Design of Visual Detection System for Large Foreign Body in Belt Conveyor

-

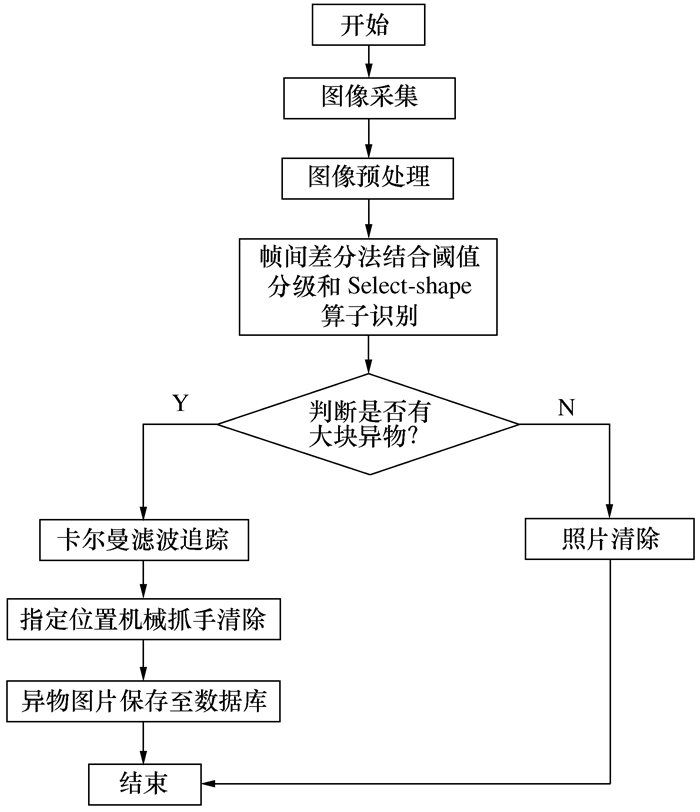

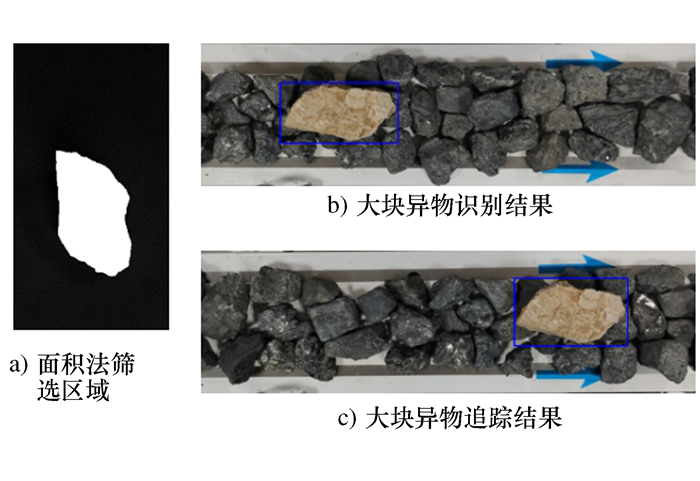

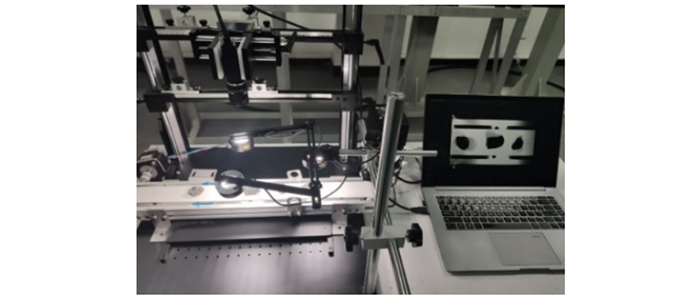

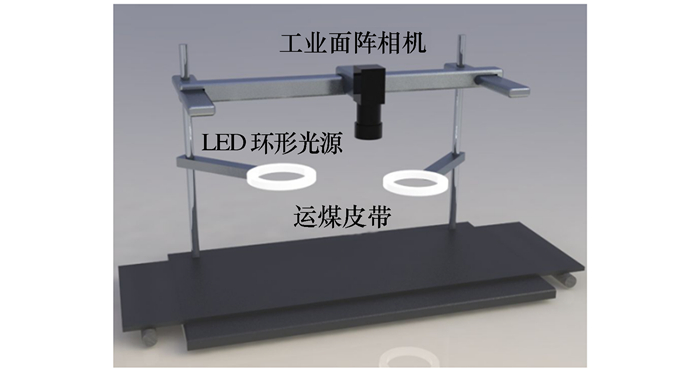

摘要: 为了提高煤矿井下带式输送机大块异物检测的效率和准确性,设计了基于机器视觉的大块异物检测系统。构建了大块异物检测系统的总体框架,并进行了硬件设计与选型;给出了大块异物检测系统的流程,设计了基于帧间差分法、阈值分级和Select-Shape算子的带式输送机大块异物识别算法, 并采用卡尔曼滤波对大块异物进行追踪;最后,设计了大块异物检测系统上位机软件,搭建了大块异物检测实验台,并开展相关实验。实验结果表明:对于超过设定阈值的大块异物,识别准确率为99.5%。研究成果对预防皮带撕裂、维持带式输送机稳定运行、实现煤矿企业智能化生产具有重要意义。Abstract: In order to improve the efficiency and accuracy of the large foreign body detection of belt conveyor in the underground coal mine, a large foreign body detection system based on machine vision is designed. The overall framework of the detection system for large foreign bodies is constructed, and the hardware design and selection are carried out. The flow chart of the large foreign body detection system is given. Based on the frame difference method, the threshold classification and Select-Shape operator, the algorithm of the large foreign body recognition for belt conveyor is designed, and the large foreign body is tracked by using Kalman filter. Finally, the host computer software of large foreign body detection system is designed, an experimental platform for the foreign body detection is built, and the relevant experiments are carried out. The experimental results show that the recognition accuracy is of 99.5% for the large foreign body exceeding the set threshold. The results are of great significance for preventing the belt tearing, maintaining the stable operation of belt conveyor and realizing the intelligent production in the coal mine enterprises.

-

Key words:

- large foreign body detection /

- machine vision /

- frame difference method /

- Kalman filter

-

表 1 工业面阵相机参数

相机型号 MV-CA050-11UM/UC 传感器型号 Sony IMX264 数据接口 USB3.0 最大帧率 35fps@2448×2048 信噪比 40.2 dB 表 2 大块异物识别结果数据统计

异物序号 测量面积/cm2 识别准确率/% 1 20 100 2 15 100 3 10 100 4 7 98 -

[1] 吴守鹏. 基于机器视觉的运煤皮带异物识别方法研究[D]. 徐州: 中国矿业大学, 2019WU S P. Research on detection method of foreign object on coal conveyor belt based on computer vision[D]. Xuzhou: China University of Mining and Technology, 2019 (in Chinese) [2] 武国平. 哈尔乌素智能干选射线识别技术及其防护研究[J]. 煤炭技术, 2018, 37(12): 317-320 https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201812113.htmWU G P. TDS Ray identification and protection research of Ha'erwusu[J]. Coal Technology, 2018, 37(12): 317-320 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201812113.htm [3] 袁华昕. 基于X射线图像的煤矸石智能分选控制系统研究[D]. 沈阳: 东北大学, 2014YUAN H X. Research on coal and gangue smart sorting control system based on X-ray image[D]. Shenyang: Northeastern University, 2014 (in Chinese) [4] 孔力, 李红, 徐恕宏, 等. 双能γ射线透射法煤矸石在线识别与分选系统[J]. 华中理工大学学报, 1997, 25(10): 107-108, 112 https://www.cnki.com.cn/Article/CJFDTOTAL-HZLG710.032.htmKONG L, LI H, XU S H, et al. The on line identification and separation system for coal gangues based on double energy γ-ray transmission[J]. Journal of Huazhong University of Science and Technology, 1997, 25(10): 107-108, 112 (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HZLG710.032.htm [5] 王靖宇, 王霰禹, 张科, 等. 工业机器人视觉图像的质量评价方法研究[J]. 机械科学与技术, 2018, 37(4): 575-580 doi: 10.13433/j.cnki.1003-8728.2018.0413WANG J Y, WANG X Y, ZHANG K, et al. Research on image quality assessment for industrial robot vision system[J]. Mechanical Science and Technology for Aerospace Engineering, 2018, 37(4): 575-580 (in Chinese) doi: 10.13433/j.cnki.1003-8728.2018.0413 [6] 苗长云, 王春华, 李现国. 基于机器视觉的带式输送机监控系统中输送带积水检测[J]. 天津工业大学学报, 2019, 38(6): 52-57 doi: 10.3969/j.issn.1671-024x.2019.06.009MIAO C Y, WANG C H, LI X G. Water detection in belt conveyor monitoring system based on computer vision[J]. Journal of Tianjin Polytechnic University, 2019, 38(6): 52-57 (in Chinese) doi: 10.3969/j.issn.1671-024x.2019.06.009 [7] LINS R G, GIVIGI S N. Automatic crack detection and measurement based on image analysis[J]. IEEE Transactions on Instrumentation and Measurement, 2016, 65(3): 583-590 doi: 10.1109/TIM.2015.2509278 [8] 蔡述庭, 王雪岩, 陈学松, 等. 一种基于Halcon的美标电源线缺陷检测方法[J]. 机床与液压, 2019, 47(8): 134-139 doi: 10.3969/j.issn.1001-3881.2019.08.030CAI S T, WANG X Y, CHEN X S, et al. A defects detection method for American standard power line based on Halcon[J]. Machine Tool & Hydraulics, 2019, 47(8): 134-139 (in Chinese) doi: 10.3969/j.issn.1001-3881.2019.08.030 [9] KAUR H, SAHAMBI J S. Vehicle tracking in video using fractional feedback Kalman filter[J]. IEEE Transactions on Computational Imaging, 2016, 2(4): 550-561 [10] 陈涛, 张洪丹, 陈东, 等. 基于优先像素与卡尔曼滤波追踪的车道线检测[J]. 汽车工程, 2016, 38(2): 200-205, 220 doi: 10.3969/j.issn.1000-680X.2016.02.011CHEN T, ZHANG H D, CHEN D, et al. Lane detection based on high priority pixels and tracking by Kalman filter[J]. Automotive Engineering, 2016, 38(2): 200-205, 220 (in Chinese) doi: 10.3969/j.issn.1000-680X.2016.02.011 [11] VITHU P, MOSES J A. Machine vision system for food grain quality evaluation: a review[J]. Trends in Food Science & Technology, 2016, 56: 13-20 [12] YANG Y L, MIAO C Y, LI X G, et al. On-line conveyor belts inspection based on machine vision[J]. Optik, 2014, 125(19): 5803-5807 doi: 10.1016/j.ijleo.2014.07.070 [13] 刘国才, 王帅卿. 多方向几何非线性扩散图像去噪方法[J]. 湖南大学学报, 2016, 43(8): 135-141 doi: 10.3969/j.issn.1674-2974.2016.08.020LIU G C, WANG S Q. Multi-directional geometric nonlinear diffusion method for image denoising[J]. Journal of Hunan University, 2016, 43(8): 135-141 (in Chinese) doi: 10.3969/j.issn.1674-2974.2016.08.020 [14] KAUR H, SAHAMBI J S. Vehicle tracking in video using fractional feedback Kalman filter[J]. IEEE Transactions on Computational Imaging, 2016, 2(4): 550-561 [15] ZHU Y M, YOU Z S, ZHAO J, et al. The optimality for the distributed Kalman filtering fusion with feedback[J]. Automatica, 2001, 37(9): 1489-1493 doi: 10.1016/S0005-1098(01)00074-7 -

下载:

下载: