Exploring Low-speed Dynamic Impact Response of AluminumHoneycomb Sandwich Panel

-

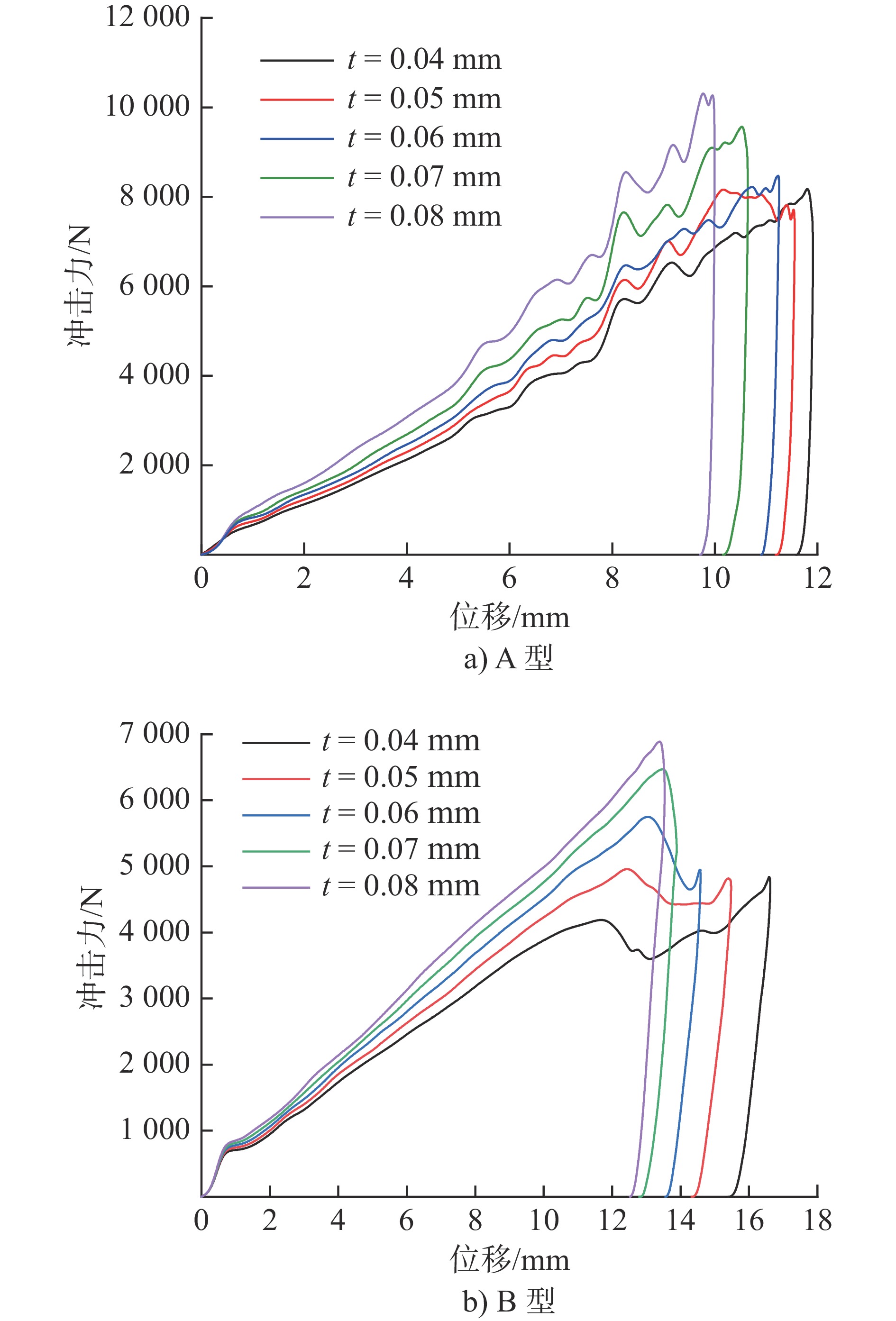

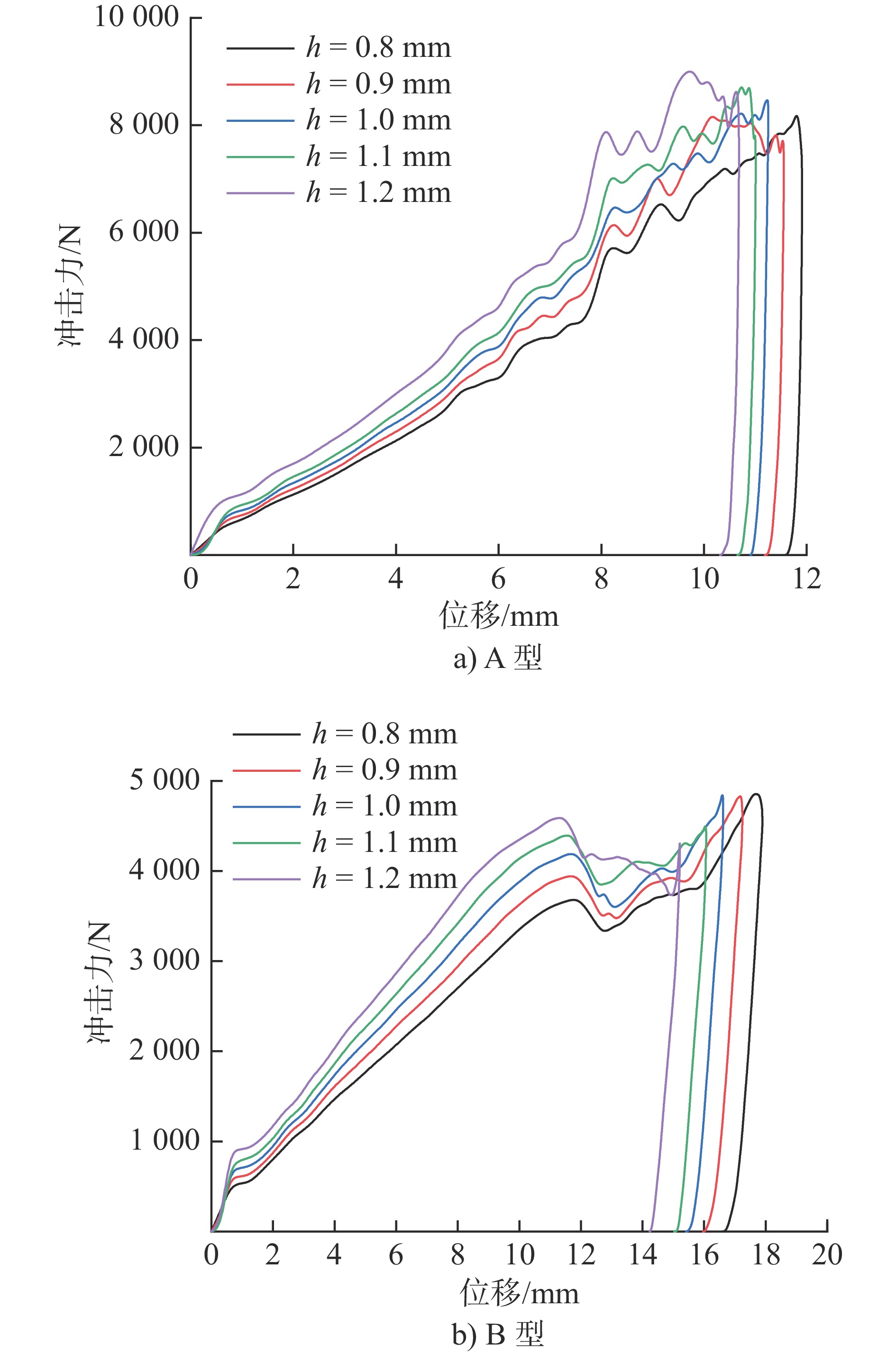

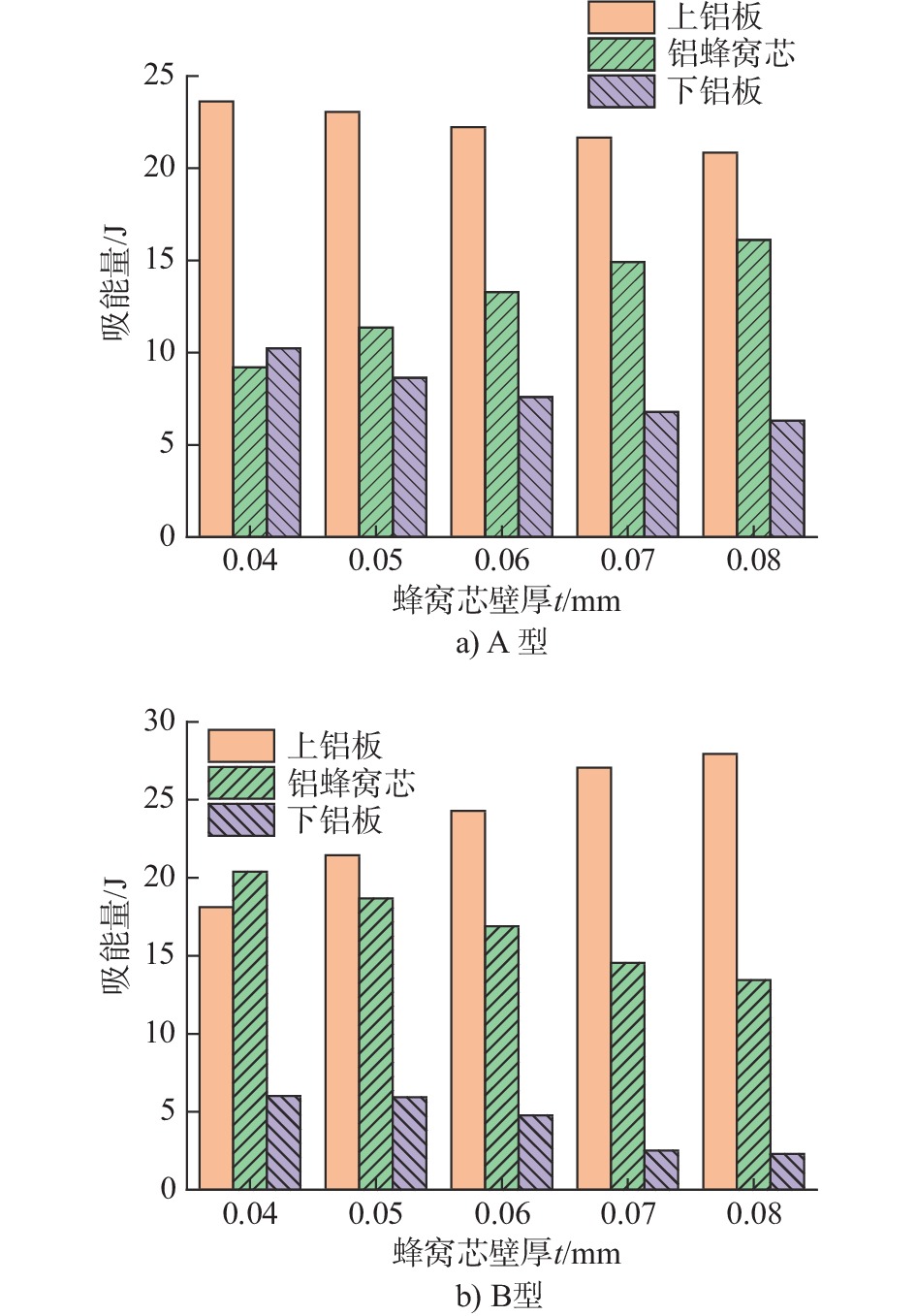

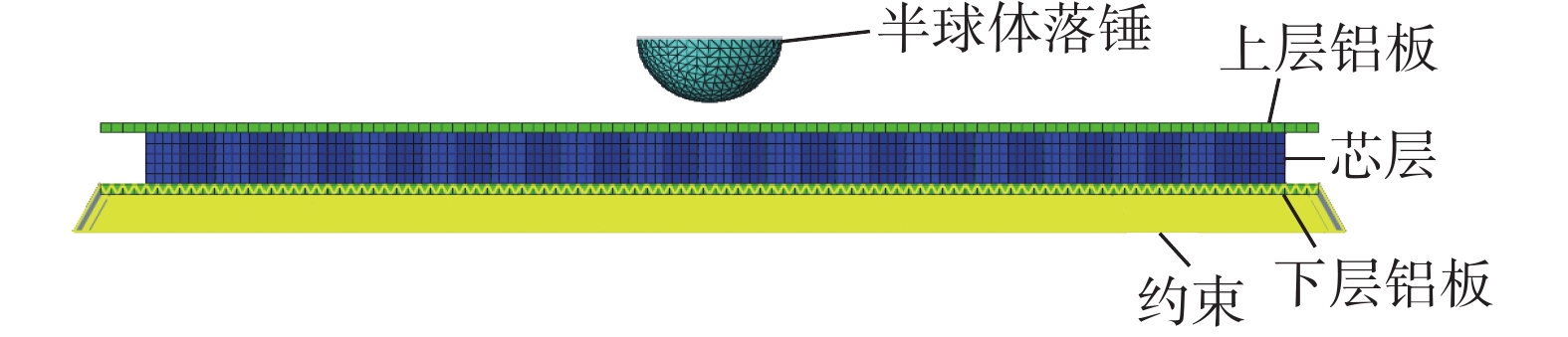

摘要: 为研究不同结构参数对质量相同、强度不同的两种铝蜂窝夹芯板低速动态冲击响应的影响,建立了铝蜂窝夹芯板受半球型落锤低速冲击的数值模型,并将有限元计算结果与试验结果进行对比,检验了模型的可靠性。在此基础上,对比研究了不同上下铝板厚度和不同蜂窝芯壁厚对两种铝蜂窝夹芯板在低速冲击下吸能效果的影响。结果表明:在质量相同的情况下,强度小、高度大的夹芯板在低速冲击下力-位移曲线更易出现双峰模式,增加蜂窝芯壁厚或是上下铝板厚度都会使第一次的峰值力增加,第二次峰值力降低;强度小、高度大的夹芯板蜂窝芯在低速冲击中吸能占比更多,强度大、高度小的则是上层铝板吸收的能量更多,前者的质量、体积比吸能更高;铝蜂窝夹芯板质量比吸能和体积比吸能与壁厚边长比、板厚芯高比均呈幂次关系。Abstract: To study the influence of different structural parameters on the low-speed dynamic impact response of two aluminum honeycomb sandwich panels that have the same mass and different strength, the numerical model of the aluminum honeycomb sandwich panel subjected to the low-speed impact of a half-ball drop hammer was established. The results on its finite element calculation and test were compared to verify the reliability of the model. On this basis, the effects of different upper and lower aluminum panel thickness and honeycomb core wall thickness on the energy absorption of the aluminum honeycomb sandwich panel under low-speed impact were studied. The results show that, under the condition of the same mass, the force-displacement curve of the sandwich panel with small strength and large height is more likely to appear in the bimodal mode under low-speed impact. Increasing the honeycomb core wall thickness or the upper and lower aluminum panel thickness may increase the first peak force but reduce the second peak force. The honeycomb core of the sandwich panel with small strength but large height occupies more energy absorption ratio in low-speed impact, while the upper aluminum panel with large strength but small height absorbs more energy, and the mass and volume of the former are higher than the energy absorption ratio of the latter. The mass and volume specific energy absorption ratio of the aluminum honeycomb sandwich panel is dependent on the ratio of wall thickness to side length and the ratio of plate thickness to core thickness.

-

图 2 蜂窝夹芯板接触面冲击力对比[6]

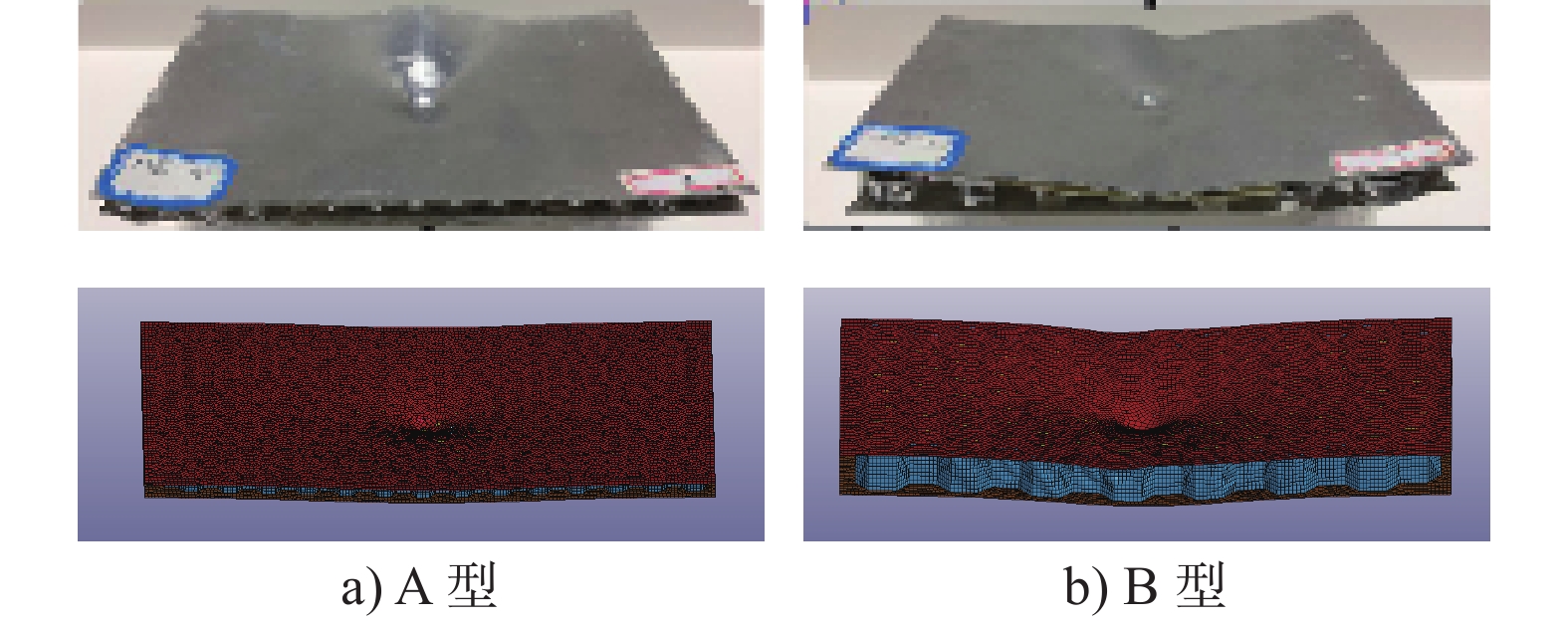

图 3 落锤冲击结束后试验和仿真的结果对比[6]

表 1 两种类型蜂窝的尺寸

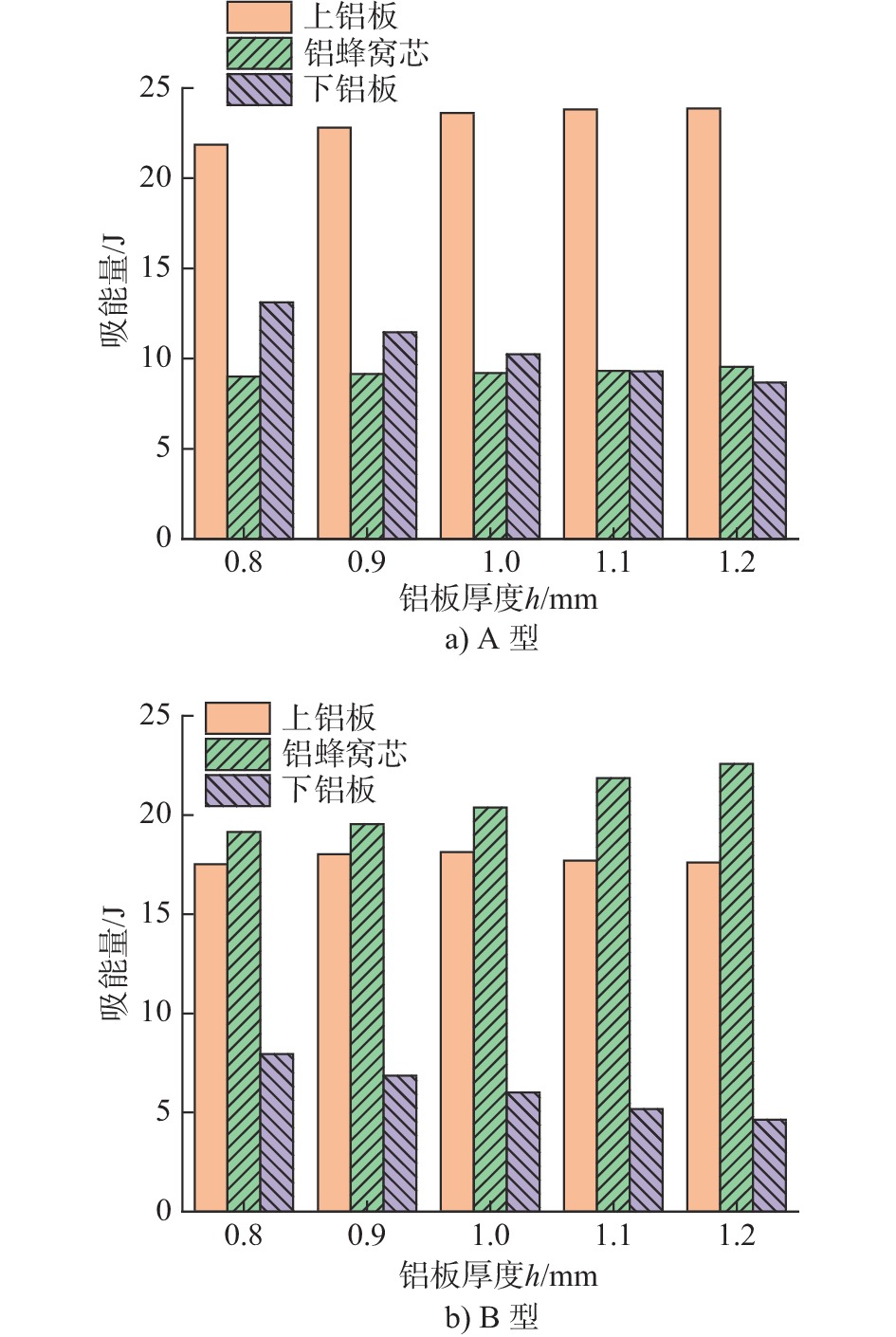

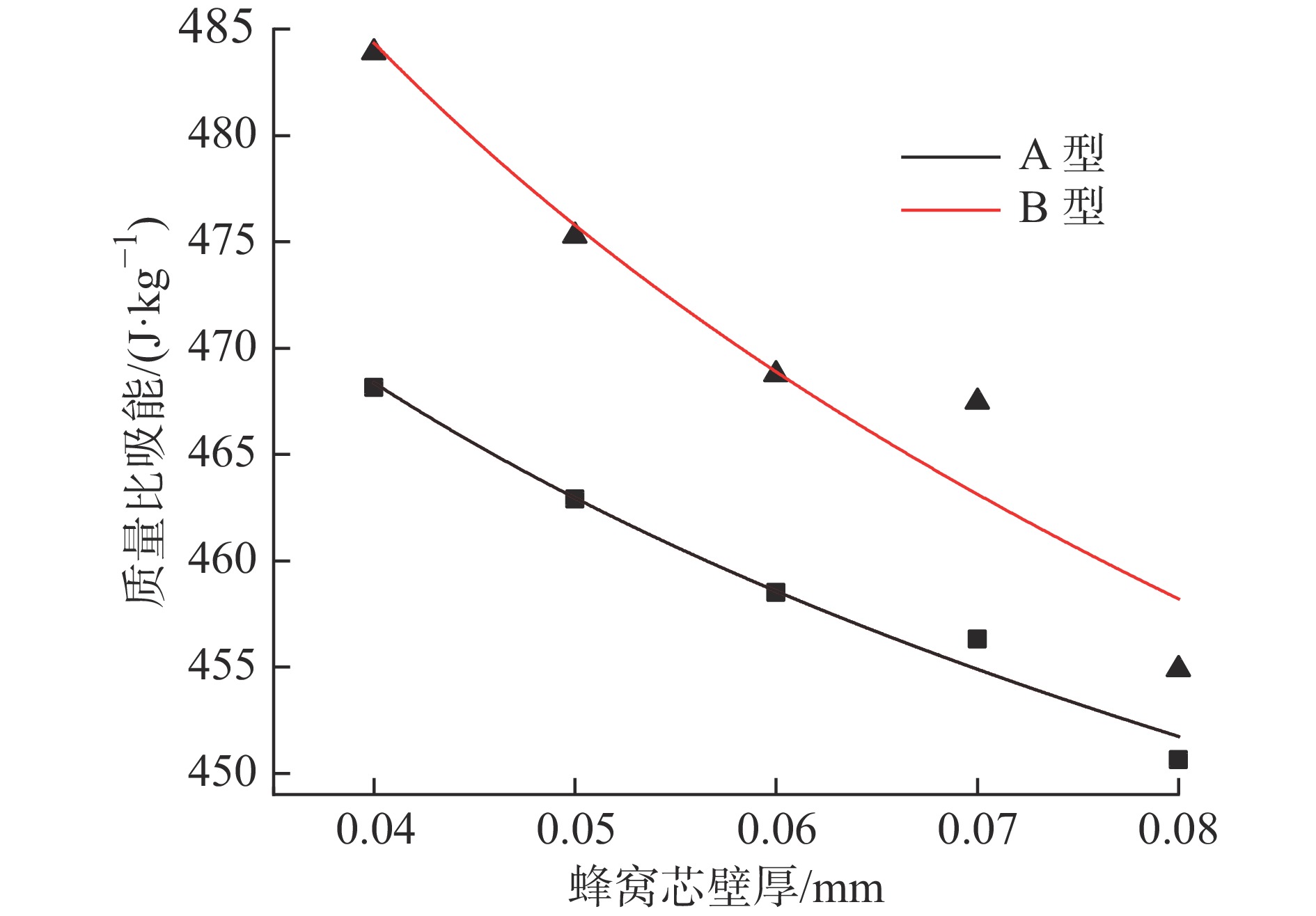

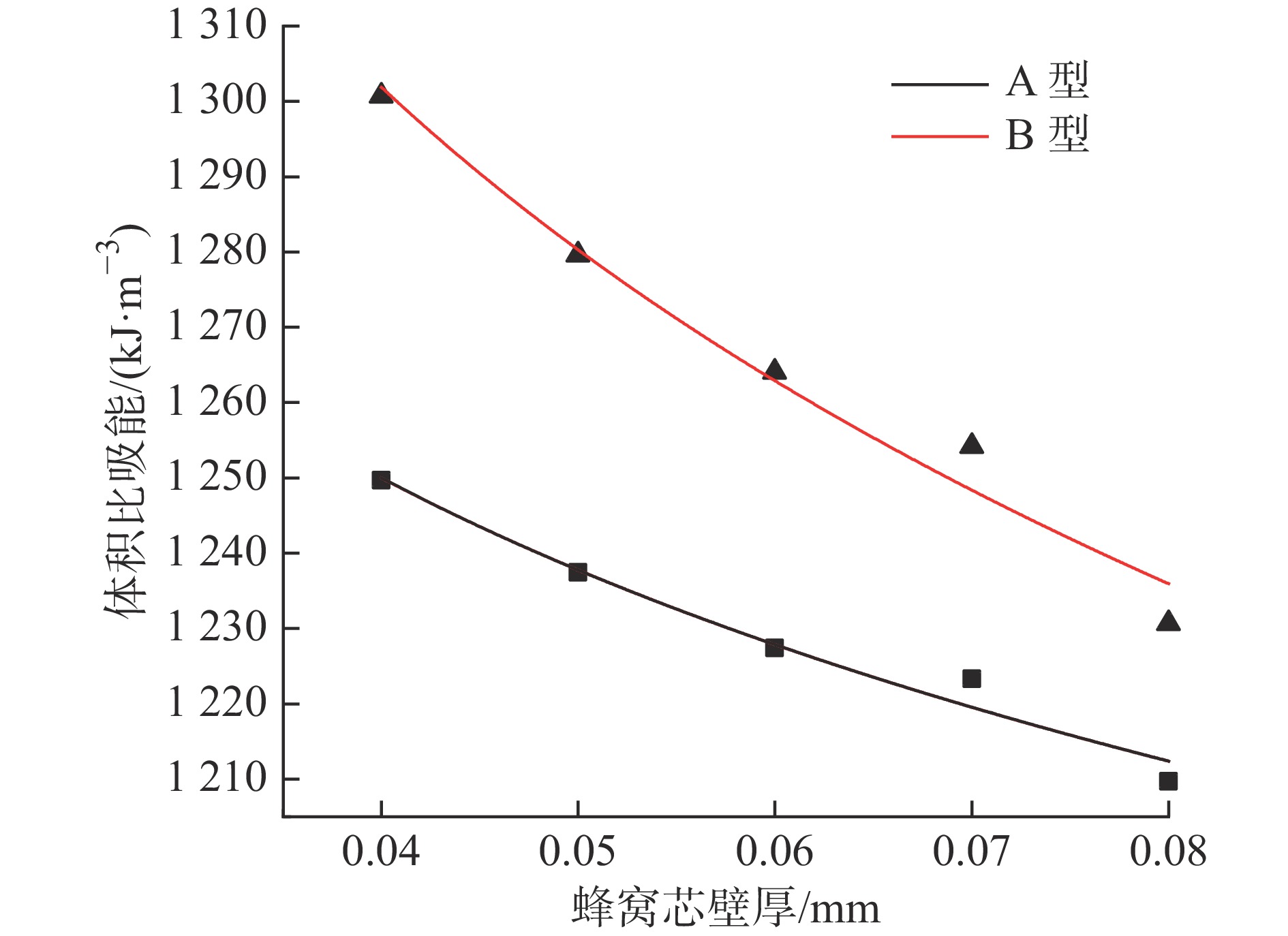

蜂窝类型 胞元边长/mm 胞元壁厚/mm 蜂窝高度/mm A 3.5 0.04 5 B 7.0 0.04 10 表 2 两种类型夹芯板在不同铝蜂窝芯壁厚下的吸能总量

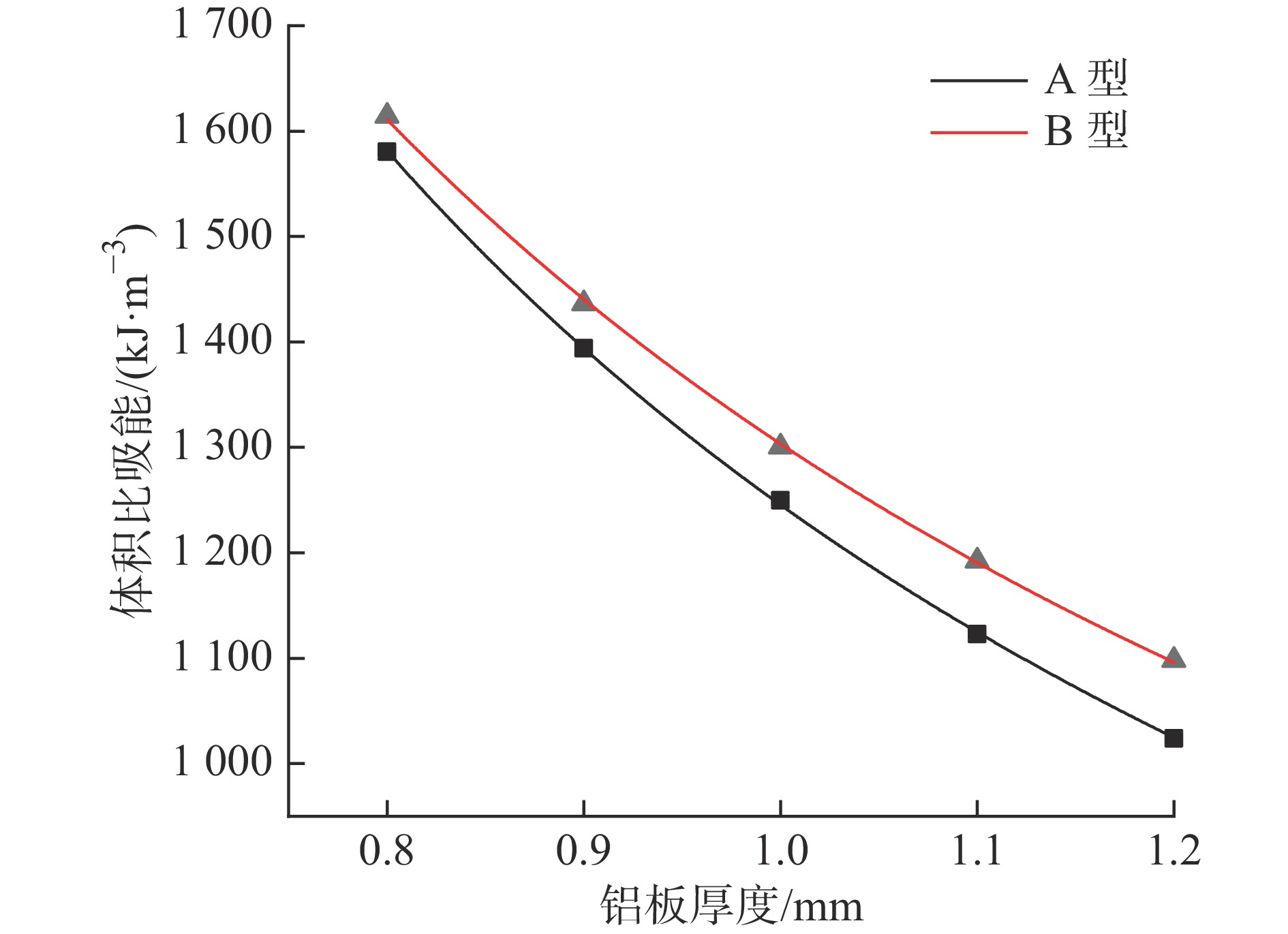

铝蜂窝芯壁厚t/mm A型吸能总量/J B型吸能总量/J 0.04 43.07 44.52 0.05 43.05 44.20 0.06 43.1 44.06 0.07 43.35 44.11 0.08 43.26 43.67 表 3 两种类型夹芯板在不同铝板厚度下的吸能总量

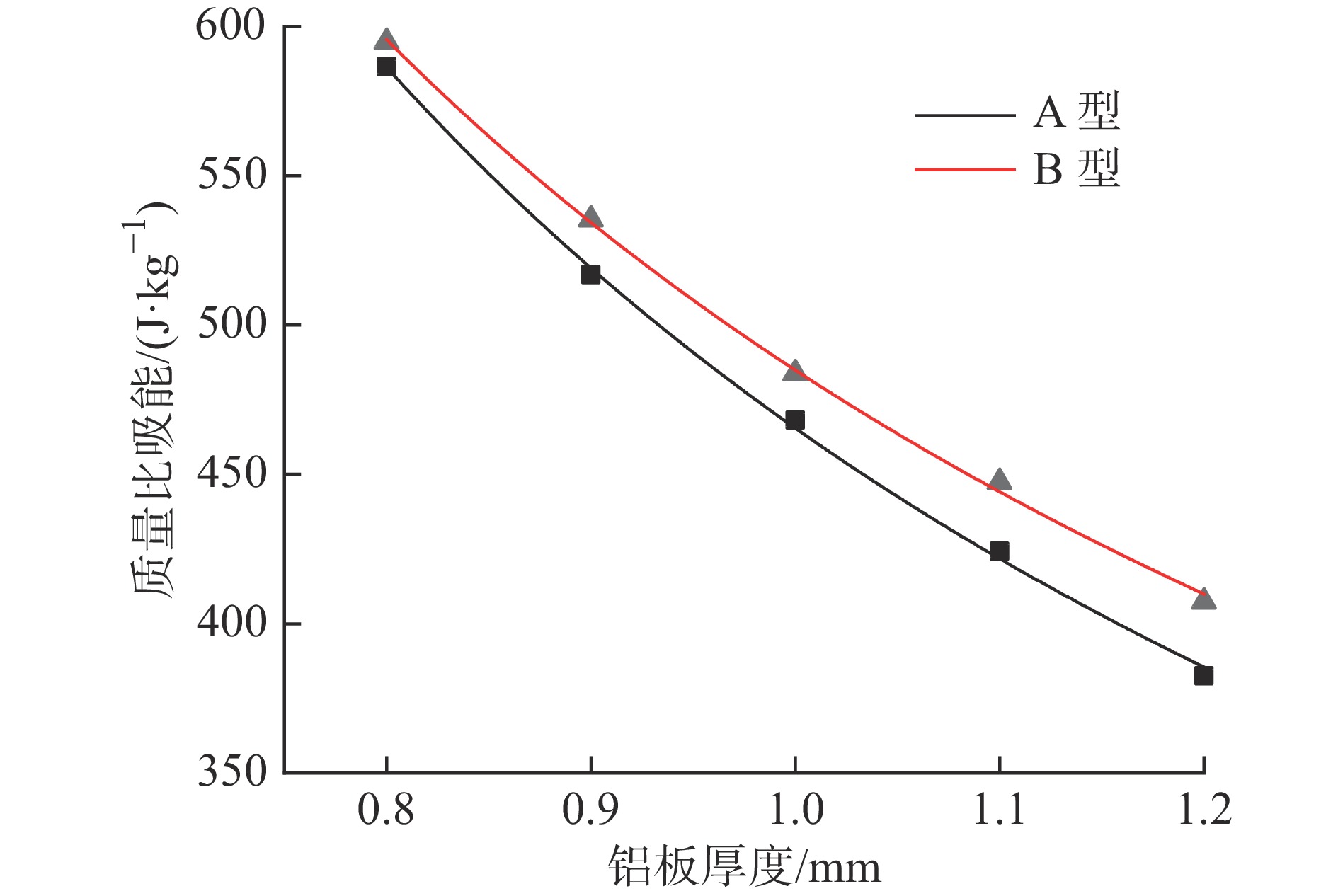

铝板厚度h/mm A型吸能总量/J B型吸能总量/J 0.8 43.98 44.61 0.9 43.42 44.43 1.0 43.07 44.52 1.1 42.42 44.75 1.2 42.08 44.82 -

[1] WOWK D, REYNO T, YEUNG R, et al. An experimental and numerical investigation of core damage size in honeycomb sandwich panels subject to low-velocity impact[J]. Composite Structures, 2020, 254: 112739. doi: 10.1016/j.compstruct.2020.112739 [2] DAI X J, YUAN T Y, ZU Z, et al. Experimental investigation on the response and residual compressive property of honeycomb sandwich structures under single and repeated low velocity impacts[J]. Materials Today Communications, 2020, 25: 101309. doi: 10.1016/j.mtcomm.2020.101309 [3] 陈博, 张彦飞, 王智, 等. PVC泡沫夹芯板低速冲击响应数值模拟[J]. 玻璃钢/复合材料, 2016(2): 29-34.CHEN B, ZHANG Y F, WANG Z, et al. Simulating the response of the PVC foam sandwich panels subjected to low-velocity impact[J]. Fiber Reinforced Plastics/Composites, 2016(2): 29-34. (in Chinese) [4] 辛亚军, 张立伟, 刘小蛮, 等. 蜂窝铝夹芯板动态冲击试验研究[J]. 机械强度, 2018, 40(4): 802-809. doi: 10.16579/j.issn.1001.9669.2018.04.007XIN Y J, ZHANG L W, LIU X M, et al. Impact test on aluminum honeycomb sandwich panels[J]. Journal of Mechanical Strength, 2018, 40(4): 802-809. (in Chinese) doi: 10.16579/j.issn.1001.9669.2018.04.007 [5] ZHANG D H, JIANG D, FEI Q G, et al. Experimental and numerical investigation on indentation and energy absorption of a honeycomb sandwich panel under low-velocity impact[J]. Finite Elements in Analysis and Design, 2016, 117-118: 21-30. doi: 10.1016/j.finel.2016.04.003 [6] 罗伟铭, 石少卿, 廖瑜, 等. 成层式铝蜂窝夹芯结构冲击响应试验研究[J]. 材料导报, 2018, 32(8): 1328-1332. doi: 10.11896/j.issn.1005-023X.2018.08.023LUO W M, SHI S Q, LIAO Y, et al. An Experimental investigation upon the impact response of the layered aluminum honeycomb sandwich structure[J]. Materials Review, 2018, 32(8): 1328-1332. (in Chinese) doi: 10.11896/j.issn.1005-023X.2018.08.023 [7] SUN M Q, WOWK D, MECHEFSKE C, et al. An analytical study of the plasticity of sandwich honeycomb panels subjected to low-velocity impact[J]. Composites Part B:Engineering, 2019, 168: 121-128. doi: 10.1016/j.compositesb.2018.12.071 [8] XIE Z H, ZHAO W, WANG X N, et al. Low-velocity impact behaviour of titanium honeycomb sandwich structures[J]. Journal of Sandwich Structures & Materials, 2018, 20(8): 1009-1027. [9] LIU P F, LI X K, LI Z B. Finite element analysis of dynamic mechanical responses of aluminum honeycomb sandwich structures under low-velocity impact[J]. Journal of Failure Analysis and Prevention, 2017, 17(6): 1202-1207. doi: 10.1007/s11668-017-0358-4 [10] 谢鑫, 段玥晨, 齐佳旗. 冲击角度对铝蜂窝夹芯板低速冲击性能的影响[J]. 复合材料科学与工程, 2020(4): 19-27. doi: 10.3969/j.issn.1003-0999.2020.04.003XIE X, DUAN Y C, QI J Q. Effect of impact angle on the low-velocity impact performance of aluminum honeycomb sandwich plate[J]. Composites Science and Engineering, 2020(4): 19-27. (in Chinese) doi: 10.3969/j.issn.1003-0999.2020.04.003 [11] 齐佳旗, 段玥晨, 铁瑛, 等. 结构参数对CFRP蒙皮-铝蜂窝夹层板低速冲击性能的影响[J]. 复合材料学报, 2020, 37(6): 1352-1363. doi: 10.13801/j.cnki.fhclxb.20190815.001QI J Q, DUAN Y C, TIE Y, et al. Effect of structural parameters on the low-velocity impact performance of aluminum honeycomb sandwich plate with CFRP face sheets[J]. Acta Materiae Compositae Sinica, 2020, 37(6): 1352-1363. (in Chinese) doi: 10.13801/j.cnki.fhclxb.20190815.001 [12] 孙光永, 张敬涛, 李世强, 等. 爆炸载荷下层级蜂窝铝夹芯板的动力响应分析[J]. 华南理工大学学报(自然科学版), 2017, 45(5): 141-146.SUN G Y, ZHANG J T, LI S Q, et al. Dynamic response analysis of hierarchical aluminum honeycomb sandwich structure subjected to explosive load[J]. Journal of South China University of Technology (Natural Science Edition), 2017, 45(5): 141-146. (in Chinese) [13] 杨森, 冯凇, 王顺尧, 等. 爆炸冲击作用下铝蜂窝板失稳研究[J]. 高压物理学报, 2017, 31(2): 193-201. doi: 10.11858/gywlxb.2017.02.013YANG S, FENG S, WANG S Y, et al. Instability of aluminum honeycomb sandwich panel under blast loading[J]. Chinese Journal of High Pressure Physics, 2017, 31(2): 193-201. (in Chinese) doi: 10.11858/gywlxb.2017.02.013 [14] 王堃, 孙勇, 彭明军, 等. 基于ANSYS的铝蜂窝夹芯板低速冲击仿真模拟研究[J]. 材料导报, 2012, 26(8): 157-160. doi: 10.3969/j.issn.1005-023X.2012.08.040WANG K, SUN Y, PENG M J, et al. Simulation of low-velocity impact of aluminium honeycomb sandwich panels with ANSYS[J]. Materials Review, 2012, 26(8): 157-160. (in Chinese) doi: 10.3969/j.issn.1005-023X.2012.08.040 [15] 陈尚军, 秦庆华, 张威, 等. 低速冲击下金属蜂窝夹芯板抗侵彻性能的试验研究[J]. 航空学报, 2018, 39(2): 157-163.CHEN S J, QIN Q H, ZHANG W, et al. Experimental investigation on against penetration of metallic honeycomb sandwich plates under low-velocity impact[J]. Acta Aeronautica et Astronautica Sinica, 2018, 39(2): 157-163. (in Chinese) -

下载:

下载: