Simulation and Optimization of Fatigue Life for Electric Commercial Vehicle Frame

-

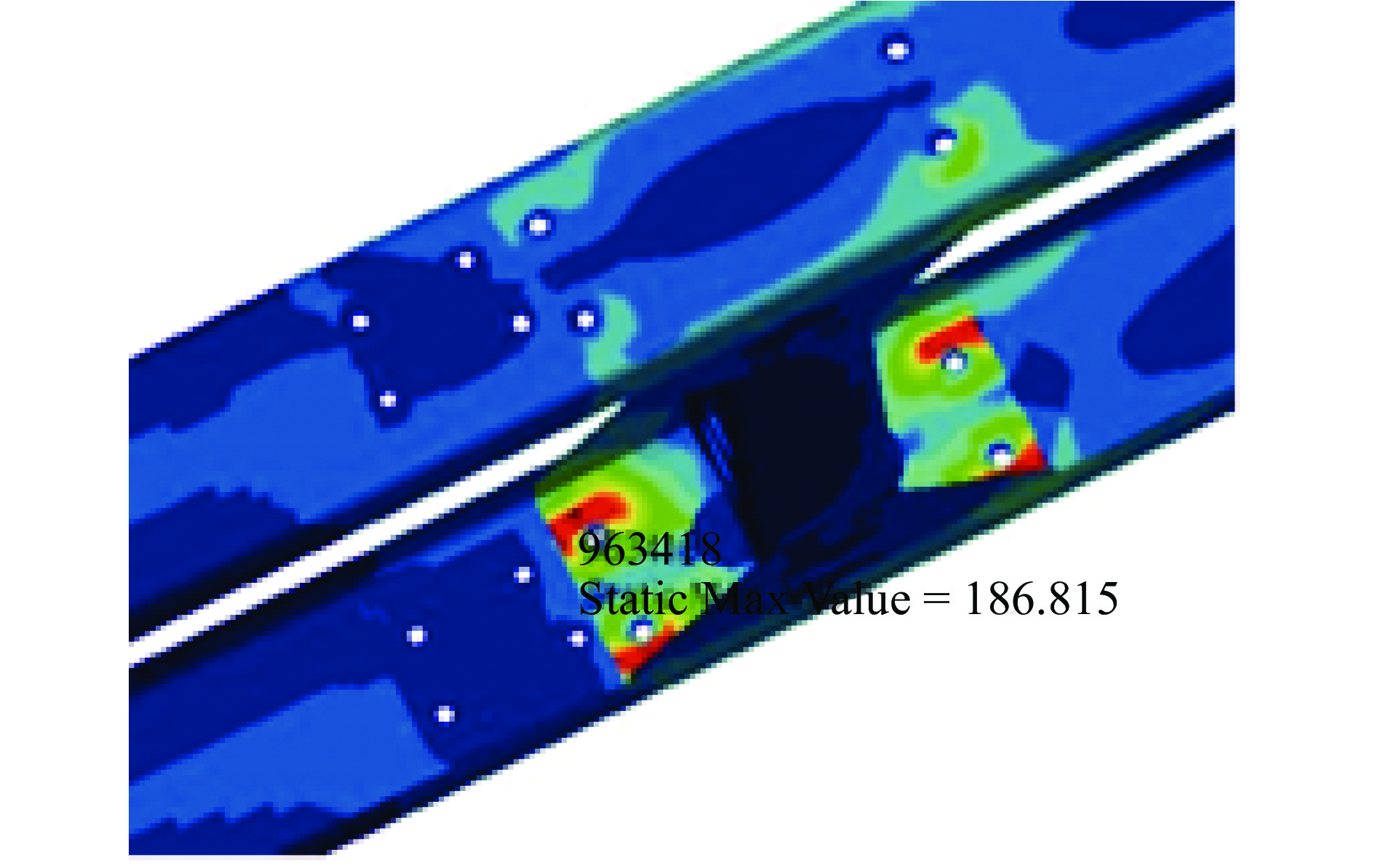

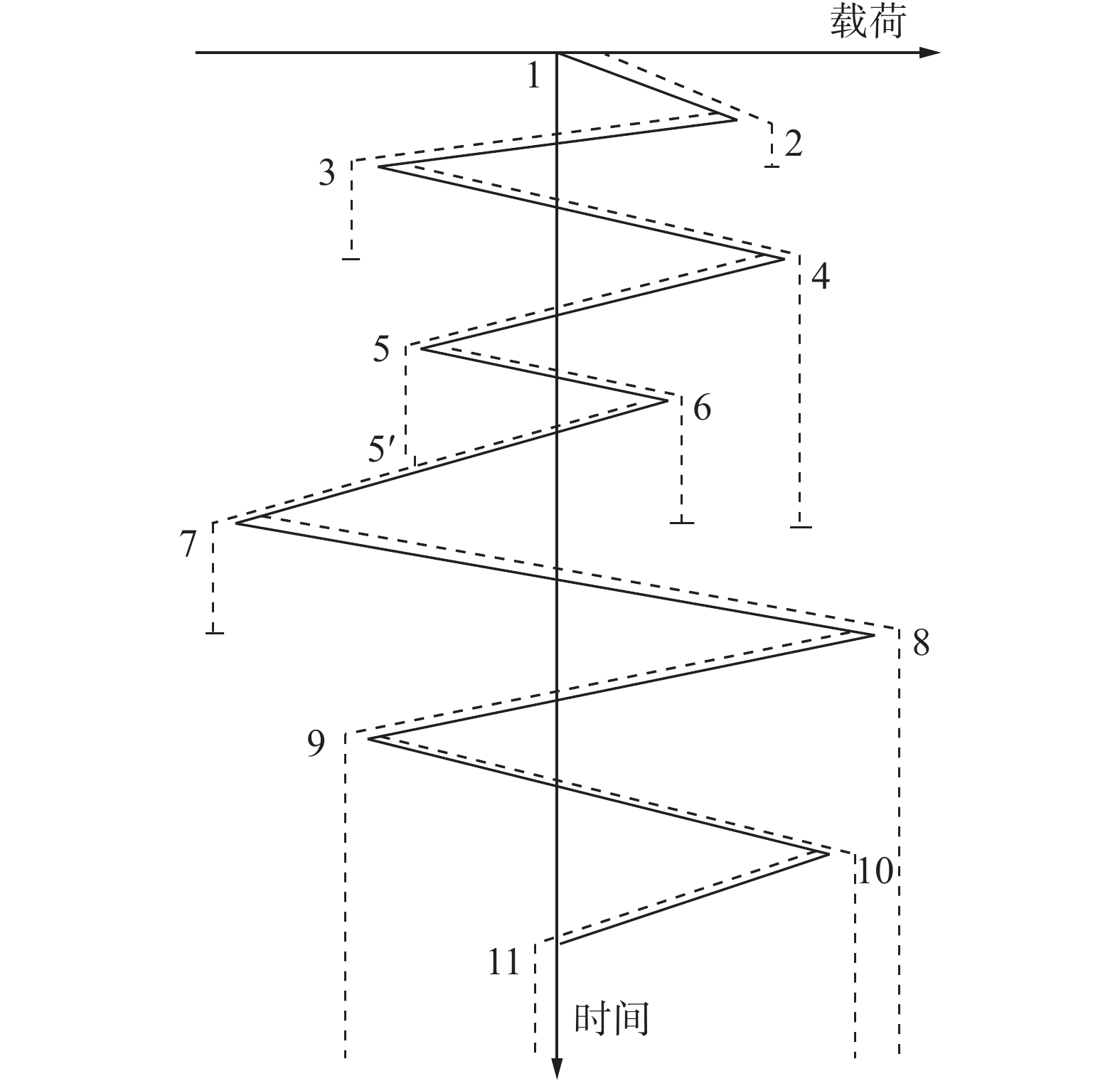

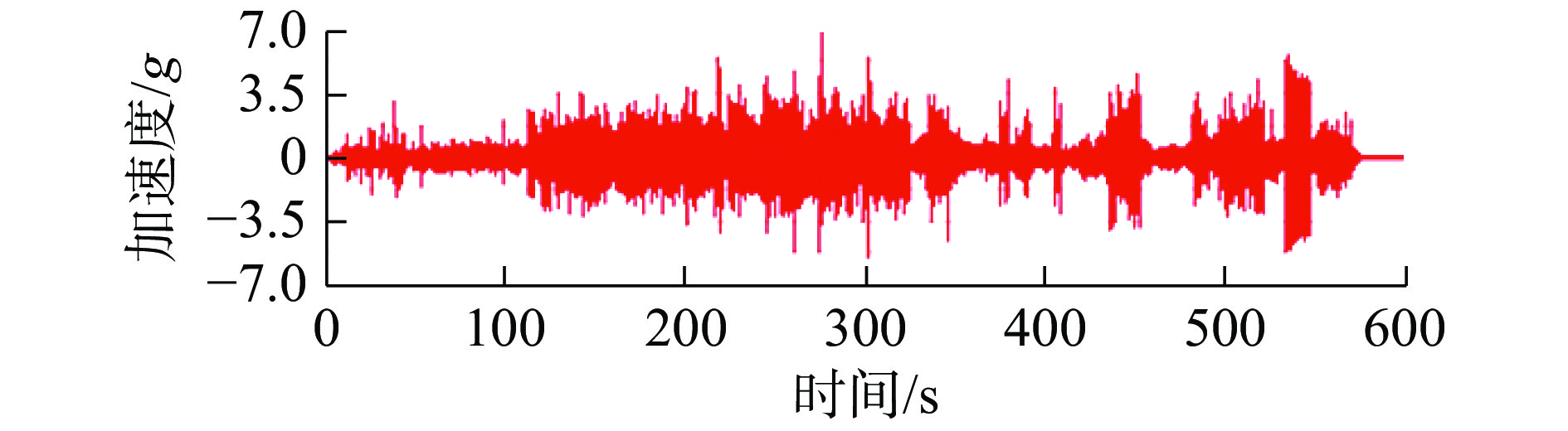

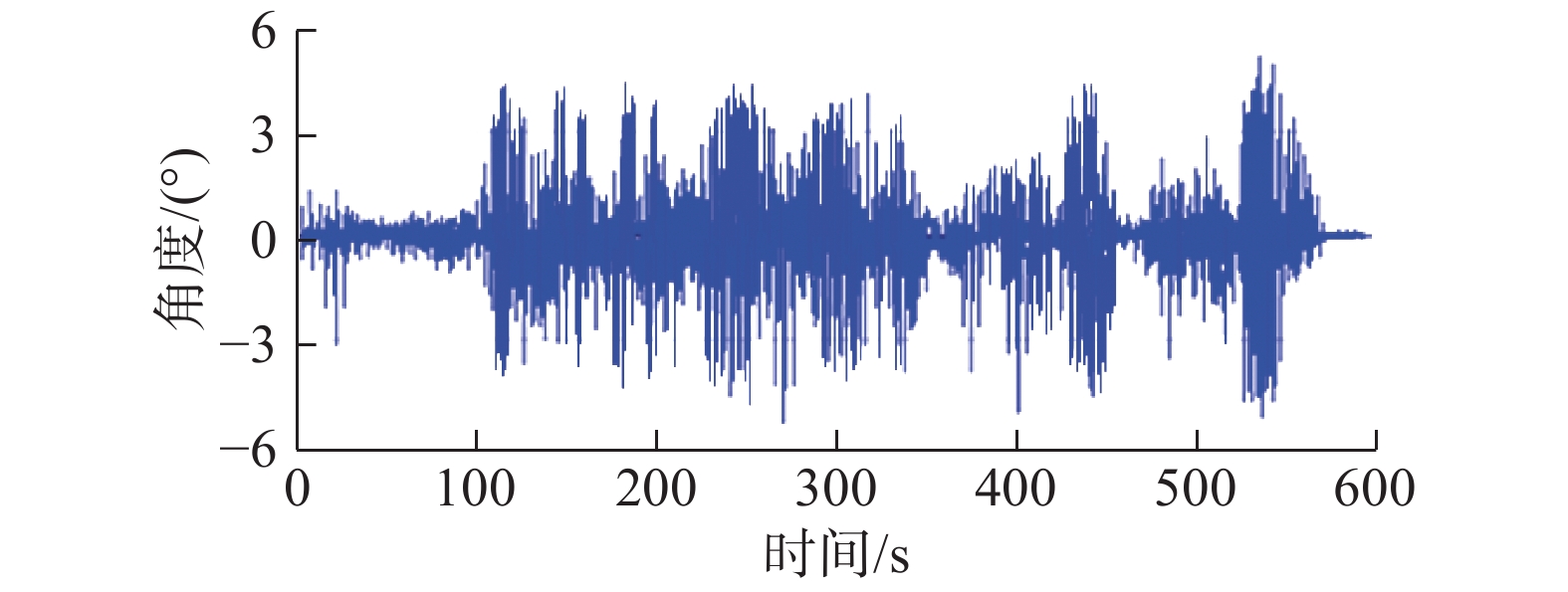

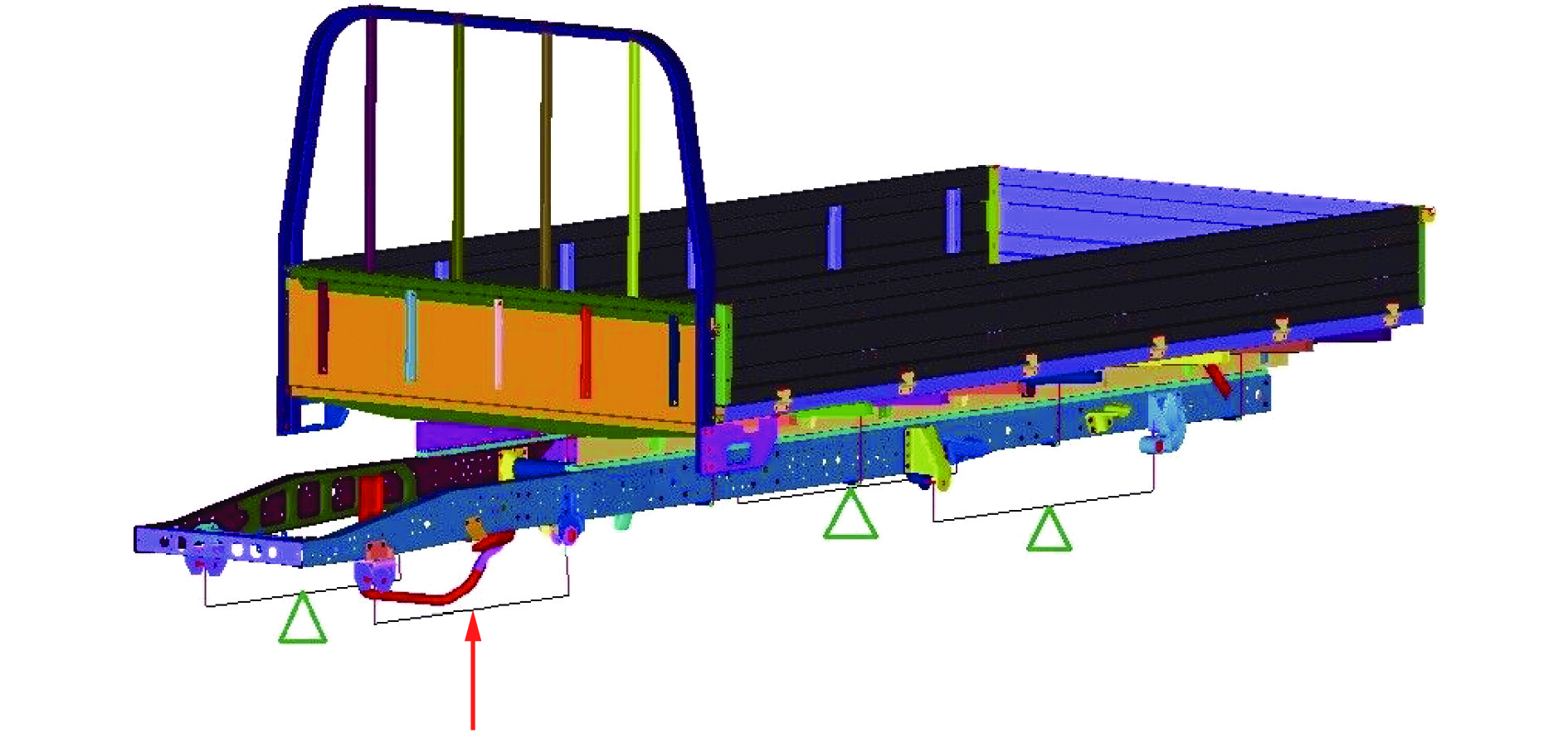

摘要: 为精确预测电动商用车车架疲劳寿命,通过建立车架有限元模型并进行强度仿真,确定疲劳失效危险位置。采集危险位置载荷谱,分析疲劳损伤值,采用Miner疲劳损伤理论和雨流计数法将应力谱时域信号转化成雨流矩阵,最终建立车架台架实验与道路试验疲劳寿命间的当量折算关系。设计实验方法并制作实验台架,对比道路试验与台架实验结果,验证了所建立当量折算关系的准确性。表明所建立的实验方法可提高车架疲劳寿命预测精度与可靠性,缩短道路疲劳试验周期。Abstract: In order to accurately predict the fatigue life of the electric commercial vehicle frame, the finite element model for frame was established and the strength simulation was carried out to determine the dangerous position of fatigue failure. Collecting the load spectrum of the fatigue risk position of the frame, and analyzing the fatigue damage value. The time domain signal of stress spectrum was transformed into rain flow matrix by rain flow counting method and Miner theory. The equivalent conversion relationship between the bench test and the road test of the fatigue life of the frame was established. Designing the experimental bench and method, the comparison between the road fatigue test and the bench fatigue test results shows that the equivalent conversion relation is valid, and the test method can improve the accuracy and reliability of the fatigue life prediction of the frame, shorten the time of the road fatigue test.

-

Key words:

- frame /

- simulation /

- bench test /

- methods validation /

- fatigue prediction

-

表 1 车架左侧纵梁损伤结果

编号 实验工况 单次损伤 1 −1°~1° 1.17×10−6 2 −2°~2° 1.89×10−6 3 −3°~3° 3.86×10−6 4 −4°~4° 9.77×10−6 -

[1] 徐华俊, 汤萍, 黄鹤. 汽车车门玻璃升降系统性能耐久试验机构设计[J]. 机械, 2018, 45(8): 40-44. doi: 10.3969/j.issn.1006-0316.2018.08.009XU H J, TANG P, HUANG H. Design of performance & durability test mechanism for car door glass lifting system[J]. Machinery, 2018, 45(8): 40-44. (in Chinese) doi: 10.3969/j.issn.1006-0316.2018.08.009 [2] 徐扬威. 某轿车前副车架疲劳试验台优化及试验研究[D]. 长春: 吉林大学, 2018XU Y W. Optimization and experimental study of fatigue test rig for a car front sub-frame[D]. Changchun: Jilin University, 2018. (in Chinese) [3] 吴江生. 基于汽车伪损伤等效的道路模拟试验方法应用研究[D]. 上海: 上海交通大学, 2016WU J S. Road simulation test method research based on vehilce pseudo-damage equivalent[D]. Shanghai: Shanghai Jiao Tong University, 2016. (in Chinese) [4] PETRONE N, MENEGHETTI G. Fatigue life prediction of lightweight electric moped frames after field load spectra collection and constant amplitude fatigue bench tests[J]. International Journal of Fatigue, 2019, 127: 564-575. doi: 10.1016/j.ijfatigue.2019.05.019 [5] BAKIR M, OZMEN B, DONERTAS C, et al. Correlation of simulation, test bench and rough road testing in terms of strength and fatigue life of a leaf spring[J]. Procedia Engineering, 2018, 213: 303-312. doi: 10.1016/j.proeng.2018.02.031 [6] SARANIK M, JÉZÉQUEL L, LENOIR D. Experimental and numerical study for Fatigue life prediction of bolted connection[J]. Procedia Engineering, 2013, 66: 354-368. doi: 10.1016/j.proeng.2013.12.090 [7] 田洪雷, 孙维光, 杨文超, 等. 大型结构部件多损伤点疲劳试验载荷等效方法研究[J]. 机械强度, 2021, 43(2): 434-441. doi: 10.16579/j.issn.1001.9669.2021.02.026TIAN H L, SUN W G, YANG W C, et al. Load equivalence test method for fatigue life of multi-site-damage large size structure part[J]. Journal of Mechanical Strength, 2021, 43(2): 434-441. (in Chinese) doi: 10.16579/j.issn.1001.9669.2021.02.026 [8] 杜建, 于人杰, 董国疆, 等. 变截面钢板弹簧台架疲劳载荷谱编辑研究[J]. 机械科学与技术, 2022, 41(3): 371-378. doi: 10.13433/j.cnki.1003-8728.20200347DU J, YU R J, DONG G J, et al. Study on fatigue bench load spectrum of leaf spring with variable section[J]. Mechanical Science and Technology for Aerospace Engineering, 2022, 41(3): 371-378. (in Chinese) doi: 10.13433/j.cnki.1003-8728.20200347 [9] 王璋, 罗燕, 肖介平, 等. 基于瞬态疲劳分析的汽车A柱上端开裂问题研究[J]. 北京汽车, 2020(5): 21-24. doi: 10.14175/j.issn.1002-4581.2020.05.005WANG Z, LUO Y, XIAO J P, et al. Crack problem of automobile a-pillar upper end based on transient fatigue analysis[J]. Beijing Automotive Engineering, 2020(5): 21-24. (in Chinese) doi: 10.14175/j.issn.1002-4581.2020.05.005 [10] 张泽俊, 刘宗成, 颜伏伍, 等. 基于实测道路谱的车身疲劳耐久性能改进[J]. 汽车零部件, 2020(4): 16-20. doi: 10.19466/j.cnki.1674-1986.2020.04.004ZHANG Z J, LIU Z C, YAN F W, et al. Durability improvement of BIW based on measured road spectrum[J]. Automobile Parts, 2020(4): 16-20. (in Chinese) doi: 10.19466/j.cnki.1674-1986.2020.04.004 [11] 李鹏, 谭志军, 倪城琳, 等. 基于台架试验的重型商用车车架研究[J]. 四川兵工学报, 2014, 35(7): 64-66.LI P, TAN Z J, NI C L, et al. Heavy-duty commercial vehicle frame based on the bench test[J]. Journal of Sichuan Ordnance, 2014, 35(7): 64-66. (in Chinese) [12] KEPKA M, KEPKA JR M, VÁCLAVÍK J, et al. Fatigue life of a bus structure in normal operation and in accelerated testing on special tracks[J]. Procedia Structural Integrity, 2019, 17: 44-50. doi: 10.1016/j.prostr.2019.08.007 [13] 嵇应凤. 矩当量概率Miner疲劳累积损伤准则[D]. 南京: 南京航空航天大学, 2014JI Y F. Statistical Miner's rule based on equivalent statistical moment of fatigue damage[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2014 (in Chinese) [14] 李斌潮, 唐靖, 殷之平. 基于频率雨流计数法的发动机振动疲劳载荷谱编制[J]. 航空工程进展, 2021, 12(1): 24-29. doi: 10.16615/j.cnki.1674-8190.2021.01.003LI B C, TANG J, YIN Z P. The load spectrum compilation of engine vibration fatigue based on frequency rain-flow counting method[J]. Advances in Aeronautical Science and Engineering, 2021, 12(1): 24-29. (in Chinese) doi: 10.16615/j.cnki.1674-8190.2021.01.003 [15] 赵霞军, 张伟, 赵铭. 机载电子设备随机振动频域法疲劳仿真分析[J]. 西安航空学院学报, 2019, 37(3): 48-52. doi: 10.3969/j.issn.1008-9233.2019.03.009ZHAO X J, ZHANG W, ZHAO M. Simulated analysis of random vibration fatigue of an electronic equipment based on frequency domain method[J]. Journal of Xi'an Aeronautical University, 2019, 37(3): 48-52. (in Chinese) doi: 10.3969/j.issn.1008-9233.2019.03.009 [16] 孙钰, 袁强, 温小飞, 等. 基于雨流计数法及Corten Dolan准则的轴承疲劳寿命预测[J]. 船舶工程, 2020, 42(1): 68-73.SUN Y, YUAN Q, WEN X F, et al. Prediction of bearing fatigue life based on rain-flow counting method and Corten Dolan criterion[J]. Ship Engineering, 2020, 42(1): 68-73. (in Chinese) [17] 秦瑶, 纵文斌, 张伟伟, 等. 基于雨流计数法的压缩机曲轴疲劳寿命分析[J]. 压缩机技术, 2015(6): 1-6. doi: 10.3969/j.issn.1006-2971.2015.06.001QIN Y, ZONG W B, ZHANG W W, et al. The compressor crankshaft fatigue life analysis based on rain flow count method[J]. Compressor Technology, 2015(6): 1-6. (in Chinese) doi: 10.3969/j.issn.1006-2971.2015.06.001 [18] RYCHLIK I, GUPTA S. Rain-flow fatigue damage for transformed Gaussian loads[J]. International Journal of Fatigue, 2007, 29(3): 406-420. doi: 10.1016/j.ijfatigue.2006.05.006 [19] 徐敏敏, 杨春兰, 段月星, 等. 基于雨流计数法的疲劳寿命预测[J]. 机械设计与研究, 2016, 32(5): 184-187. doi: 10.13952/j.cnki.jofmdr.2016.0217XU M M, YANG C L, DUAN Y X, et al. Fatigue life prediction based on rain-flow counting method[J]. Machine Design & Research, 2016, 32(5): 184-187. (in Chinese) doi: 10.13952/j.cnki.jofmdr.2016.0217 [20] 王陶, 王良模, LI T, 等. 基于真实路谱再现的商用车驾驶室疲劳破坏[J]. 华中科技大学学报(自然科学版), 2017, 45(5): 61-66. doi: 10.13245/j.hust.170512WANG T, WANG L M, LI T, et al. Fatigue failure assessment based on loading reproduction for commercial vehicle cab[J]. Journal of Huazhong University of Science & Technology (Natural Science Edition), 2017, 45(5): 61-66. (in Chinese) doi: 10.13245/j.hust.170512 [21] 张冰战, 牛占占, 邰丽君. 实测载荷谱下传动轴疲劳寿命研究[J]. 机械设计与制造, 2020(10): 119-122. doi: 10.3969/j.issn.1001-3997.2020.10.027ZHANG B Z, NIU Z Z, TAI L J. Fatigue life research of transmission shaft based on testing load[J]. Machinery Design & Manufacture, 2020(10): 119-122. (in Chinese) doi: 10.3969/j.issn.1001-3997.2020.10.027 -

下载:

下载: