Study on Non-contact Identification Method of Idler Faults

-

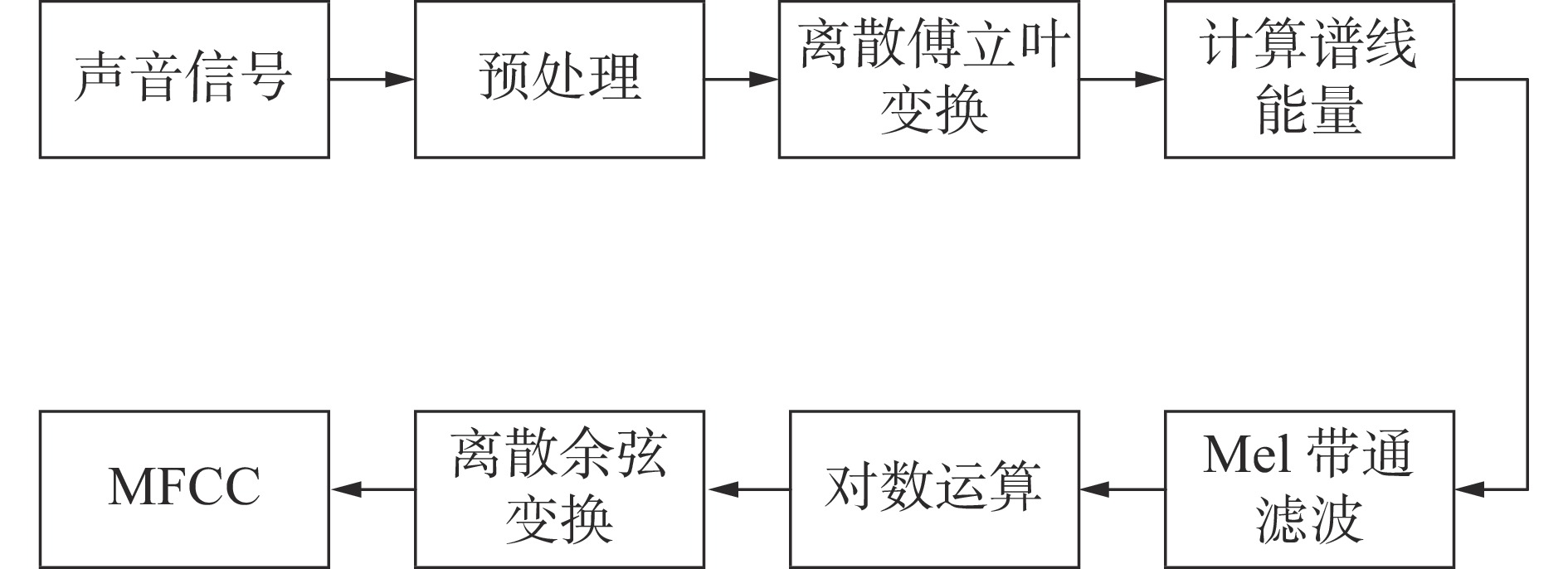

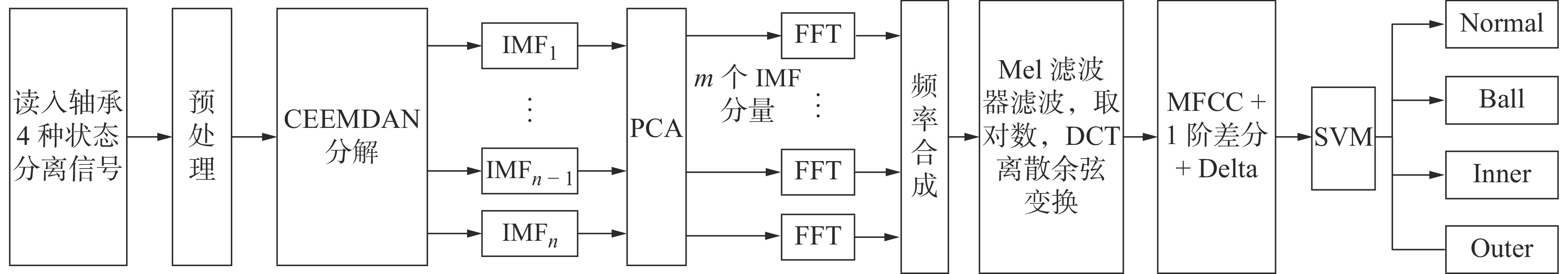

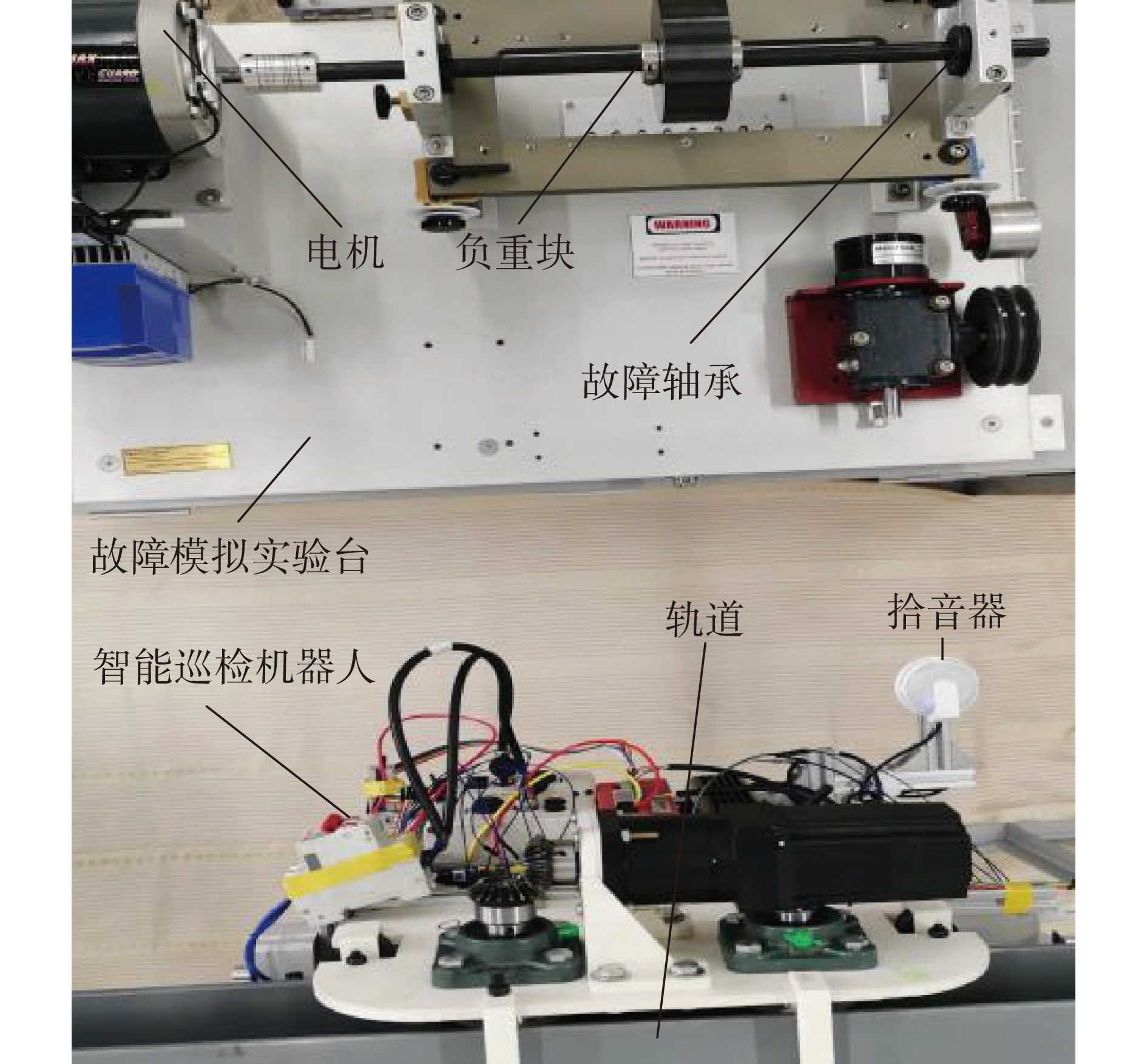

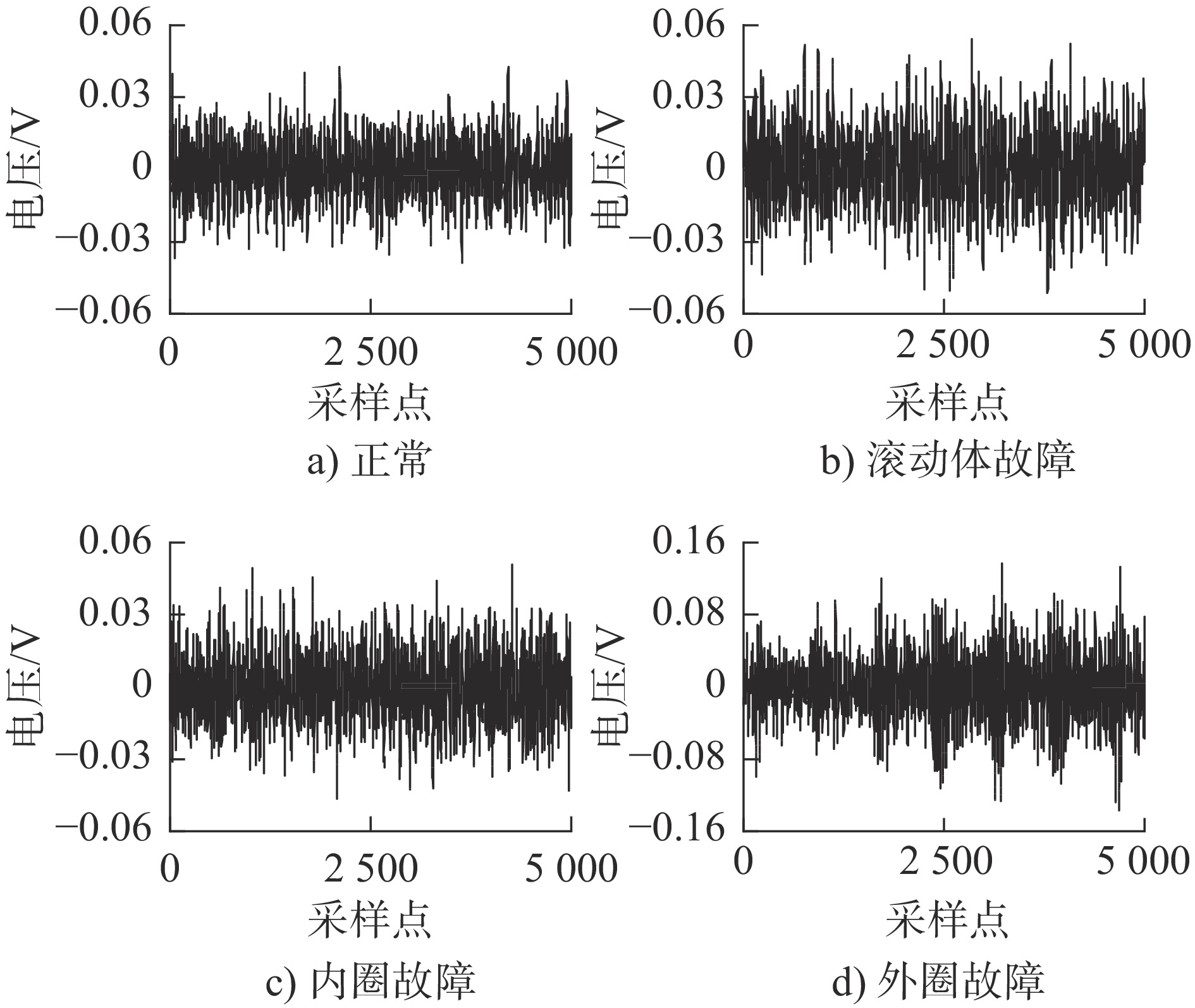

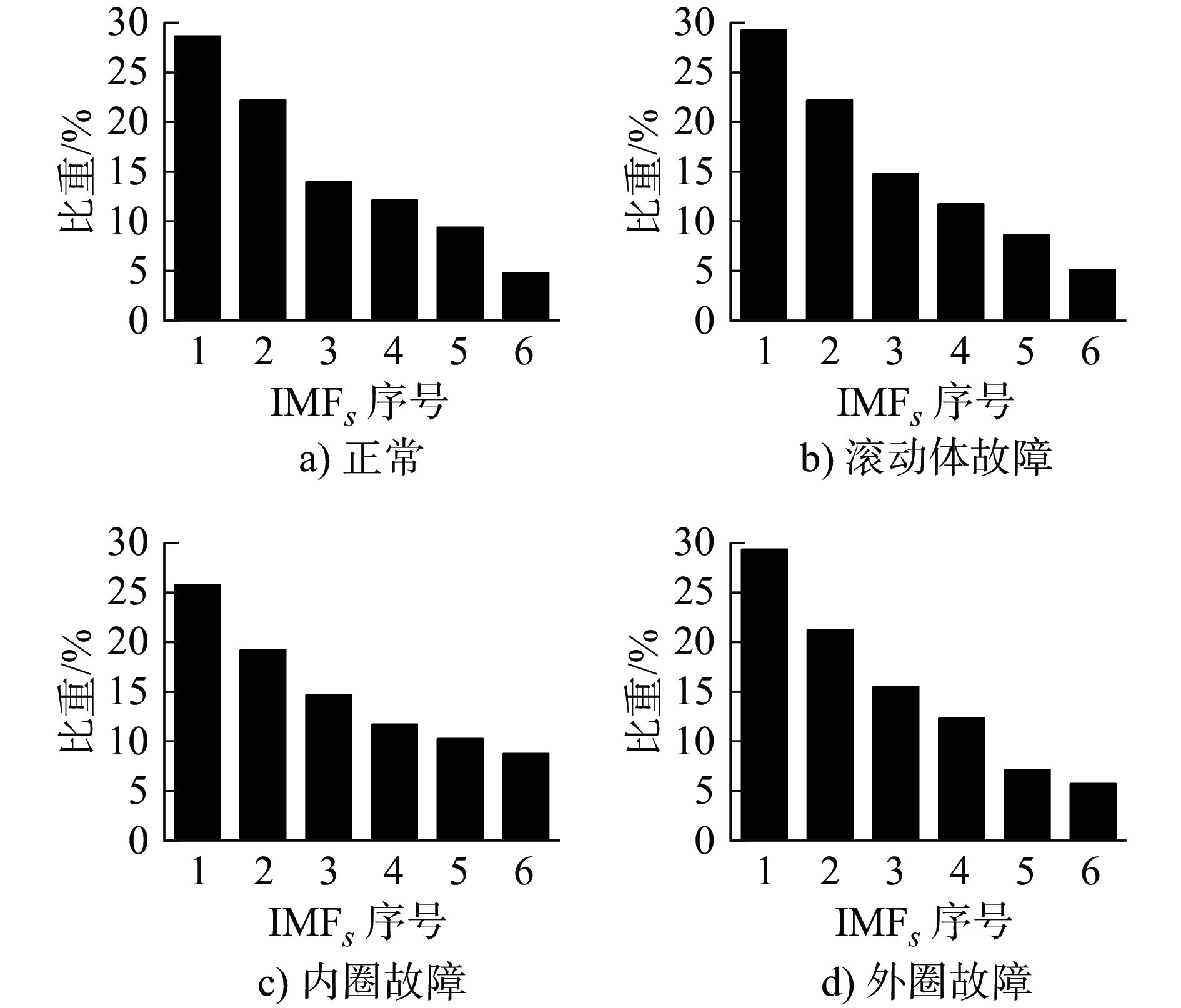

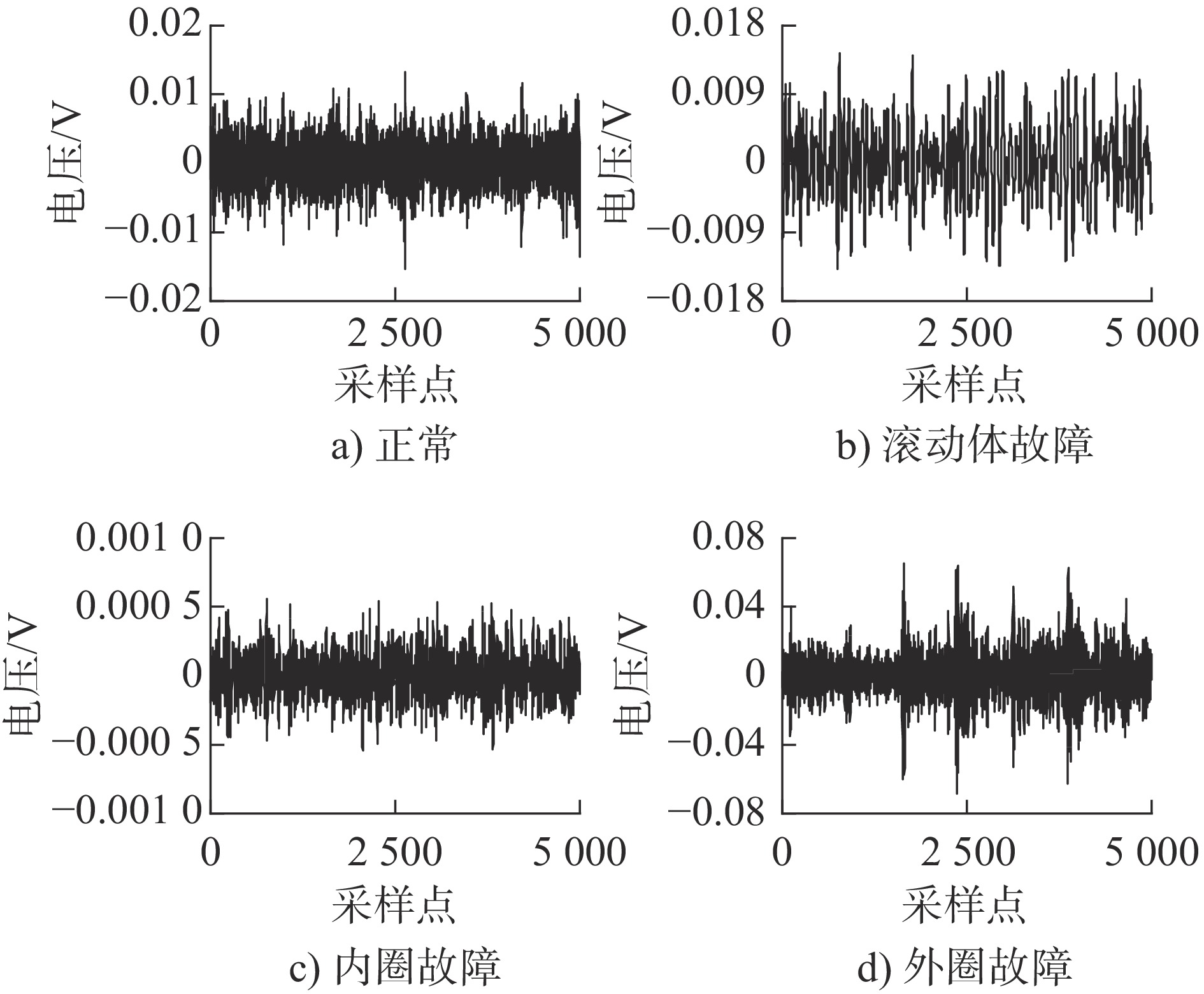

摘要: 因托辊故障引发的远程带式输送机事故越来越多,而传统的人工巡检已不能满足需求,且现有接触式加速度信号检测方式存在传感器需求量大及数据收集难的问题,所以有必要通过智能巡检机器人搭载拾音器进行非接触式巡检。托辊运行环境嘈杂,为剔除信号中的噪声,提出基于完全噪声辅助集合经验模态分解(CEEMDAN)、主成分分析(PCA)和鲁棒性独立分量分析(RobustICA)的单通道盲源分离(SCBSS)去噪方法;托辊信号具有非平稳、非线性的特点,仅用梅尔倒谱系数(MFCC)不能完美刻画信号特征参数,提出基于CEEMDAN、PCA、MFCC、MFCC的1阶差分系数和Delta值的自适应特征参数提取方法;最后采用支持向量机(SVM)作为分类器进行故障识别,识别率达到97.2%。Abstract: There are more and more accidents of the long-distance belt conveyors caused by idler failure, however, the traditional manual inspection cannot meet the demand, and a great number of sensors are demanded in the existing contact measuring method which has a difficulty of data collection, so it is necessary to carry out non-contact inspection by using an intelligent inspection robot equipped with a sound picker. In order to eliminate the noise in the test signal, the single channel blind source separation (SCBSS) denoising method based on the complete ensemble empirical mode decomposition with adaptive noise (CEEMDAN), the principal component analysis (PCA) and the robust independent component analysis (RobustICA) is proposed. Since the idler signal has the characteristics of non-smooth and nonlinear, and the Mel-frequency cepstral coefficient (MFCC) alone cannot perfectly depict the signal feature, the adaptive feature parameters extraction method based on CEEMDAN, PCA, MFCC, MFCC' first order difference coefficients and Delta value is proposed. Finally, the fault identification is carried out by supporting vector machine as classifier and its recognition rate reaches up to 97.2%.

-

Key words:

- idler /

- single-channel blind source separation /

- MFCC /

- fault identification

-

表 1 各分离信号与源信号相关性值

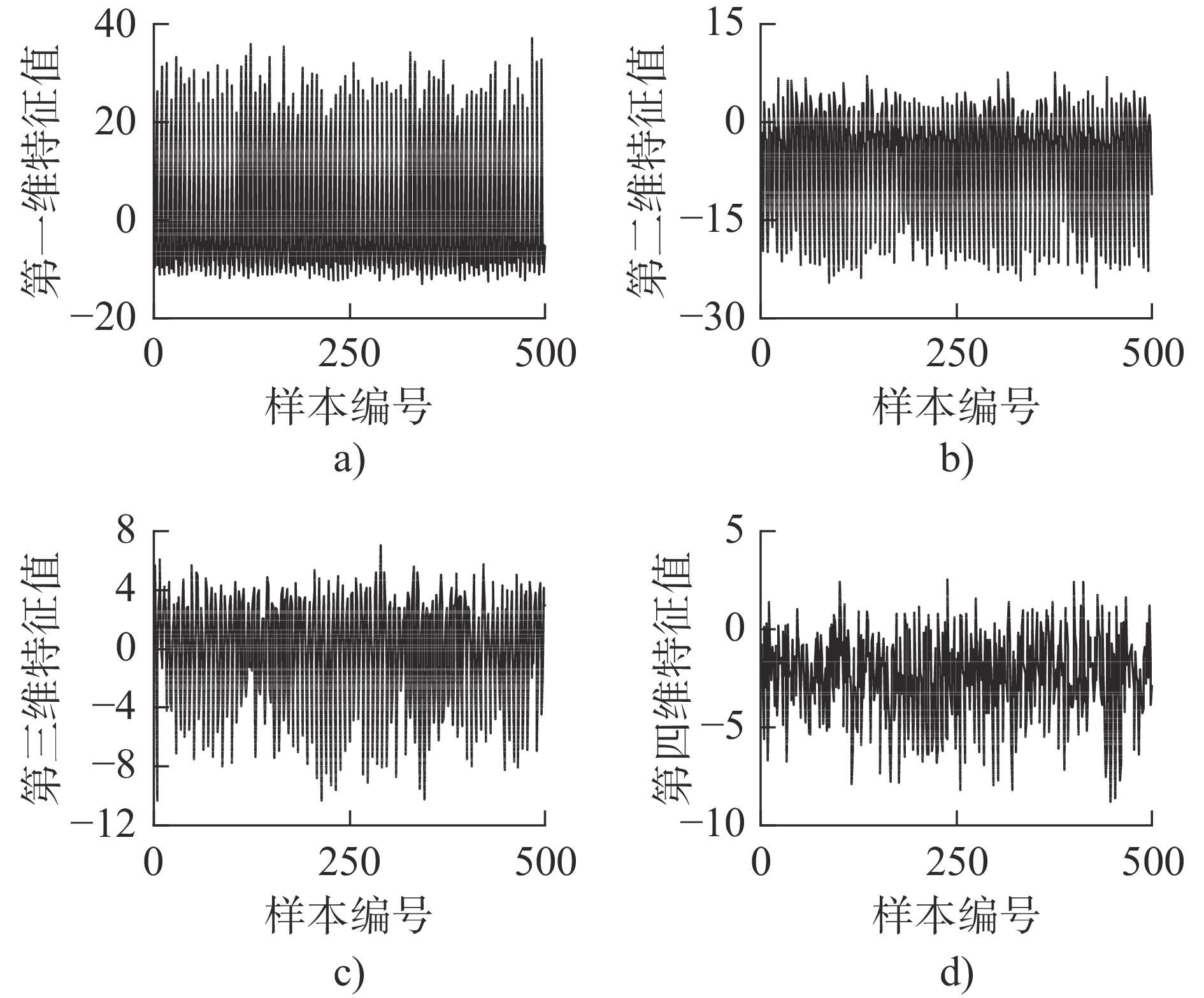

分离信号 正常 滚动体故障 内圈故障 外圈故障 ${s_1}$ −0.15 0.23 0.39 0.03 ${s_2}$ 0.42 −0.58 0.25 −0.46 ${s_3}$ −0.04 −0.26 0.02 0.27 ${s_4}$ −0.76 0.01 0.28 0.09 ${s_5}$ 0.40 0.15 0.78 −0.41 ${s_6}$ 0.06 0.69 0.02 0.63 表 2 特征提取方案

特征参数提取方法 简记 MFCC MFCC EMD + MFCC + 差分系数 E + MFCC + 差分 CEEMDAN + MFCC + 差分系数 C + MFCC + 差分 SCBSS + CEEMDAN + MFCC + 差分系数 B + C + MFCC + 差分 表 3 不同特征提取方法的识别结果

特征参数 故障

类型识别

率/%整体识

别率/%训练时

间/minMFCC 正常 91.5 71.4 19.8 滚动体故障 51.0 内圈故障 45.4 外圈故障 97.8 E + MFCC + 差分 正常 61.2 72.6 19.9 滚动体故障 62.8 内圈故障 69.7 外圈故障 96.8 C + MFCC + 差分 正常 72.6 90 20 .0 滚动体故障 71.8 内圈故障 72.8 外圈故障 98.2 B + C + MFCC + 差分 正常 98.2 97.2 19.9 滚动体故障 95.0 内圈故障 95.6 外圈故障 99.9 -

[1] TANG C Q, ZHOU G B, GAO Z X, et al. A novel rail inspection robot and fault detection method for the coal mine hoisting system[J]. IEEE Intelligent Transportation Systems Magazine, 2019, 11(2): 110-121. doi: 10.1109/MITS.2019.2903540 [2] ZHAO X Y, LIU Z Y, LIU Y C, et al. Structure design and application of combination track intelligent inspection robot used in substation indoor[J]. Procedia Computer Science, 2017, 107: 190-195. doi: 10.1016/j.procs.2017.03.077 [3] 吴勇. 基于振动信号的滚动轴承故障诊断技术研究[D]. 哈尔滨: 哈尔滨工业大学, 2019WU Y. Research on fault diagnosis technology of rolling bearing based on vibration signal[D]. Harbin: Harbin Institute of Technology, 2019. (in Chinese) [4] 黄知涛, 王翔, 彭耿, 等. 欠定盲源分离理论与技术[M]. 北京: 国防工业出版社, 2018HUANG Z T, WANG X, PENG G, et al. Theory and technology on underdetermined blind source separation[M]. Beijing: National Defense Industry Press, 2018. (in Chinese) [5] 王川川, 曾勇虎. 欠定盲源分离算法的研究现状及展望[J]. 北京邮电大学学报, 2018, 41(6): 103-109. doi: 10.13190/j.jbupt.2018-004WANG C C, ZENG Y H. Research status and prospects of underdetermined blind source separation algorithms[J]. Journal of Beijing University of Posts and Telecommunications, 2018, 41(6): 103-109. (in Chinese) doi: 10.13190/j.jbupt.2018-004 [6] 李静娇. 基于声学信号的滚动轴承故障诊断研究及应用[D]. 石家庄: 石家庄铁道大学, 2017LI J J. Research and application of the fault diagnosis of rolling bearing based on the sound signal[D]. Shijiazhuang: Shijiazhuang Tiedao University, 2017. (in Chinese) [7] XU W, YAN X Z. Application of single channel blind separation algorithm based on EEMD-PCA-RobustICA in bearing fault diagnosis[J]. International Journal of Communications, Network and System Sciences, 2017, 10(8): 138-147. doi: 10.4236/ijcns.2017.108B015 [8] 吴微, 彭华, 张帆. FastICA和RobustICA算法在盲源分离中的性能分析[J]. 计算机应用研究, 2014, 31(1): 95-98. doi: 10.3969/j.issn.1001-3695.2014.01.022WU W, PENG H, ZHANG F. Performance analysis of FastICA and RobustICA on blind sources separation[J]. Application Research of Computers, 2014, 31(1): 95-98. (in Chinese) doi: 10.3969/j.issn.1001-3695.2014.01.022 [9] CAO J W, ZHAO T, WANG J Z, et al. Excavation equipment classification based on improved MFCC features and ELM[J]. Neurocomputing, 2017, 261: 231-241. doi: 10.1016/j.neucom.2016.03.113 [10] 王前, 于嘉成, 宁永杰. 基于MFCC与PCA的滚动轴承故障诊断[J]. 组合机床与自动化加工技术, 2017, 59(12): 103-105. doi: 10.13462/j.cnki.mmtamt.2017.12.025WANG Q, YU J C, NING Y J. fault diagnosis of rolling bearing based on MFCC and PCA[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2017, 59(12): 103-105. (in Chinese) doi: 10.13462/j.cnki.mmtamt.2017.12.025 [11] SAMADI E, ALIPOOR G. Efficient band selection for improving the robustness of the EMD-based cepstral features[J]. Sādhanā, 2019, 44(3): 54. [12] 张华竹. 基于鲁棒独立分量分析的结构损伤特征提取方法研究[D]. 西安: 长安大学, 2019ZHANG H Z. Research on structural damage feature extraction method based on robust independent component analysis[D]. Xi'an: Chang'an University, 2019. (in Chinese) [13] 刘宏骏. 基于RobustICA的轮式装载机驾驶室噪声源识别及控制研究[D]. 天津: 天津大学, 2014LIU H J. Research on cab noise source identification and control of wheel loader based on RobustICA[D]. Tianjin: Tianjin University, 2014. (in Chinese) [14] 王婷婷. 基于CEEMDAN的滚动轴承故障诊断研究[D]. 鞍山: 辽宁科技大学, 2019WANG T T. Research on fault diagnosis of rolling bearing based on CEEMDAN[D]. Anshan: University of Science and Technology Liaoning, 2019. (in Chinese) [15] 常甜甜. 支持向量机学习算法若干问题的研究[D]. 西安: 西安电子科技大学, 2010CHANG T T. Research on some problems of support vector machine learning algorithm[D]. Xi'an: Xidian University, 2010. (in Chinese) [16] 陈净和. 基于噪声辅助经验模态分解的低温高速轴承故障诊断方法研究[D]. 北京: 北京交通大学, 2019CHEN J H. Research on fault diagnosis of low temperature and high speed bearing based on noise-assisted empirical mode decomposition[D]. Beijing: Beijing Jiaotong University, 2019. (in Chinese) [17] 张兰, 王太勇, 王鹏, 等. 改进的CEEMDAN故障诊断算法及在加工装备中的应用[J]. 机械科学与技术, 2019, 38(9): 1313-1318. doi: 10.13433/j.cnki.1003-8728.20190009ZHANG L, WANG T Y, WANG P, et al. An improved CEEMDAN fault diagnosis algorithm and its application in machining equipment[J]. Mechanical Science and Technology for Aerospace Engineering, 2019, 38(9): 1313-1318. (in Chinese) doi: 10.13433/j.cnki.1003-8728.20190009 [18] 吉敏. 基于PCA-SVM的轴承故障诊断研究[J]. 电子设计工程, 2019, 27(17): 14-18. doi: 10.3969/j.issn.1674-6236.2019.17.004JI M. Research on bearing fault diagnosis based on PCA-SVM[J]. Electronic Design Engineering, 2019, 27(17): 14-18. (in Chinese) doi: 10.3969/j.issn.1674-6236.2019.17.004 [19] 孙晨光. 基于PSO优化SVM的滚动轴承剩余使用寿命预测研究[D]. 石家庄: 石家庄铁道大学, 2019SUN C G. Research on remaining useful life prediction of rolling bearing based on PSO optimized SVM[D]. Shijiazhuang: Shijiazhuang Tiedao University, 2019. (in Chinese) [20] 罗义胜. 基于盲源分离的滚动轴承故障诊断研究[D]. 上海: 上海工程技术大学, 2016LUO Y S. Research of rolling bearing fault diagnosis based on blind source separation[D]. Shanghai: Shanghai University of Engineering Science, 2016. (in Chinese) [21] BI F R, LI L, ZHANG J, et al. Source identification of gasoline engine noise based on continuous wavelet transform and EEMD-RobustICA[J]. Applied Acoustics, 2015, 100: 34-42. doi: 10.1016/j.apacoust.2015.07.007 [22] GONG C S A, SU C H S, TSENG K H. Implementation of machine learning for fault classification on vehicle power transmission system[J]. IEEE Sensors Journal, 2020, 20(24): 15163-15176. doi: 10.1109/JSEN.2020.3010291 [23] 李宏全, 郭兴明, 郑伊能. 基于EMD和MFCC的舒张期心杂音的分类识别[J]. 振动与冲击, 2017, 36(11): 8-13. doi: 10.13465/j.cnki.jvs.2017.11.002LI H Q, GUO X M, ZHENG Y N. Classification and recognition of diastolic heart murmurs based on EMD and MFCC[J]. Journal of Vibration and Shock, 2017, 36(11): 8-13. (in Chinese) doi: 10.13465/j.cnki.jvs.2017.11.002 [24] 杨路飞, 章新华, 吴秉坤, 等. 基于MFCC特征的被动水声目标深度学习分类方法[J]. 舰船科学技术, 2020, 42(19): 129-133. doi: 10.3404/j.issn.1672-7649.2020.10.025YANG L F, ZHANG X H, WU B K, et al. Research on the classification method of passive acoustic target depth learning based on MFCC[J]. Ship Science and Technology, 2020, 42(19): 129-133. (in Chinese) doi: 10.3404/j.issn.1672-7649.2020.10.025 -

下载:

下载: