Simulation Study on Heat Dissipation Enhancement Characteristics of Axial and Radial Mixed Ventilation Structure for Medium-sized High-voltage Motor

-

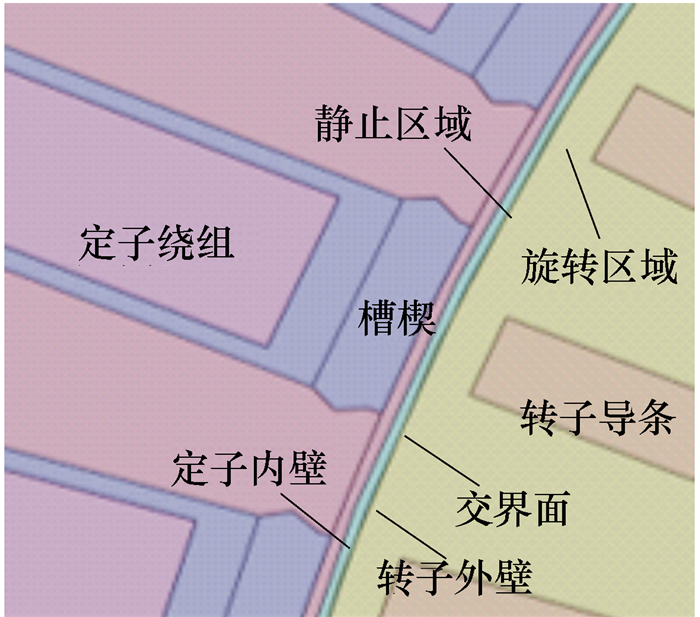

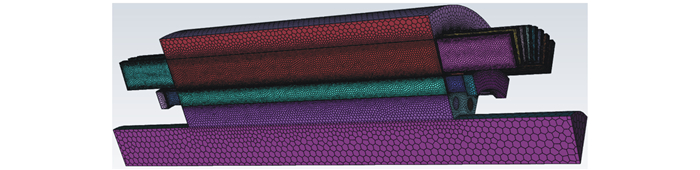

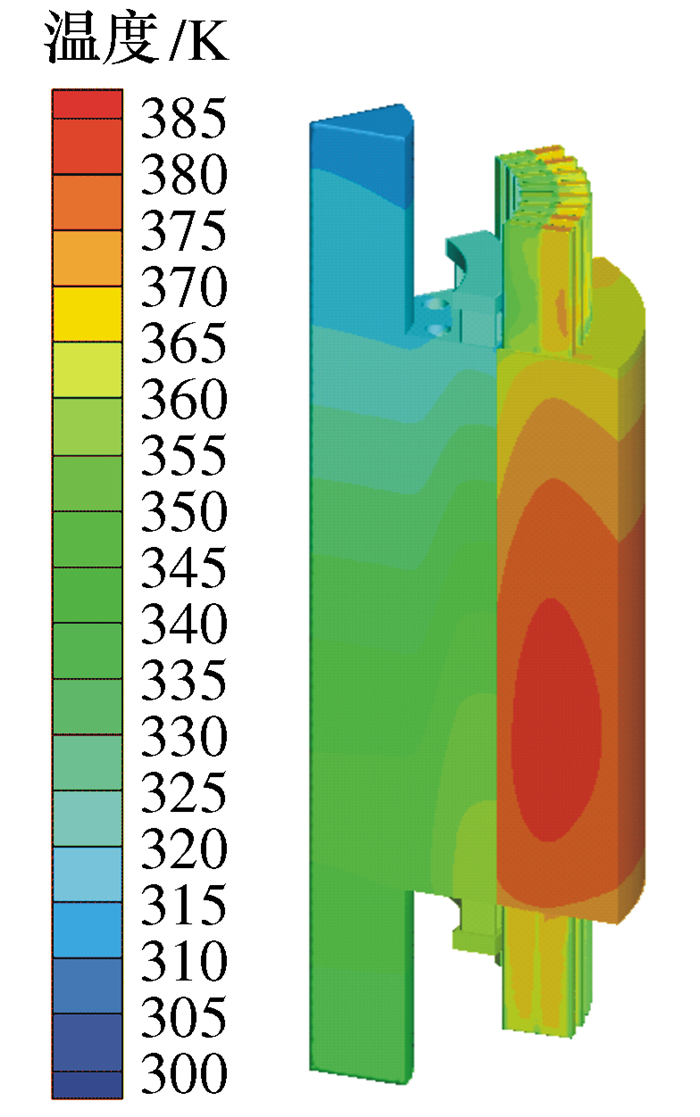

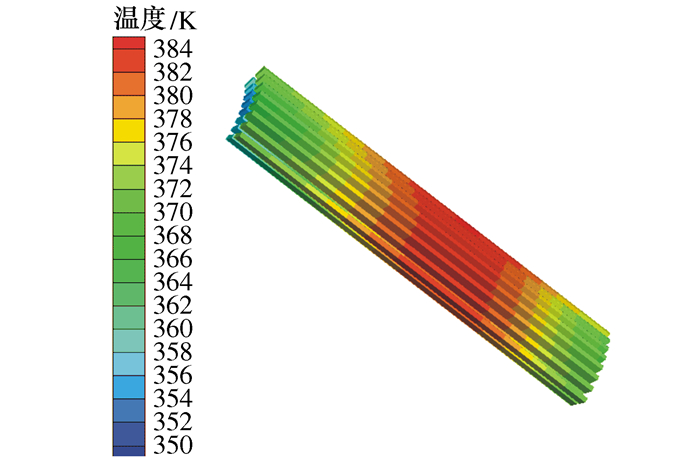

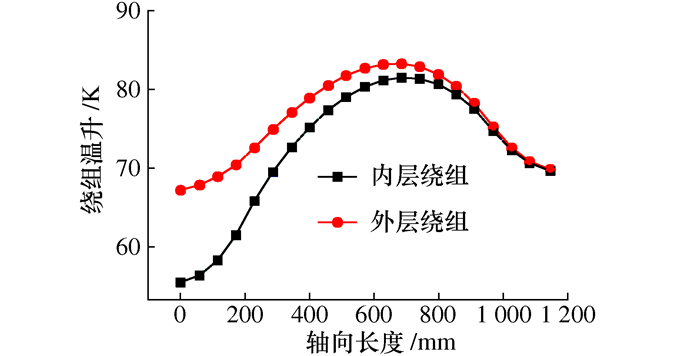

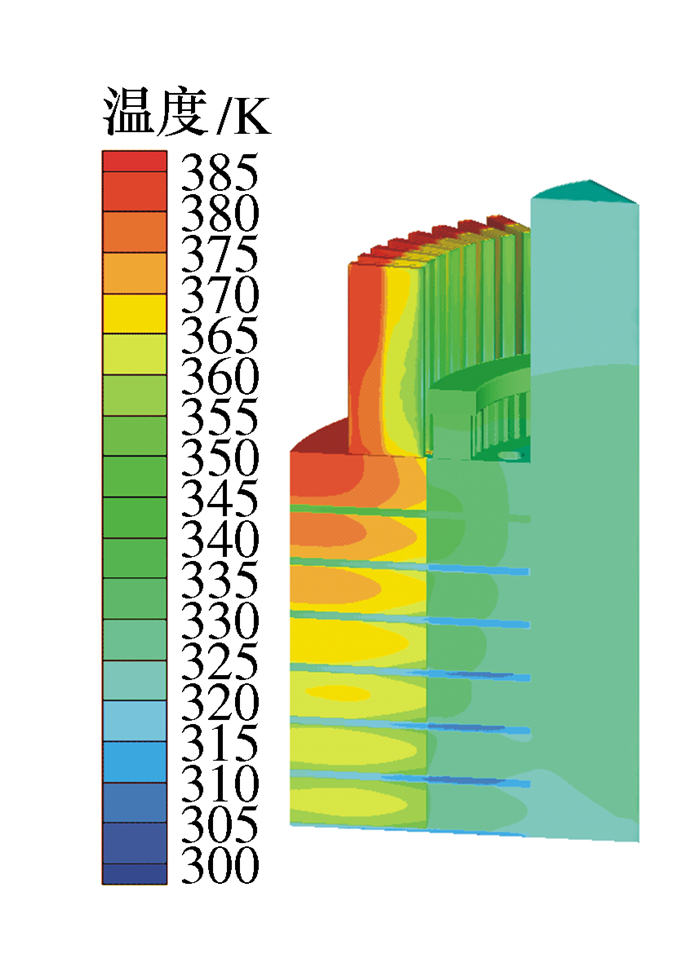

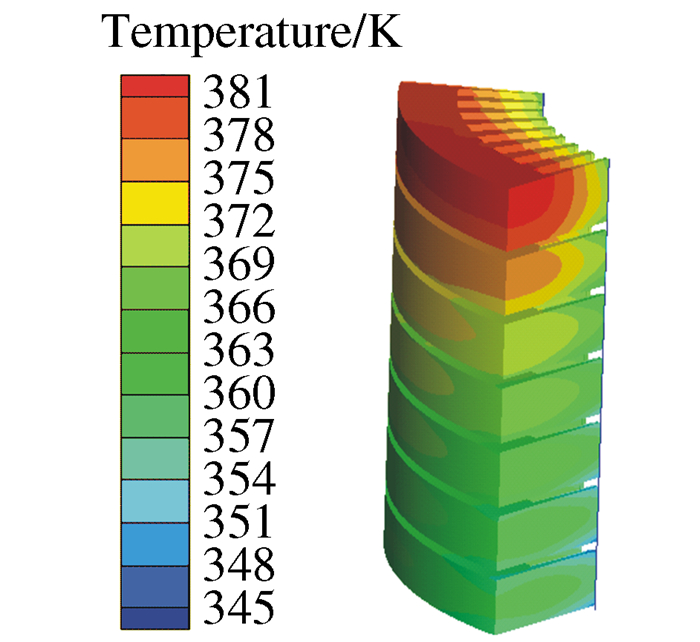

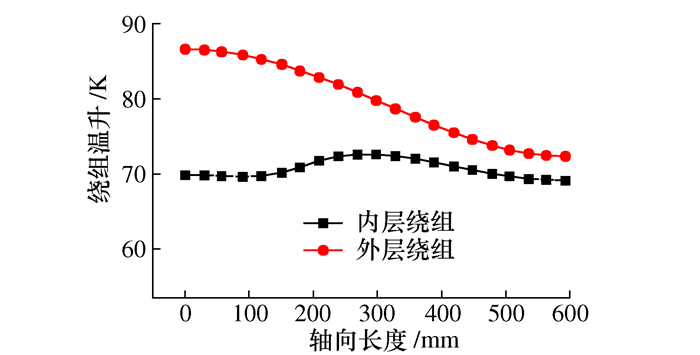

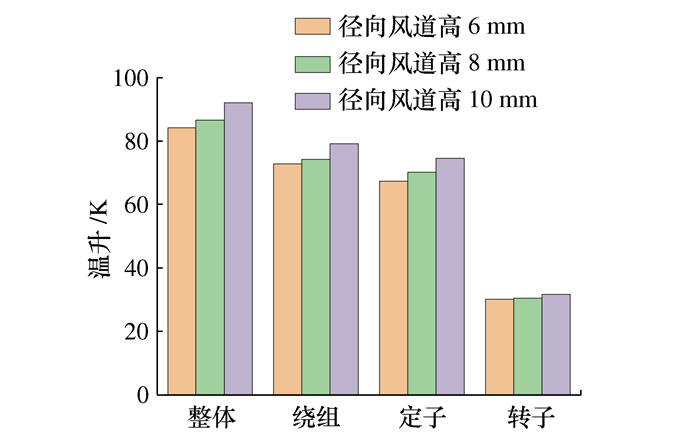

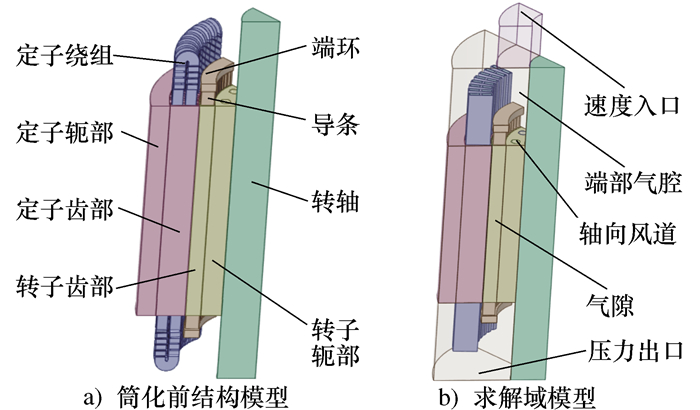

摘要: 为了提升电机的通风冷却性能、降低其运行温升,以一台400 kW中型高压电机为例,采用轴径向混合通风结构,通过磁-流-固耦合模拟研究整体电机稳态条件下温升影响规律,提出温升均匀性系数对两种通风结构的冷却效果进行量化评价。研究结果表明:相对于轴向通风结构,混合通风结构温升分布更加均匀,在电机内层和外层绕组温升均匀性系数分别提高了85.78%和6.23%;进一步探讨了径向风道高度及数量对电机温升的影响,径向风道高度为6 mm、径向风道数量为13个时冷却效果最好。Abstract: The axial and radial mixed ventilation structure is adopted in order to improve the ventilation and cooling performance and reduce the operating temperature rise of the motor. Taking a 400 kW medium-sized high voltage motor as an research object, the influence law of temperature rise of the integral motor under steady state condition is studied through magnetic-fluid-solid coupling simulation. The cooling effect of the ventilation structure is quantitatively evaluated by proposing temperature rise uniformity coefficient. The results show that the temperature rise distribution of mixed ventilation structure is more uniform, and the uniformity coefficient of temperature rise is 85.78% and 6.23% higher than that of axial ventilation structure in the inner and outer winding of motor, respectively. The influence of the height and number of radial air ducts on motor temperature rise is further studied. Cooling effect is the best when the height is 6 mm and the number of radial duct is 13.

-

表 1 电机基本参数

参数 数值 功率/kW 400 转速/(r·min-1) 991 定子内外径/mm 450/740 转子内外径/mm 230/446.8 气隙长度/mm 1.6 铁芯长度/mm 790 表 2 网格无关性验证

网格数量/×104 265 320 367 412 绕组温升/K 76.9 76.0 75.3 74.9 表 3 两种结构温升分布均匀性系数

均匀性系数η 轴向通风结构 轴径向混合通风结构 提高幅度 内层绕组 8.51 1.21 85.78% 外层绕组 5.62 5.27 6.23% 表 4 不同径向风道高度电机各部件损耗

损耗/W 径向风道高度/mm 6 8 10 绕组铜耗 4 302.37 4 393.82 4 507.90 定子铁耗 4 550.23 4 705.15 4 864.55 转子铜耗 3 427.27 3 441.90 3 448.46 杂散损耗 5 080.00 5 080.00 5 080.00 表 5 不同径向风道数电机各部件损耗

损耗/W 径向风道数量/个 12 13 14 绕组铜耗 4 291.74 4 302.37 4 324.04 定子铁耗 4 515.94 4 550.23 4 583.92 转子铜耗 3 429.59 3 427.27 3 436.07 杂散损耗 5 080.00 5 080.00 5 080.00 -

[1] JURKOVIC S, RAHMAN K M, MORGANTE J C, et al. Induction machine design and analysis for general motors e-assist electrification technology[J]. IEEE Transactions on Industry Applications, 2015, 51(1): 631-639 doi: 10.1109/TIA.2014.2330057 [2] 杜海, 曲延滨, 张鹏. 新型旋转电磁热机流体流动与传热的耦合计算与实验[J]. 电工技术学报, 2015, 30(12): 291-297 https://www.cnki.com.cn/Article/CJFDTOTAL-DGJS201512036.htmDU H, QU Y B, ZHANG P. Coupling calculation and experiment of fluid flow and heat transfer of a new rotating induction heater[J]. Transactions of China Electrotechnical Society, 2015, 30(12): 291-297 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DGJS201512036.htm [3] KRAIKITRAT K, RUANGSINCHAIWANICH S. Thermal effect of unbalanced voltage conditions in induction motor by FEM[C]//2011 International Conference on Electrical Machines and Systems (ICEMS). Beijing: IEEE, 2011: 1-4 [4] 刘苹, 张小平, 匡斯建, 等. 电机温度场分析中三维有限元模型网格划分方法[J]. 电子测量与仪器学报, 2019, 33(8): 173-178 https://www.cnki.com.cn/Article/CJFDTOTAL-DZIY201908023.htmLIU P, ZHANG X P, KUANG S J, et al. 3D finite element model mesh division method in motor temperature field analysis[J]. Journal of Electronic Measurement and Instrumentation, 2019, 33(8): 173-178 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DZIY201908023.htm [5] LI Y, XIE Y, WANG Z. Three-dimensional fluid field and thermal field research of squirrel-cage induction motors operating in broken bar fault[C]//2015 IEEE International Magnetics Conference (INTERMAG). Beijing: IEEE, 2015 [6] 丁树业, 夏之慧, 李海玲, 等. 径向通风电机流体流动及传热特性分析[J]. 哈尔滨理工大学学报, 2019, 24(1): 34-40 https://www.cnki.com.cn/Article/CJFDTOTAL-HLGX201901007.htmDING S Y, XIA Z H, LI H L, et al. Analysis of fluid flow and heat transfer characteristics for radial ventilation generator[J]. Journal of Harbin University of Science and Technology, 2019, 24(1): 34-40 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HLGX201901007.htm [7] 丁树业, 仵程程. 具有径向通风结构的5兆瓦双馈风力发电机内流热特性[J]. 电机与控制学报, 2019, 23(10): 68-76 https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ201910009.htmDING S Y, WU C C. Characteristics of fluid flow and heat transfer for a 5 megawatt wind generator with radial ventilation structure[J]. Electric Machines and Control, 2019, 23(10): 68-76 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ201910009.htm [8] 霍菲阳, 李勇, 李伟力, 等. 大型空冷汽轮发电机定子通风结构优化方案的计算与分析[J]. 中国电机工程学报, 2010, 30(6): 69-75 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC201006012.htmHUO F Y, LI Y, LI W L, et al. Calculation and analysis on stator ventilation structure of different optimum proposal in air-cooled turbogenerator[J]. Proceedings of the CSEE, 2010, 30(6): 69-75 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC201006012.htm [9] 李伟力, 杨雪峰, 顾德宝, 等. 多风路空冷汽轮发电机定子内流体流动与传热耦合计算与分析[J]. 电工技术学报, 2009, 24(12): 24-31 https://www.cnki.com.cn/Article/CJFDTOTAL-DGJS200912006.htmLI W L, YANG X F, GU D B, et al. Calculation and analysis of fluid flow and heat transfer of air-cooled turbo-generator with multipath ventilation[J]. Transactions of China Electrotechnical Society, 2009, 24(12): 24-31 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DGJS200912006.htm [10] 李伟力, 王耀玉, 黄东洙, 等. 转子通风结构对永磁电机转子流体场和温度场的影响[J]. 北京交通大学学报, 2015, 39(2): 48-54 https://www.cnki.com.cn/Article/CJFDTOTAL-BFJT201502009.htmLI W L, WANG Y Y, HUANG D Z, et al. Influence of the rotor ventilation structure on the rotor fluid and temperature field of the PMSM[J]. Journal of Beijing Jiaotong University, 2015, 39(2): 48-54 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BFJT201502009.htm [11] XIONG B, GU G B, RUAN L, et al. Studies on the structure of radial ventilation channel to improve the cooling capacity of large turbo generator stator[C]//2014 17th International Conference on Electrical Machines and Systems (ICEMS). Hangzhou: IEEE, 2014: 354-357 [12] LI W L, HAN J C, HUO F Y, et al. Influence of the end ventilation structure change on the temperature distribution in the end region of large water-hydrogen-hydrogen cooled turbogenerator[J]. IEEE Transactions on Energy Conversion, 2013, 28(2): 278-288 [13] 温嘉斌, 鄢鸿羽. 定子通风槽钢对通风沟内流体流动形态的影响[J]. 电机与控制学报, 2010, 14(11): 58-62+68 https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ201011011.htmWEN J B, YAN H Y. Influence of stator ventilation channel on fluid flow pattern inside ventilation duct[J]. Electric Machines and Control, 2010, 14(11): 58-62+68 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ201011011.htm [14] 温嘉斌, 侯健, 于喜伟. 定子通风槽钢对中型高压电机内温度场的影响[J]. 电机与控制学报, 2016, 20(8): 40-47 https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ201608007.htmWEN J B, HOU J, YU X W. Influence of stator ventilation channel on the temperature field in the middle-size high voltage motor[J]. Electric Machines and Control, 2016, 20(8): 40-47 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ201608007.htm [15] 温嘉斌, 刘艳翠, 姜天一, 等. 中型高压电机内风扇流体分析与温升计算[J]. 电机与控制学报, 2018, 22(4): 33-41 https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ201804006.htmWEN J B, LIU Y C, JIANG T Y, et al. Analysis of fluid field of the internal fan and calculation of temperature rise for medium-size high-voltage asynchronous motor[J]. Electric Machines and Control, 2018, 22(4): 33-41 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ201804006.htm [16] 韩家德, 孙鹏, 朱凌波, 等. 立式鼠笼异步电动机三维CFD热计算[J]. 电机与控制学报, 2020, 24(12): 55-61 https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ202012008.htmHAN J D, SUN P, ZHU L B, et al. 3D CFD thermal calculation for a vertical asynchronous motor with a squirrel-cage rotor[J]. Electric Machines and Control, 2020, 24(12): 55-61 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ202012008.htm [17] 谢颖, 郭金鹏, 单雪婷, 等. 油田抽油机用感应电动机三维瞬态温度场计算分析[J]. 电机与控制学报, 2019, 23(10): 59-67 https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ201910008.htmXIE Y, GUO J P, SHAN X T, et al. Three-dimensional transient temperature field calculation and analysis of induction motor for oilfield pumping unit[J]. Electric Machines and Control, 2019, 23(10): 59-67 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ201910008.htm [18] 张凤阁, 蒋晓东, 李应光, 等. 新型磁障转子无刷双馈电机热计算[J]. 中国电机工程学报, 2018, 38(9): 2745-2752 https://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC201809024.htmZHANG F G, JIANG X D, LI Y G, et al. Thermal calculation on brushless doubly-fed machines with a magnetic barrier rotor[J]. Proceedings of the CSEE, 2018, 38(9): 2745-2752 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGDC201809024.htm [19] 谢颖, 李洋洋, 单雪婷. 笼型感应电机流体流动对温度场分布的影响[J]. 电机与控制学报, 2017, 21(2): 55-62 https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ201702007.htmXIE Y, LI Y Y, SHAN X T. Influences of 3D fluid field for squirrel-cage induction motors on thermal field distribution[J]. Electric Machines and Control, 2017, 21(2): 55-62 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-DJKZ201702007.htm [20] XIE Y, GUO J P, CHEN P, et al. Coupled fluid-thermal analysis for induction motors with broken bars operating under the rated load[J]. Energies, 2018, 11(8): 2024 [21] HATZIATHANASSIOU V, XYPTERAS J, ARCHONTOULAKIS G. Electrical-thermal coupled calculation of an asynchronous machine[J]. Archiv für Elektrotechnik, 1994, 77(2): 117-122 [22] 贾志超. 产品型式试验报告[R]. 湘潭: 湘潭电机股份有限公司, 2020JIA Z C. Product type test report[R]. Xiangtan: Xiangtan Electric Manufacturing Co., Ltd., 2020 (in Chinese) [23] 陈世坤. 电机设计[M]. 2版. 北京: 机械工业出版社, 2013CHEN S K. Motor design[M]. 2nd ed. Beijing: China Machine Press, 2013 (in Chinese) -

下载:

下载: