Proportional-integral-differential Control Method on Solving Structural Topology Optimization Problems

-

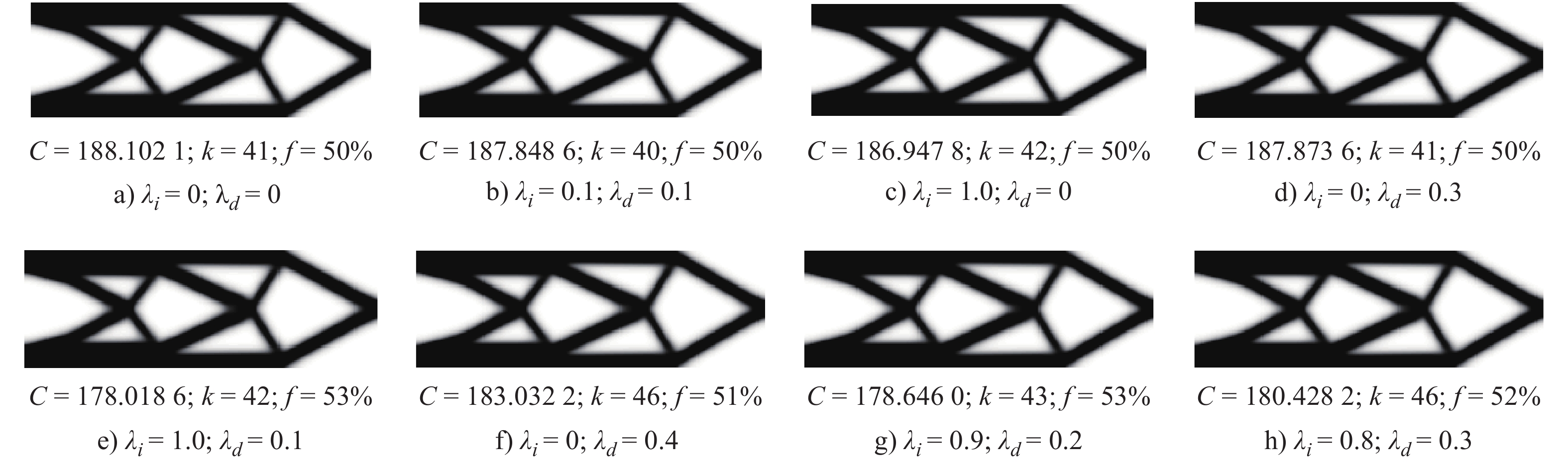

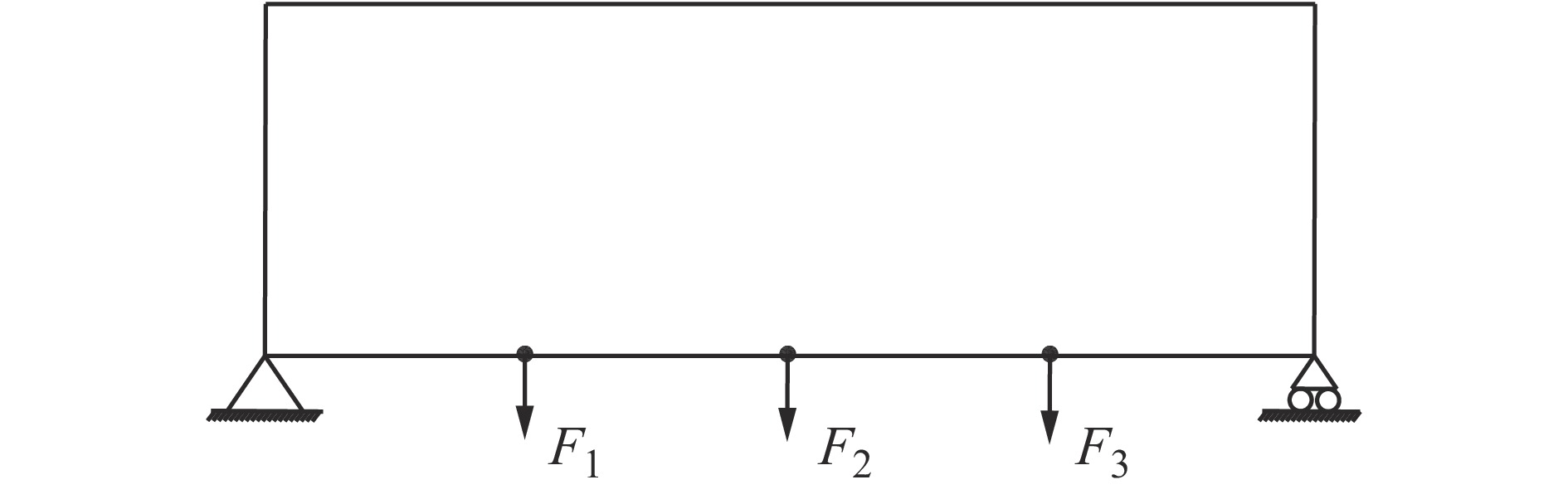

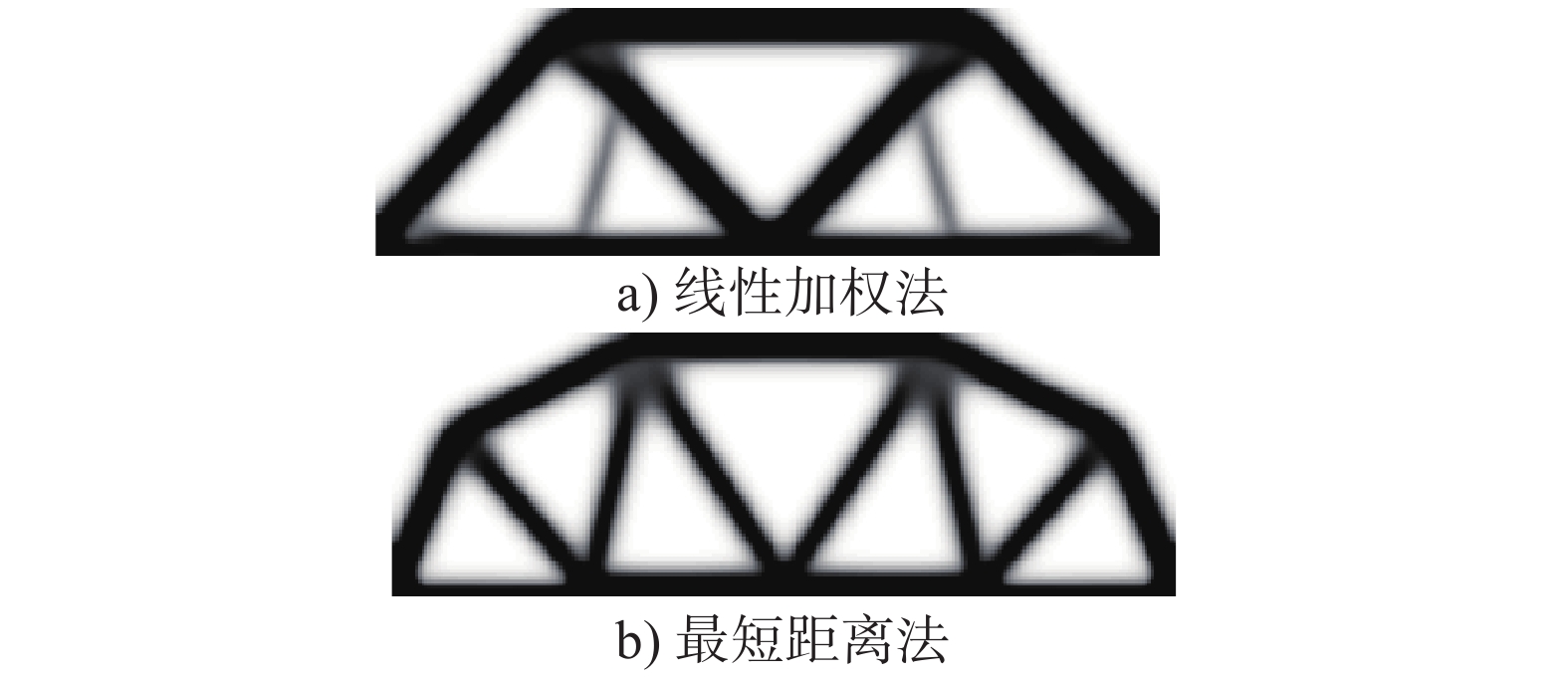

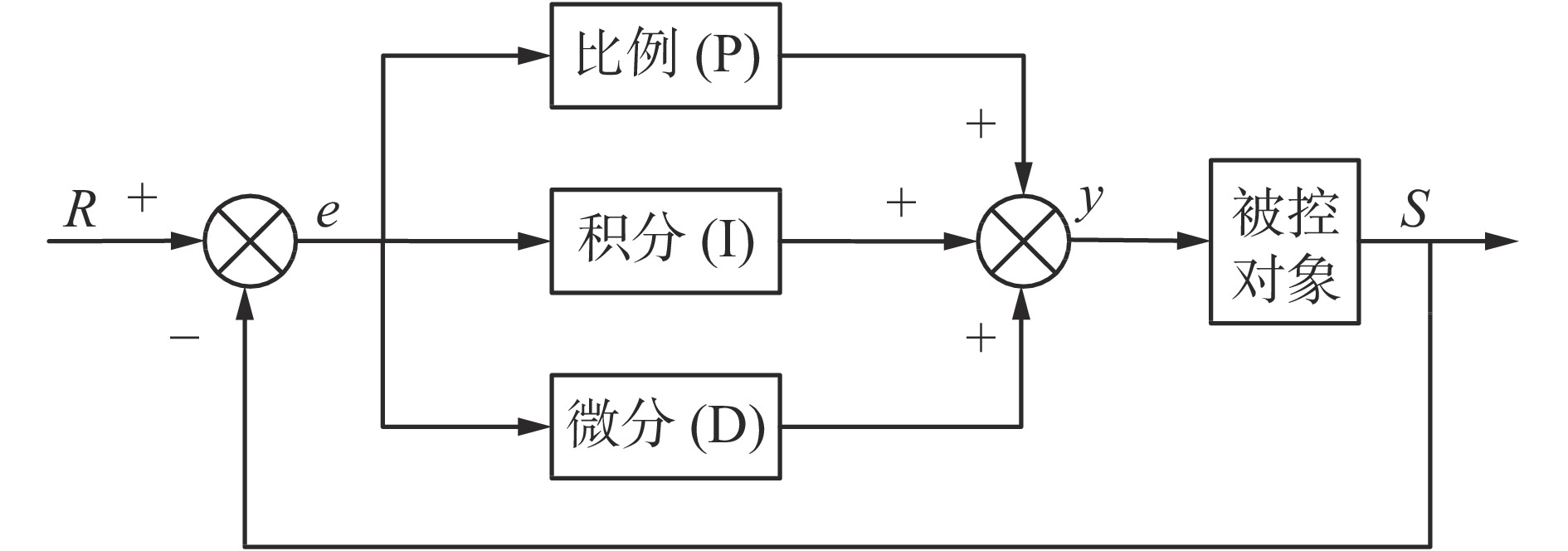

摘要: 拓扑优化具有设计变量多、目标性能与约束条件为设计变量的非线性、非单调隐式函数的特征,计算效率值得商榷。因此探索高效稳定的求解方法是结构拓扑优化的核心问题。提出一种基于PID控制算法的拓扑优化求解方法,采用固体各向同性微结构材料惩罚模型(SIMP)方法建立单工况条件下质量约束条件下结构柔度最小化拓扑优化模型,推导出基于PID法的设计变量迭代格式,引入基于Helmholtz偏微分方程的过滤方式抑制出现的数值不稳定问题,并将所提方法扩展到两类多工况结构拓扑优化问题,通过与优化准则法(Optimality criteria, OC)和移动渐近线法(Method of moving asymptotes,MMA)进行数值结果比较可知,PID控制方法具有设置简便、高效求解、收敛稳定且无需梯度信息的优点。Abstract: Under the inherent characteristics of nonlinear and non-monotonic implicit function with tremendous design variables, the corresponding computational efficiency of topology optimization must be considered. Therefore, the kernel question is to explore efficient and stable solution strategy. The solution methodology based on the proportional-integral-differential (PID) control algorithm is proposed, under the solid isotropic microstructures material penalty (SIMP) model. The structural compliance minimization topology optimization model under the condition of single working condition is established. The iterative format of the design variables of PID algorithm is illustrated, and the filter method of Helmholtz partial differential equation is introduced to suppress the numerical instability problem. Then the proposed method is extended to the multi-loading condition topology optimization problems. Through the comparison of the optimization criteria method (OC) and the moving asymptote method (MMA), the numerical results demonstrated that the PID method exhibits the property of easy implementation, efficient solution, stable convergence and non-gradient information.

-

Key words:

- topology optimization /

- PID control /

- SIMP model /

- non-gradient

-

表 1 单工况条件下结构柔度最小值与最大值

方法 F1 F2 F3 Cmin Cmax 迭代次数 Cmin Cmax 迭代次数 Cmin Cmax 迭代次数 PID 23.7787 221.6250 73 3235.3469 25519.7488 21 23.7787 221.6250 73 OC 23.6413 221.6250 187 3227.9401 25519.7488 27 23.6413 221.6250 187 MMA 23.6303 221.6250 387 3221.3308 25519.7488 106 23.6290 221.6250 387 -

[1] BENDSØE M P, KIKUCHI N. Generating optimal topologies in structural design using a homogenization method[J]. Computer Methods in Applied Mechanics and Engineering, 1988, 71(2): 197-224 doi: 10.1016/0045-7825(88)90086-2 [2] DEATON J D, GRANDHI R V. A survey of structural and multidisciplinary continuum topology optimization: post 2000[J]. Structural and Multidisciplinary Optimization, 2014, 49(1): 1-38 doi: 10.1007/s00158-013-0956-z [3] SIGMUND O, MAUTE K. Topology optimization approaches: a comparative review[J]. Structural and Multidisciplinary Optimization, 2013, 48(6): 1031-1055 doi: 10.1007/s00158-013-0978-6 [4] 杨畅. 基于拓扑优化方法的汽车传动轴轻量化设计[D]. 武汉: 湖北工业大学, 2019YANG C. Lightweight design of vehicle propeller shaft based on topology optimization method[D]. Wuhan: Hubei University of Technology, 2019 (in Chinese) [5] 金娜. 柱盘结构的拓扑优化及其MATLAB实现[D]. 吉林: 东北电力大学, 2019JIN N. Topology optimization of column-disk structure and its realization in MATLAB[D]. Jilin: Northeast Electric Power University, 2019 (in Chinese) [6] 宋丽平, 王聪兴, 赵德祥. 重载挂车承载梁结构拓扑优化设计[J]. 现代机械, 2019(1): 11-14SONG L P, WANG C X, ZHAO D X. Topological optimization design of the bearing beam structure of heavy-duty trailer[J]. Modern Machinery, 2019(1): 11-14 (in Chinese) [7] BENDSØE M P, SIGMUND O. Topology optimization theory, methods and application[M]. 2nd ed. Berlin: Springer, 2003 [8] HASSANI B, HINTON E. A review of homogenization and topology optimization III-topology optimization using optimality criteria[J]. Computers & Structures, 1998, 69(6): 739-756 [9] LIU K, TOVAR A. An efficient 3D topology optimization code written in Matlab[J]. Structural and Multidisciplinary Optimization, 2014, 50(6): 1175-1196 doi: 10.1007/s00158-014-1107-x [10] HERBSTER A F, ROMERO M A. Rigorous and optimized few-mode erbium-doped fiber amplifier design by using topology optimization and genetic algorithms[J]. Optical Engineering, 2017, 56(4): 046102 doi: 10.1117/1.OE.56.4.046102 [11] MARJANI A, SHIRAZIAN S, ASADOLLAHZADEH M. Topology optimization of neural networks based on a coupled genetic algorithm and particle swarm optimization techniques (c-GA-PSO-NN)[J]. Neural Computing and Applications, 2018, 29(11): 1073-1076 doi: 10.1007/s00521-016-2619-7 [12] YOO K S, HAN S Y. Topology optimum design of compliant mechanisms using modified ant colony optimization[J]. Journal of Mechanical Science and Technology, 2015, 29(8): 3321-3327 doi: 10.1007/s12206-015-0729-2 [13] 王威, 杨平. 智能PID控制方法的研究现状及应用展望[J]. 自动化仪表, 2008, 29(10): 1-3, 7 doi: 10.3969/j.issn.1000-0380.2008.10.001WANG W, YANG P. Intelligent PID control of the status and the application of prospect[J]. Process Automation Instrumentation, 2008, 29(10): 1-3, 7 (in Chinese) doi: 10.3969/j.issn.1000-0380.2008.10.001 [14] 王东风, 韩璞. 基于粒子群优化的混沌系统比例-积分-微分控制[J]. 物理学报, 2006, 55(4): 1644-1650 doi: 10.3321/j.issn:1000-3290.2006.04.019WANG D F, HAN P. Proportional-integral-derivative chaotic system control algorithm based on particle swarm optimization[J]. Acta Physica Sinica, 2006, 55(4): 1644-1650 (in Chinese) doi: 10.3321/j.issn:1000-3290.2006.04.019 [15] 吴宏鑫, 沈少萍. PID控制的应用与理论依据[J]. 控制工程, 2003, 10(1): 37-42 doi: 10.3969/j.issn.1671-7848.2003.01.009WU H X, SHEN S P. Basis of theory and applications on PID control[J]. Control Engineering of China, 2003, 10(1): 37-42 (in Chinese) doi: 10.3969/j.issn.1671-7848.2003.01.009 [16] 崔明涛, 陈建军, 拓耀飞, 等. 区间参数柔性机构设计的混合元胞自动机方法[J]. 机械工程学报, 2007, 43(7): 39-43 doi: 10.3321/j.issn:0577-6686.2007.07.008CUI M T, CHEN J J, TUO Y F, et al. Compliant mechanism design with interval parameters using the hybrid cellular automaton method[J]. Chinese Journal of Mechanical Engineering, 2007, 43(7): 39-43 (in Chinese) doi: 10.3321/j.issn:0577-6686.2007.07.008 [17] 赵龙彪, 高亮, 陈志敏, 等. 基于比例微分优化准则的拓扑优化方法[J]. 中国机械工程, 2011, 22(3): 345-350ZHAO L B, GAO L, CHEN Z M, et al. A proportional and differential optimality criterion method for topology optimization[J]. China Mechanical Engineering, 2011, 22(3): 345-350 (in Chinese) [18] TOVAR A, KHANDELWAL K. Topology optimization for minimum compliance using a control strategy[J]. Engineering Structures, 2013, 48: 674-682 doi: 10.1016/j.engstruct.2012.12.008 [19] BIYIKLI E, TO A C. Proportional topology optimization: a new non-sensitivity method for solving stress constrained and minimum compliance problems and its implementation in MATLAB[J]. PLoS One, 2015, 10(12): e0145041 doi: 10.1371/journal.pone.0145041 [20] BENDSØE M P, SIGMUND O. Material interpolation schemes in topology optimization[J]. Archive of Applied Mechanics, 1999, 69(9-10): 635-654 doi: 10.1007/s004190050248 [21] STOLPE M, SVANBERG K. An alternative interpolation scheme for minimum compliance topology optimization[J]. Structural and Multidisciplinary Optimization, 2001, 22(2): 116-124 doi: 10.1007/s001580100129 [22] SIGMUND O. Morphology-based black and white filters for topology optimization[J]. Structural and Multidisciplinary Optimization, 2007, 33(4-5): 401-424 doi: 10.1007/s00158-006-0087-x [23] LAZAROV B S, SIGMUND O. Filters in topology optimization based on Helmholtz-type differential equations[J]. International Journal for Numerical Methods in Engineering, 2011, 86(6): 765-781 doi: 10.1002/nme.3072 [24] ANDREASSEN E, CLAUSEN A, SCHEVENELS M, et al. Efficient topology optimization in MATLAB using 88 lines of code[J]. Structural and Multidisciplinary Optimization, 2011, 43(1): 1-16 doi: 10.1007/s00158-010-0594-7 [25] MIN S, NISHIWAKI S, KIKUCHI N. Unified topology design of static and vibrating structures using multiobjective optimization[J]. Computers & Structures, 2000, 75(1): 93-116 -

下载:

下载: