Numerical Simulation and Deformation Analysis of Single-pass Multi-layer Stress Field in Arc Additive Manufacturing

-

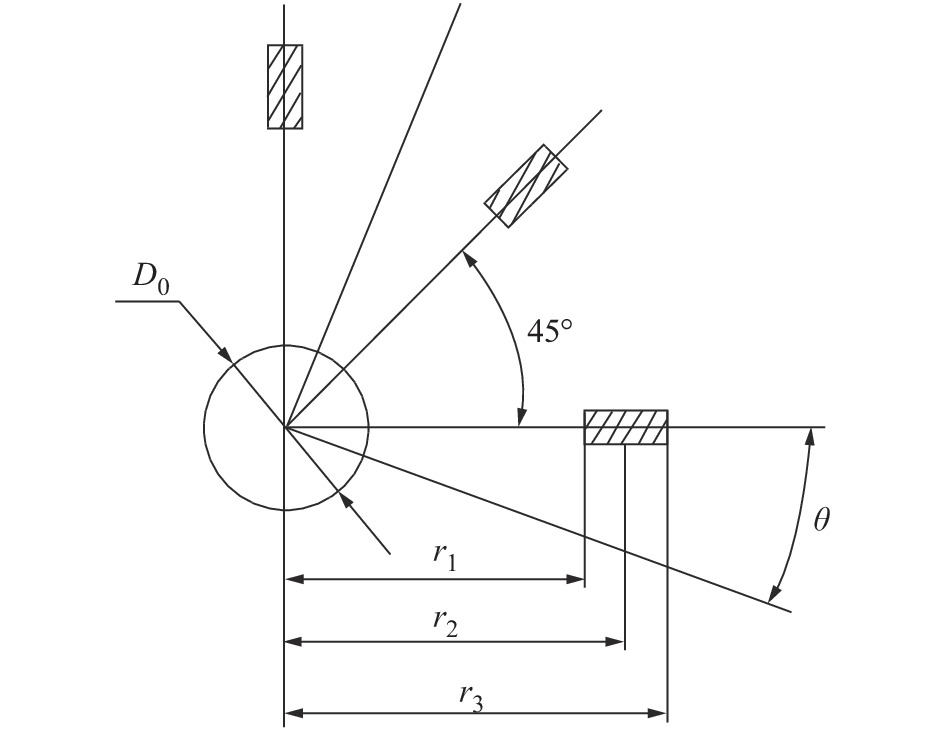

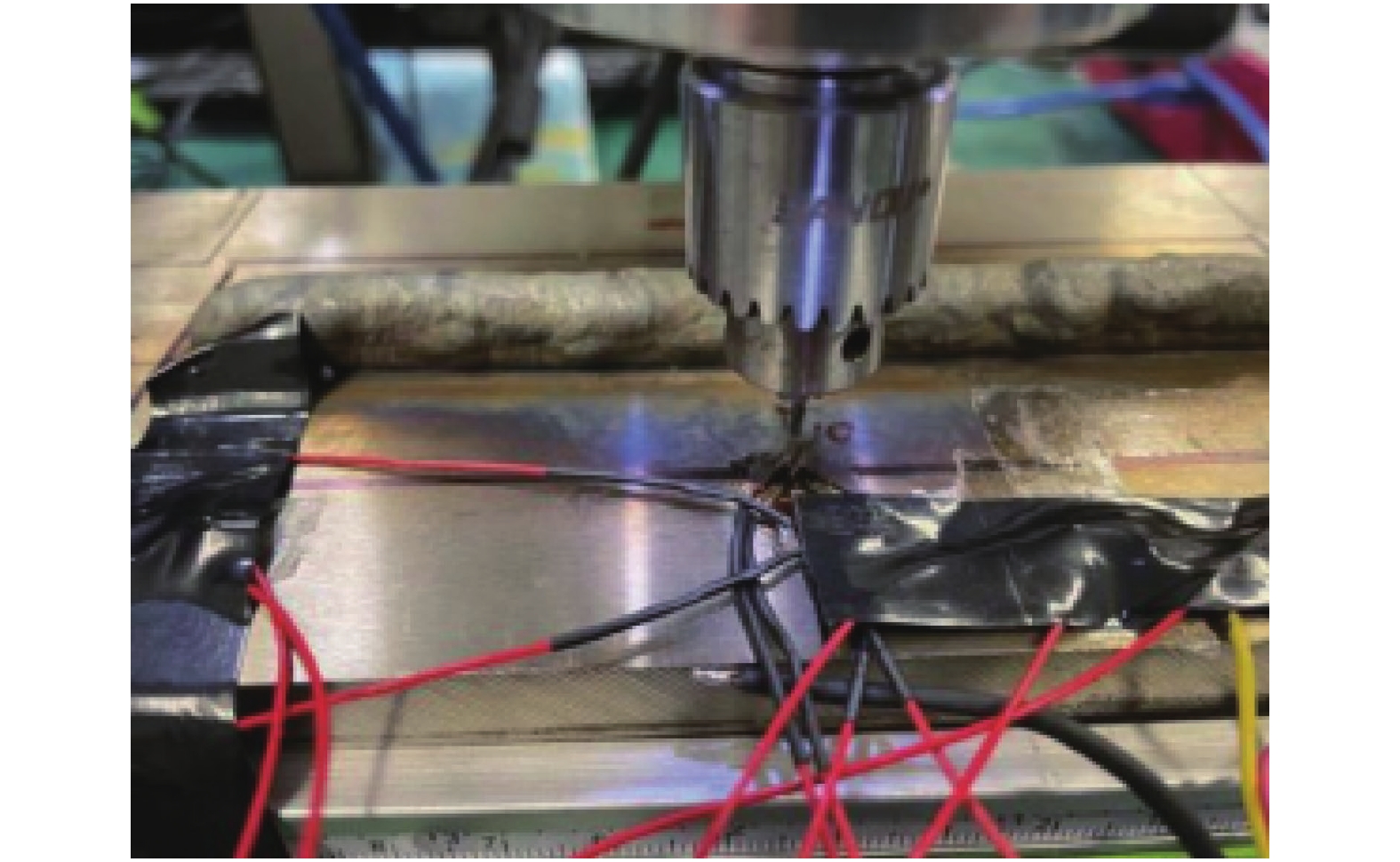

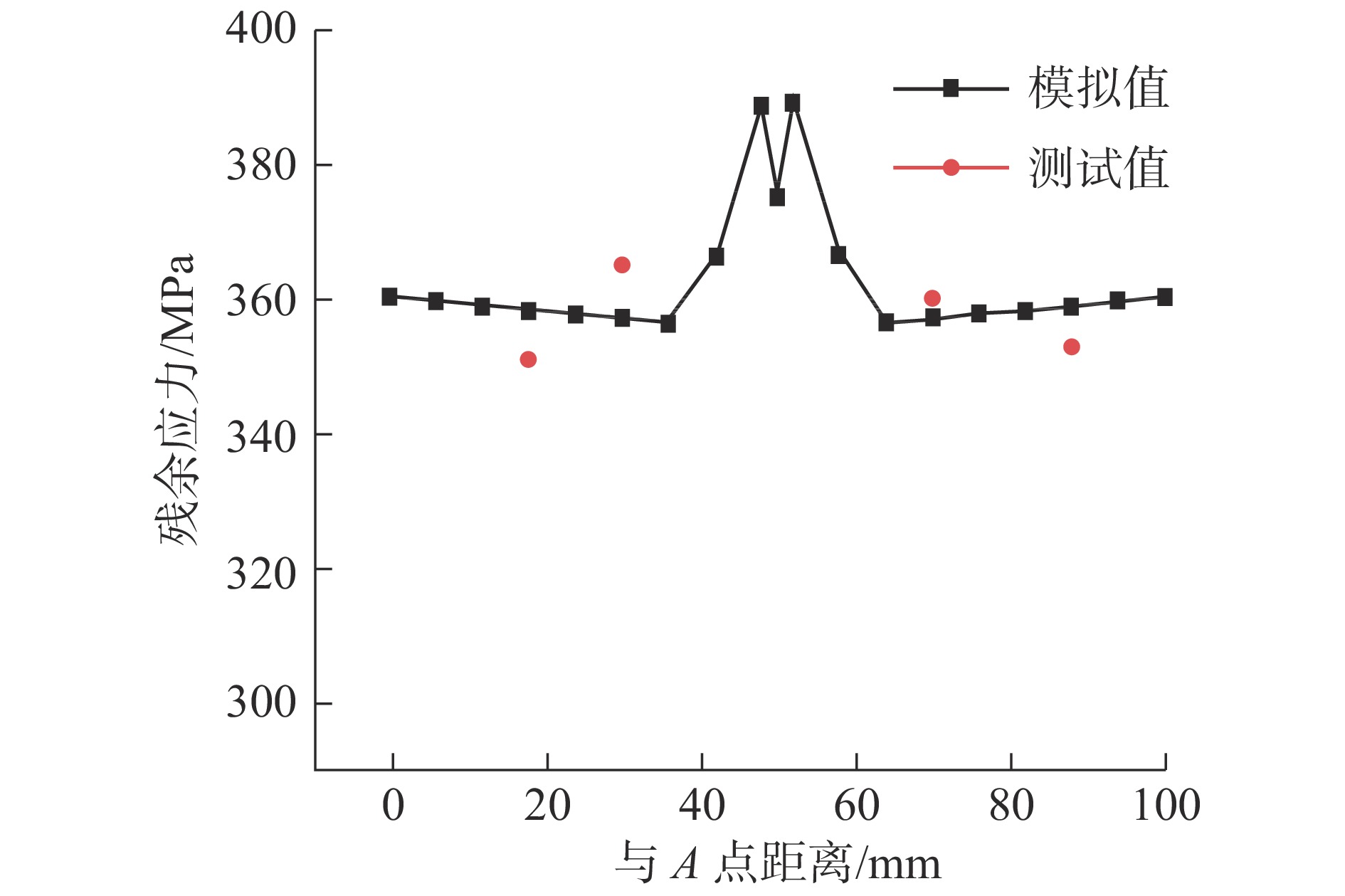

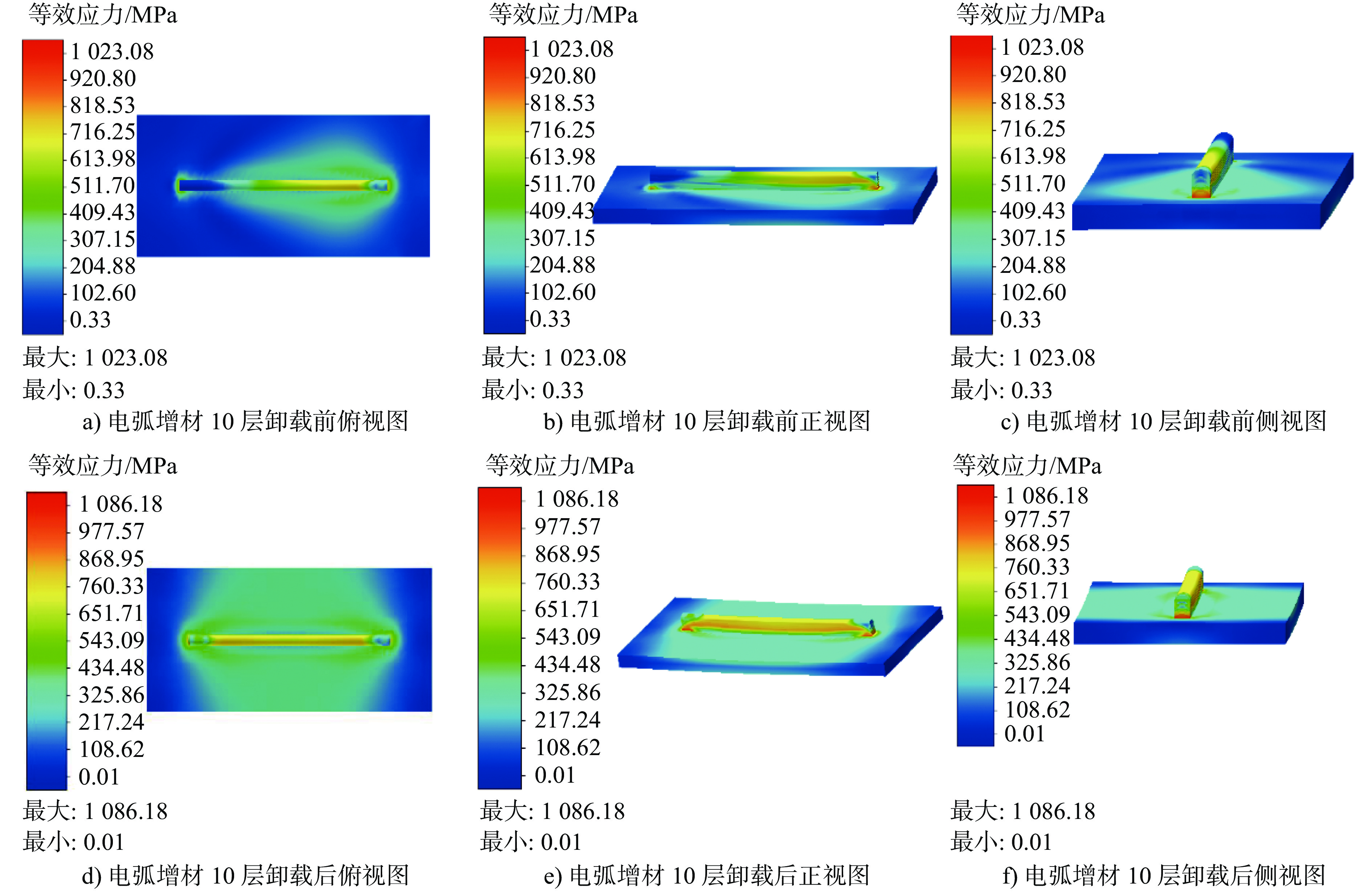

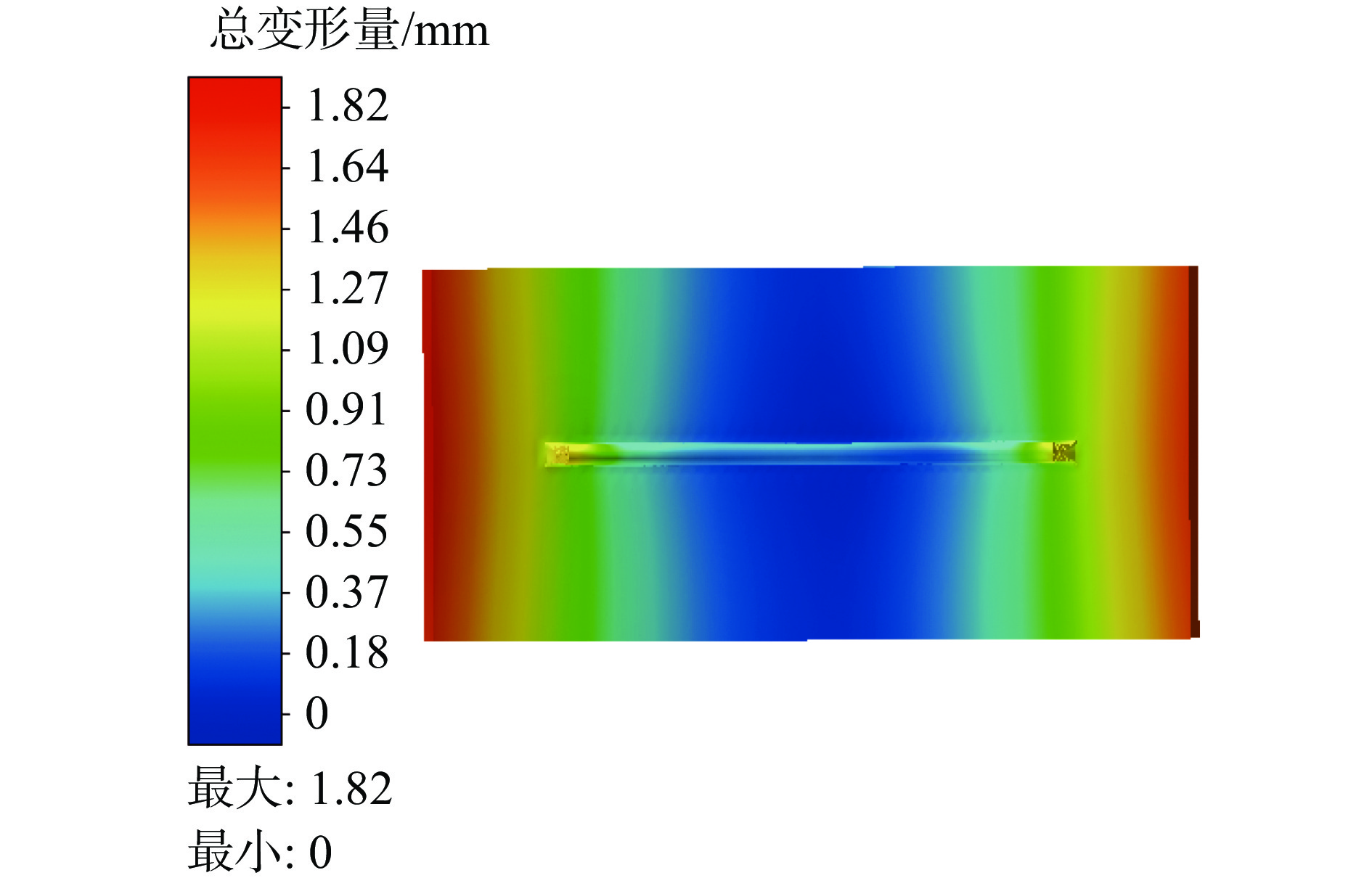

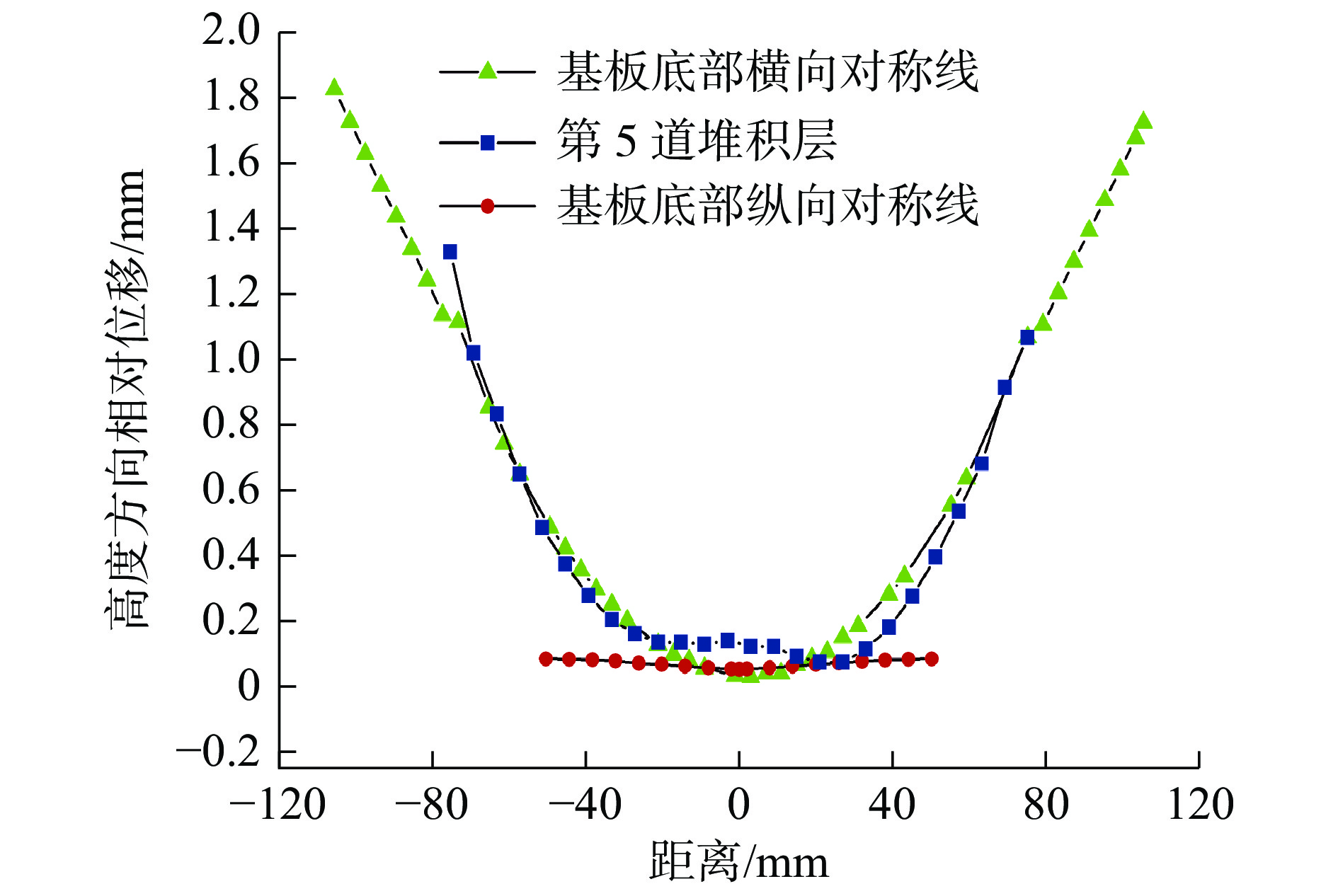

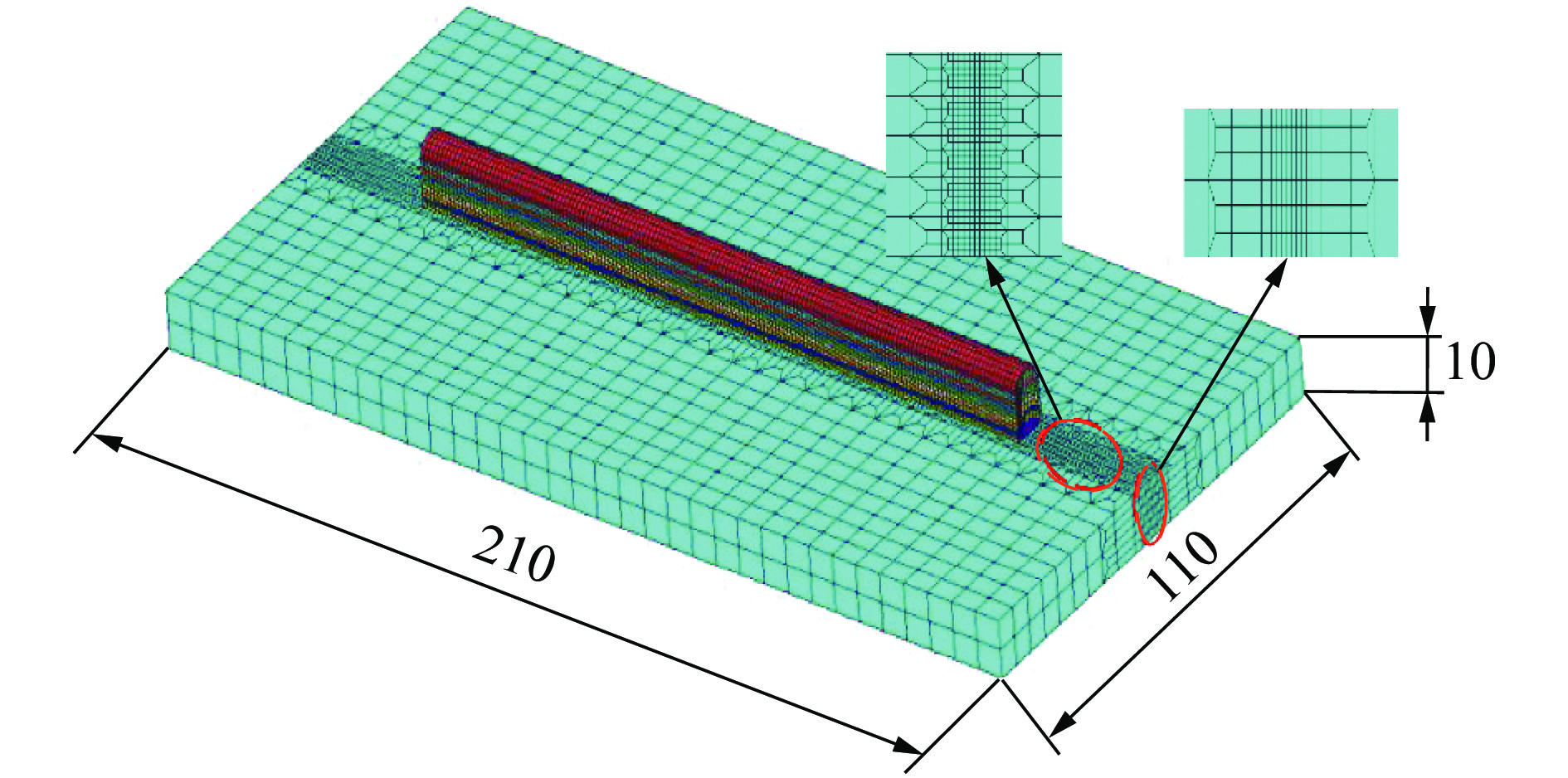

摘要: 利用Simufact Welding有限元分析软件,采用生死单元法对镍基高温合金GH4169钨极惰性气体(TIG)保护焊电弧增材单道多层应力场进行数值模拟。采用盲孔法测试选取的基板上垂直于焊缝中垂线上各点残余应力,得到实测值与模拟值误差在10 MPa内,误差百分比约为2.8%。对增材工件进行变形分析,结果表明:重复热循环作用使得成形件内应力不断骤升骤降,且应力峰值逐层递减。成形卸载后,残余应力主要集中于成形件起弧与熄弧处底端。成形件冷却至室温后总变形量呈对称分布且在横向方向上翘曲程度最大,总变形量达到1.82 mm。Abstract: The single pass and multi-layer stress field of arc additive in tungsten inert gas (TIG) shielded welding of Superalloy GH4169 was numerically simulated with the life and death element method with the finite element analysis software Simulact welding. The blind hole method is used to test the residual stress at each point on the selected substrate perpendicular to the vertical line of the weld, and the error between the measured value and the simulated is within 10 MPa, and the error percentage is about 2.8%. Deformation analysis of the additive workpiece shows that the repeated thermal cycle action causes the internal stress of the formed part to rise and fall continuously, and the peak stress decreases gradually. After forming and unloading, the residual stress is mainly concentrated on the bottom end of the arc starting and extinguishing part of the forming part. The total deformation of the formed part is symmetrically distributed after cooling to room temperature, and the degree of warping in the transverse direction is the largest, and the total deformation reaches 1.82 mm.

-

Key words:

- arc additive manufacturing /

- numerical simulation /

- stress field /

- deformation

-

表 1 焊接双椭球体热源模型参数

前端长度/mm 后端长度/mm 熔池半宽度/mm 熔池高度/mm 热源功率/kW 热源效率 4.5 9 4.5 3 2.16 0.75 -

[1] TOFAIL S A M, KOUMOULOS E P, BANDYOPADHYAY A, et al Additive manufacturing: scientific and technological challenges, market uptake and opportunities[J]. Materials Today, 2018, 21(1): 22-37. doi: 10.1016/j.mattod.2017.07.001 [2] WILLIAMS S W, MARTINA F, ADDISON A C, et al. Wire + arc additive manufacturing[J]. Materials Science and Technology, 2016, 32(7): 641-647. doi: 10.1179/1743284715Y.0000000073 [3] DING D H, PAN Z X, CUIURI D, et al. Wire-feed additive manufacturing of metal components: technologies, developments and future interests[J]. The International Journal of Advanced Manufacturing Technology, 2015, 81(1-4): 465-481. doi: 10.1007/s00170-015-7077-3 [4] 张建生, 董旭刚, 张普, 等. 大型电弧熔丝增材装备研究进展及现状[J]. 锻压装备与制造技术, 2020, 55(1): 7-10. doi: 10.16316/j.issn.1672-0121.2020.01.001ZHANG J S, DONG X G, ZHANG P, et al. Research progress and status of large arc fuse additive equipment[J]. China Metalforming Equipment & Manufacturing Technology, 2020, 55(1): 7-10. (in Chinese) doi: 10.16316/j.issn.1672-0121.2020.01.001 [5] CUNNINGHAM C R, FLYNN J M, SHOKRANI A, et al. Invited review article:Strategies and processes for high quality wire arc additive manufacturing[J]. Additive Manufacturing, 2018, 22: 672-686. [6] KAMBLE A G, RAO R V. Effects of process parameters and thermo-mechanical simulation of gas metal arc welding process[J]. International Journal of Modelling and Simulation, 2016, 36(4): 170-182. doi: 10.1080/02286203.2016.1188343 [7] ZHAO H H, ZHANG G J, YIN Z Q, et al. Three-dimensional finite element analysis of thermal stress in single-pass multi-layer weld-based rapid prototyping[J]. Journal of Materials Processing Technology, 2012, 212(1): 276-285. doi: 10.1016/j.jmatprotec.2011.09.012 [8] LEI Y Y, XIONG J, LI R. Effect of inter layer idle time on thermal behavior for multi-layer single-pass thin-walled parts in GMAW-based additive manufacturing[J]. The International Journal of Advanced Manufacturing Technology, 2018, 96(1-4): 1355-1365. doi: 10.1007/s00170-018-1699-1 [9] MONTEVECCHI F, VENTURINI G, SCIPPA A, et al. Finite element modelling of wire-arc-additive-manufacturing process[J]. Procedia CIRP, 2016, 55: 109-114. doi: 10.1016/j.procir.2016.08.024 [10] DING J, COLEGROVE P, MEHNEN J, et al. A computationally efficient finite element model of wire and arc additive manufacture[J]. The International Journal of Advanced Manufacturing Technology, 2014, 70(1-4): 227-236. doi: 10.1007/s00170-013-5261-x [11] DING J, COLEGROVE P, MEHNEN J, et al. Thermo-mechanical analysis of wire and arc additive layer manufacturing process on large multi-layer parts[J]. Computational Materials Science, 2011, 50(12): 3315-3322. doi: 10.1016/j.commatsci.2011.06.023 [12] 王桂兰, 梅飞翔, 张海鸥, 等. 基板厚度对电弧熔积成形应力场及基板翘曲变形的影响[J]. 热加工工艺, 2017, 46(11): 181-184. doi: 10.14158/j.cnki.1001-3814.2017.11.050WANG G L, MEI F X, ZHANG H O, et al. Influence of substrate thickness on stress field and warping deformation of substrate in arc deposition forming[J]. Hot Working Technology, 2017, 46(11): 181-184. (in Chinese) doi: 10.14158/j.cnki.1001-3814.2017.11.050 [13] 王桂兰, 侯军华, 张海鸥, 等. 筒形件电弧增材成形的残余应力模拟分析[J]. 焊接技术, 2014, 43(5): 7-10 . doi: 10.13846/j.cnki.cn12-1070/tg.2014.05.002WANG G L, HOU J H, ZHANG H O, et al. FEM analysis of residual stress of arc additive manufacturing cylindrical work pieces[J]. Welding Technology, 2014, 43(5): 7-10 . (in Chinese) doi: 10.13846/j.cnki.cn12-1070/tg.2014.05.002 [14] 周祥曼, 田启华, 杜义贤, 等. 外加稳态磁场作用下的焊接电弧数值仿真[J]. 机械科学与技术, 2018, 37(7): 1068-1075. doi: 10.13433/j.cnki.1003-8728.20180124ZHOU X M, TIAN Q H, DU Y X, et al. Numerical simulation of welding arc under external static magnetic field[J]. Mechanical Science and Technology for Aerospace Engineering, 2018, 37(7): 1068-1075. (in Chinese) doi: 10.13433/j.cnki.1003-8728.20180124 [15] 柏兴旺, 张海鸥, 王桂兰. 外加磁场下GMAW熔池电磁力的有限元计算[J]. 焊接学报, 2016, 37(1): 46-50.BAI X W, ZHANG H O, WANG G L. Finite element analysis of electromagnetic force in GMAW melt pool induced by external magnetic field[J]. Transactions of the China Welding Institution, 2016, 37(1): 46-50. (in Chinese) -

下载:

下载: