈金周. 感性工学方法论及其在产品设计过程中的应用研究进展[J]. 湖南包装, 2016, 31(4): 23-27. doi: 10.3969/j.issn.1671-4997.2016.04.008LI H, ZHANG S H, CHEN J Z. Research progress of Kansei engineering methodology and its application in product design process[J]. Hunan Packaging, 2016, 31(4): 23-27. (in Chinese) doi: 10.3969/j.issn.1671-4997.2016.04.008 [18] 康慧, 杨随先, 邓淑文, 等. 产品操作界面元素布局多目标优化设计[J]. 包装工程, 2020, 41(8): 149-153 . doi: 10.19554/j.cnki.1001-3563.2020.08.020KANG H, YANG S X, DENG S W, et al. Multi-objective optimization design of product operation interface element layout[J]. Packaging Engineering, 2020, 41(8): 149-153 . (in Chinese) doi: 10.19554/j.cnki.1001-3563.2020.08.020 [19] 路艳雪. NSGA-Ⅱ多目标优化算法的改进及应用研究[D]. 太原: 太原理工大学, 2017LU Y X. research on improvement and application of NSGA-Ⅱ multi-objective optimization method[D]. Taiyuan: Taiyuan University of Technology, 2017. (in Chinese) [20] SHENG W X, LIU K Y, LIU Y, et al. Optimal placement and sizing of distributed generation via an improved nondominated sorting genetic Algorithm II[J]. IEEE Transactions on Power Delivery, 2015, 30(2): 569-578. doi: 10.1109/TPWRD.2014.2325938 [21] 钱辉仲, 顾克秋, 彭迪, 等. 基于NSGA-II算法的超轻型火炮摇架多目标优化设计[J]. 机械设计, 2012, 29(6): 36-40. doi: 10.3969/j.issn.1001-2354.2012.06.009QIAN H Z, GU K Q, PENG D, et al. Multi-objective optimization design of ultra lightweight artillery cradle based on NSGA-II algorithm[J]. Journal of Machine Design, 2012, 29(6): 36-40. (in Chinese) doi: 10.3969/j.issn.1001-2354.2012.06.009 [22] 李琳, 王旭鹏. 基于NSGA-Ⅱ多目标遗传算法的宿舍室内空间布局优化研究[J]. 西安理工大学学报, 2019, 35(3): 338-342. doi: 10.19322/j.cnki.issn.1006-4710.2019.03.011LI L, WANG X P. Research on optimization of dormitory interior space layout based on NSGA-Ⅱ multi-objective genetic algorithm[J]. Journal of Xi'an University of Technology, 2019, 35(3): 338-342. (in Chinese) doi: 10.19322/j.cnki.issn.1006-4710.2019.03.011 [23] 冯青, 余隋怀, 杨雷. 基于Kano模型的应急通信车造型设计[J]. 机械设计, 2015, 32(9): 111-115. doi: 10.13841/j.cnki.jxsj.2015.09.022FENG Q, YU S H, YANG L. Modeling design of emergency communication vehicle based on Kano model[J]. Journal of Machine Design, 2015, 32(9): 111-115. (in Chinese) doi: 10.13841/j.cnki.jxsj.2015.09.022 -

下载:

下载: