Curved Layer Slicing for Improving Accuracy in Rapid Prototyping

-

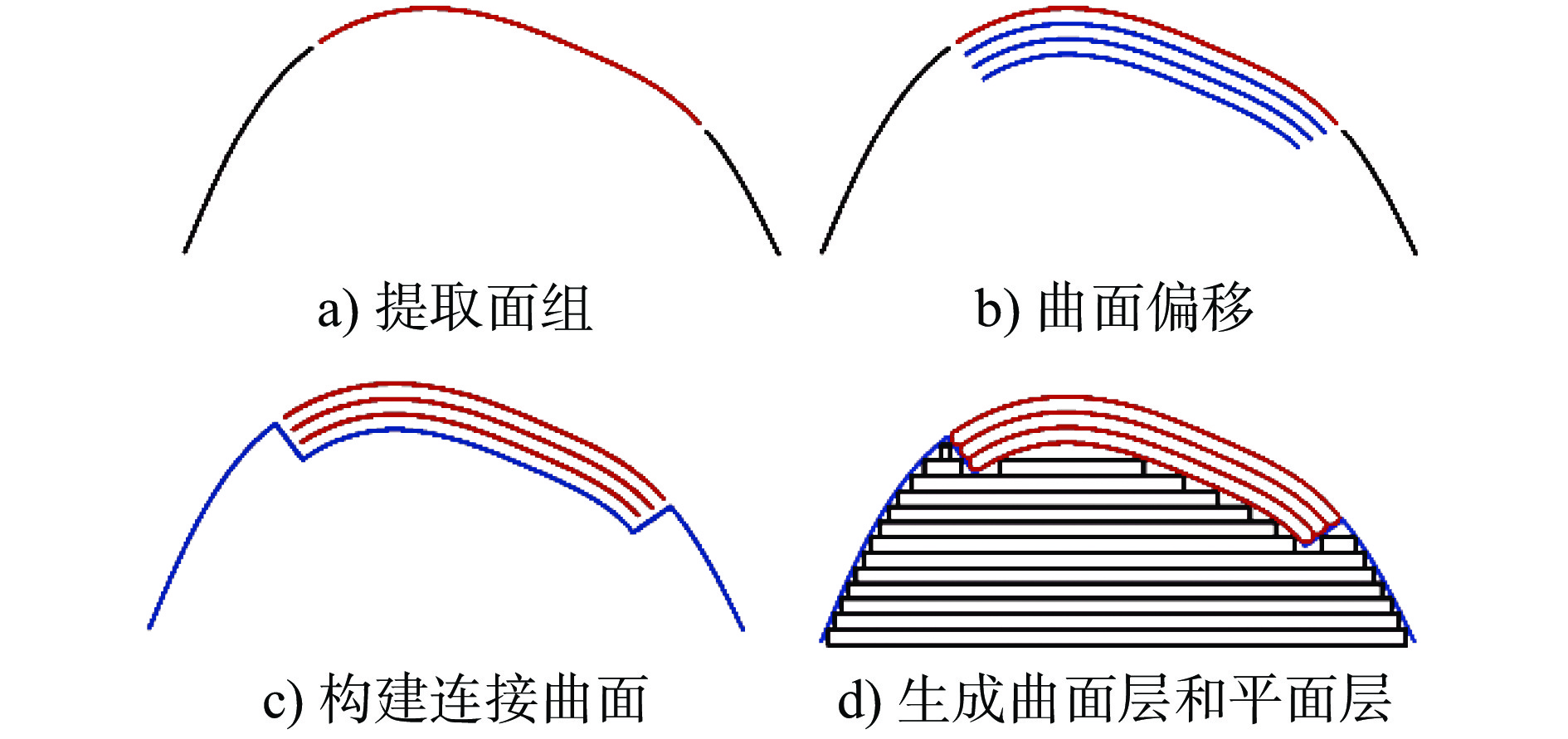

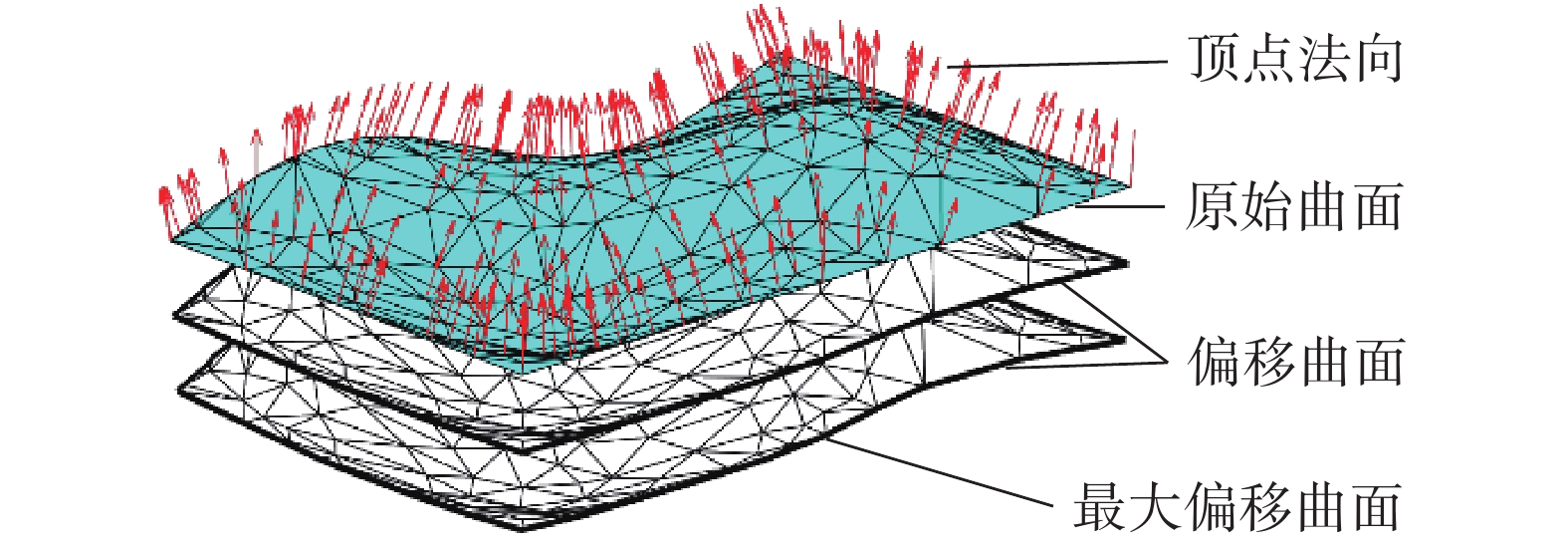

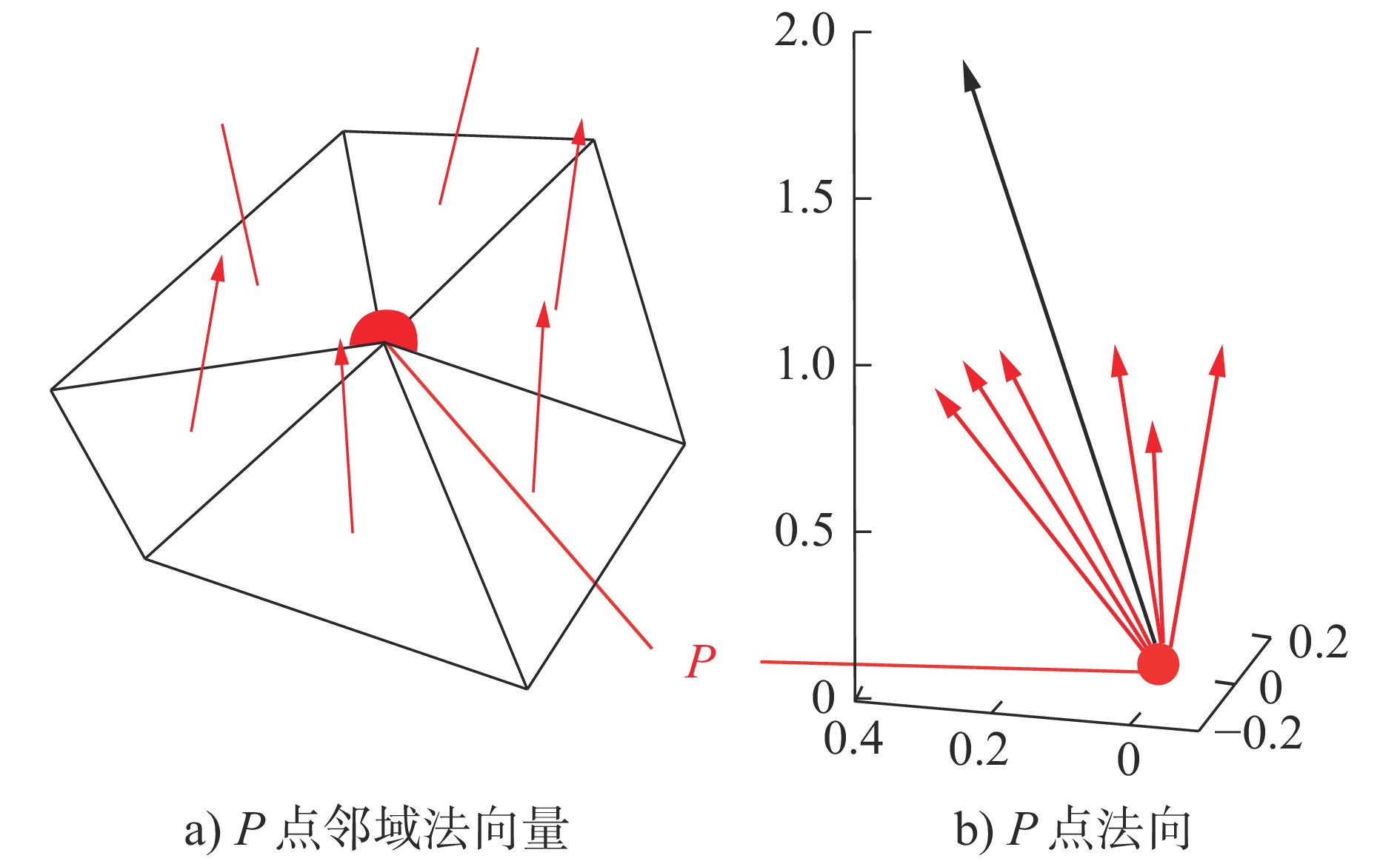

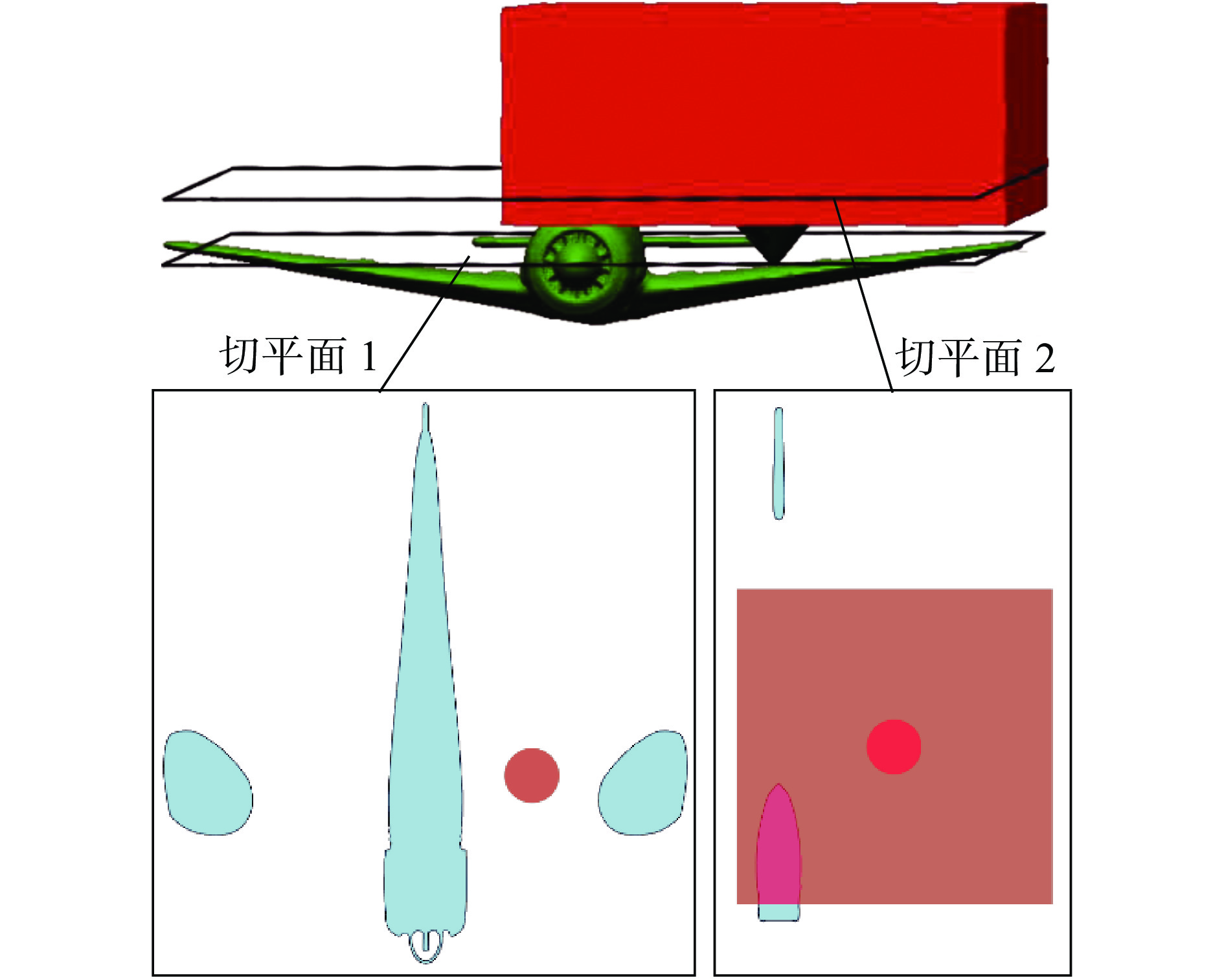

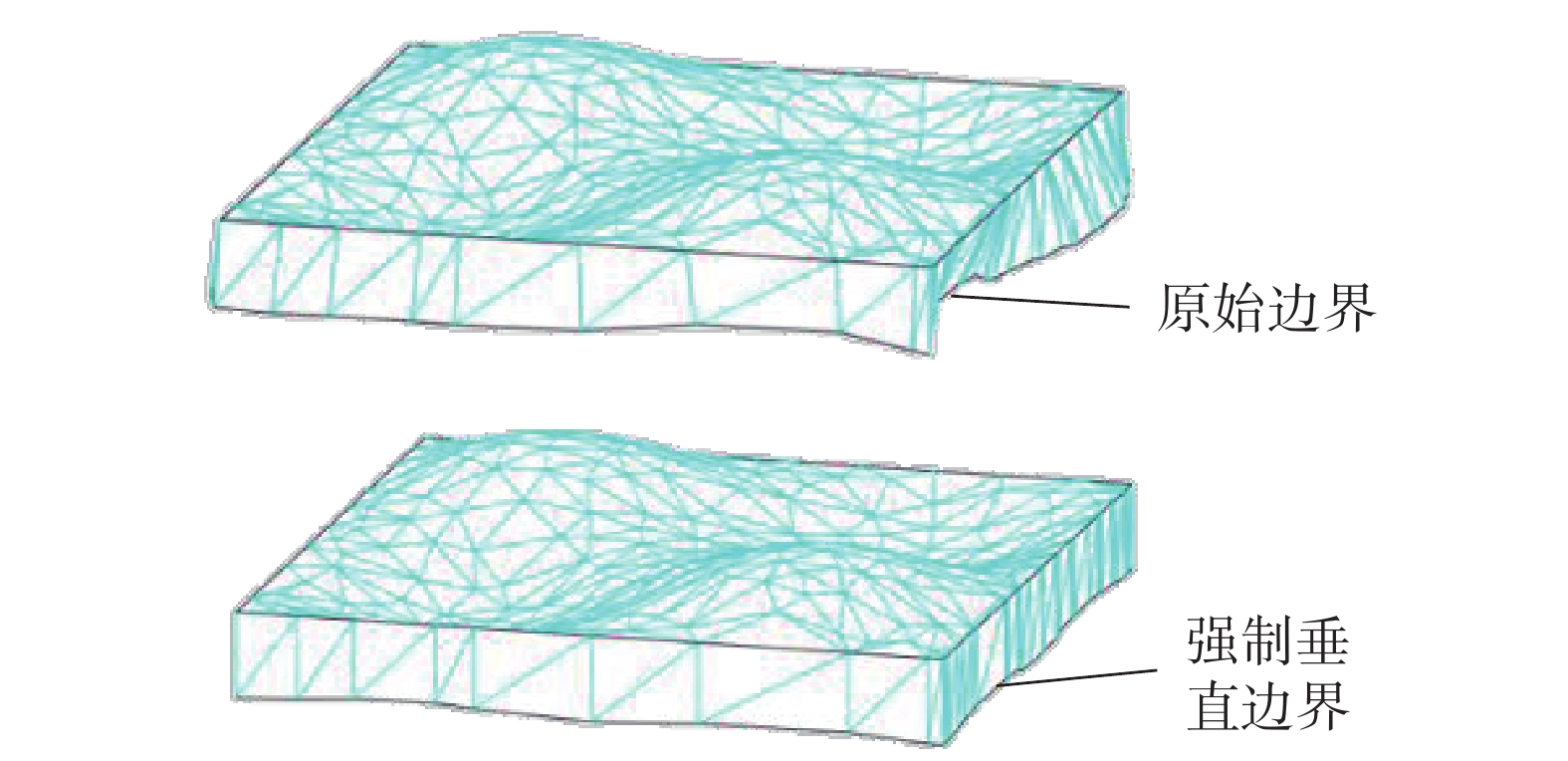

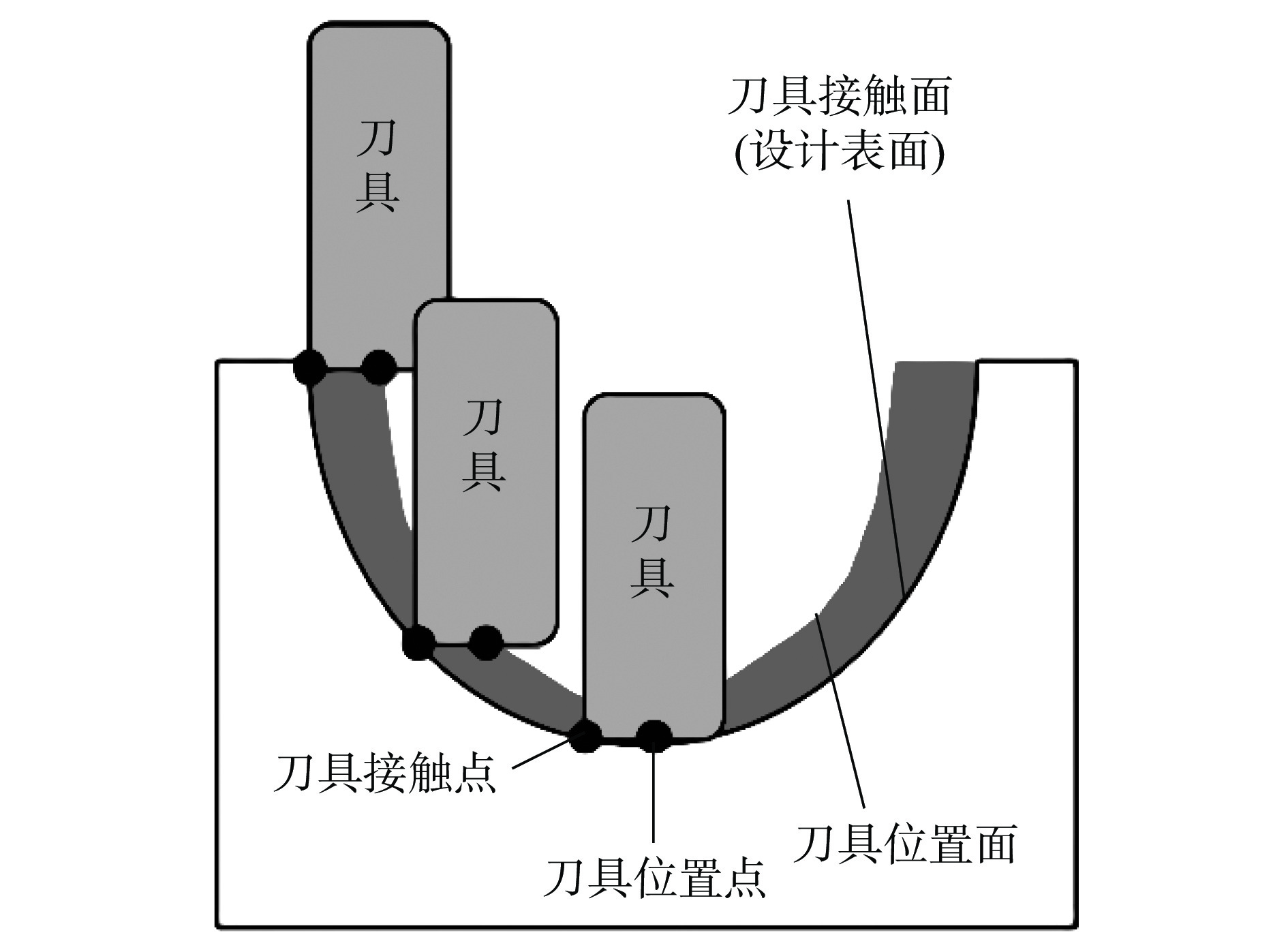

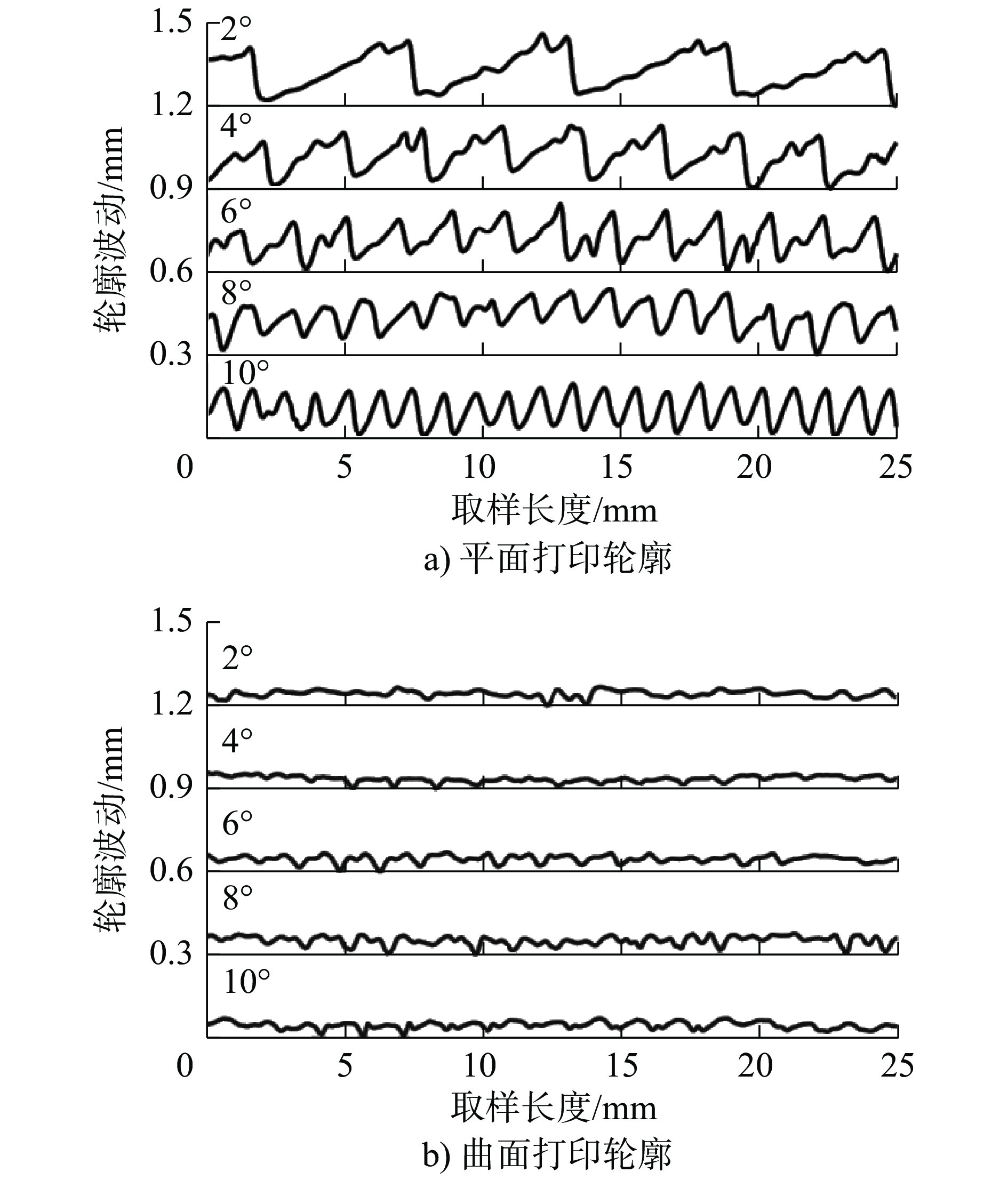

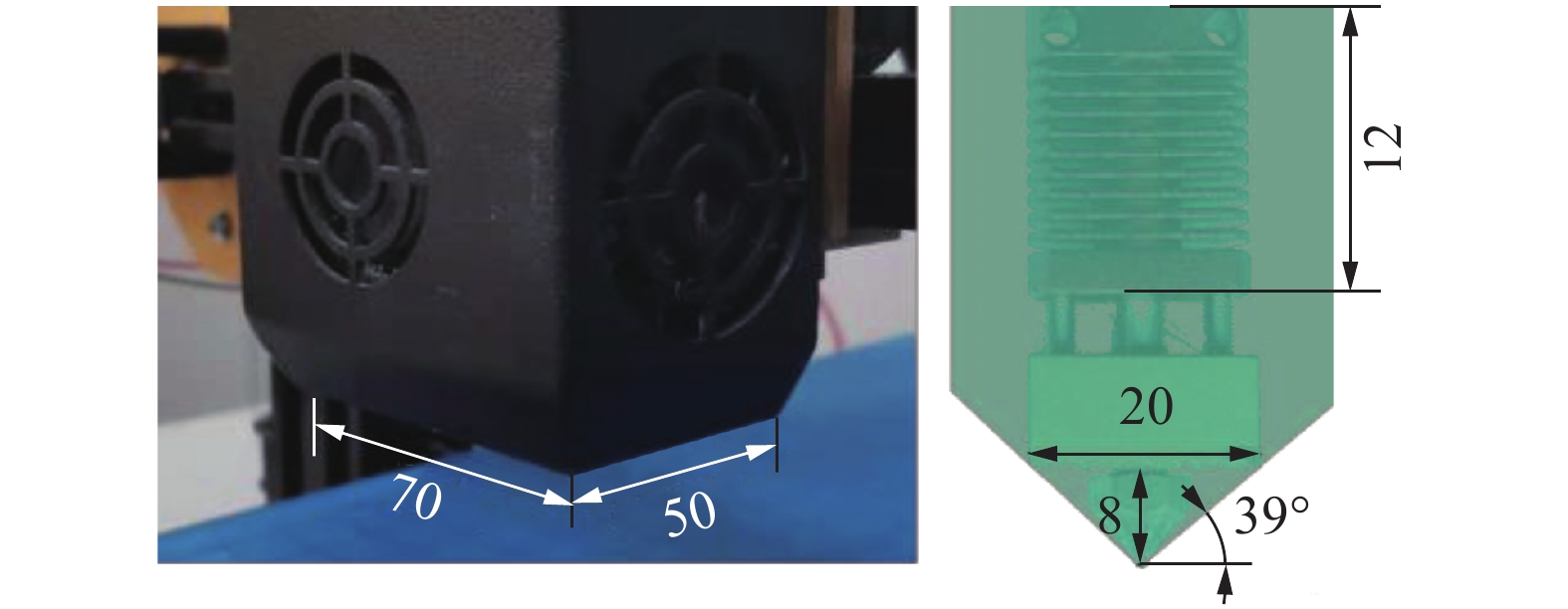

摘要: 传统成型方式只使用平面层造成零件表面精度不高,针对这一问题研究了曲面混合分层切片,并提出了一种检测成型整体精度的方法。自动检测模型中可以曲面打印的部分,使用更加精准的邻域法向均值算法计算偏移曲面,并对原始模型进行处理生成平面基底;针对实际中较为复杂模型,编写了碰撞检测和成型顺序规划算法,可根据实际成型设备的情况生成无碰撞的刀具路径。最后,实测打印多个零件对比,证明曲面打印能够大幅提升表面质量,拥有更低的表面粗糙度和更高的整体精度。Abstract: The traditional forming method uses the plane layer only, which cause the low surface accuracy of the parts, aiming at this problem, a novel curved mix-layer slicing method is studied, and a method to detect the overall accuracy of model is proposed. For a model for automatically detection printable surface for curved printing, and the more accurate neighbor-normal mean algorithm is used to calculate the offset surface and generate the plane base layer according to the original model. A collision detection and forming sequence planning process are also included for the complex model, which can generate collision free tool path according to the actual situation of forming equipment. Finally, the comparison results of multiple parts show that curved slicing can greatly improve the surface quality with lower surface roughness and higher overall accuracy.

-

Key words:

- rapid prototyping /

- curved-layer slicing /

- printing accuracy

-

表 1 成型表面质量对比

打印模式 Ra/μm Rz/μm Rsm/μm 2°平面打印 129.3 230.3 5.31 2°曲面打印 42.4 57.8 0.89 4°平面打印 118.1 217.0 2.90 4°曲面打印 37.5 53.8 0.74 6°平面打印 113.4 214.3 1.87 6°曲面打印 44.8 59.6 0.83 8°平面打印 88.6 192.8 1.34 8°曲面打印 60.6 72.8 0.82 10°平面打印 96.4 173.1 1.17 10°曲面打印 43.6 57.2 0.85 表 2 模型偏差对比

mm 模型 打印模式 平均偏差 标准偏差 离散值 飞机 曲面 0.0035 0.0541 0.0029 平面 0.0888 0.0677 0.0046 波浪面 曲面 0.0017 0.0704 0.005 平面 0.0985 0.0819 0.0086 扇叶 曲面 −0.006 0.0588 0.0062 平面 0.0936 0.0926 0.086 海龟 曲面 0.0069 0.0807 0.012 平面 0.1035 0.1043 0.071 -

[1] 王耀, 王春香, 周国勇, 等. 快速成型技术中分层算法的研究综述[J]. 计算机集成制造系统, 2021, 21(3): 828-841. doi: 10.13196/j.cims.2021.03.015WANG Y, WANG C X, ZHOU G Y, et al. Review of research on slicing algorithm in rapid prototyping technology[J]. Computer Integrated Manufacturing Systems, 2021, 21(3): 828-841. (in Chinese) doi: 10.13196/j.cims.2021.03.015 [2] CHAKRABORTY D, REDDY B A, CHOUDHURY A R. Extruder path generation for curved layer fused deposition modeling[J]. Computer-Aided Design, 2008, 40(2): 235-243. doi: 10.1016/j.cad.2007.10.014 [3] ETIENNE J, RAY N, PANOZZO D, et al. CurviSlicer: slightly curved slicing for 3-axis printers[J]. ACM Transactions on Graphics, 2019, 38(4): 81. [4] LLEWELLYN-JONES T, ALLEN R, TRASK R. Curved layer fused filament fabrication using automated toolpath generation[J]. 3D Printing and Additive Manufacturing, 2016, 3(4): 236-243. doi: 10.1089/3dp.2016.0033 [5] ALSHARHAN A T, CENTEA T, GUPTA S K. Enhancing mechanical properties of thin-walled structures using non-planar extrusion based additive manufacturing[C]//Proceedings of the ASME 2017 12th International Manufacturing Science and Engineering Conference collocated with the JSME/ASME 2017 6th International Conference on Materials and Processing. Los Angeles: ASME, 2017: V002T01A016 [6] 冯晓静, 崔滨, 刘亚雄, 等. 利用模型分解的曲面分层五轴挤出打印装置及工艺[J]. 西安交通大学学报, 2019, 53(4): 24-30. doi: 10.7652/xjtuxb201904004FENG X J, CUI B, LIU Y X, et al. 5-axis curved layer material extrusion modeling device and processing based on model decomposition[J]. Journal of Xi′an Jiaotong University, 2019, 53(4): 24-30. (in Chinese) doi: 10.7652/xjtuxb201904004 [7] KHURANA J B, DINDA S, SIMPSON T W. Active-Z printing: a new approach to increasing 3D printed part strength[C]//Solid Freeform Fabrication 2017: Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium-An Additive Manufacturing Conference. 2017: 1627-1644 [8] JIN Y, DU J K, HE Y, et al. Modeling and process planning for curved layer fused deposition[J]. The International Journal of Advanced Manufacturing Technology, 2017, 91(1-4): 273-285. doi: 10.1007/s00170-016-9743-5 [9] SINGAMNENI S, DIEGEL O, HUANG B, et al. Curved-layer fused deposition modelling[J]. Journal for New Generation Sciences, 2010, 8(2): 95-107. [10] HUANG B. Development of a software procedure for curved layered fused deposition modelling (CLFDM)[D]. Auckland: Auckland University of Technology, 2009 [11] AHLERS D, WASSERFALL F, HENDRICH N, et al. 3D printing of nonplanar layers for smooth surface generation[C]//Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering. Vancouver: IEEE, 2019: 1737-1743 [12] 牛其华. 基于体素的电弧增材制造曲面分层及路径规划方法研究[D]. 武汉: 华中科技大学, 2019NIU Q H. Research of curved layer and path planning method based on voxel for wire arc additive manufacturing[D]. Wuhan: Huazhong University of Science and Technology, 2019. (in Chinese) [13] 金宇鹏. 机器人增材制造曲面分层与中轴路径规划算法研究[D]. 哈尔滨: 哈尔滨工业大学, 2019JIN Y P. Surface layering and central axis path planning algorithm for robotic additive manufacturing[D]. Harbin: Harbin Institute of Technology, 2019. (in Chinese) [14] 刘灏强, 曹良成, 朱文, 等. 曲面共形3D打印轨迹路径的生成方法[J]. 机械科学与技术, 2018, 37(3): 418-423. doi: 10.13433/j.cnki.1003-8728.2018.0314LIU H Q, CAO L C, ZHU W, et al. Path generation method for surface conformal 3D printing[J]. Mechanical Science and Technology for Aerospace Engineering, 2018, 37(3): 418-423. (in Chinese) doi: 10.13433/j.cnki.1003-8728.2018.0314 [15] HUANG B, SINGAMNENI S. A mixed-layer approach combining both flat and curved layer slicing for fused deposition modelling[J]. Proceedings of the Institution of Mechanical Engineers, Part B:Journal of Engineering Manufacture, 2015, 229(12): 2238-2249. doi: 10.1177/0954405414551076 [16] ZHAO D H, GUO W Z, GAO F. Research on curved layer fused deposition modeling with a variable extruded filament[J]. Journal of Computing and Information Science in Engineering, 2020, 20(4): 041014. doi: 10.1115/1.4045637 [17] 余道洋. 3D打印机G代码预处理优化算法[J]. 中国机械工程, 2019, 30(1): 85-89 + 112. doi: 10.3969/j.issn.1004-132X.2019.01.012YU D Y. G code preprocessing optimization algorithm for 3D printers[J]. China Mechanical Engineering, 2019, 30(1): 85-89 + 112. (in Chinese) doi: 10.3969/j.issn.1004-132X.2019.01.012 -

下载:

下载: