|

[1]

|

KUMAR K, RAWAL S K, SINGH V P, et al. Experimental study on diametric expansion and taper rate in EDM drilling for high aspect ratio micro holes in high strength materials[J]. Materials Today: Proceedings, 2018, 5(2): 7363-7372 doi: 10.1016/j.matpr.2017.11.406

|

|

[2]

|

FENG G L, YANG X D, CHI G X. Experimental and simulation study on micro hole machining in EDM with high-speed tool electrode rotation[J]. The International Journal of Advanced Manufacturing Technology, 2019, 101(1): 367-375

|

|

[3]

|

NI H, GONG H, DONG Y H, et al. A comparative investigation on hybrid EDM for drilling small deep holes[J]. The International Journal of Advanced Manufacturing Technology, 2018, 95(1-4): 1465-1472 doi: 10.1007/s00170-017-1282-1

|

|

[4]

|

TANJILUL M, AHMED A, KUMAR A S, et al. A study on EDM debris particle size and flushing mechanism for efficient debris removal in EDM-drilling of Inconel 718[J]. Journal of Materials Processing Technology, 2018, 255: 263-274 doi: 10.1016/j.jmatprotec.2017.12.016

|

|

[5]

|

刘泽祥, 张斌. 微小深孔加工综述[J]. 新技术新工艺, 2019(1): 1-10LIU Z X, ZHANG B. Summary of micro deep holes machining[J]. New Technology & New Process, 2019(1): 1-10 (in Chinese)

|

|

[6]

|

贾宝贤, 王振龙, 赵万生. 基于特种加工的微小孔加工技术[J]. 电加工与模具, 2005(2): 1-5 doi: 10.3969/j.issn.1009-279X.2005.02.001JIA B X, WANG Z L, ZHAO W S. Techniques of machiningmicro holes based on non-traditional machining[J]. Electromachining & Mould, 2005(2): 1-5 (in Chinese) doi: 10.3969/j.issn.1009-279X.2005.02.001

|

|

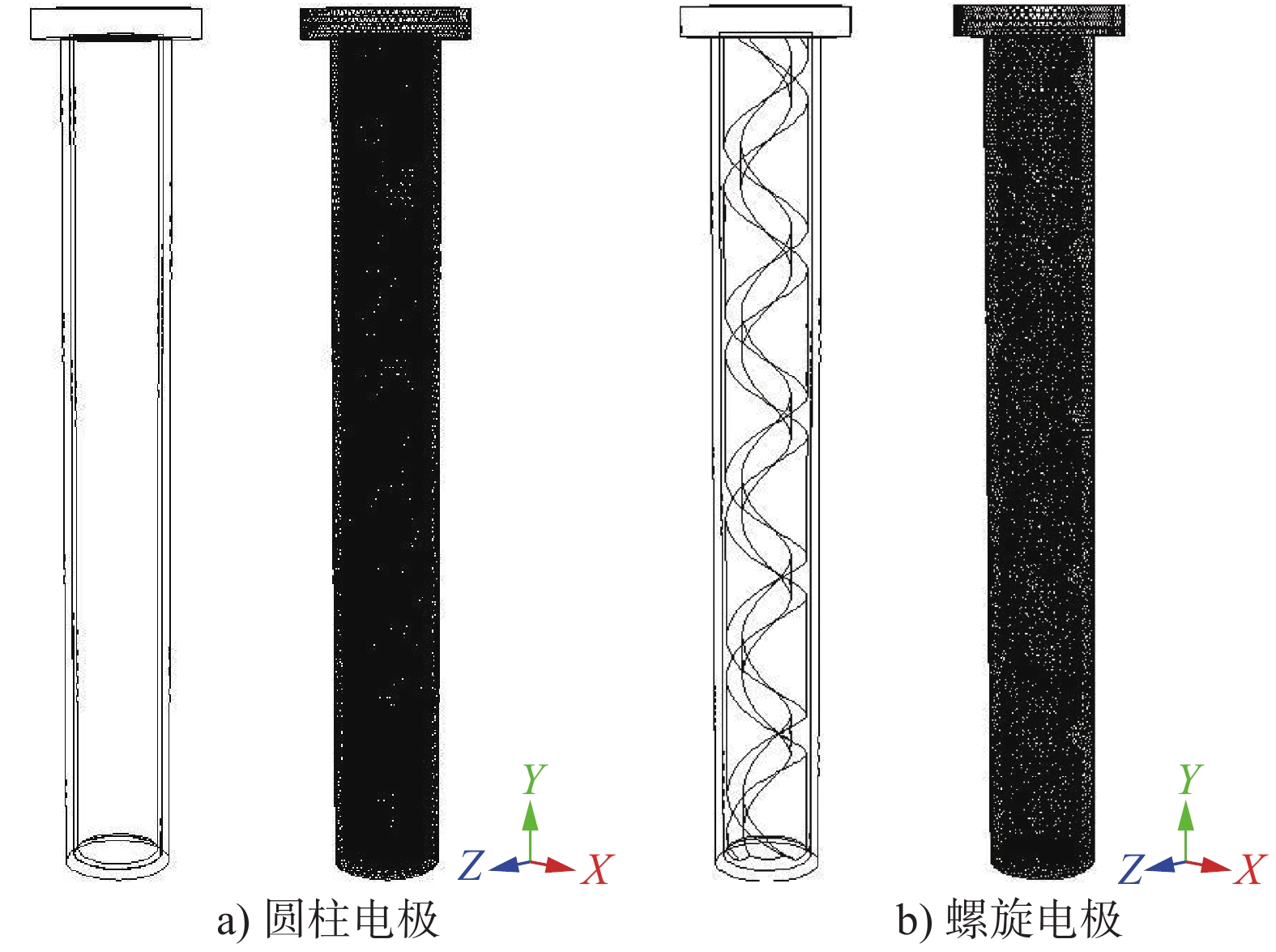

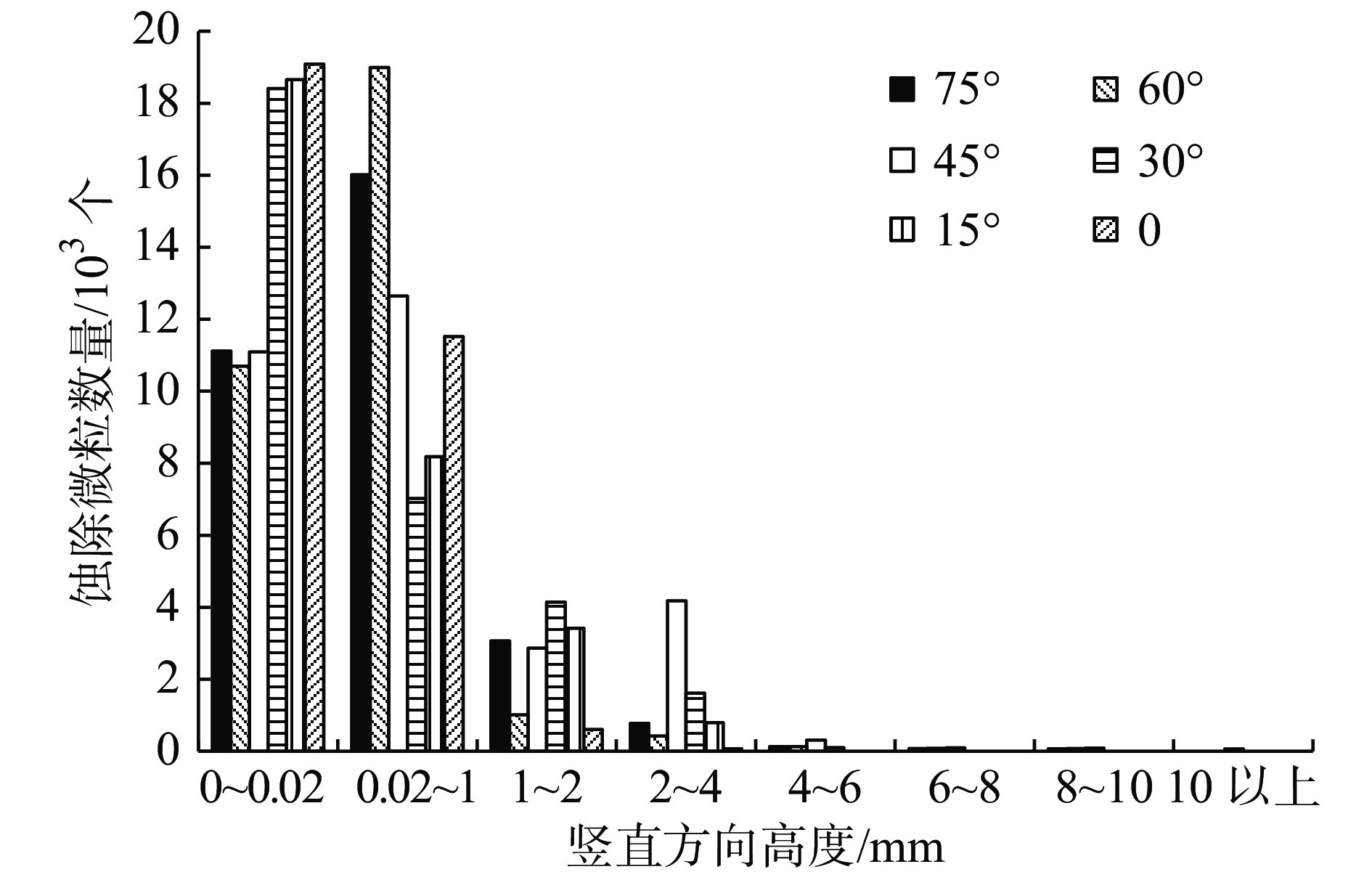

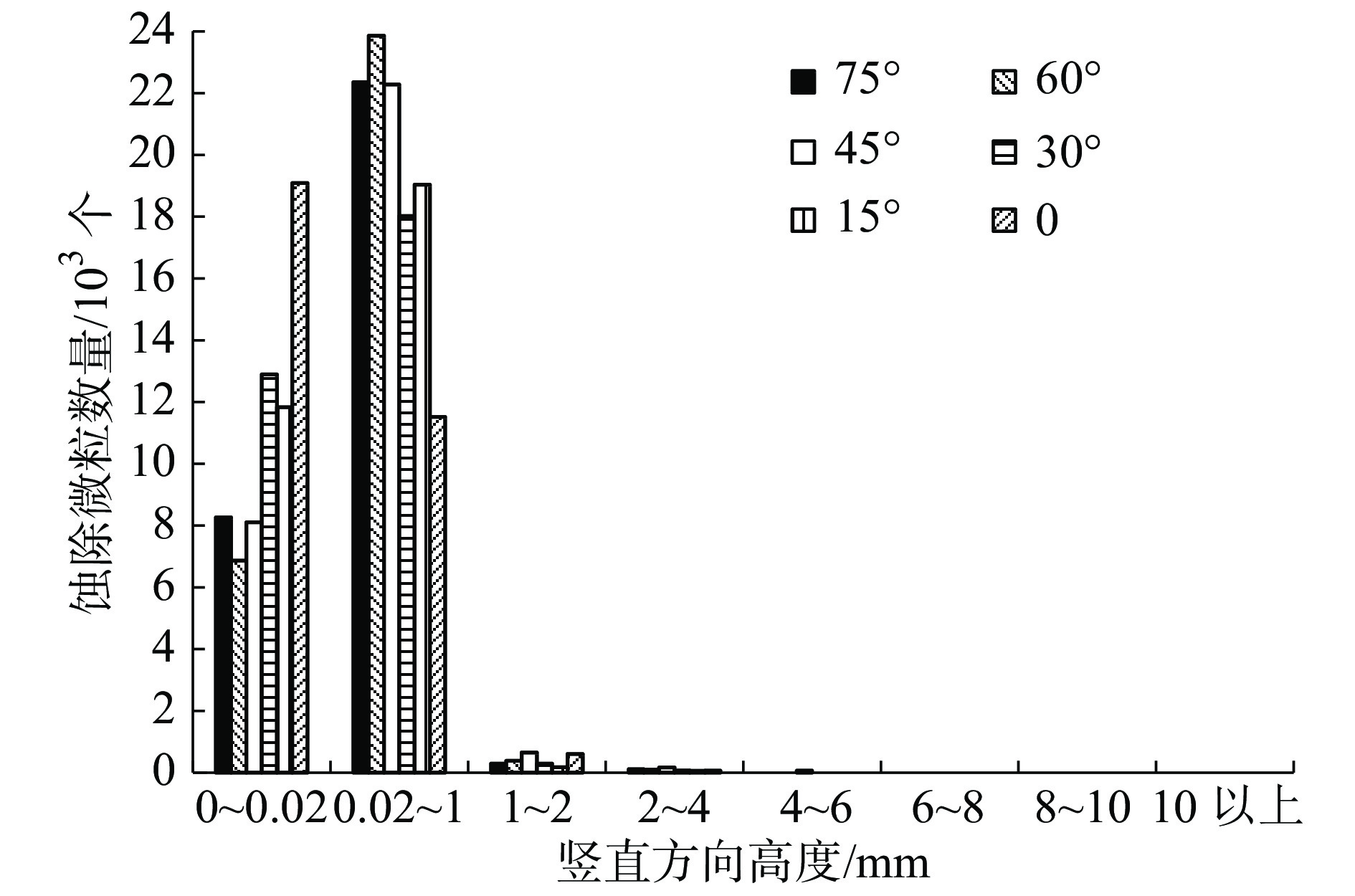

[7]

|

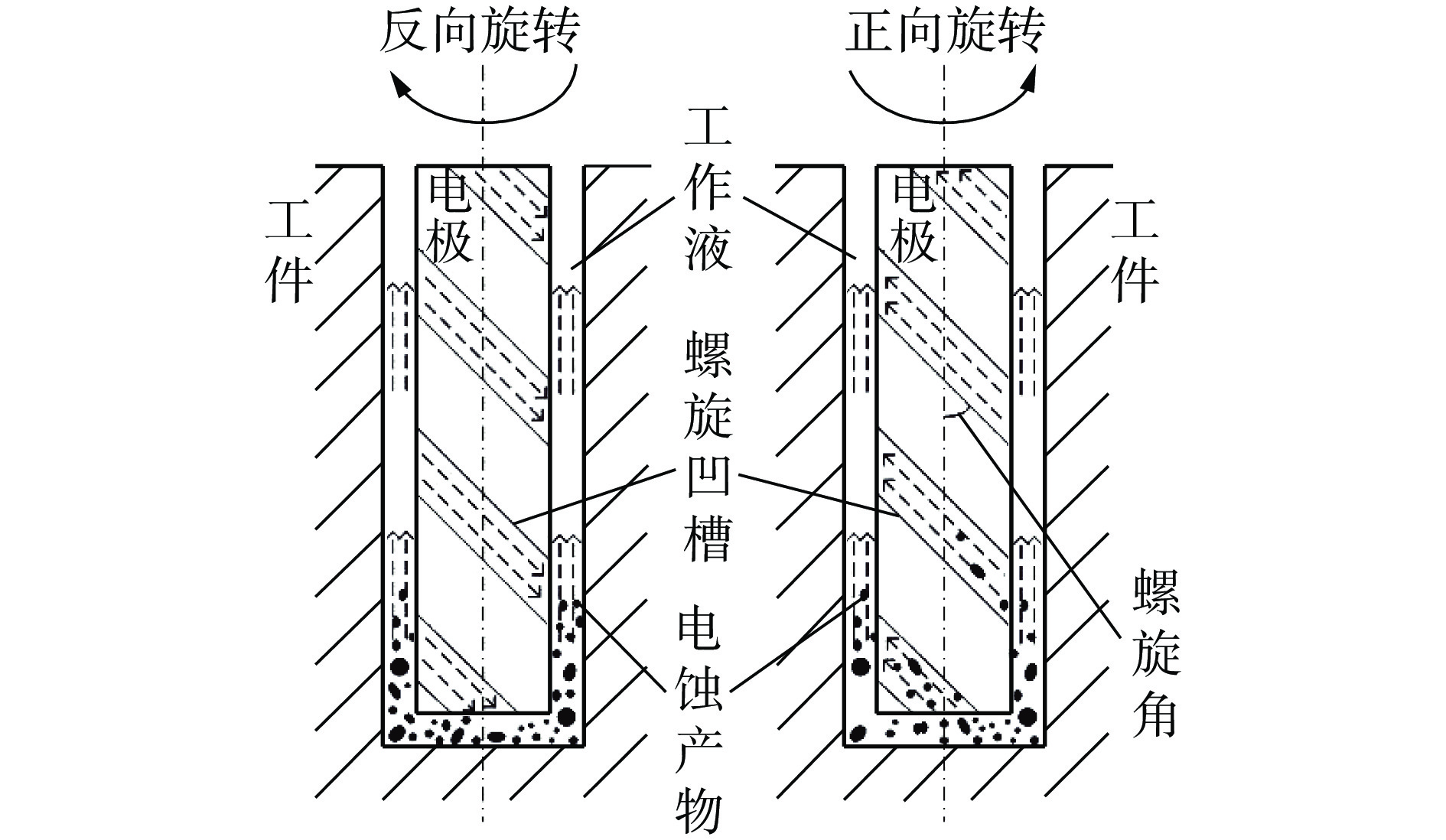

王志强, 宫虎, 房丰洲. 双螺旋电极在深微孔电火花加工中的研究[J]. 中南大学学报, 2015, 46(8): 2857-2862 doi: 10.11817/j.issn.1672-7207.2015.08.014WANG Z Q, GONG H, FANG F Z. Micro hole machining using double helix electrodes in electro discharge machining[J]. Journal of Central South University , 2015, 46(8): 2857-2862 (in Chinese) doi: 10.11817/j.issn.1672-7207.2015.08.014

|

|

[8]

|

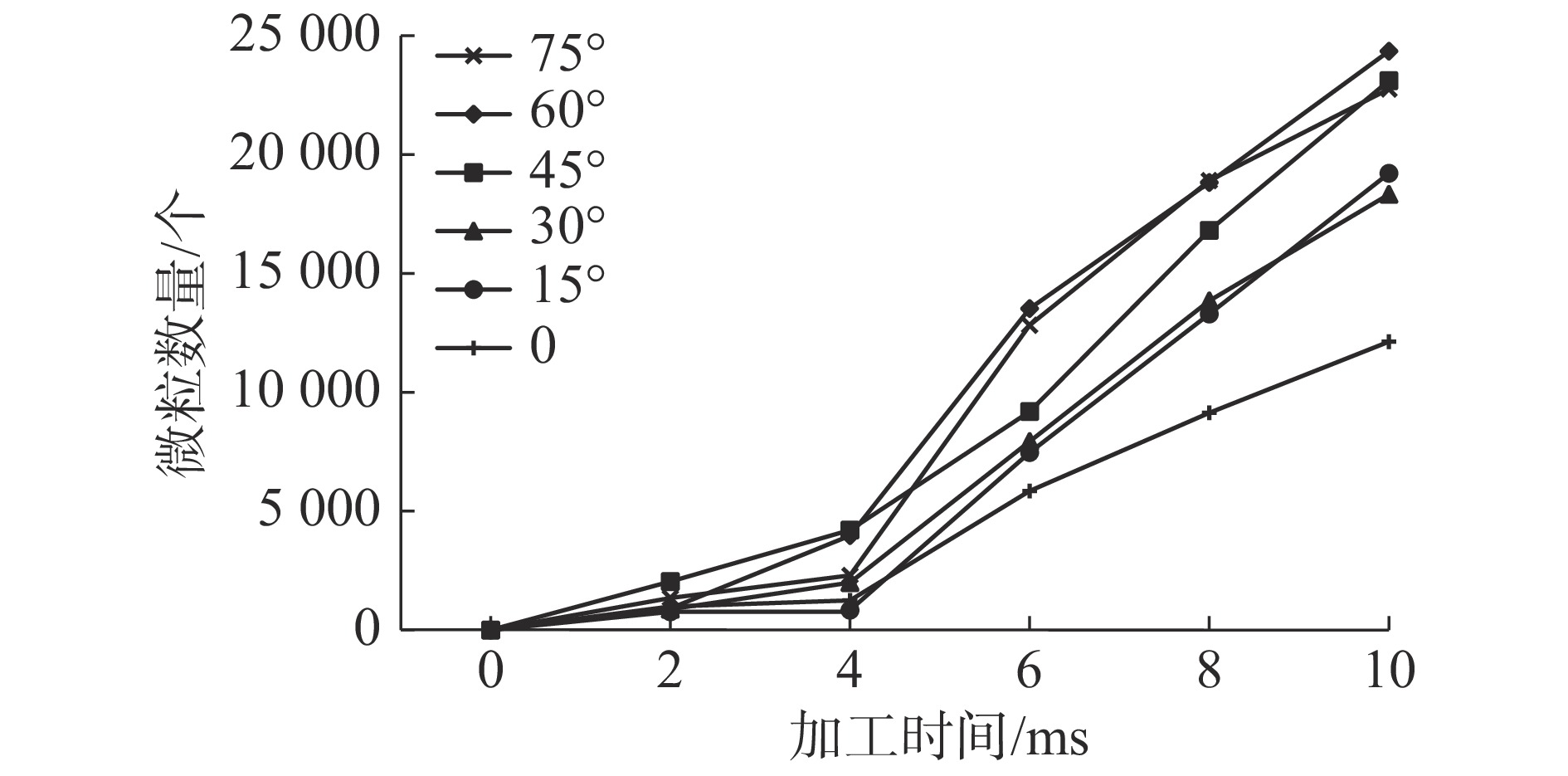

曹一龙, 曹明让, 郝岳峰, 等. 螺旋电极电火花小孔加工排屑仿真和试验[J]. 机械设计与研究, 2015, 31(1): 89-92CAO Y L, CAO M R, HAO Y F, et al. The chip removal simulation and experimental research of EDM drilling with spiral electrode for small hole[J]. Machine Design and Research, 2015, 31(1): 89-92 (in Chinese)

|

|

[9]

|

陈远军. 基于流场分析的螺旋电极电解加工孔的研究[D]. 成都: 西华大学, 2015CHEN Y J. Based on flow field analysis of the spiral electrode electrochemical machining hole[D]. Chengdu: Xihua University, 2015 (in Chinese)

|

|

[10]

|

梁智权. 流体力学[M]. 3版. 重庆: 重庆大学出版社, 2008LIANG Z Q. Fluid mechanics[M]. 3rd ed. Chongqing: Chongqing University Press, 2008 (in Chinese)

|

|

[11]

|

朱红钧. FLUENT15.0流场分析实战指南[M]. 北京: 人民邮电出版社, 2015ZHU H J. FLUENT 15.0 practical guide for flow field analysis[M]. Beijing: Post & Telecom Press, 2015 (in Chinese)

|

|

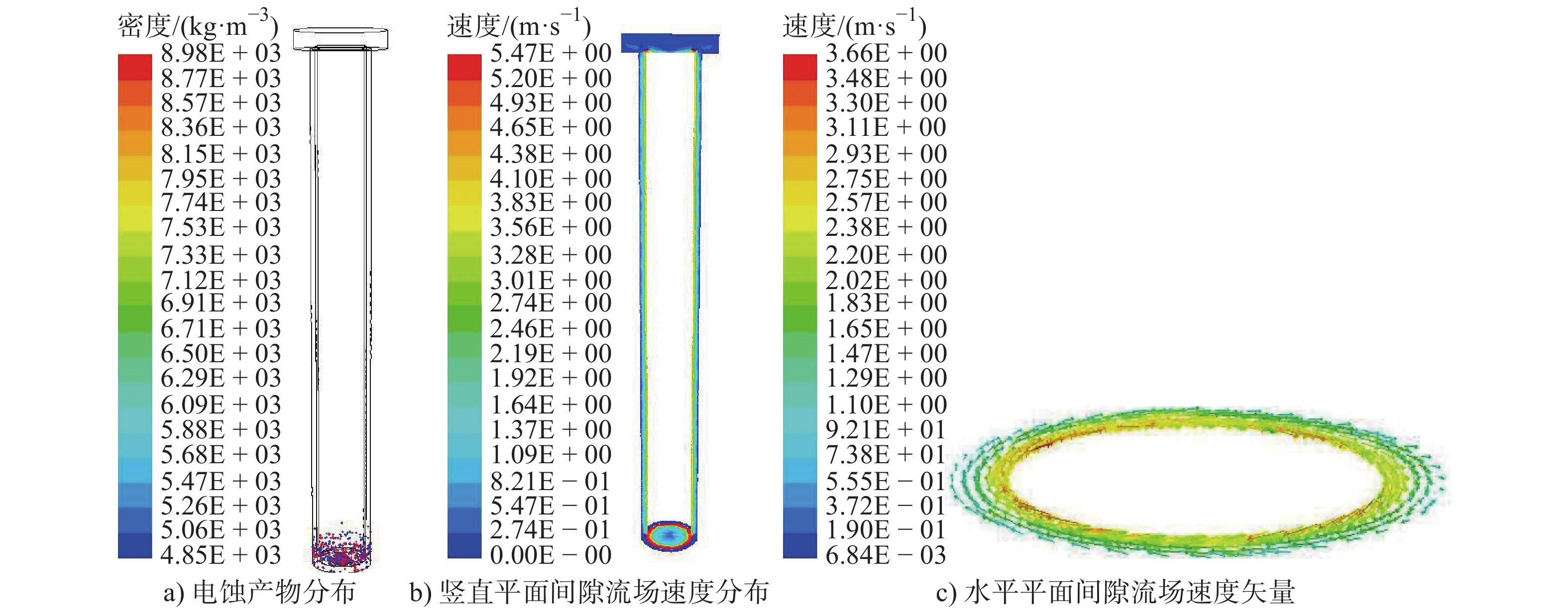

[12]

|

YOSHIDA M, KUNIEDA M. Study on the distribution of scattered debris generated by a single pulse discharge in EDM process[J]. International Journal of Electrical Machining, 1998(3): 39-46

|

|

[13]

|

WANG J, HAN F Z. Simulation model of debris and bubble movement in consecutive-pulse discharge of electrical discharge machining[J]. International Journal of Machine Tools and Manufacture, 2014, 77: 56-65 doi: 10.1016/j.ijmachtools.2013.10.007

|

|

[14]

|

LIU Y, ZHANG W C, ZHANG S F, et al. The simulation research of tool wear in small hole EDM machining on titanium alloy[J]. Applied Mechanics and Materials, 2014, 624: 249-254 doi: 10.4028/www.scientific.net/AMM.624.249

|

|

[15]

|

常伟杰, 陈远龙, 张建华, 等. 超声振动辅助电火花铣削流场与蚀除颗粒分布场仿真[J]. 应用基础与工程科学学报, 2015, 23(S1): 151-157CHANG W J, CHEN Y L, ZHANG J H, et al. Ultrasonic vibration aided electrical-discharge milling flow field and debris distribution field simulation[J]. Journal of Basic Science and Engineering, 2015, 23(S1): 151-157 (in Chinese)

|

下载:

下载: