Position Error Modeling and Compensation for Robot Bonnet Polishing

-

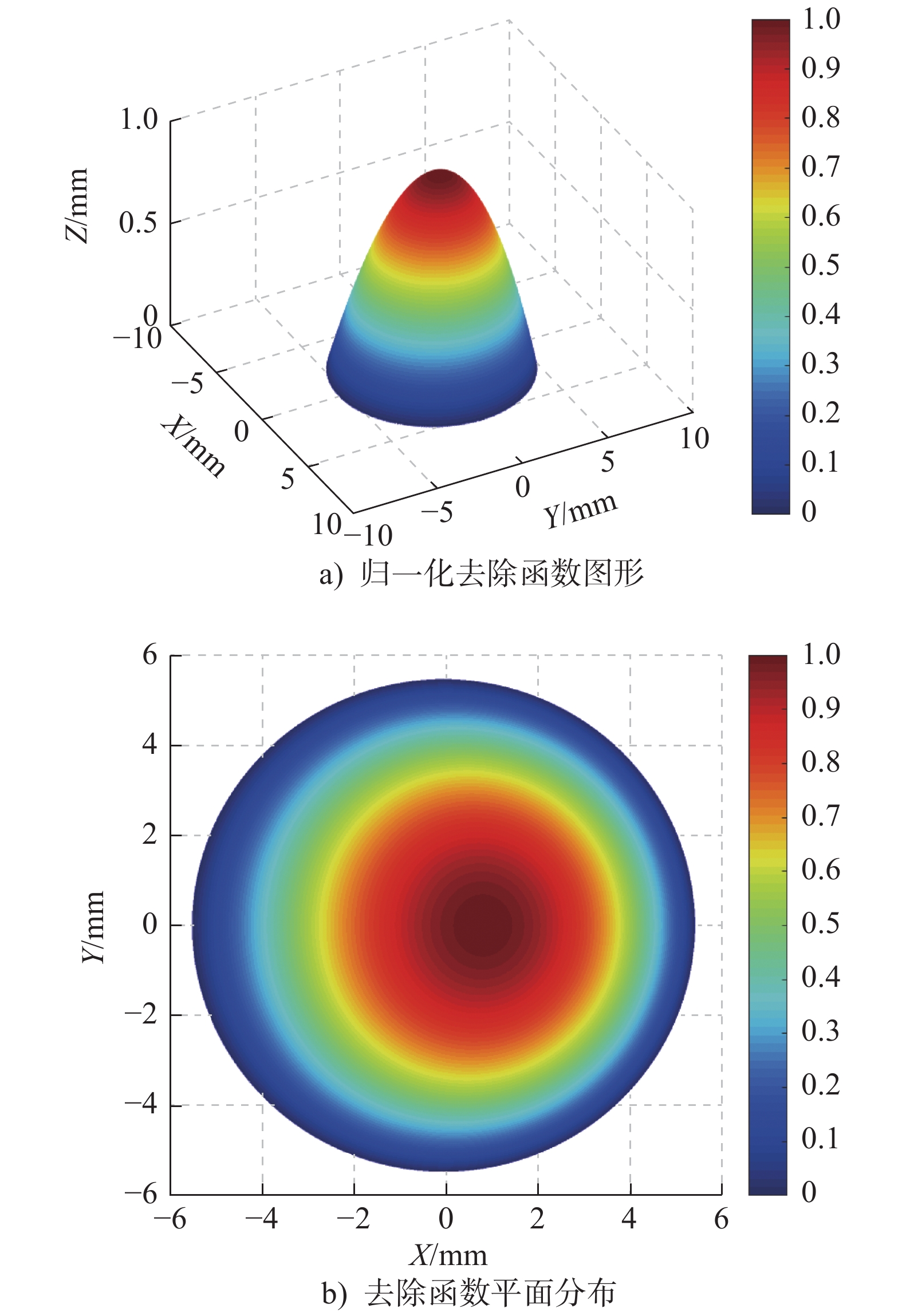

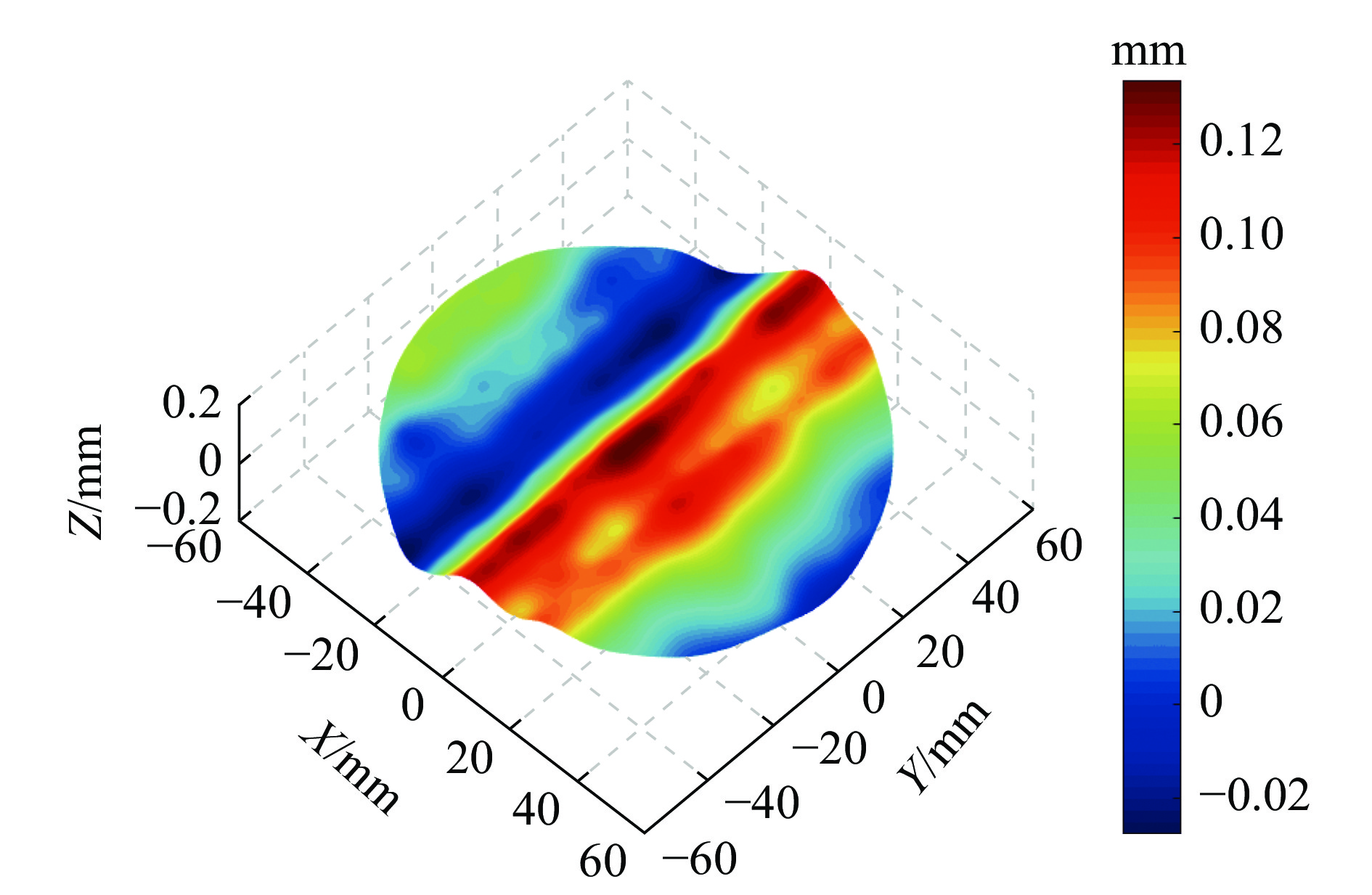

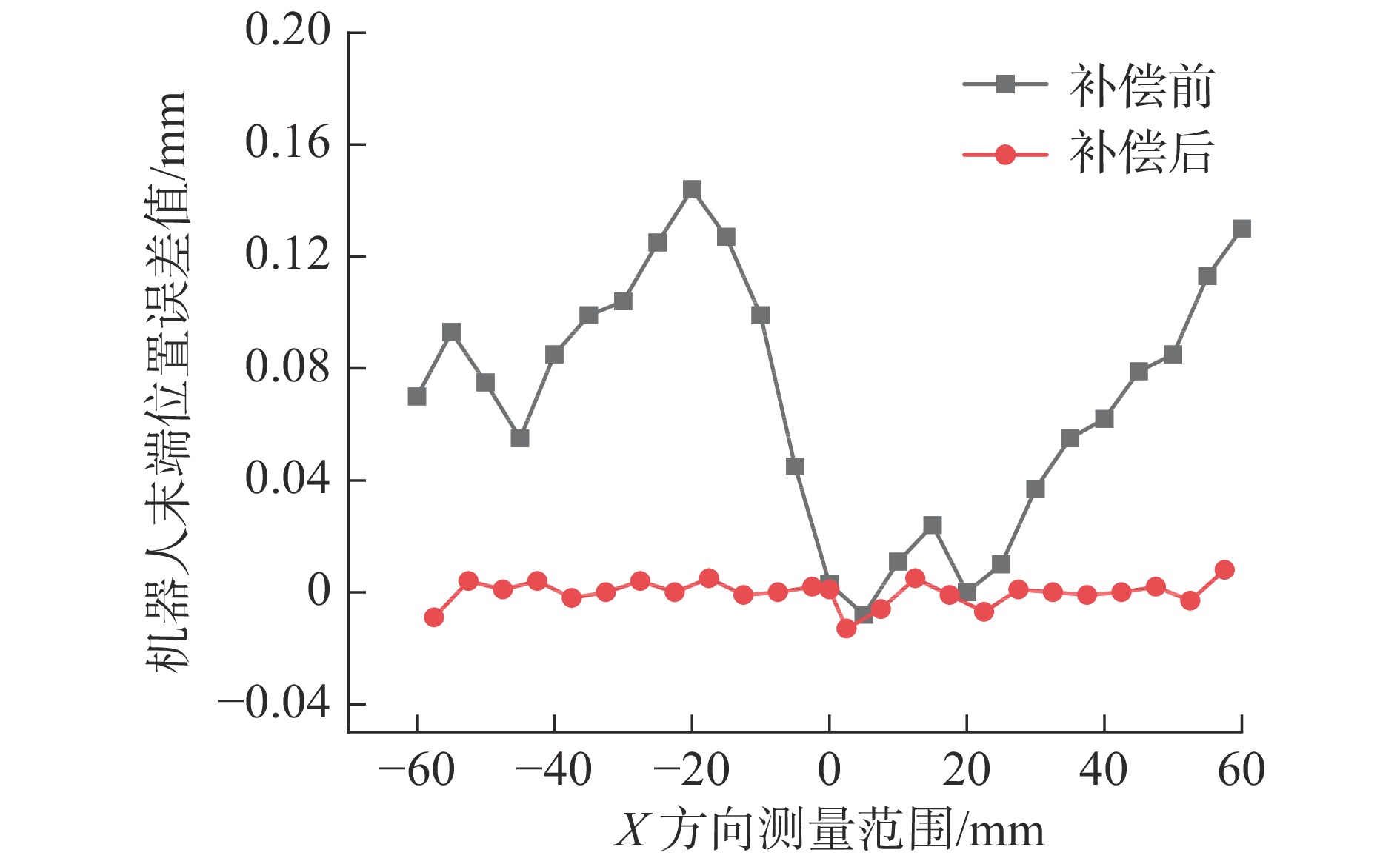

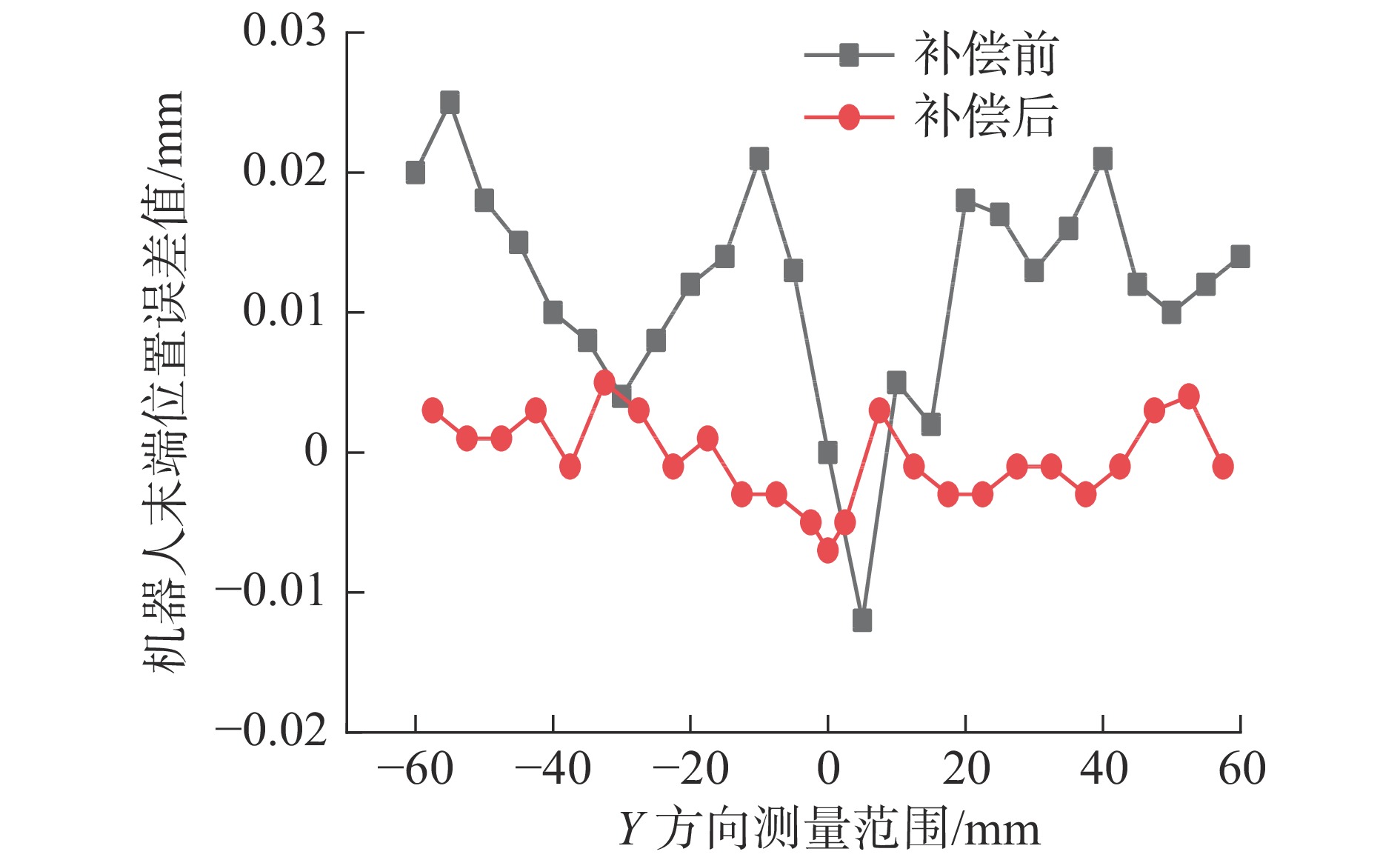

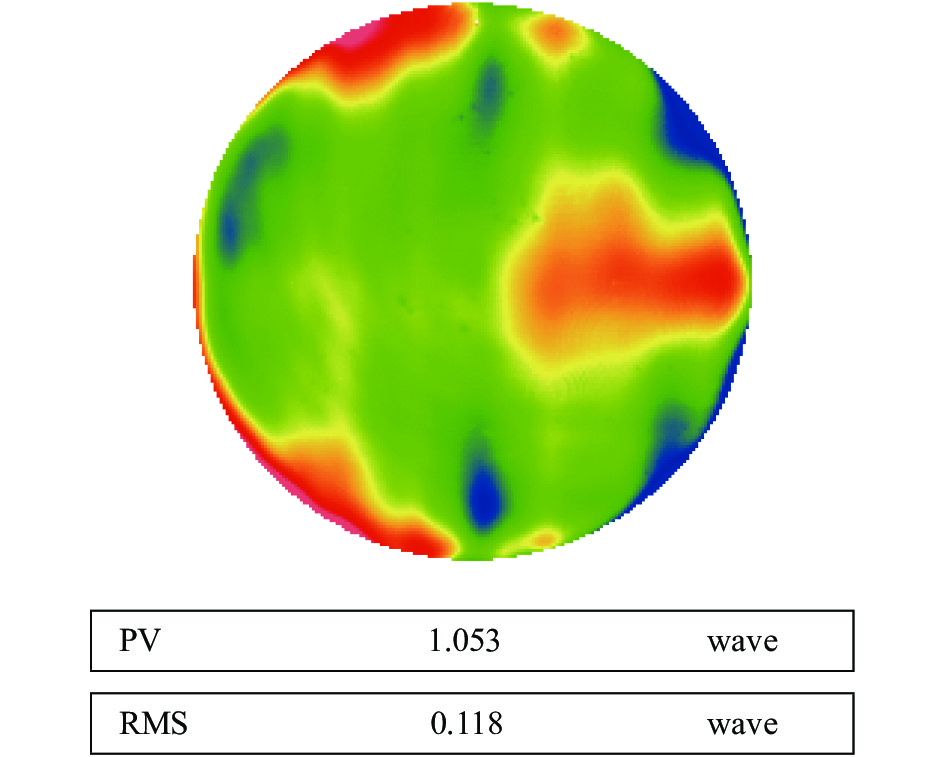

摘要: 针对机器人气囊抛光中抛光压力波动的问题,分析影响抛光压力稳定的因素,提出误差补偿法来降低抛光压力波动对加工面形的影响。首先,分析气囊抛光的运动过程,根据Preston方程建立材料去除函数模型,使用MATLAB对去除函数进行仿真分析。然后针对由机器人末端位置波动引入的系统误差,提出网格式误差补偿法,根据误差数据模型对加工点位进行即时修正,从而降低由机器人引入的抛光压力波动误差。实验数据表明:补偿后机器人末端位置X,Y方向误差波动值分别下降了86.2%,67.6%,机器人末端位置精度明显提高,最终加工面形精度的RMS为0.118λ。证明了该方法能够有效的减小抛光压力的波动,改善加工面形质量。Abstract: To remove polishing pressure fluctuation during robot bonnet polishing, the factors affecting the stability of polishing pressure were analyzed. The error compensation method was proposed to reduce the influence of polishing pressure fluctuation on the machining surface. Firstly, according to the motion model of bonnet polishing, the motion process was analyzed, and the material removal function model was established according to the Preston equation. The removal function was simulated and analyzed with the MATLAB. Then, in view of the system error caused by the end position fluctuation of the robot and according to the error data model, the machining point position is corrected immediately so as to reduce the polishing pressure fluctuation error introduced by the robot. The experimental results show that the error values in X and Y directions of the end position of the robot after compensation decrease by 86.2 % and 67.6 % respectively. The accuracy of the robot′s end position is significantly improved, and the RMS of final machining surface accuracy is 0.118λ. It is proved that the error compensation method can effectively reduce the fluctuation of polishing pressure and improve the quality of the machining surface.

-

Key words:

- industrial robot /

- bonnet polishing /

- removal function /

- error compensation /

- polishing force

-

表 1 气囊抛光实验参数表

参数 数值 磨头转速/(r·min−1) 300 充气压力/MPa 0.1 进动角/(°) 15 抛光压力/N 10 抛光液种类 氧化铈 抛光液浓度/% 10 栅格间距h/mm 0.5 -

[1] 孟晓辉, 王永刚, 李文卿, 等. Ф420 mm高次非球面透镜的加工与检测[J]. 光学 精密工程, 2016, 24(12): 3068-3075. doi: 10.3788/OPE.20162412.3068MENG X H, WANG Y G, LI W Q, et al. Fabricating and testing of Ф420 mm high-order aspheric lens[J]. Optics and Precision Engineering, 2016, 24(12): 3068-3075. (in Chinese) doi: 10.3788/OPE.20162412.3068 [2] 温凌峰, 姚亚斌, 周启飚, 等. 离轴非球面反射镜设计与超精密加工技术[J]. 新技术新工艺, 2017(2): 75-78. doi: 10.16635/j.cnki.1003-5311.2017.02.022WEN L F, YAO Y B, ZHOU Q B, et al. Design and technology of ultra-precision machining for off-axis aspheric mirror[J]. New Technology & New Process, 2017(2): 75-78. (in Chinese) doi: 10.16635/j.cnki.1003-5311.2017.02.022 [3] 陈登铃, 彭云峰, 王振忠, 等. 大口径光学非球面超精密磨削装备与技术[J]. 航空制造技术, 2020, 63(8): 46-53. doi: 10.16080/j.issn1671-833x.2020.08.046CHEN D L, PENG Y F, WANG Z Z, et al. Ultra-precision grinding equipment and technology for large-size optical aspheric surface components[J]. Aeronautical Manufacturing Technology, 2020, 63(8): 46-53. (in Chinese) doi: 10.16080/j.issn1671-833x.2020.08.046 [4] 王朋, 叶斯哲, 张昊, 等. 非球面气囊抛光的材料均匀去除研究[J]. 航空制造技术, 2019, 62(9): 68-73. doi: 10.16080/j.issn1671-833x.2019.09.068WANG P, YE S Z, ZHANG H, et al. Uniform material removal of aspherical surface by bonnet polishing[J]. Aeronautical Manufacturing Technology, 2019, 62(9): 68-73. (in Chinese) doi: 10.16080/j.issn1671-833x.2019.09.068 [5] 王飞, 张健, 彭利荣, 等. 气囊抛光过程的运动精度控制[J]. 光学 精密工程, 2015, 23(8): 2220-2228. doi: 10.3788/OPE.20152308.2220WANG F, ZHANG J, PENG L R, et al. Motion-precision control in bonnet-polishing[J]. Optics and Precision Engineering, 2015, 23(8): 2220-2228. (in Chinese) doi: 10.3788/OPE.20152308.2220 [6] WALKER D, DUNN C, YU G Y, et al. The role of robotics in computer controlled polishing of large and small optics[C]//Proceedings of SPIE 9575, Optical Manufacturing and Testing XI. San Diego: SPIE, 2015: 95750B [7] MÁRQUEZ J J, PÉREZ J M, RÍOS J, et al. Process modeling for robotic polishing[J]. Journal of Materials Processing Technology, 2005, 159(1): 69-82. doi: 10.1016/j.jmatprotec.2004.01.045 [8] KALTSOUKALAS K, MAKRIS S, CHRYSSOLOURIS G, et al. On generating the motion of industrial robot manipulators[J]. Robotics and Computer-Integrated Manufacturing, 2015, 32: 65-71. doi: 10.1016/j.rcim.2014.10.002 [9] 黄智, 周涛, 吴湘, 等. 机器人气囊抛光SiC光学元件加工特性研究[J]. 西安交通大学学报, 2020, 54(12): 22-29.HUANG Z, ZHOU T, WU X, et al. SiC optical element processing properties under robot bonnet polishing[J]. Journal of Xi′an Jiaotong University, 2020, 54(12): 22-29. (in Chinese) [10] WU X, HUANG Z, WAN Y J, et al. A novel force-controlled spherical polishing tool combined with self-rotation and co-rotation motion[J]. IEEE Access, 2020, 8: 108191-108200. doi: 10.1109/ACCESS.2020.2997968 [11] CHENG K, SHAO Y Z, JADVA M, et al. Development of the improved Preston equation for abrasive flow machining of aerofoil structures and components[J]. Proceedings of the Institution of Mechanical Engineers, Part J:Journal of Engineering Tribology, 2019, 233(9): 1397-1404. doi: 10.1177/1350650118817694 [12] 宋剑锋, 姚英学, 谢大纲, 等. 气囊抛光工艺参数的正交实验分析[J]. 光学技术, 2009, 35(2): 315-318. doi: 10.3321/j.issn:1002-1582.2009.02.003SONG J F, YAO Y X, XIE D G, et al. Orthogonal experiment and analysis on polishing parameters of bonnet polishing[J]. Optical Technique, 2009, 35(2): 315-318. (in Chinese) doi: 10.3321/j.issn:1002-1582.2009.02.003 [13] RAO Z M, GUO B, ZHANG Q L, et al. Form error compensation in soft wheel polishing by contact force optimization[J]. The International Journal of Advanced Manufacturing Technology, 2017, 91(1-4): 1197-1207. doi: 10.1007/s00170-016-9798-3 [14] 曾灿灿, 倪磊, 倪晋. 机器人气囊抛光工具的参数标定[J]. 机械科学与技术, 2020, 39(7): 1060-1065. doi: 10.13433/j.cnki.1003-8728.20190245ZENG C C, NI L, NI J, et al. A method for calibrating parameters of robot airbag polishing tool[J]. Mechanical Science and Technology for Aerospace Engineering, 2020, 39(7): 1060-1065. (in Chinese) doi: 10.13433/j.cnki.1003-8728.20190245 [15] 徐连香, 郭春红, 刘薇娜, 等. 非球面数控磨床的误差建模与补偿研究[J]. 机床与液压, 2017, 45(7): 64-69. doi: 10.3969/j.issn.1001-3881.2017.07.016XU L X, GUO C H, LIU W N, et al. Error modeling and compensation research of aspheric CNC grinding machine[J]. Machine Tool & Hydraulics, 2017, 45(7): 64-69. (in Chinese) doi: 10.3969/j.issn.1001-3881.2017.07.016 [16] 朱江新, 刘吉刚, 田硕, 等. 两步误差补偿法提高工业机器人绝对定位精度[J]. 机械科学与技术, 2020, 39(4): 547-553. doi: 10.13433/j.cnki.1003-8728.20190178ZHU J X, LIU J G, TIAN S, et al. Two-step error compensation method for improving absolute positioning accuracy of industrial robots[J]. Mechanical Science and Technology for Aerospace Engineering, 2020, 39(4): 547-553. (in Chinese) doi: 10.13433/j.cnki.1003-8728.20190178 [17] 李洪玉, 张伟, 于国彧. 空间光学元件超精密气囊抛光的去除特性研究[J]. 光学学报, 2009, 29(3): 811-817. doi: 10.3788/AOS20092903.0811LI H Y, ZHANG W, YU G Y. Removing characteristics of ultraprecise bonnet polishing on spatial optics elements[J]. Acta Optica Sinica, 2009, 29(3): 811-817. (in Chinese) doi: 10.3788/AOS20092903.0811 -

下载:

下载: