Application of PCA-TOPSIS Method to Optimization of Processing Parameters in Wire Arc Additive Manufacturing of Stainless Steel

-

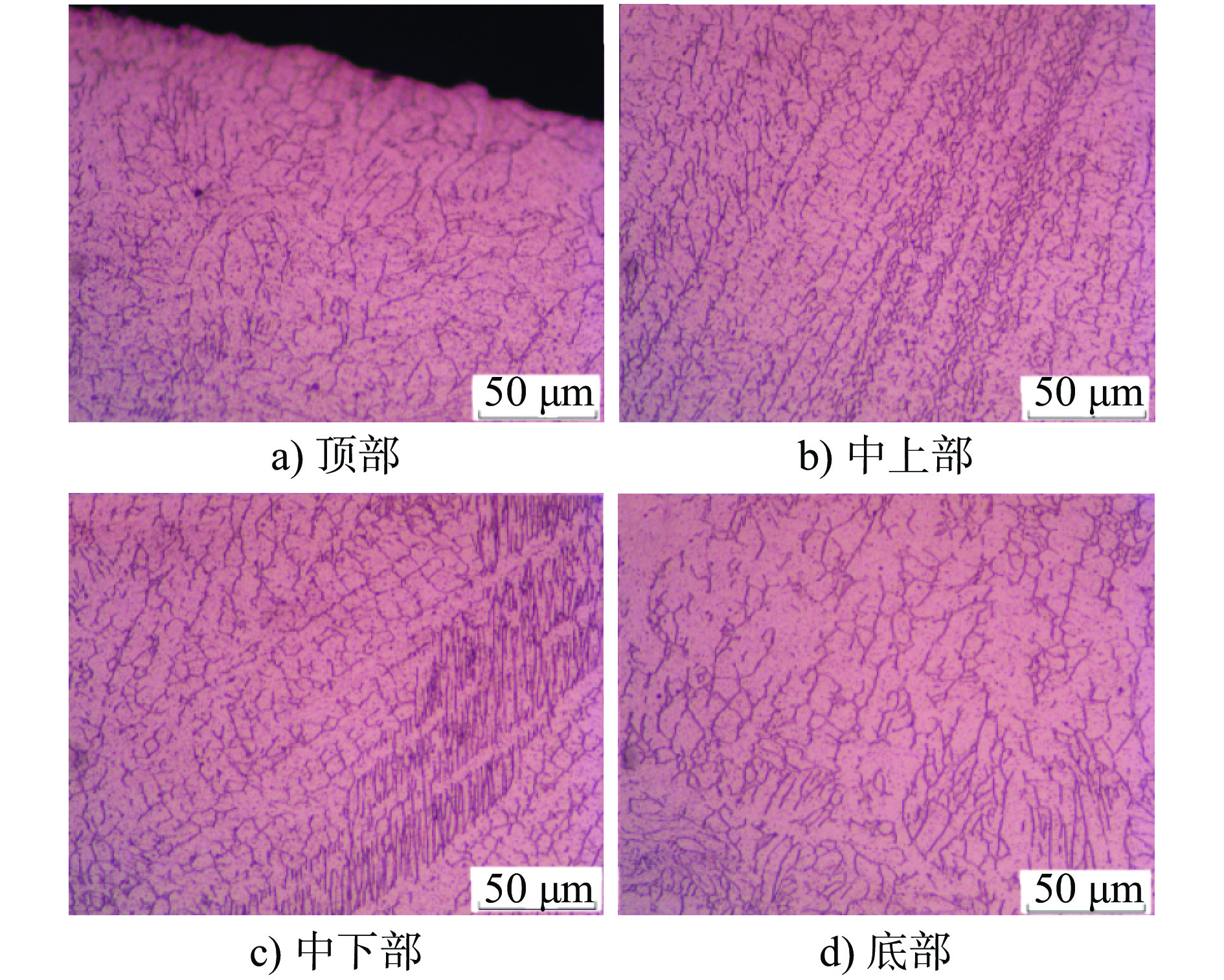

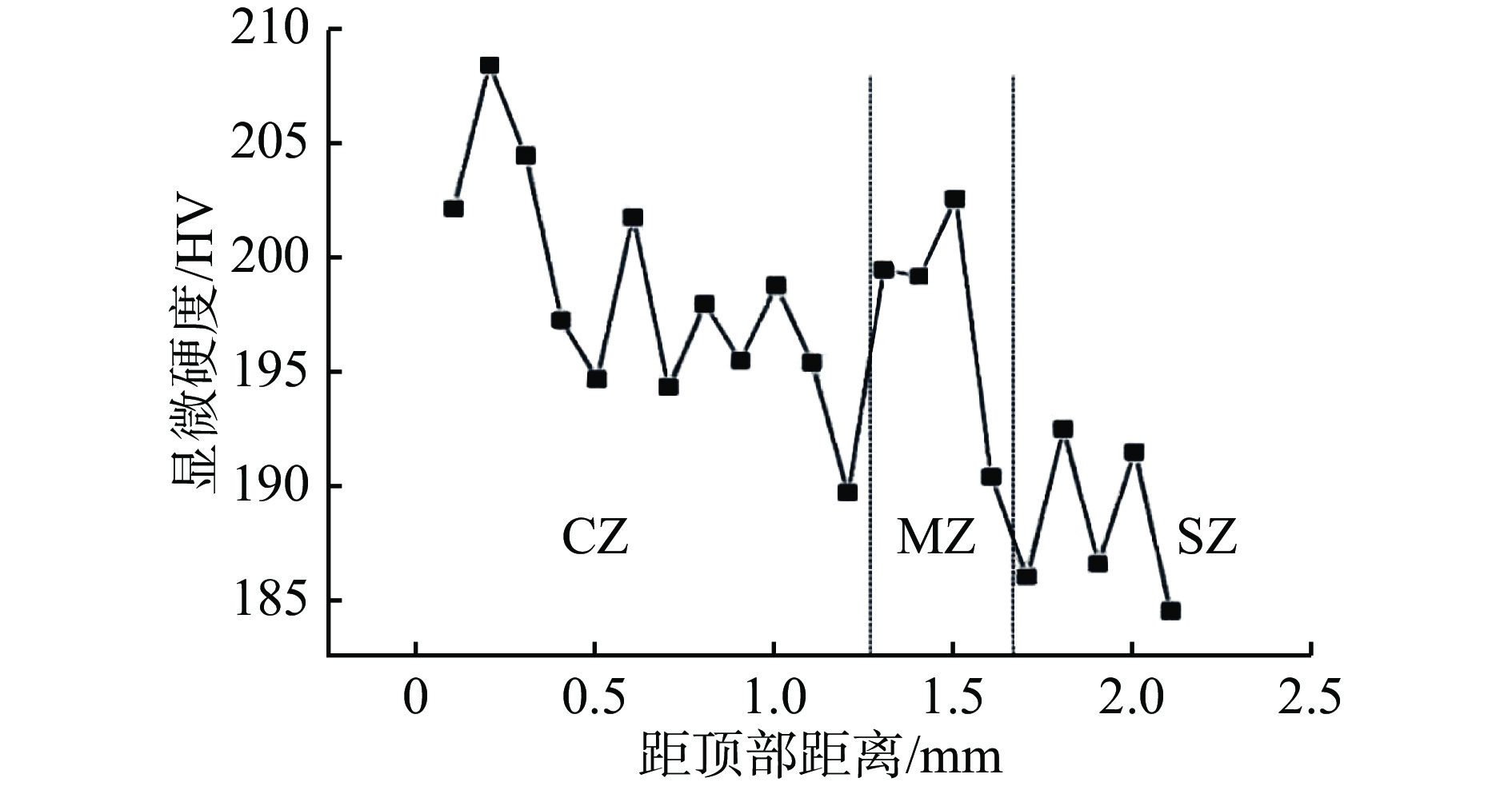

摘要: 为了提高不锈钢电弧增材工艺的增材效率,利用308不锈钢丝材在304不锈钢基体上进行电弧增材。利用正交试验法设计工艺参数,运用光学显微镜分析增材组织的形貌,通过显微硬度计测试增材组织的显微硬度分布。依据熔覆层的熔池尺寸,采用PCA-TOPSIS法作为评价方法。以熔宽、余高最大,熔深最小为优化目标,通过MATLAB计算得出最佳工艺参数为电弧电流I = 200 A,焊接速度Vs = 42 cm/min,送丝速度Vf = 180 cm/min。结果表明,该工艺参数下的熔覆层与基体呈现良好的冶金结合,无气孔和裂纹等缺陷。

-

关键词:

- 电弧增材 /

- 增材效率 /

- 工艺参数 /

- PCA-TOPSIS法

Abstract: In order to improve the additive efficiency of the stainless steel fabricated by the wire arc additive manufacturing, the 308 stainless steel wire was used to conduct the arc additive on the 304 stainless steel matrix.The processing parameters were designed by using the orthogonal test, the microstructure of the additive tissue was analyzed by using optical microscope, and the microhardness distribution of the additive tissue was tested by microhardness tester. The PCA-TOPSIS(Principal Component Analysis-Technique for Order Preference by Similarity to an Ideal Solution)method was used to evaluate the melting size of cladding. For the optimization objectives of melting width, maximum melting height and minimum melting depth, the optimal processing parameters were obtained thatthe arc current I was 200 A, welding speed Vs was 42 cm/min, and wire feeding speed Vf was 180 cm/min via Matlab.Under the processing parameters, the cladding layer shows the good metallurgical bonding with the matrix, and there are no defects such as pores and cracks. -

表 1 基材和丝材的化学成分

元素 基材304不锈钢 焊丝308不锈钢 C ≤0.08 ≤0.08 Mn ≤2.00 ≤2.00 P ≤0.045 ≤0.045 S ≤0.03 ≤0.03 Si ≤1.0 ≤0.75 Cr 18.0 ~ 20.0 19.0 ~ 21.0 Ni 8.0 ~ 10.5 10.0 ~ 12.0 表 2 电弧增材工艺参数

等级 因素 焊接电流I/A 焊接速度

Vs /(cm·min−1)送丝速度

Vf /(cm·min−1)1 180 14 130 2 190 28 180 3 200 42 230 表 3 正交试验方案

序号 因素水平 I Vs Vf 1 1 1 1 2 1 2 2 3 1 3 3 4 2 1 2 5 2 2 3 6 2 3 1 7 3 1 3 8 3 2 1 9 3 3 2 表 4 正交试验设计及结果

序号 I/A Vs /(cm·min−1) Vf /(cm·min−1) B/mm H/mm h/mm 1 180 14 130 8.53 1.64 1.88 2 180 28 180 4.06 1.29 1.18 3 180 42 230 5.29 0.75 1.10 4 190 14 180 8.50 1.65 3.13 5 190 28 230 5.98 1.11 0.91 6 190 42 130 5.34 0.19 1.15 7 200 14 230 10.88 1.28 2.71 8 200 28 130 7.19 1.06 0.95 9 200 42 180 5.45 1.26 0.4 表 5 正交试验的数据分析

参数 B/mm H/mm h/mm k1 k2 k3 r k1 k2 k3 r k1 k2 k3 r I/A 33.9 33.1 39.2 6.2 6.2 4.9 6.0 1.2 6.9 8.7 6.8 1.9 Vs/(cm·min−1) 46.5 32.8 26.8 19.7 7.6 5.8 3.7 3.9 12.9 5.1 4.4 8.5 Vf/(cm·min−1) 35.1 34.1 36.9 2.8 4.8 7.0 5.2 2.2 6.6 7.9 7.9 1.2 表 6 主成分对应的贡献率

主成分 贡献率 熔宽B 0.02 余高H 0.2 熔深h 0.72 表 7 决策矩阵

序号 B/mm H/mm h/mm 1 0.008 0.09 0.115 2 0.004 0.07 0.180 3 0.005 0.04 0.194 4 0.008 0.09 0.065 5 0.006 0.06 0.238 6 0.005 0.01 0.187 7 0.010 0.07 0.079 8 0.007 0.06 0.223 9 0.005 0.07 0.533 表 8 熔池尺寸的相对接近度

序号 ${D^ - } $ ${D^ + } $ ${C^ + } $ 1 0.095 0.418 0.18 2 0.130 0.353 0.27 3 0.133 0.342 0.28 4 0.080 0.468 0.15 5 0.180 0.297 0.38 6 0.122 0.355 0.26 7 0.062 0.454 0.12 8 0.166 0.311 0.35 9 0.472 0.021 0.96 -

[1] 熊江涛, 耿海滨, 林鑫, 等. 电弧增材制造研究现状及在航空制造中应用前景[J]. 航空制造技术, 2015(23-24): 79-85XIONG J T, GENG H B, LIN X, et al. Research status of wire and arc additive manufacture and its application in aeronautical manufacturing[J]. Aeronautical Manufacturing Technology, 2015(23-24): 79-85 (in Chinese) [2] 朱胜, 柳建, 殷凤良, 等. 面向装备维修的增材再制造技术[J]. 装甲兵工程学院学报, 2014, 28(1): 81-85 doi: 10.11732/j.issn.1672-1497.2014.01.017ZHU S, LIU J, YIN F L, et al. Additive remanufacturing technology used in equipment repair[J]. Journal of Academy of Armored Force Engineering, 2014, 28(1): 81-85 (in Chinese) doi: 10.11732/j.issn.1672-1497.2014.01.017 [3] KHAJAVI S H, PARTANEN J, HOLMSTRÖM J. Additive manufacturing in the spare parts supply Chain[J]. Computers in Industry, 2014, 65(1): 50-63 doi: 10.1016/j.compind.2013.07.008 [4] 田彩兰, 陈济轮, 董鹏, 等. 国外电弧增材制造技术的研究现状及展望[J]. 航天制造技术, 2015(2): 57-60TIAN C L, CHEN J L, DONG P, et al. Current state and future development of the wire arc additive manufacture technology abroad[J]. Aerospace Manufacturing Technology, 2015(2): 57-60 (in Chinese) [5] 熊俊. 多层单道GMA增材制造成形特性及熔敷尺寸控制[D]. 哈尔滨: 哈尔滨工业大学, 2014.XIONG J. Forming characteristics in multi-layer single-bead GMA additive manufacturing and control for deposition dimension[D]. Harbin: Harbin Institute of Technology, 2014 (in Chinese). [6] 周龙早, 刘顺洪, 丁冬平. 基于三维焊接熔敷的快速成形技术[J]. 电加工与模具, 2004(4): 1-5 doi: 10.3969/j.issn.1009-279X.2004.04.001ZHOU L Z, LIU S H, DING D P. Rapid prototyping technology based on three-dimensional welding deposition[J]. Electromachining & Mould, 2004(4): 1-5 (in Chinese) doi: 10.3969/j.issn.1009-279X.2004.04.001 [7] 杨继东, 牛燃恒, 王飞龙. 电弧增材制造中轮廓环优化处理研究[J]. 机械工程师, 2018(12): 10-13 doi: 10.3969/j.issn.1002-2333.2018.12.003YANG J D, NIU R H, WANG F L. Research on optimization process of contour ring in wire arc additive manufacturing[J]. Mechanical Engineer, 2018(12): 10-13 (in Chinese) doi: 10.3969/j.issn.1002-2333.2018.12.003 [8] 毛军军, 李侠, 吴涛. 结合粗集模糊熵和PCA载荷阵改进的TOPSIS方法[J]. 计算机工程与应用, 2011, 47(18): 56-59MAO J J, LI X, WU T. Applying fuzzy entropy of rough set and PCA loading matrix to improvements of TOPSIS method[J]. Computer Engineering and Applications, 2011, 47(18): 56-59 (in Chinese) [9] MARZBAN J, GHASEMINEJAD P, AHMADZADEH M H, et al. Experimental investigation and statistical optimization of laser surface cladding parameters[J]. The International Journal of Advanced Manufacturing Technology, 2015, 76(5-8): 1163-1172 doi: 10.1007/s00170-014-6338-x [10] 朱刚贤, 张安峰, 李涤尘. 激光熔覆工艺参数对熔覆层表面平整度的影响[J]. 中国激光, 2010, 37(1): 296-301 doi: 10.3788/CJL20103701.0296ZHU G X, ZHANG A F, LI D C. Effect of process parameters on surface smoothness in laser cladding[J]. Chinese Journal of Lasers, 2010, 37(1): 296-301 (in Chinese) doi: 10.3788/CJL20103701.0296 [11] HEMMATI I, OCELIK V, DE HOSSON J T M. Dilution effects in laser cladding of Ni-Cr-B-Si-C hardfacing alloys[J]. Materials Letters, 2012, 84: 69-72 doi: 10.1016/j.matlet.2012.06.054 [12] 陈菊芳, 陈国炎, 孙凌燕, 等. H13钢表面激光熔覆层稀释率及强化效果研究[J]. 激光技术, 2017, 41(4): 596-601 doi: 10.7510/jgjs.issn.1001-3806.2017.04.028CHEN J F, CHEN G Y, SUN L Y, et al. Investigation of dilution ratio and strengthening effect of laser cladded coating on H13 steel[J]. Laser Technology, 2017, 41(4): 596-601 (in Chinese) doi: 10.7510/jgjs.issn.1001-3806.2017.04.028 [13] 陈峰, 周金宇, 陈菊芳, 等. PCA-TOPSIS法在激光熔覆工艺参数优化中的应用[J]. 机械设计与制造, 2018(3): 120-123 doi: 10.3969/j.issn.1001-3997.2018.03.036CHEN F, ZHOU J Y, CHEN J F, et al. Optimization of process parameters for laser cladding based on PCA-TOPSIS method[J]. Machinery Design & Manufacture, 2018(3): 120-123 (in Chinese) doi: 10.3969/j.issn.1001-3997.2018.03.036 [14] 张永康, 崔承云, 肖荣诗, 等. 先进激光制造技术[M]. 镇江: 江苏大学出版社, 2011.ZHANG Y K, CUI C Y, XIAO R S, et al. Advanced laser manufacturing technology[M]. Zhenjiang: Jiangsu University Press, 2011 (in Chinese). [15] 肖雨晨. 双相不锈钢电弧增材制造的成形控制与性能分析[D]. 秦皇岛: 燕山大学, 2017.XIAO Y C. Forming control and performance analysis of duplex stainless steel based on the WAAM[D]. Qinhuangdao: Yanshan University, 2017 (in Chinese). [16] 刘勇. CMT电弧熔丝增材制造304不锈钢组织和性能研究[D]. 沈阳: 沈阳工业大学, 2018.LIU Y. Research on the microstructure and mechanical property of 304 stainless steel produced by CMT wire arc additive manufacturing[D]. Shenyang: Shenyang University of Technology, 2018 (in Chinese). [17] 孙晓娜, 雷毅, 张鹰. 厚板奥氏体不锈钢焊缝显微组织分析[J]. 金属热处理, 2006, 31(10): 21-23 doi: 10.3969/j.issn.0254-6051.2006.10.006SUN X N, LEI Y, ZHANG Y. Microstructure analysis of weld joint for austenitic stainless steel thick plate[J]. Heat Treatment of Metals, 2006, 31(10): 21-23 (in Chinese) doi: 10.3969/j.issn.0254-6051.2006.10.006 [18] LIPPOLD J C, KOTECKI D J. 不锈钢焊接冶金学及焊接性[M]. 陈剑虹, 译. 北京: 机械工业出版社, 2008.LIPPOLD J C, KOTECKI D J. Welding metallurgy and weldability of stainless steels[M]. CHEN J H, trans. Beijing: China Machine Press, 2008 (in Chinese). [19] 郝建军, 马璐萍. 熔焊基础与金属材料焊接[M]. 北京: 北京理工大学出版社, 2010.HAO J J, MA L P. Weld foundation to metal material[M]. Beijing: Beijing Institute of Technology Press, 2010 (in Chinese) [20] 王红颖, 崔承云, 周杰. 工具钢表面激光熔覆Co基合金涂层的组织及性能[J]. 吉林大学学报, 2010, 40(4): 1000-1004WANG H Y, CUI C Y, ZHOU J. Microstructure and properties of cobalt-based alloy coating on tool steel surface prepared by laser cladding[J]. Journal of Jilin University, 2010, 40(4): 1000-1004 (in Chinese) [21] 张晓东, 董世运, 徐滨士, 等. 45钢表面激光熔覆Ni35合金涂层的组织及性能[J]. 装甲兵工程学院学报, 2009, 23(3): 73-76 doi: 10.3969/j.issn.1672-1497.2009.03.017ZHANG X D, DONG S Y, XU B S, et al. Microstructure and performance of Ni35 alloy laser cladding on 45 steel substrate[J]. Journal of Academy of Armored Force Engineering, 2009, 23(3): 73-76 (in Chinese) doi: 10.3969/j.issn.1672-1497.2009.03.017 [22] XU P, LIN C X, ZHOU C Y, et al. Wear and corrosion resistance of laser cladding AISI 304 stainless steel/AL2O3 composite coatings[J]. Surface and Coatings Technology, 2014, 238: 9-14 doi: 10.1016/j.surfcoat.2013.10.028 [23] 戴晓琴, 陈瀚宁, 雷剑波, 等. 激光增材制造304不锈钢显微结构特征与性能研究[J]. 热加工工艺, 2017, 46(16): 83-86DAI X Q, CHEN H N, LEI J B, et al. Study on microstructure characteristics and properties of 304 stainless steel by laser additive manufacturing[J]. Hot Working Technology, 2017, 46(16): 83-86 (in Chinese) [24] 郭卫, 李凯凯, 柴蓉霞, 等. 扫描顺序对激光熔覆304钢组织和性能的影响[J]. 激光与红外, 2018, 48(9): 1087-1093 doi: 10.3969/j.issn.1001-5078.2018.09.004GUO W, LI K K, CHAI R X, et al. Influence of the scanning sequence on microstructure and mechanical property of 304 steel by laser cladding[J]. Laser & Infrared, 2018, 48(9): 1087-1093 (in Chinese) doi: 10.3969/j.issn.1001-5078.2018.09.004 -

下载:

下载: