Research on Stick-slip Vibration Characteristics of Drill String with Longitudinal-torsion Coupling

-

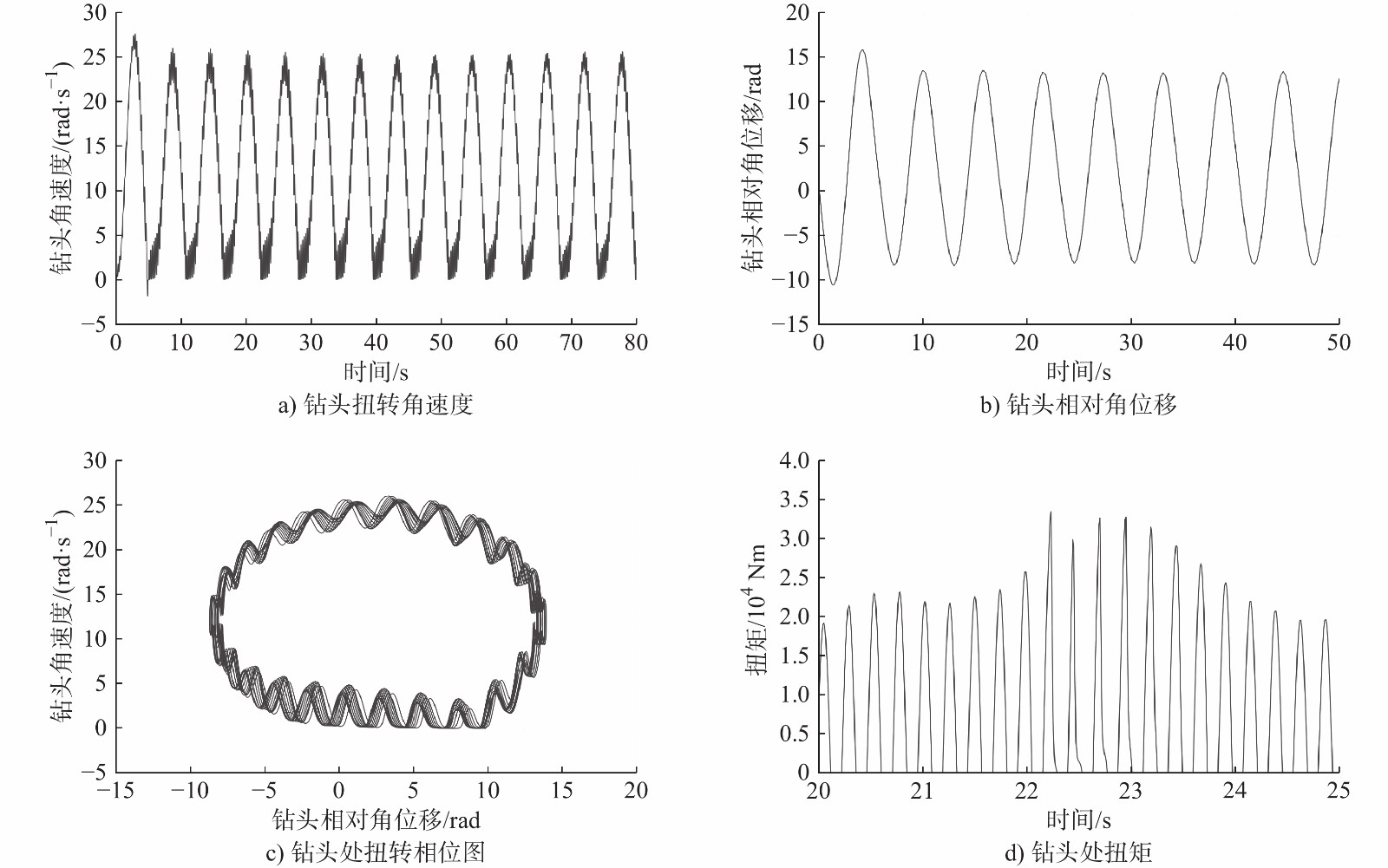

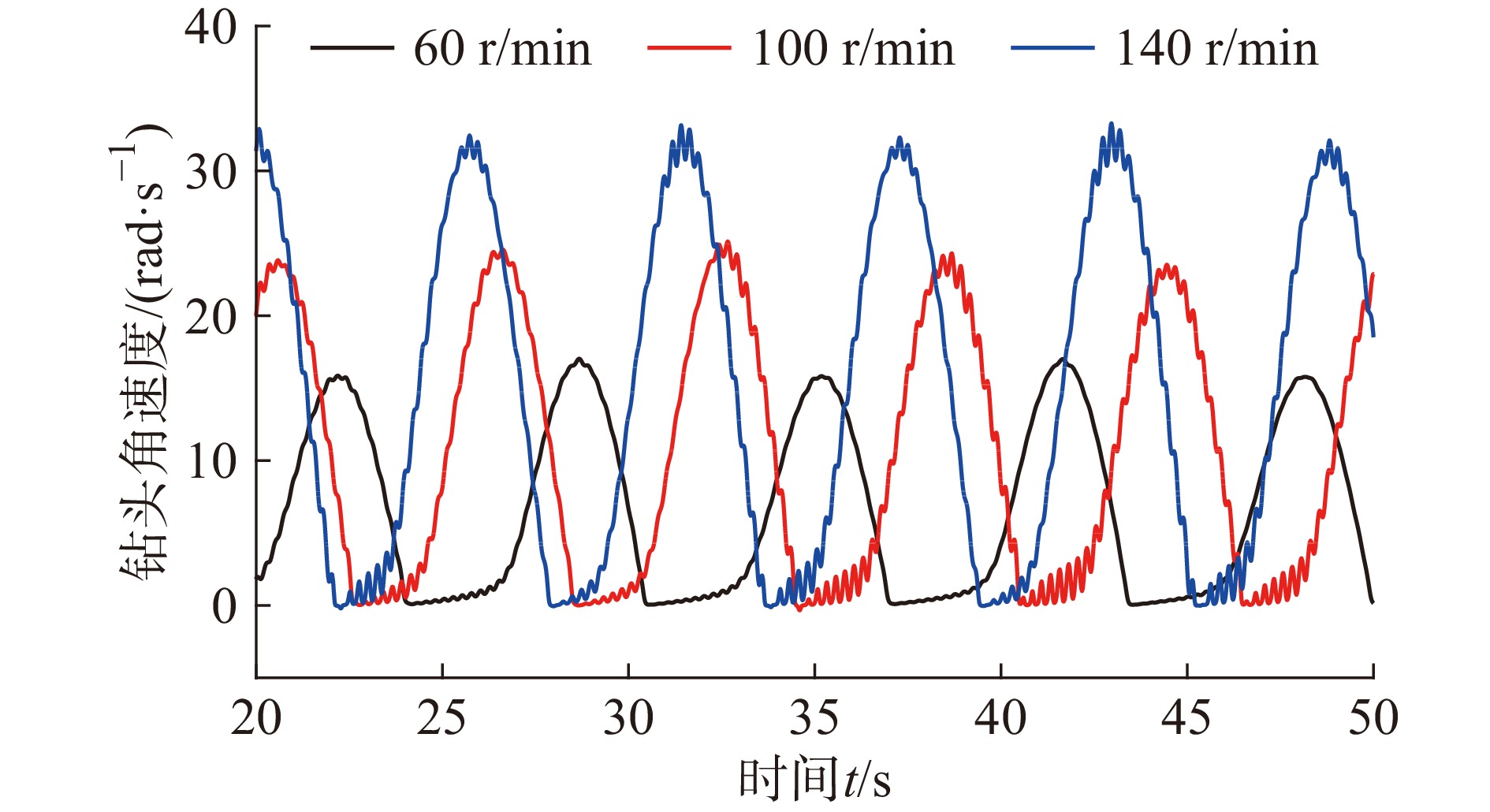

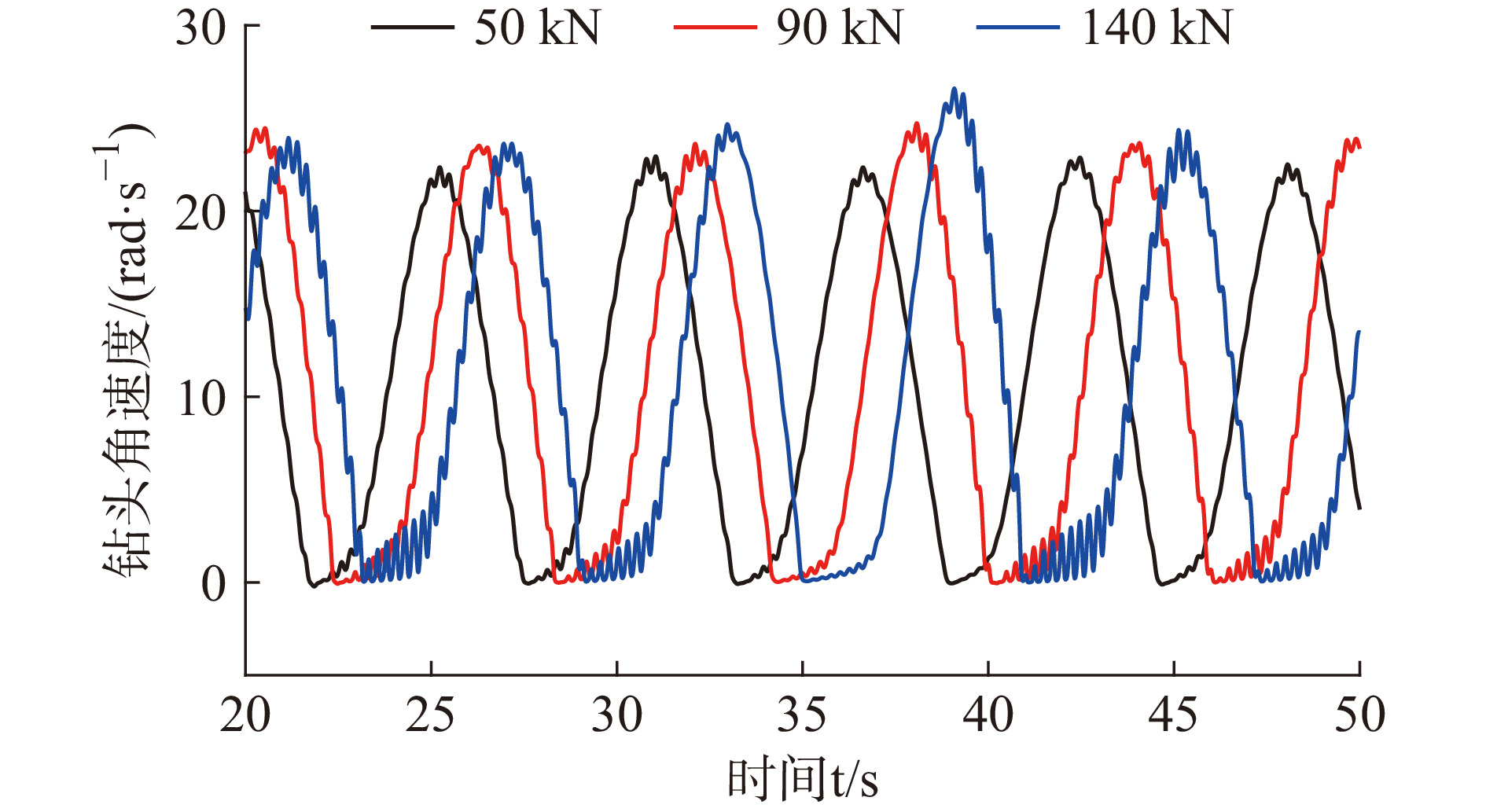

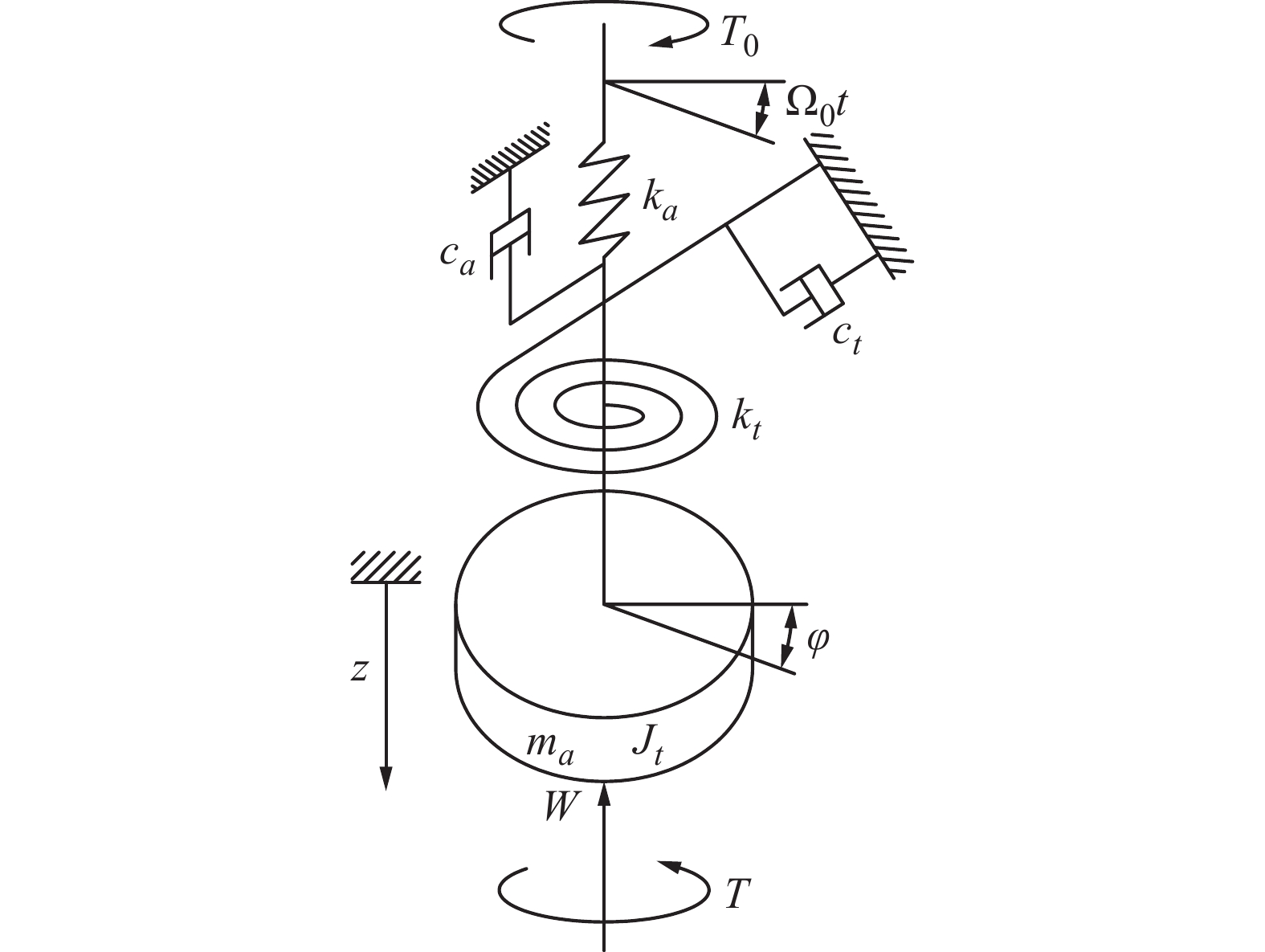

摘要: 石油钻井作业中通常伴随着剧烈的钻柱振动,导致钻井作业变得困难而低效。粘滑振动被认为是引发钻柱失效,引起钻井效率低下的主要原因之一。通过建立钻柱纵-扭耦合振动数学模型,推导相关动力学方程,分析岩石与钻头相互作用的4种形式,基于龙格库塔法以及自适应步长法对所建立的模型进行求解,结合算例分析,得到不同参数下钻头角速度和相对角位移变化。结果表明:高转速、低钻压的钻井条件下,纵-扭耦合作用的钻柱系统粘滑振动现象减弱。Abstract: Petroleum drilling operations are usually accompanied by severe drill string vibration, which makes drilling operations difficult and inefficient. Stick-slip vibration is considered to be one of the main causes of drill string failure and low drilling efficiency. This paper establishes a mathematical model of drill string longitudinal-torsional coupled vibration, derives related dynamic equations and analyzes four forms of rock-bit interaction. The established dynamic equation is solved using Runge-Kutta method with adaptive step size. Combined with the analysis of the calculation examples, the angular velocity and relative angular displacement changes of the drill bit under different parameters are obtained. The results show that the stick-slip vibration of the drill string system due to the coupling of longitudinal and torsion is weakened under the conditions of high speed and low weight-on-bit drilling.

-

Key words:

- drilling /

- coupled vibration /

- sticky /

- dynamics

-

表 1 算例基本参数

参数名称 数值 参数名称 数值 钻柱长度l/m 3000 钻头半径R/m 0.2 钻井液密度ρfl /(kg·m−3) 1500 钻铤内径Ri/m 0.0762 控制扭矩T0 /(Nm) 10000 钻铤外径Ro/m 0.2286 钢密度ρ/(kg·m−3) 7850 摩擦因数μ 0.4 杨氏模量E/GPa 210 钻井液摩擦因数μfl 0.2 剪切模量G/GPa 78 附加质量因数Cam 1.7 钻柱内径ri/m 0.095 地层刚度kc/(Nm·rad−1) 225 钻柱外径ro/m 0.127 -

[1] DE MORAES L P P, SAVI M A. Drill-string vibration analysis considering an axial-torsional-lateral nonsmooth model[J]. Journal of Sound and Vibration, 2019, 438: 220-237 doi: 10.1016/j.jsv.2018.08.054 [2] 杨塑. 钻井卡钻原因分析及对策[J]. 云南化工, 2018, 45(1): 73 doi: 10.3969/j.issn.1004-275X.2018.01.052YANG S. Cause analysis and countermeasures of stuck drilling in drilling[J]. Yunnan Chemical Technology, 2018, 45(1): 73 (in Chinese) doi: 10.3969/j.issn.1004-275X.2018.01.052 [3] 刘付蒙, 吴亚锋, 宋叔飚, 等. 抑制油气井钻柱黏滑振动控制器设计与应用[J]. 振动与冲击, 2019, 38(10): 256-261LIU F M, WU Y F, SONG S B, et al. Design and application of a control system to suppress the stick-slip vibration for oil-well drill strings[J]. Journal of Vibration and Shock, 2019, 38(10): 256-261 (in Chinese) [4] 祝效华, 汤历平, 童华. 高频扭转冲击钻进的减振与提速机理研究[J]. 振动与冲击, 2012, 31(20): 75-78,109ZHU X H, TANG L P, TONG H. Rock breaking mechanism of a high frequency torsional impact drilling[J]. Journal of Vibration and Shock, 2012, 31(20): 75-78,109 (in Chinese) [5] WANG R H, XUE Q L, HAN L J, et al. Torsional vibration analysis of push-the-bit rotary steerable drilling system[J]. Meccanica, 2014, 49(7): 1601-1615 doi: 10.1007/s11012-014-9942-9 [6] TIAN J L, YUAN C F, YANG L, et al. The vibration analysis model of pipeline under the action of gas pressure pulsation coupling[J]. Engineering Failure Analysis, 2016, 66: 328-340 doi: 10.1016/j.engfailanal.2016.05.017 [7] 周银锋,王忠民,马建敏. 旋转摩擦诱发非旋转体的粘滑振动特性[J]. 西安理工大学学报, 2006, 22(1): 78-81 doi: 10.7623/syxb201906009Zhou Y F, Wang Z M, Ma J M. Rotating friction induced stick-slip vibration characteristics of non-rotating bodies[J]. Journal of Xi′an University of Technology, 2006, 22(1): 78-81 (in Chinese) doi: 10.7623/syxb201906009 [8] 张晓东, 朱晓凤, 何石, 等. 钻柱系统粘滑振动稳定性分析及减振方法探讨[J]. 钻采工艺, 2015, 38(2): 89-90,94 doi: 10.3969/J.ISSN.1006-768X.2015.02.25ZHANG X D, ZHU X F, HE S, et al. Stability analysis of stick-slip vibration of drill string system and discussion on vibration reduction methods[J]. Drilling & Production Technology, 2015, 38(2): 89-90,94 (in Chinese) doi: 10.3969/J.ISSN.1006-768X.2015.02.25 [9] PATIL P A, TEODORIU C. Model development of torsional drillstring and investigating parametrically the stick-slips influencing factors[J]. Journal of Energy Resources Technology, 2013, 135(1): 013103 doi: 10.1115/1.4007915 [10] KONG L F, CAO S, CHIN J H, et al. Vibration suppression of drilling tool system during deep-hole drilling process using independence mode space control[J]. International Journal of Machine Tools and Manufacture, 2020, 151: 103525 doi: 10.1016/j.ijmachtools.2020.103525 [11] VIGUIÉ R, KERSCHEN G, GOLINVAL J C, et al. Using passive nonlinear targeted energy transfer to stabilize drill-string systems[J]. Mechanical Systems and Signal Processing, 2009, 23(1): 148-169 doi: 10.1016/j.ymssp.2007.07.001 [12] LIU X B, VLAJIC N, LONG X H, et al. Nonlinear motions of a flexible rotor with a drill bit: stick-slip and delay effects[J]. Nonlinear Dynamics, 2013, 72(1-2): 61-77 doi: 10.1007/s11071-012-0690-x [13] LEINE R I, VAN CAMPEN D H, KEULTJES W J G. Stick-slip whirl interaction in drillstring dynamics[J]. Journal of Vibration and Acoustics, 2002, 124(2): 209-220 doi: 10.1115/1.1452745 [14] 唐昕, 欧阳鸿武, 雷刚. 二自由度自激振荡系统中阻尼对粘滑运动的调控作用[J]. 测控技术, 2020, 39(5): 59-64TANG X, OUYANG H W, LEI G. Regulating effects of damping on stick-slip motion in 2-DOF self-excited oscillation system[J]. Measurement & Control Technology, 2020, 39(5): 59-64 (in Chinese) [15] 李子丰, 张永贵, 侯续田, 等. 钻柱纵向和扭转振动分析[J]. 工程力学, 2004, 21(6): 203-210 doi: 10.3969/j.issn.1000-4750.2004.06.034LI Z F, ZHANG Y G, HOU X T, et al. Analysis of longitudinal and torsion vibration of drillstring[J]. Engineering Mechanics, 2004, 21(6): 203-210 (in Chinese) doi: 10.3969/j.issn.1000-4750.2004.06.034 [16] LIU X B, VLAJIC N, LONG X H, et al. Coupled axial-torsional dynamics in rotary drilling with state-dependent delay: stability and control[J]. Nonlinear Dynamics, 2014, 78(3): 1891-1906 doi: 10.1007/s11071-014-1567-y [17] KAPITANIAK M, HAMANEH V V, CHÁVEZ J P, et al. Unveiling complexity of drill-string vibrations: experiments and modelling[J]. International Journal of Mechanical Sciences, 2015, 101-102: 324-337 doi: 10.1016/j.ijmecsci.2015.07.008 -

下载:

下载: