Tool Radius Compensation Algorithm for Slow Tool Servo Turning on Complex Surface

-

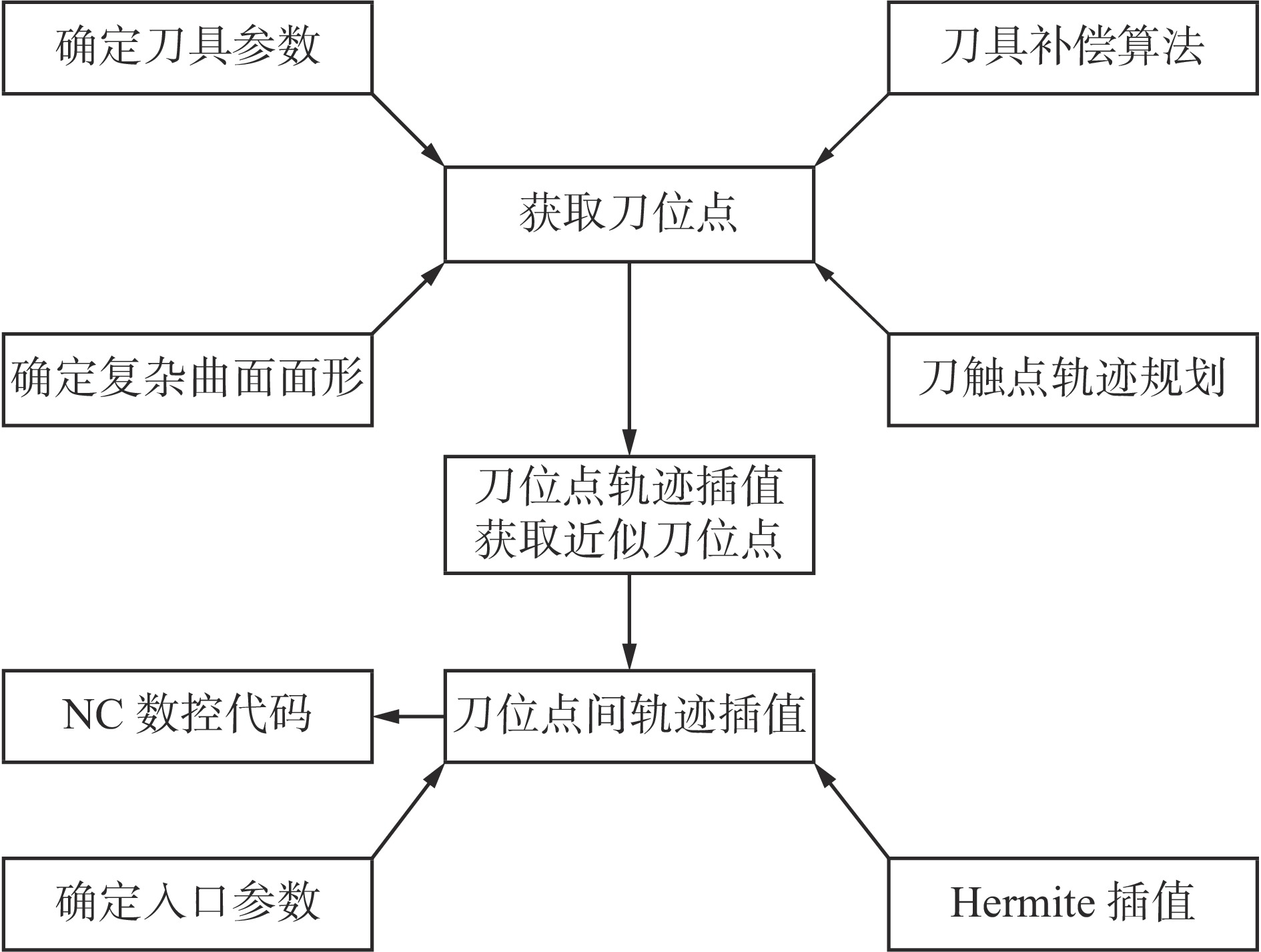

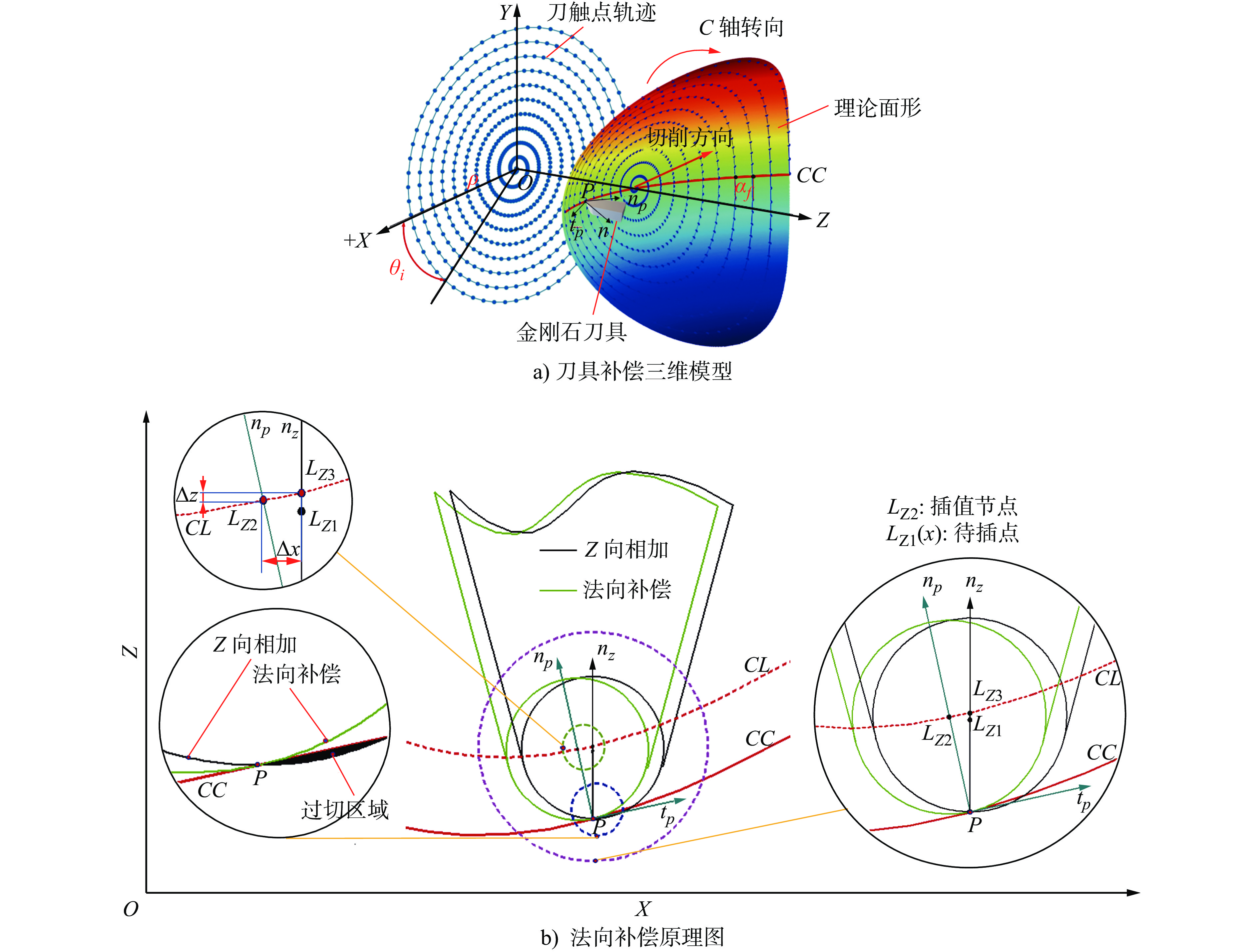

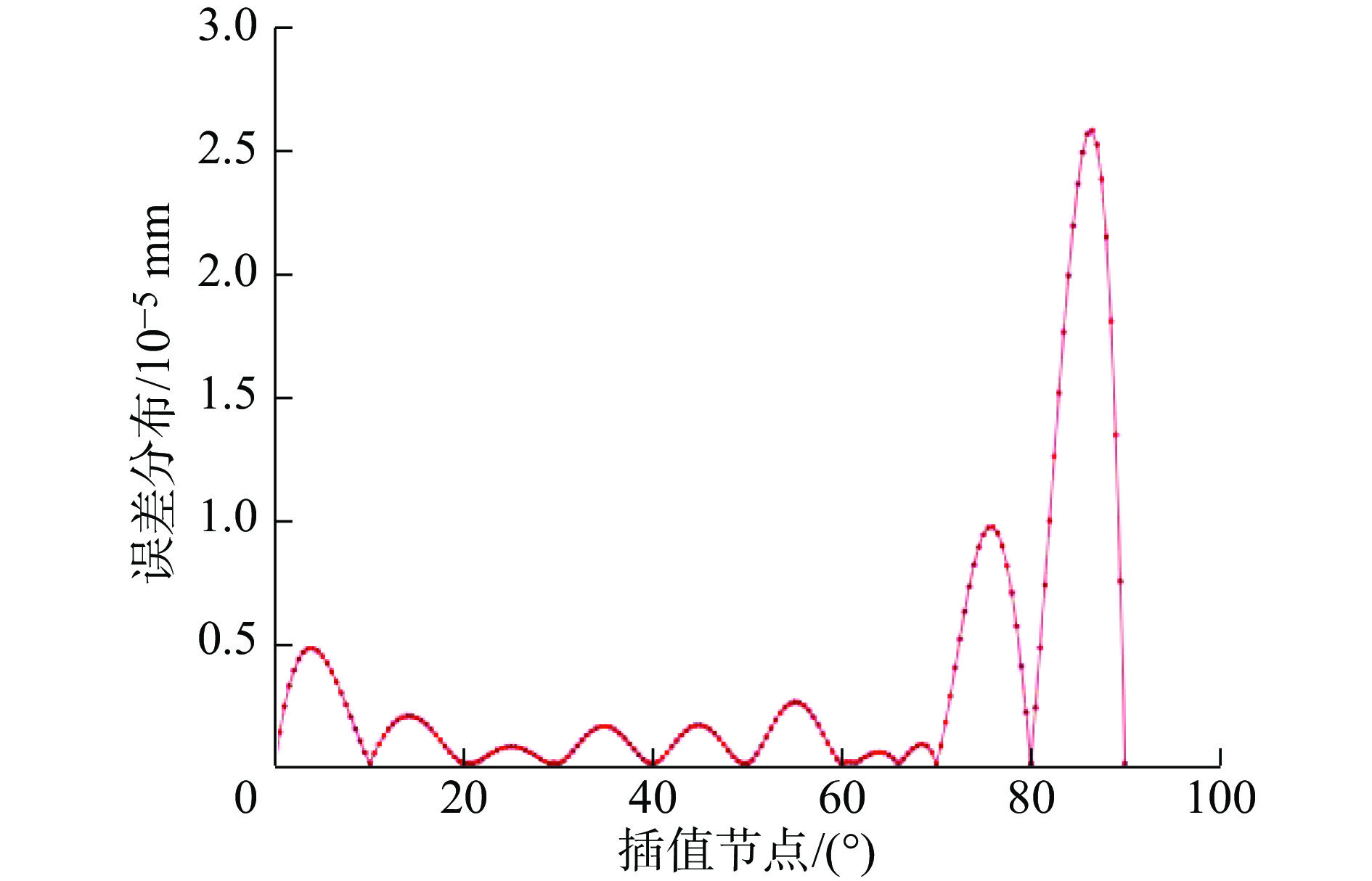

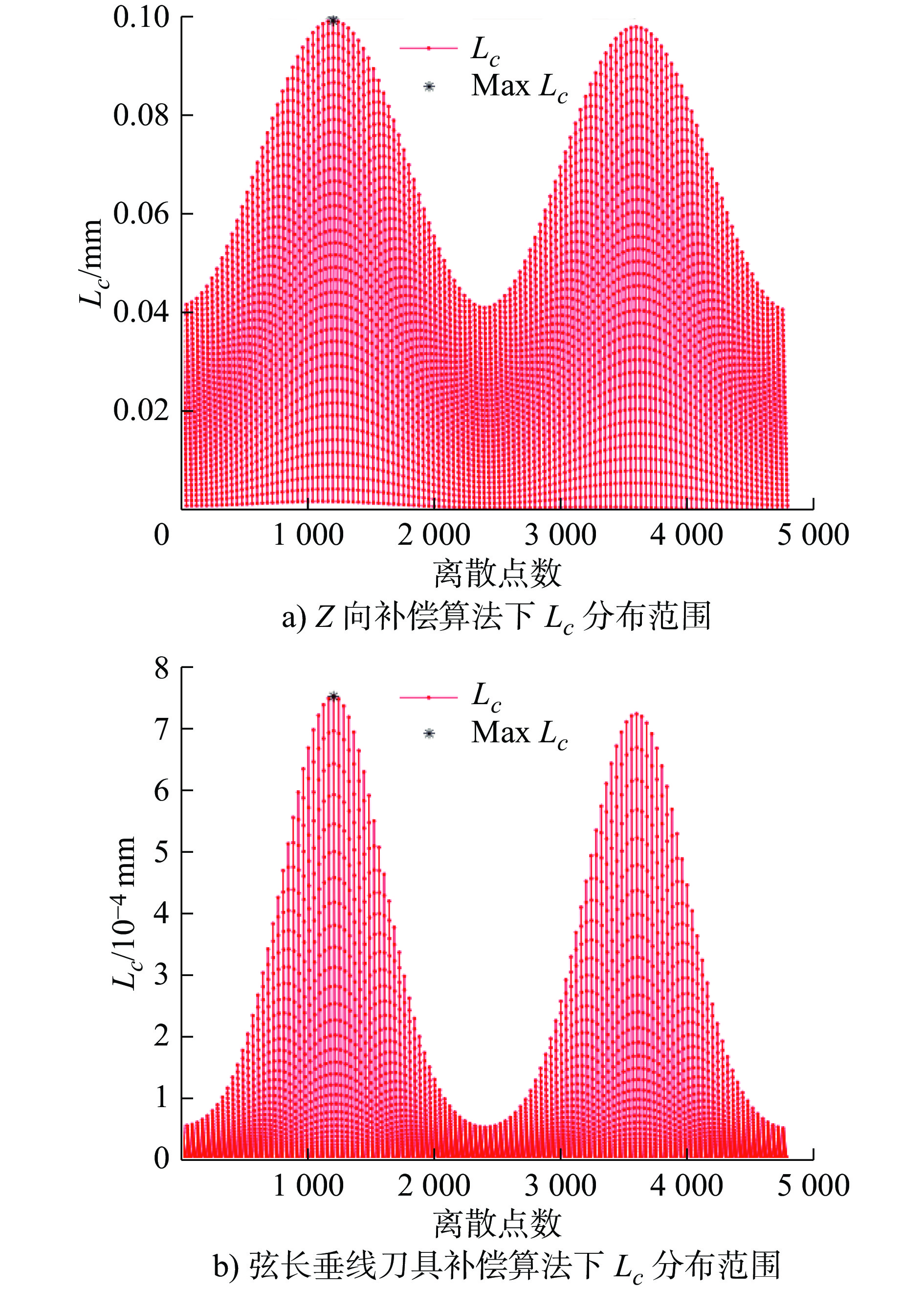

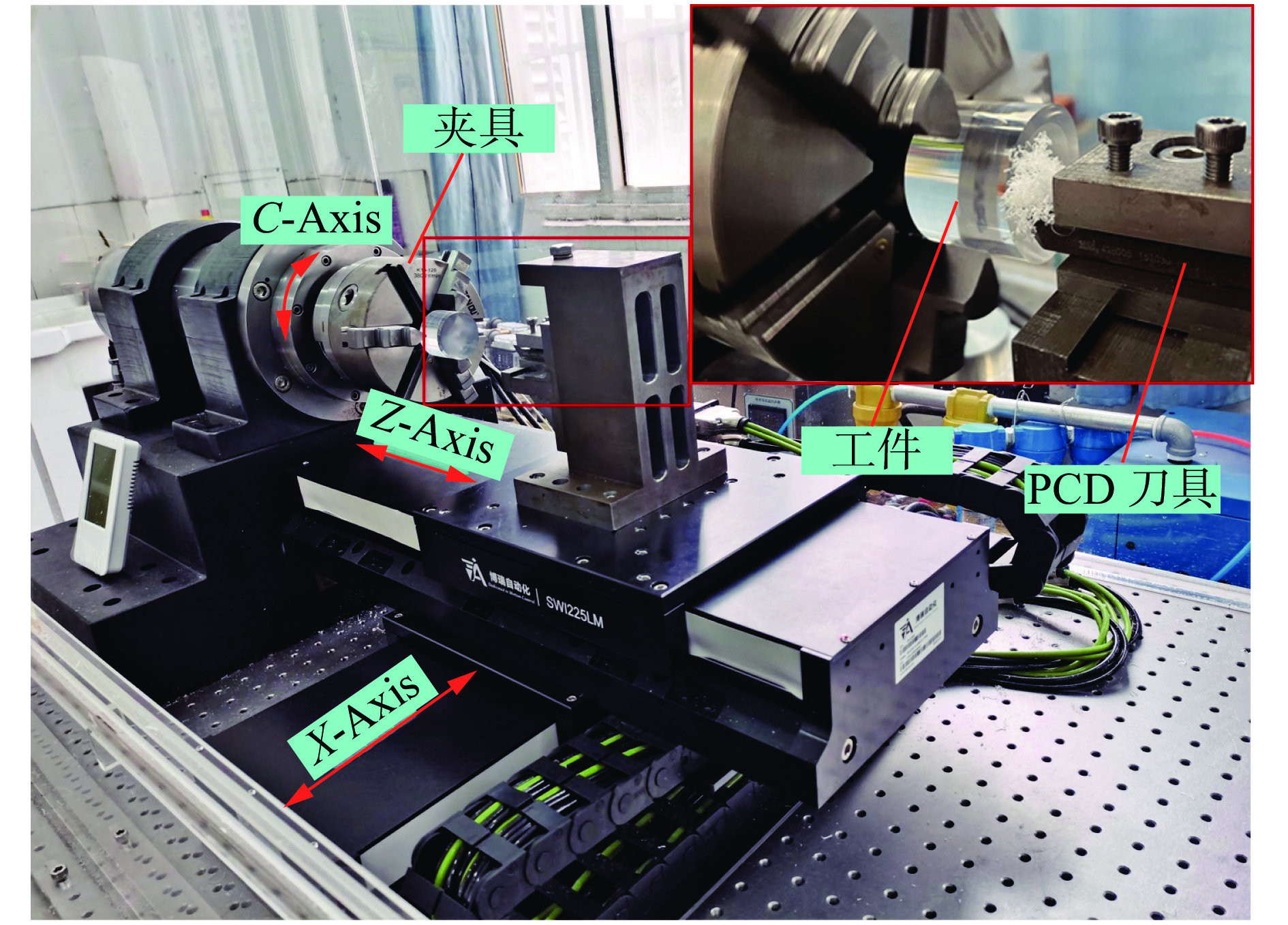

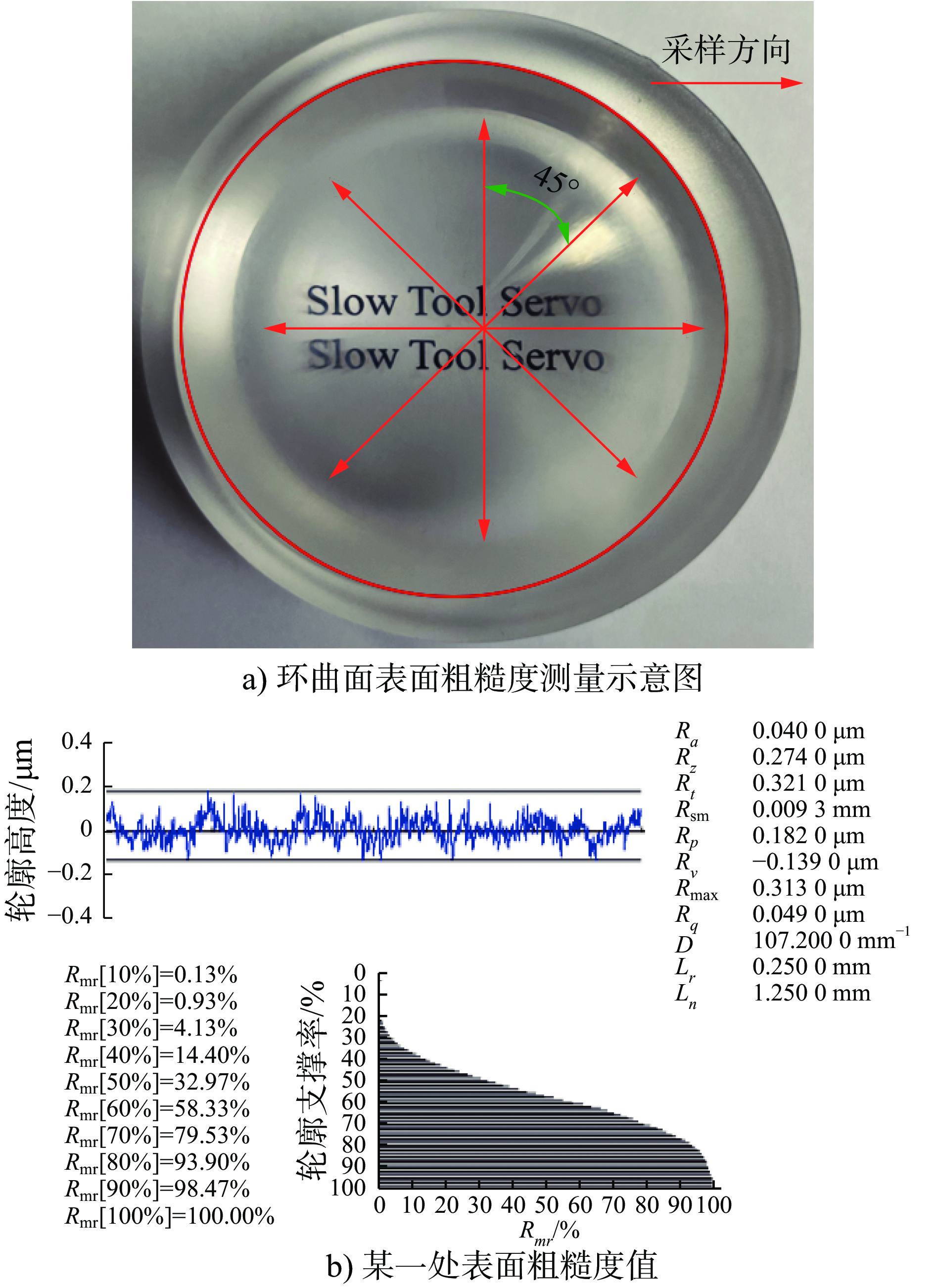

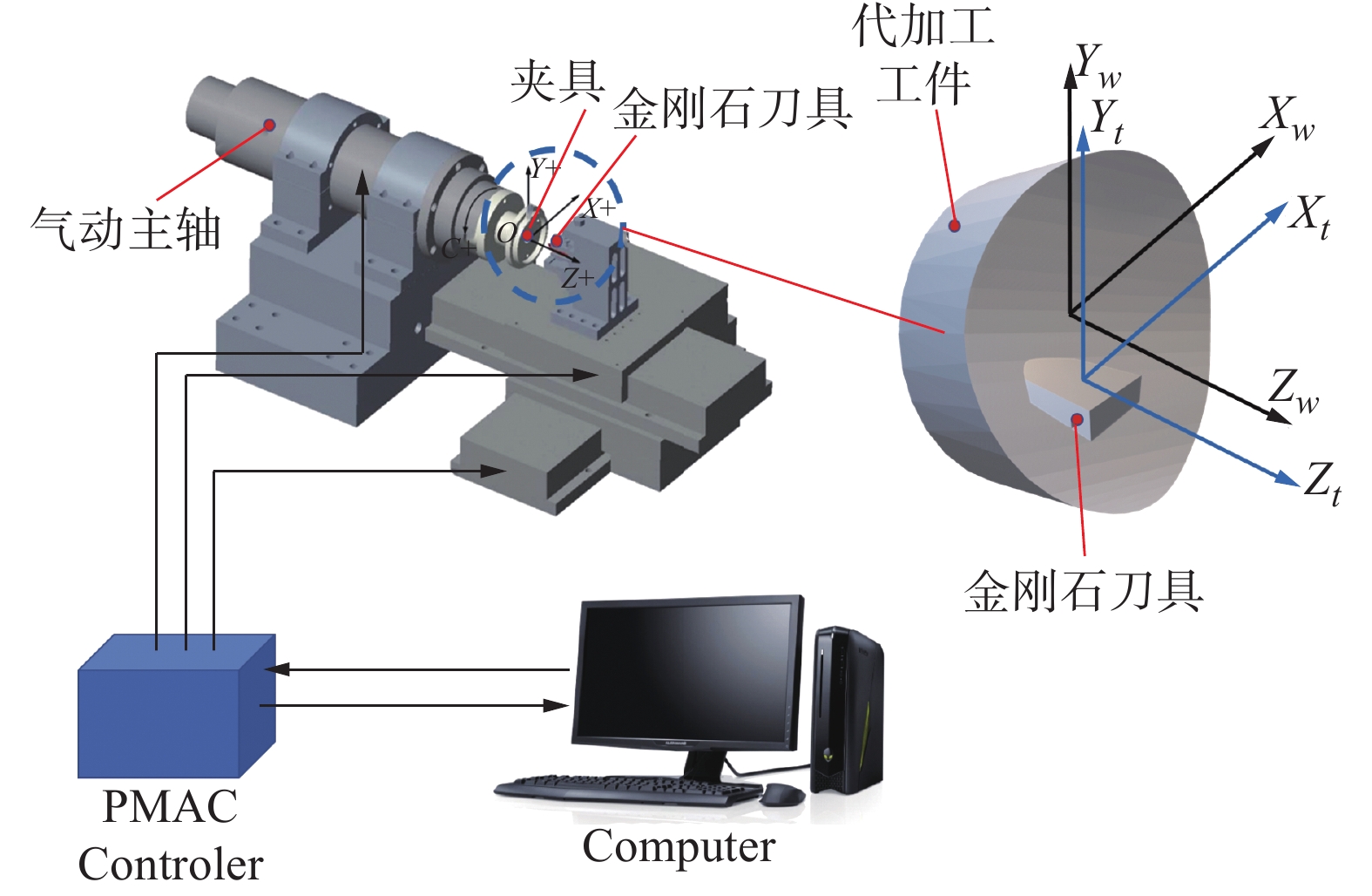

摘要: 为提高复杂曲面元件的面形加工精度,进行了慢刀伺服车削刀具路径规划,研究了刀具半径补偿算法。本文通过分析法向补偿算法和Z向补偿算法的不足,提出一种基于弦长垂线的刀具补偿算法,以环曲面为例进行仿真、车削加工验证该算法的可行性。仿真结果表明弦长垂线刀具补偿算法下所求刀位点精度较高,可实现X轴匀速运动。试验结果表明弦长垂线刀具补偿算法下面形加工精度优于法向补偿算法和Z向补偿算法,表面粗糙度受刀具补偿算法影响较小。Abstract: In order to improve the machining accuracy of complex curved components, the tool path generation of slow tool servo turning was carried out, and the tool radius compensation algorithm was studied. In this paper, a tool compensation algorithm based on chord length vertical is proposed by analyzing the shortcomings of the direction compensation algorithm and the Z-direction compensation algorithm, and the feasibility of the algorithm is verified with the simulation and turning of the torus surface. The simulation results show that the tool compensation algorithm of chord length vertical line has high precision in solving the CLPs, and the uniform motion of X axis is realized. The experimental results show that the tool compensation algorithm for chord length vertical line is better than the normal compensation algorithm and the Z-direction compensation algorithm, and the surface roughness is less affected by the tool compensation algorithm.

-

表 1 仿真参数表

参数名 参数值 离散角Δθ 3° 刀具圆弧半径Rt 0.5 mm 每圈进给量af 0.5 mm/r 两相邻点运动时间ΔT 6 ms 切削深度ap 0.1 mm 工件半径Rg 20 mm 环曲面正交弧半径R 140 mm 环曲面基弧半径a 100 mm 表 2 三坐标测量机设备参数表

测量方式 示值误差/μm 探测误/μm 环境温度/℃ 点触发式 2.7 + L/250 2.7 20 ± 2 -

[1] 董青青. 慢刀伺服车削关键技术研究[D]. 长春: 长春工业大学, 2020DONG Q Q. Research on key technology of slow tool servo[D]. Changchun: Changchun University of Technology, 2020.(in Chinese) [2] 邱昕洋, 张彦钦, 王宏斌. 慢刀伺服加工环曲面的刀具路径规划方法[J]. 国防科技大学学报, 2020, 42(3): 121-127. doi: 10.11887/j.cn.202003016QIU X Y, ZHANG Y Q, WANG H B. Tool path planning method for machining toric surface based on slow tool servo technology[J]. Journal of National University of Defense Technology, 2020, 42(3): 121-127. (in Chinese) doi: 10.11887/j.cn.202003016 [3] KONG L B, MA Y G, REN M J, et al. Generation and characterization of ultra-precision compound freeform surfaces[J]. Science Progress, 2019, 103(1): 003685041988011 [4] LI H, LI L K, NAPLES N J, et al. Micro-optical fabrication by ultraprecision diamond machining and precision molding[J]. Frontiers of Mechanical Engineering, 2017, 12(2): 181-192. doi: 10.1007/s11465-017-0444-z [5] 牛恒泰, 康敏, 王兴盛, 等. 渐进多焦点镜片的设计与慢刀伺服车削[J]. 中国机械工程, 2019, 30(6): 722-727. doi: 10.3969/j.issn.1004-132X.2019.06.014NIU H T, KANG M, WANG X S, et al. Design and slow tool servo turning of progressive-addition lenses[J]. China Mechanical Engineering, 2019, 30(6): 722-727. (in Chinese) doi: 10.3969/j.issn.1004-132X.2019.06.014 [6] WANG D F, SUI Y X, YANG H J, et al. Adaptive spiral tool path generation for diamond turning of large aperture freeform optics[J]. Materials, 2019, 12(5): 810. doi: 10.3390/ma12050810 [7] KHAGHANI A, CHENG K. Investigation on multi-body dynamics based approach to the toolpath generation for ultraprecision machining of freeform surfaces[J]. Proceedings of the Institution of Mechanical Engineers, Part B:Journal of Engineering Manufacture, 2020, 234(3): 571-583. doi: 10.1177/0954405419863961 [8] 马富荣, 靳伍银, 王安. 复杂曲面慢刀伺服加工刀具半径补偿方法[J]. 机械设计与制造, 2019(7): 189-192. doi: 10.3969/j.issn.1001-3997.2019.07.047MA F R, JIN W Y, WANG A. The method of tool radius compensation for complex surface by using slow tool servo processing[J]. Machinery Design & Manufacture, 2019(7): 189-192. (in Chinese) doi: 10.3969/j.issn.1001-3997.2019.07.047 [9] 李佳伟, 杜文浩, 韩长庆. 慢刀伺服车削刀具半径定向补偿的分段逼近求解[J]. 中国机械工程, 2020, 31(17): 2017-2023.LI J W, DU W H, HAN C Q. Directional tool radius compensation solution of STS turning based on segment approximation[J]. China Mechanical Engineering, 2020, 31(17): 2017-2023. (in Chinese) [10] 关朝亮, 铁贵鹏, 尹自强. 光学阵列器件的慢刀伺服车削加工技术[J]. 国防科技大学学报, 2009, 31(4): 31-35. doi: 10.3969/j.issn.1001-2486.2009.04.007GUAN C L, TIE G P, YIN Z Q. Fabrication of array lens optical component by using of slow tool servo diamond turning[J]. Journal of National University of Defense Technology, 2009, 31(4): 31-35. (in Chinese) doi: 10.3969/j.issn.1001-2486.2009.04.007 [11] JI S J, LI J F, ZHAO J, et al. Ultra-precision machining of a compound sinusoidal grid surface based on slow tool servo[J]. Materials, 2018, 11(6): 1001. doi: 10.3390/ma11061001 [12] 牛恒泰. 复杂曲面慢刀伺服车削刀具路径规划及测量技术研究[D]. 南京: 南京农业大学, 2018NIU H T. Research on slow tool servo turning and form accuracy measuring for complex surface[D]. Nanjing: Nanjing Agricultural University, 2018. (in Chinese) [13] 蔡洪彬, 史国权. 主动控制加工误差慢刀伺服车削轨迹生成方法[J]. 吉林大学学报(工学版), 2019, 49(4): 1221-1227. doi: 10.13229/j.cnki.jdxbgxb20180703CAI H B, SHI G Q. Tool path generation of slow tool servo for active control machining error[J]. Journal of Jilin University (Engineering and Technology Edition), 2019, 49(4): 1221-1227. (in Chinese) doi: 10.13229/j.cnki.jdxbgxb20180703 [14] CHEN X, KANG M, WANG X S, et al. Tool path optimal design for slow tool servo turning of complex optical surface[J]. Proceedings of the Institution of Mechanical Engineers, Part B:Journal of Engineering Manufacture, 2017, 231(5): 825-837. doi: 10.1177/0954405416654192 [15] GUO H Y, KANG M, ZHOU W, et al. A new optimal method of tool path generation for slow tool servo turning of complex surface[J]. Manufacturing Technology, 2020, 20(6): 733-747. doi: 10.21062/mft.2020.115 [16] SUN Z W, TO S, ZHANG G Q, et al. Flexible fabrication of micro-optics arrays with high-aspect-ratio by an offset-tool-servo diamond machining system[J]. Optics Express, 2019, 27(7): 9631-9646. doi: 10.1364/OE.27.009631 [17] WEI Y, ZHAI P, CHEN X Y, et al. Study on design and diamond turning of optical freeform surface for progressive addition lenses[J]. Mathematical Problems in Engineering, 2020, 2020: 2850606. [18] ZHU Z W, TO S, ZHU W L, et al. Cutting forces in fast-/slow tool servo diamond turning of micro-structured surfaces[J]. International Journal of Machine Tools and Manufacture, 2019, 136: 62-75. doi: 10.1016/j.ijmachtools.2018.09.003 [19] LI D, QIAO Z, WALTON K, et al. Theoretical and experimental investigation of surface topography generation in slow tool servo ultra-precision machining of freeform surfaces[J]. Materials, 2018, 11(12): 2566. doi: 10.3390/ma11122566 [20] 关朝亮, 陈燕生, 彭文强. 自由曲面慢刀伺服车削及刀具参数确定方法[J]. 国防科技大学学报, 2012, 34(5): 102-106. doi: 10.3969/j.issn.1001-2486.2012.05.020GUAN C L, CHEN Y S, PENG W Q. Freeform surface STS turning and tool geometry parameters determination method[J]. Journal of National University of Defense Technology, 2012, 34(5): 102-106. (in Chinese) doi: 10.3969/j.issn.1001-2486.2012.05.020 [21] 牛恒泰, 康敏, 何成奎, 等. 离散曲面慢刀伺服车削刀具路径规划[J]. 机械科学与技术, 2018, 37(5): 721-728. doi: 10.13433/j.cnki.1003-8728.2018.0511NIU H T, KANG M, HE C K, et al. Cutting path plan of discrete surface for slow tool servo turning[J]. Mechanical Science and Technology for Aerospace Engineering, 2018, 37(5): 721-728. (in Chinese) doi: 10.13433/j.cnki.1003-8728.2018.0511 [22] MISHRA V, BURADA D R, PANT K K, et al. Form error compensation in the slow tool servo machining of freeform optics[J]. The International Journal of Advanced Manufacturing Technology, 2019, 105(1-4): 1623-1635. doi: 10.1007/s00170-019-04359-w [23] 何改云, 刘欣, 刘佩佩, 等. 基于分割球面逼近和差分进化的复杂曲面轮廓度误差评定[J]. 中国机械工程, 2014, 25(2): 152-156. doi: 10.3969/j.issn.1004-132X.2014.02.003HE G Y, LIU X, LIU P P, et al. Evaluation of complex surface profile errors based on subdivision and sphere approximation method and differential evolution algorithm[J]. China Mechanical Engineering, 2014, 25(2): 152-156. (in Chinese) doi: 10.3969/j.issn.1004-132X.2014.02.003 [24] 刘峻峰, 何小妹, 黄翔, 等. ICP算法在叶型点云数据配准中的应用[J]. 航空制造技术, 2019, 62(12): 79-82. doi: 10.16080/j.issn1671-833x.2019.12.079LIU J F, HE X M, HUANG X, et al. Application of ICP algorithm in data registration of blade profile point cloud[J]. Aeronautical Manufacturing Technology, 2019, 62(12): 79-82. (in Chinese) doi: 10.16080/j.issn1671-833x.2019.12.079 -

下载:

下载: