A Method for Diagnosing Faults of Hydraulic Pump and Accumulator with 1D-CNN and Multi-sensor Information Fusion

-

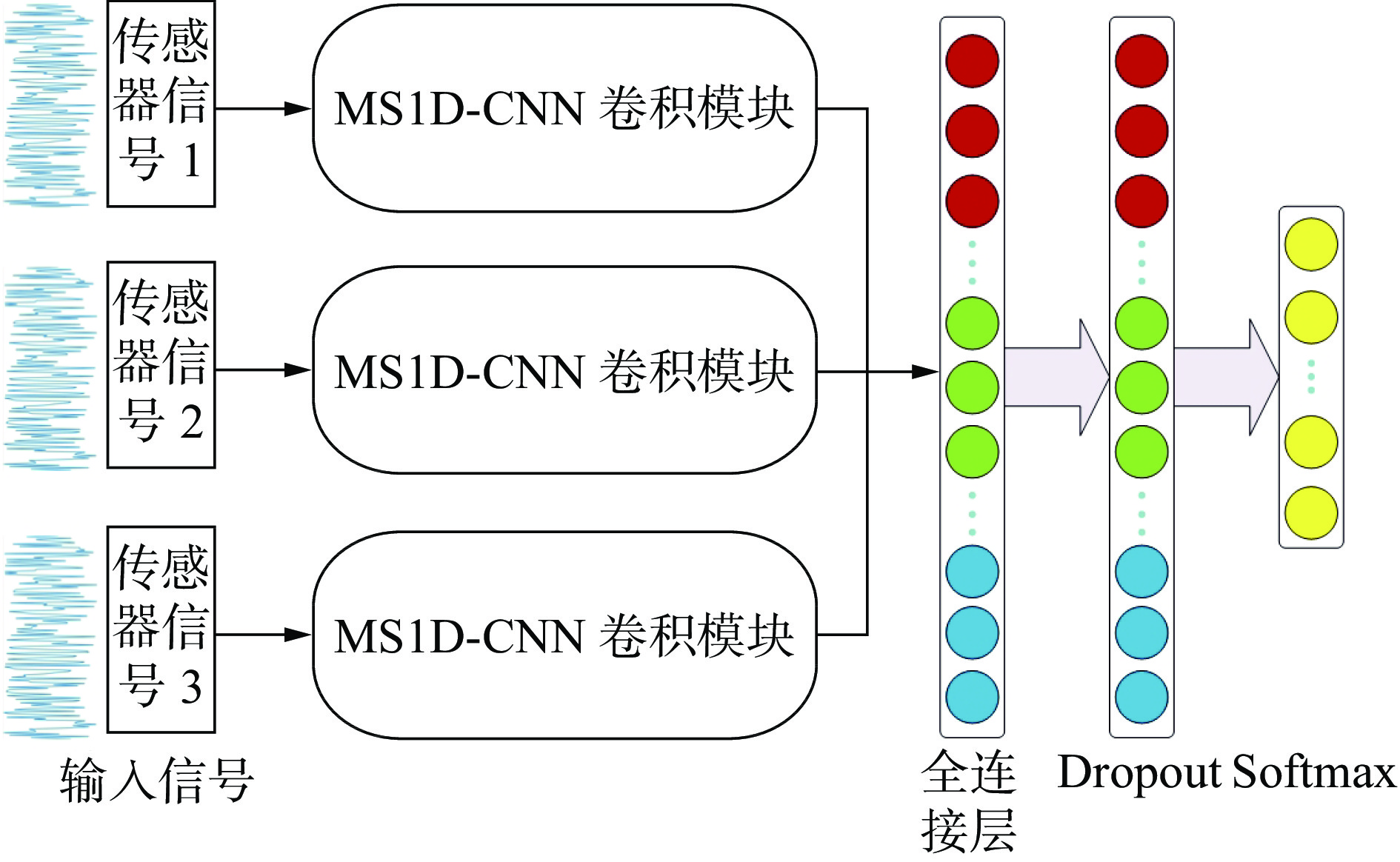

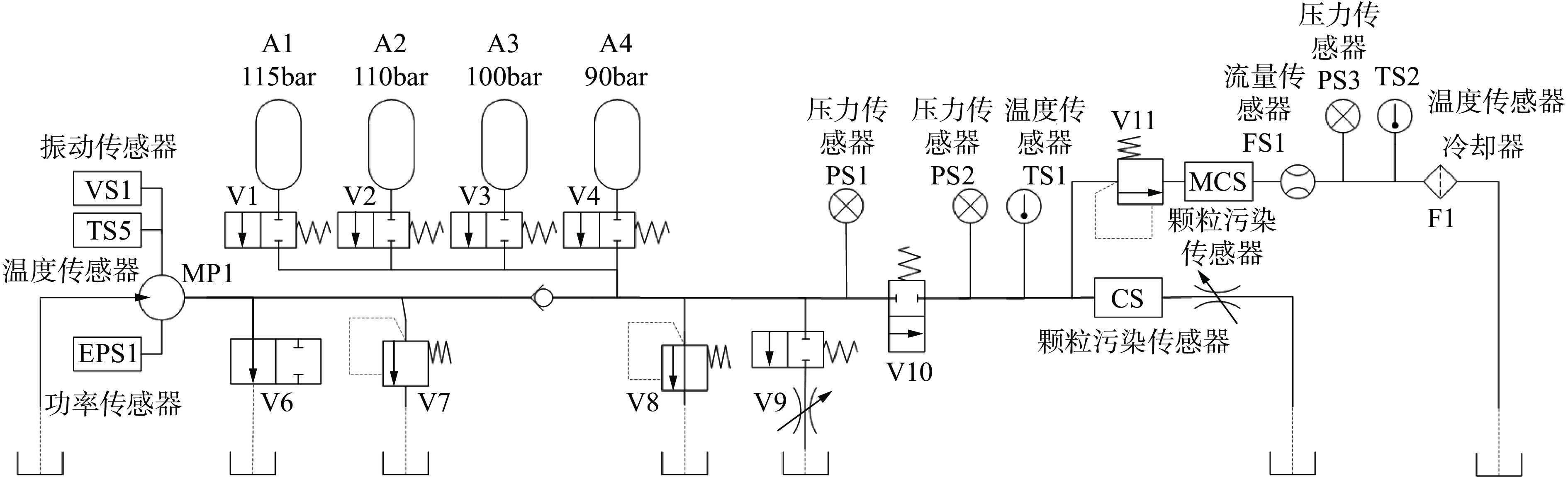

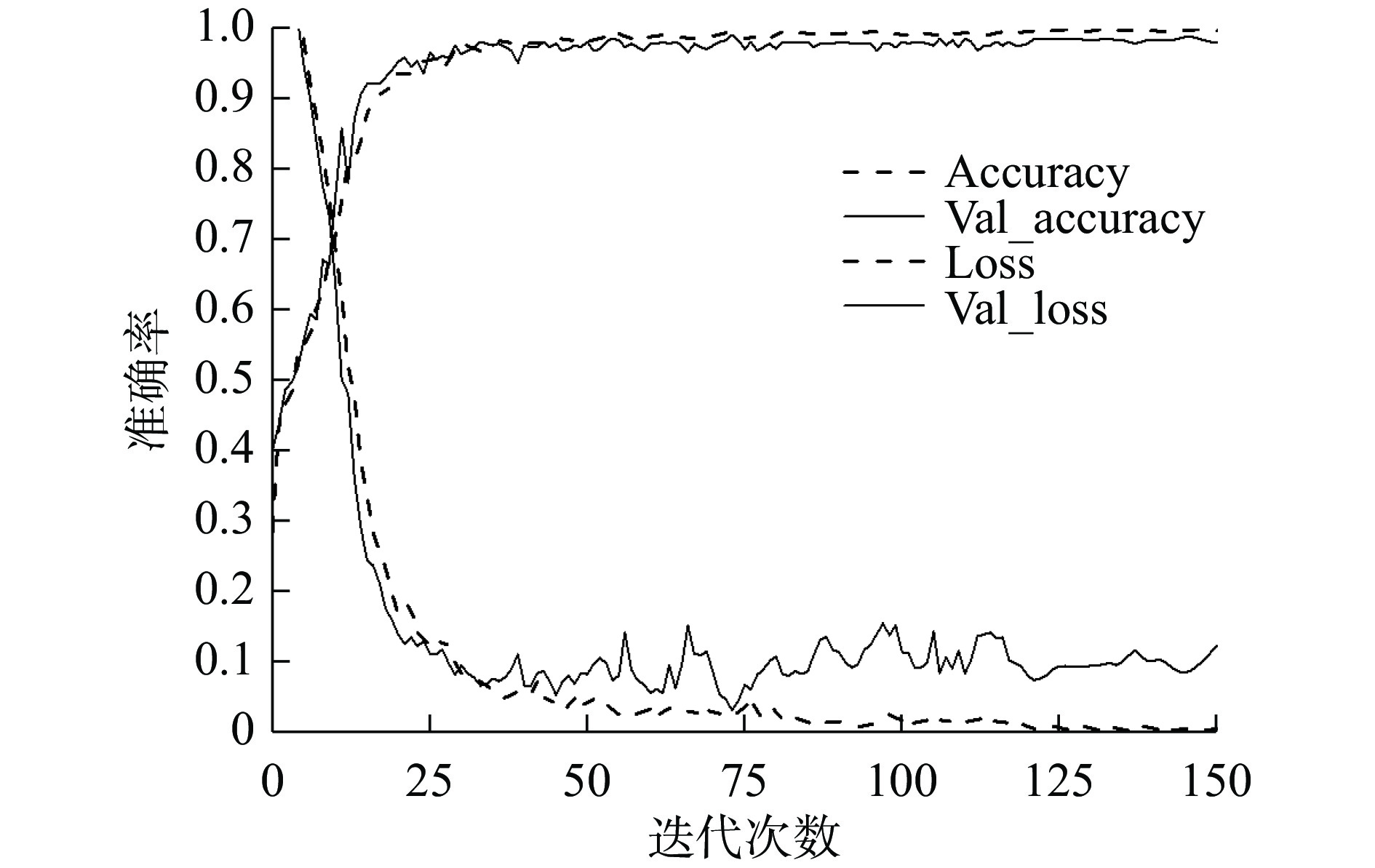

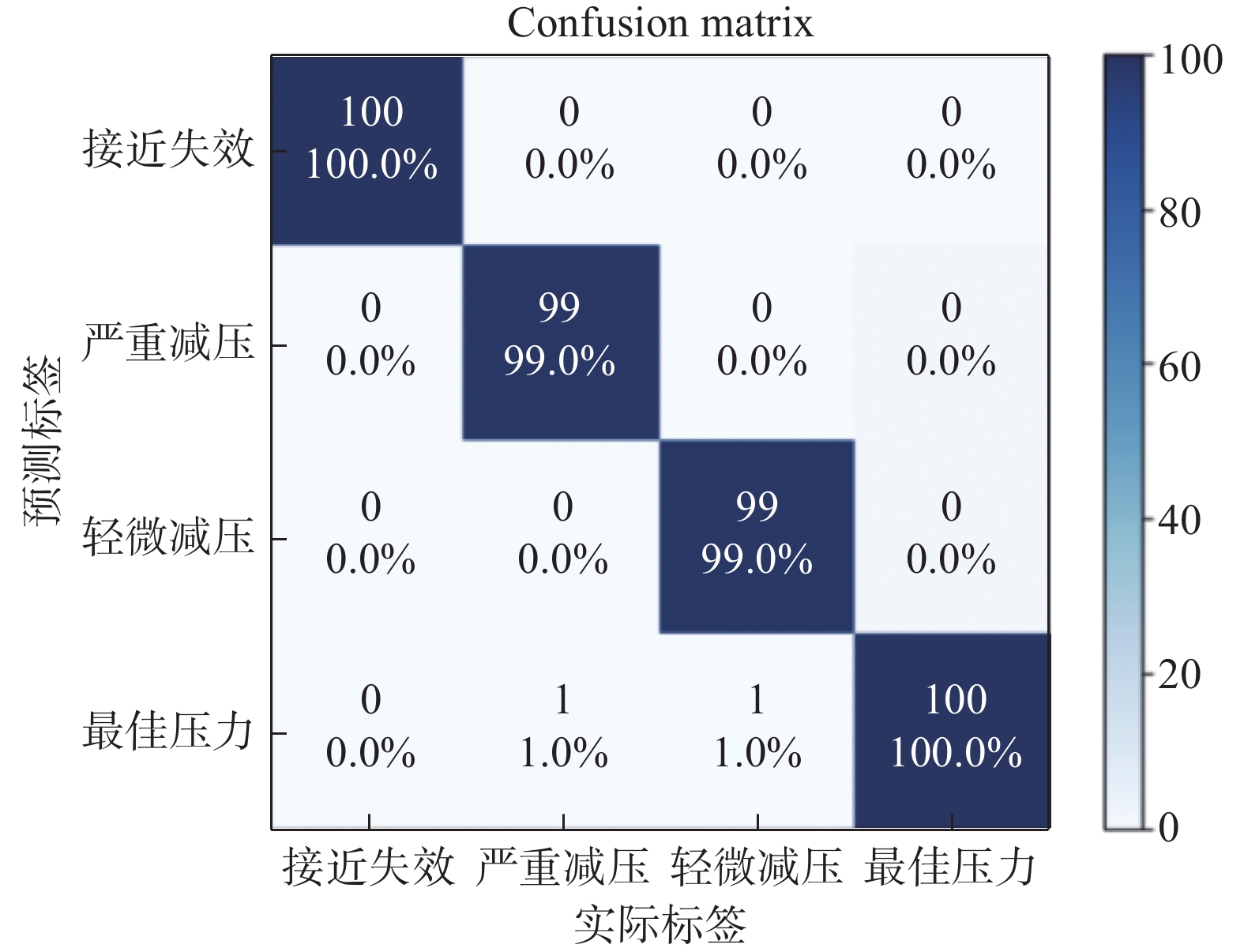

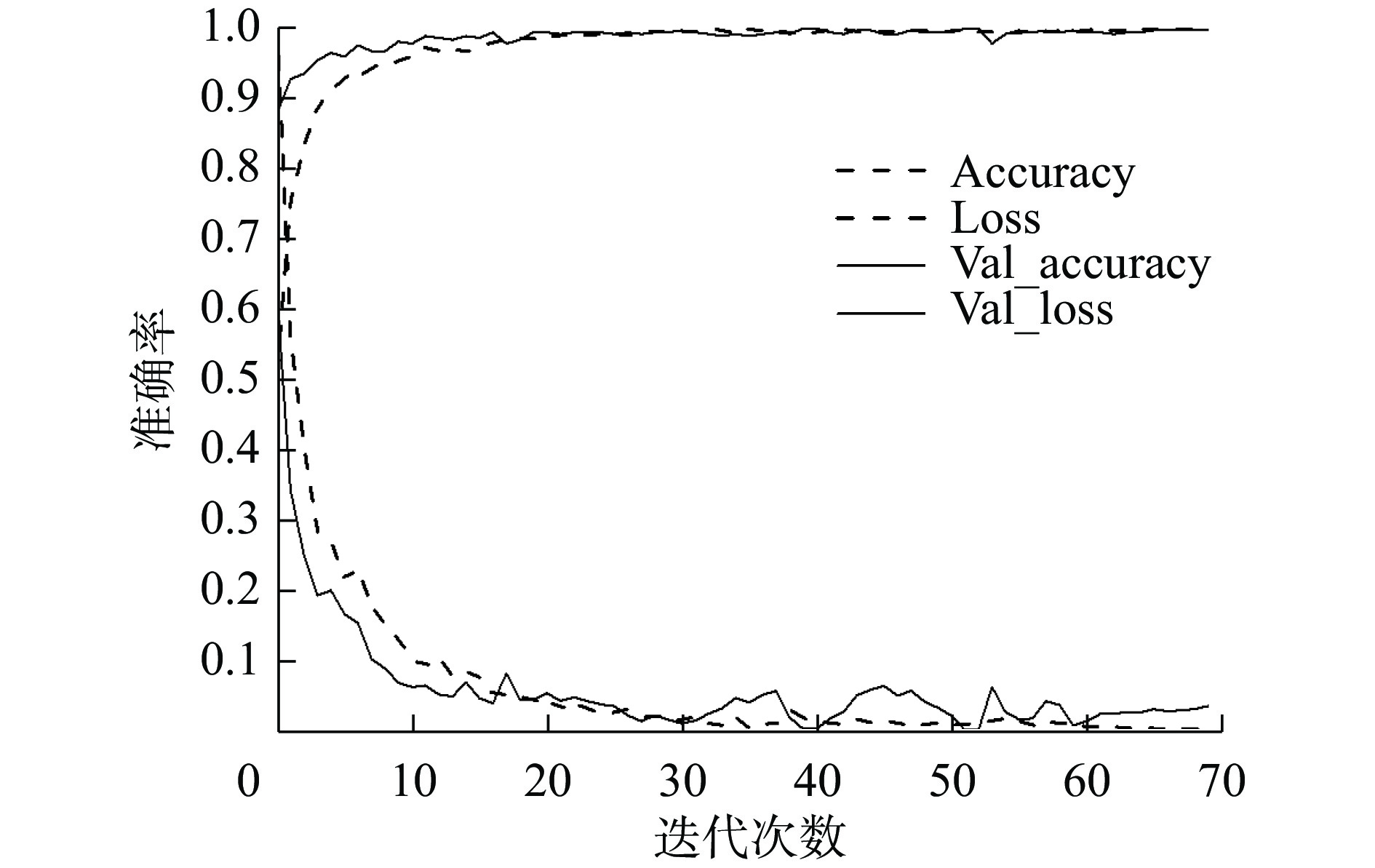

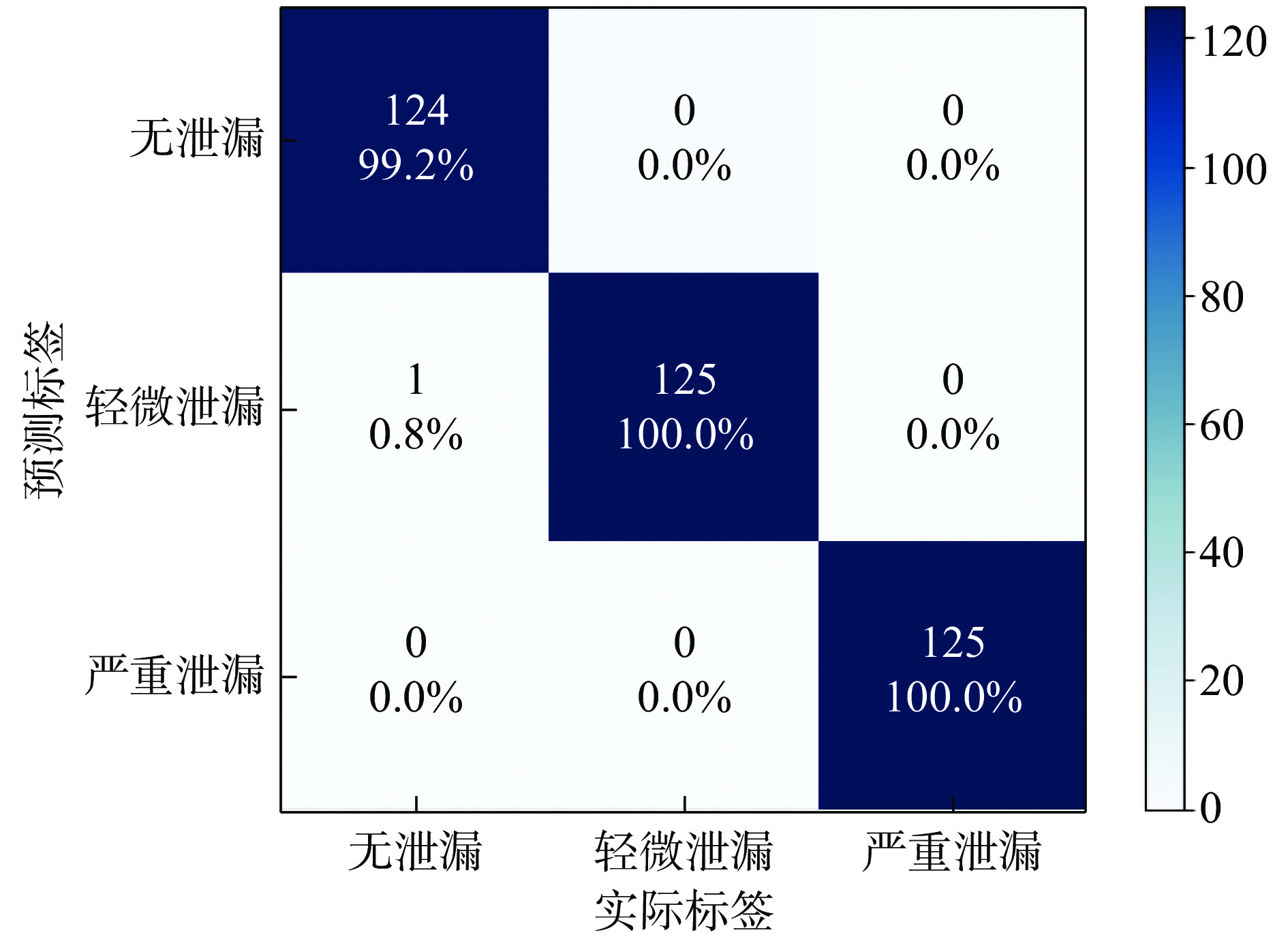

摘要: 针对液压信号复杂且难以诊断的难点,提出一种多尺度一维卷积神经网络与多传感器信息融合的深度神经网络模型(MS1D-CNN-MSIF)对液压泵与蓄能器进行故障诊断。在提出方法中,采用不同大小的卷积核对故障信号进行多尺度特征提取;然后使用多传感器信息融合策略将多个传感器的特征信号进行融合,最后使用Softmax进行分类识别。诊断蓄能器压力状态与液压泵泄漏状态的实验结果表明,与支持向量机、堆栈自编码、深度置信网络比较,提出模型具有更好的故障诊断性能,蓄能器识别精度可达99.50%,液压泵识别精度可达99.73%。Abstract: Because it is difficult to diagnosecomplex hydraulic signals, the multi-scale one-dimensional convolutional neural network and multi-sensor information fusion (MS1D-CNN-MSIF) deep neural network model is proposed to diagnose the fault of hydraulic pump and accumulator. Under the proposed method, the convolution check signals of different sizes are used to extract multi-scale features. The multi-sensor information fusion strategy is used to fuse the characteristic signals of multiple sensors, which are thenclassified and recognized with the Softmax software. The experimental results on diagnosing the accumulator pressure state and hydraulic pump leakage state show that, compared with the support vector machine, stack self coding and deep confidence network, the proposed method has a better fault diagnosis performance and that the method’s recognition accuracy of the accumulator and hydraulic pump reaches 99.50% and 99.73% respectively.

-

Key words:

- 1D-CNN /

- multiscale convolution /

- multi sensor information fusion /

- hydraulic pump /

- accumulator /

- deep neural network

-

表 1 蓄能器样本数据

蓄能器

状态样本总

数量测试样本

数量原始状态

标签故障

标签独热

编码最佳压力 350 100 130 3 0001 轻微减压 350 100 115 2 0010 严重减压 350 100 100 1 0100 接近失效 350 100 90 0 1000 表 2 蓄能器章台识别结果对比

传感器数据源 模型 平均识别准确率/% 模型 平均识别准确率/% PS1 1D-CNN 96.30 MS1D-CNN 98.50 PS2 1D-CNN 88.52 MS1D-CNN 91.67 PS3 1D-CNN 84.62 MS1D-CNN 90.55 PS1、PS2、PS3 ELM 84.77 SSAE 98.30 PS1、PS2、PS3 SVM 93.25 MS1D-CNN-MSIF 99.20 表 3 液压泵样本数据

液压泵

状态样本总

数量测试样本

数量原始状态

标签故障

标签独热

编码无泄漏 450 125 0 0 100 轻微泄漏 450 125 1 1 010 严重泄漏 450 125 2 2 001 表 4 液压泵状态识别结果对比

传感器数据源 模型 平均识别准确率/% 模型 平均识别准确率/% FS1 1D-CNN 96.43 MS1D-CNN 99.35 PS2 1D-CNN 80.50 MS1D-CNN 81.36 PS3 1D-CNN 88.29 MS1D-CNN 91.17 PS1、PS2、PS3、FS1 ELM 87.65 SVM 91.50 PS1、PS2、PS3、FS1 SSAE 97.41 DBN 98.77 PS2、PS3、FS1 MS1D-CNN-MSIF 99.79 -

[1] 孙群丽, 刘长良, 甄成刚. 隐马尔科夫模型在滚动轴承故障诊断中的应用[J]. 热能动力工程, 2018, 33(10): 95-100. doi: 10.16146/j.cnki.rndlgc.2018.10.014SUN Q L, LIU C L, ZHEN C G. Application of hidden Markov model in fault diagnosis of rolling bearing[J]. Journal of Engineering for Thermal Energy and Power, 2018, 33(10): 95-100. (in Chinese) doi: 10.16146/j.cnki.rndlgc.2018.10.014 [2] 刘金刚, 周晓群, 王凯. 基于PCA和SVM的盾构液压系统故障诊断[J]. 计算机仿真, 2017, 34(12): 426-430. doi: 10.3969/j.issn.1006-9348.2017.12.094LIU J G, ZHOU X Q, WANG K. Fault diagnosis of hydraulic system for shield machine based on PCA and SVM[J]. Computer Simulation, 2017, 34(12): 426-430. (in Chinese) doi: 10.3969/j.issn.1006-9348.2017.12.094 [3] 张捍东, 陶刘送. 粒子群优化BP算法在液压系统故障诊断中应用[J]. 系统仿真学报, 2016, 28(5): 1186-1190. doi: 10.16182/j.cnki.joss.2016.05.025ZHANG H D, TAO L S. Application of PSO-BP algorithm in hydraulic system fault diagnosis[J]. Journal of System Simulation, 2016, 28(5): 1186-1190. (in Chinese) doi: 10.16182/j.cnki.joss.2016.05.025 [4] 徐活耀, 陈里里, 何颖. 基于深度置信网络的液压泵内泄漏状态的诊断[J]. 机床与液压, 2020, 48(16): 212-217. doi: 10.3969/j.issn.1001-3881.2020.16.042XU H Y, CHEN L L, HE Y. Research on diagnosing method of internal leakage state of hydraulic pump based on deep belief network[J]. Machine Tool & Hydraulics, 2020, 48(16): 212-217. (in Chinese) doi: 10.3969/j.issn.1001-3881.2020.16.042 [5] 杜名喆, 王宝中. 基于经验小波分解和卷积神经网络的液压泵故障诊断[J]. 液压与气动, 2020(1): 163-170. doi: 10.11832/j.issn.1000-4858.2020.01.027DU M Z, WANG B Z. Fault diagnosis of hydraulic pump based on empirical wavelet transform and convolutional neural network[J]. Chinese Hydraulics & Pneumatics, 2020(1): 163-170. (in Chinese) doi: 10.11832/j.issn.1000-4858.2020.01.027 [6] 陈里里, 何颖, 董绍江. 基于深度神经网络的液压泵泄漏状态识别[J]. 仪器仪表学报, 2020, 41(4): 86-94.CHEN L L, HE Y, DONG S J. Recognition of hydraulic pump leakage status based on deep neural network[J]. Chinese Journal of Scientific Instrument, 2020, 41(4): 86-94. (in Chinese) [7] HOANG D T, KANG H J. Rolling element bearing fault diagnosis using convolutional neural network and vibration image[J]. Cognitive Systems Research, 2019, 53: 42-50. doi: 10.1016/j.cogsys.2018.03.002 [8] LIANG P F, DENG C, WU J, et al. Compound fault diagnosis of gearboxes via multi-label convolutional neural network and wavelet transform[J]. Computers in Industry, 2019, 113: 103132. doi: 10.1016/j.compind.2019.103132 [9] 姜保军, 王帅杰, 董绍江. 基于深度学习的液压监测系统蓄能装置故障诊断[J]. 组合机床与自动化加工技术, 2019(9): 89-92. doi: 10.13462/j.cnki.mmtamt.2019.09.022JIANG B J, WANG S J, DONG S J. Fault diagnosis of accumulators in hydraulic monitoring system based on deep learning[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2019(9): 89-92. (in Chinese) doi: 10.13462/j.cnki.mmtamt.2019.09.022 [10] 李思琦, 蒋志坚. 基于EEMD-CNN的滚动轴承故障诊断方法[J]. 机械强度, 2020, 42(5): 1033-1038. doi: 10.16579/j.issn.1001.9669.2020.05.003LI S Q, JIANG Z J. Fault diagnosis method of rolling bearing based on EEMD-CNN[J]. Journal of Mechanical Strength, 2020, 42(5): 1033-1038. (in Chinese) doi: 10.16579/j.issn.1001.9669.2020.05.003 [11] KIRANYAZ S, AVCI O, ABDELJABER O, et al. 1D convolutional neural networks and applications: A survey[J]. Mechanical Systems and Signal Processing, 2021, 151: 107398. doi: 10.1016/j.ymssp.2020.107398 [12] LI S, WANG H Q, SONG L Y, et al. An adaptive data fusion strategy for fault diagnosis based on the convolutional neural network[J]. Measurement, 2020, 165: 108122. doi: 10.1016/j.measurement.2020.108122 [13] 吴定海, 任国全, 王怀光, 等. 基于卷积神经网络的机械故障诊断方法综述[J]. 机械强度, 2020, 42(5): 1024-1032.WU D H, REN G Q, WANG H G, et al. The review of mechanical fault diagnosis methods based on convolutional neural network[J]. Journal of Mechanical Strength, 2020, 42(5): 1024-1032. (in Chinese) [14] WU C Z, JIANG P C, DING C, et al. Intelligent fault diagnosis of rotating machinery based on one-dimensional convolutional neural network[J]. Computers in Industry, 2019, 108: 53-61. doi: 10.1016/j.compind.2018.12.001 [15] WANG X, MAO D X, LI X D. Bearing fault diagnosis based on vibro-acoustic data fusion and 1D-CNN network[J]. Measurement, 2021, 173: 108518. doi: 10.1016/j.measurement.2020.108518 [16] WANG H Q, LI S, SONG L Y, et al. A novel convolutional neural network based fault recognition method via image fusion of multi-vibration-signals[J]. Computers in Industry, 2019, 105: 182-190. doi: 10.1016/j.compind.2018.12.013 [17] HUANG W Y, CHENG J S, YANG Y, et al. An improved deep convolutional neural network with multi-scale information for bearing fault diagnosis[J]. Neurocomputing, 2019, 359: 77-92. doi: 10.1016/j.neucom.2019.05.052 [18] WANG J Y, MIAO J G, WANG J L, et al. Fault diagnosis of electrohydraulic actuator based on multiple source signals: An experimental investigation[J]. Neurocomputing, 2020, 417: 224-238. doi: 10.1016/j.neucom.2020.05.102 [19] 朱丹宸, 张永祥, 潘洋洋, 等. 基于多传感器信号和卷积神经网络的滚动轴承故障诊断[J]. 振动与冲击, 2020, 39(4): 172-178.ZHU D C, ZHANG Y X, PAN Y Y, et al. Fault diagnosis for rolling element bearings based on multi-sensor signals and CNN[J]. Journal of Vibration and Shock, 2020, 39(4): 172-178. (in Chinese) [20] HELWIG N, PIGNANELLI E, SCHÜTZE A. Condition monitoring of a complex hydraulic system using multivariate statistics[C]//2015 IEEE International Instrumentation and Measurement Technology Conference (I2MTC) Proceedings. Pisa: IEEE, 2015: 210-215 -

下载:

下载: