Kinematics Characteristics and Experimental Analysis of Longitudinal Torsional Ultrasonic Grinding for Zirconia Ceramics

-

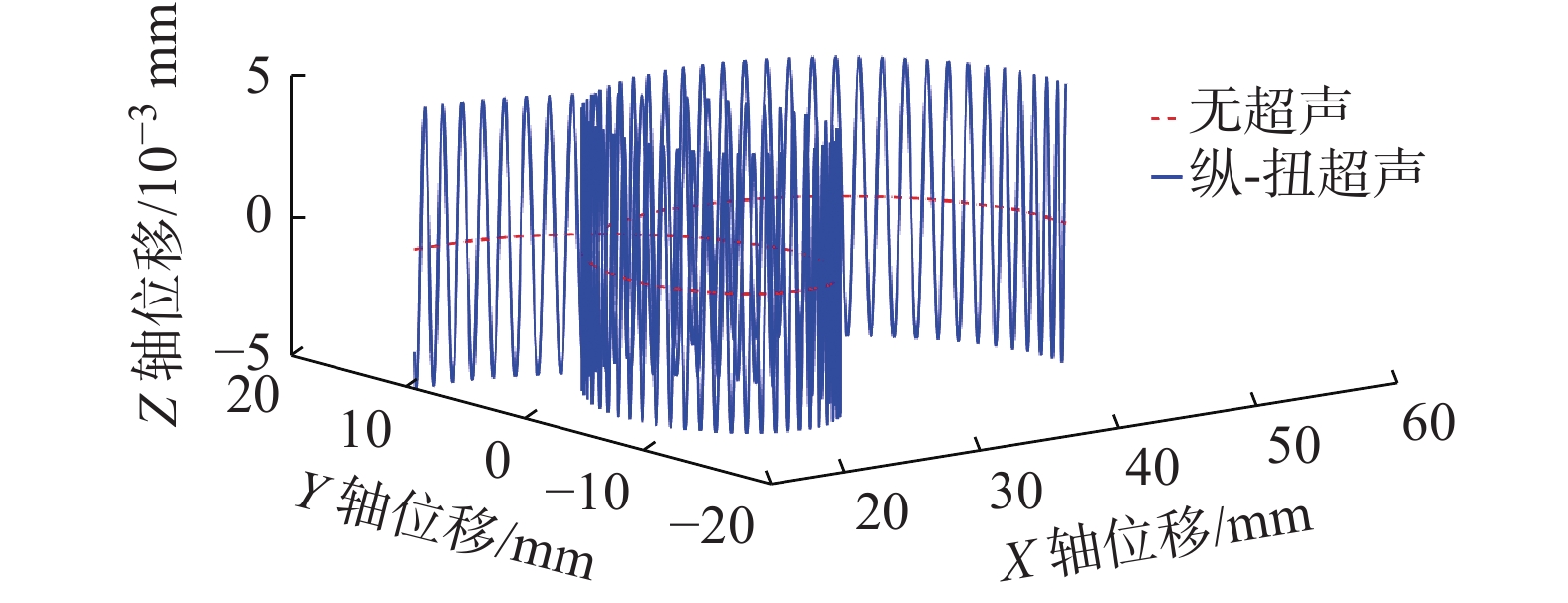

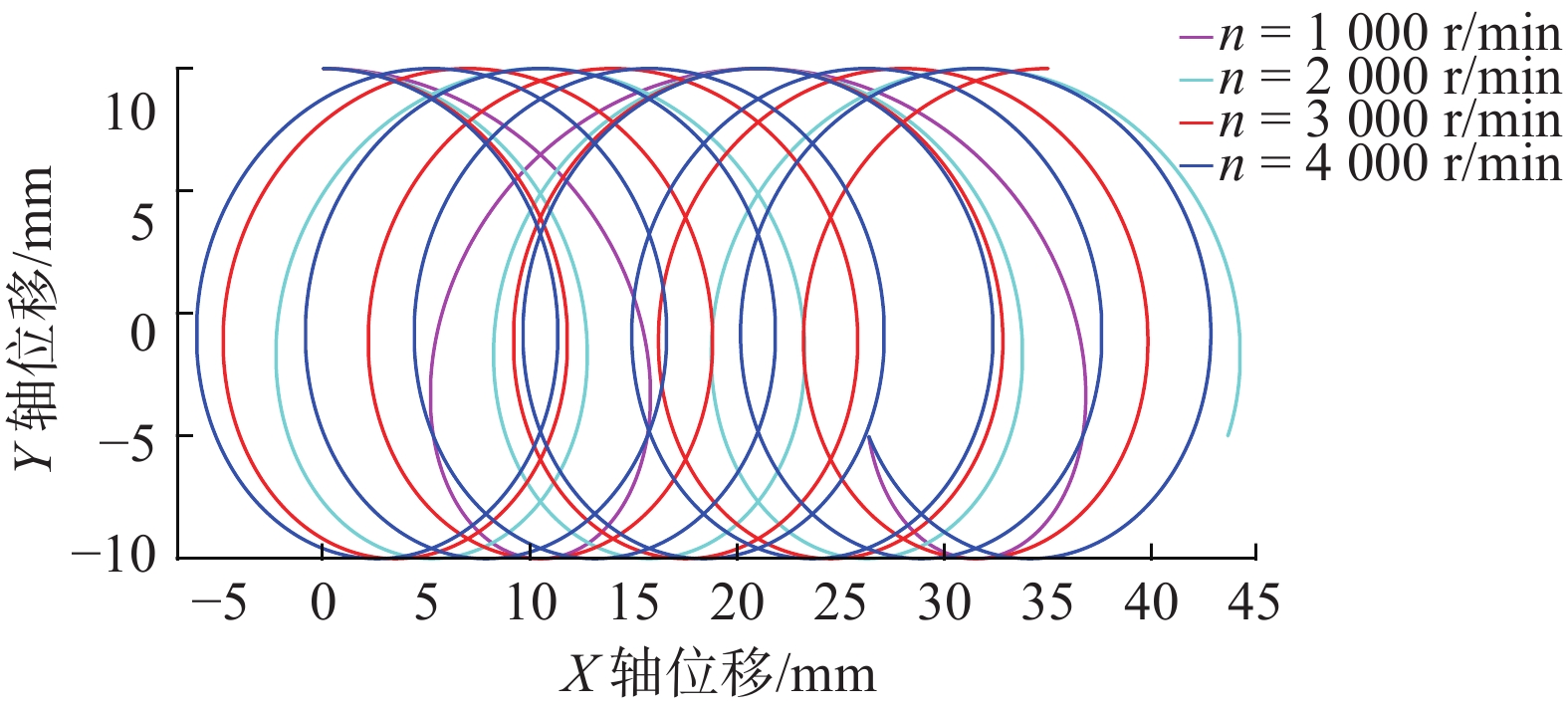

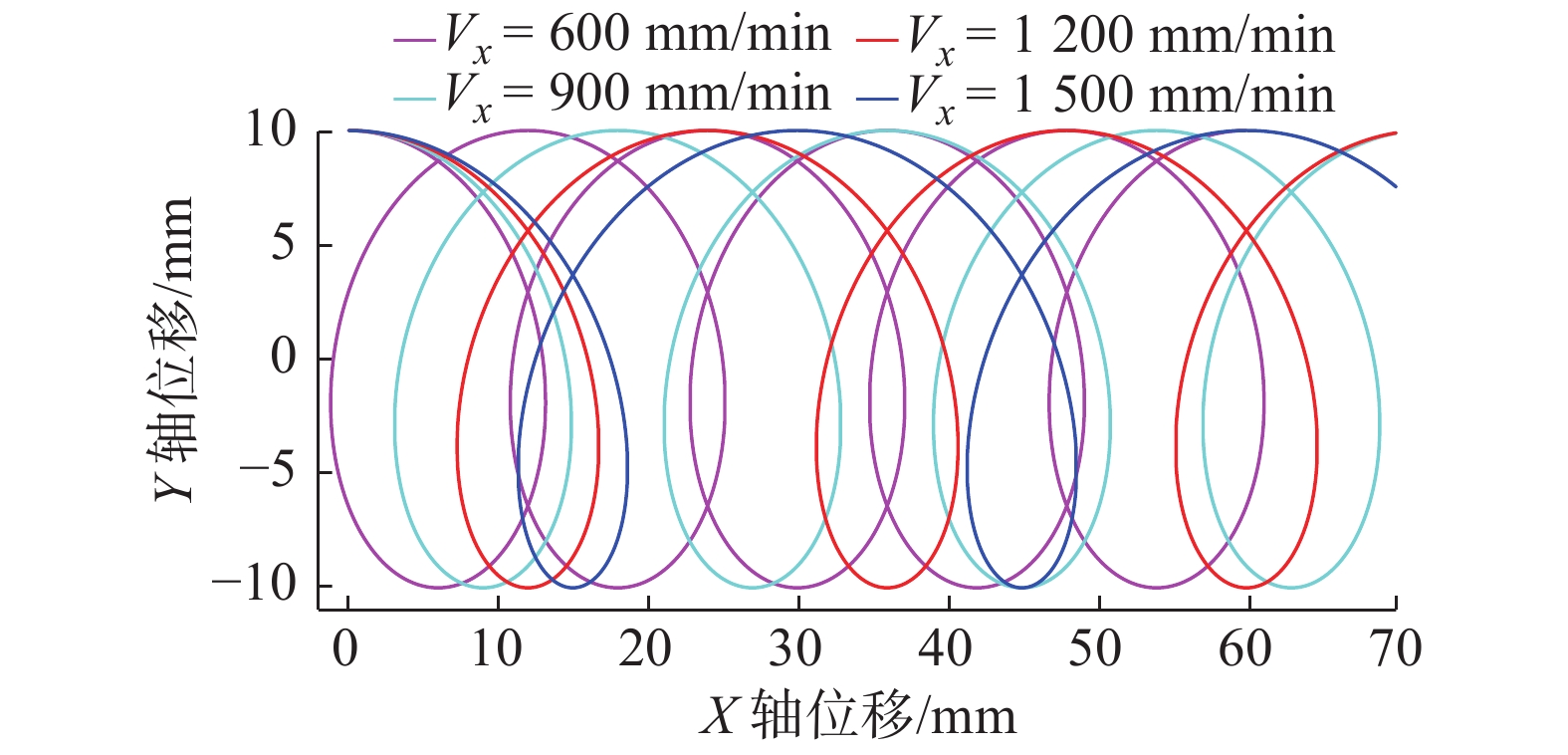

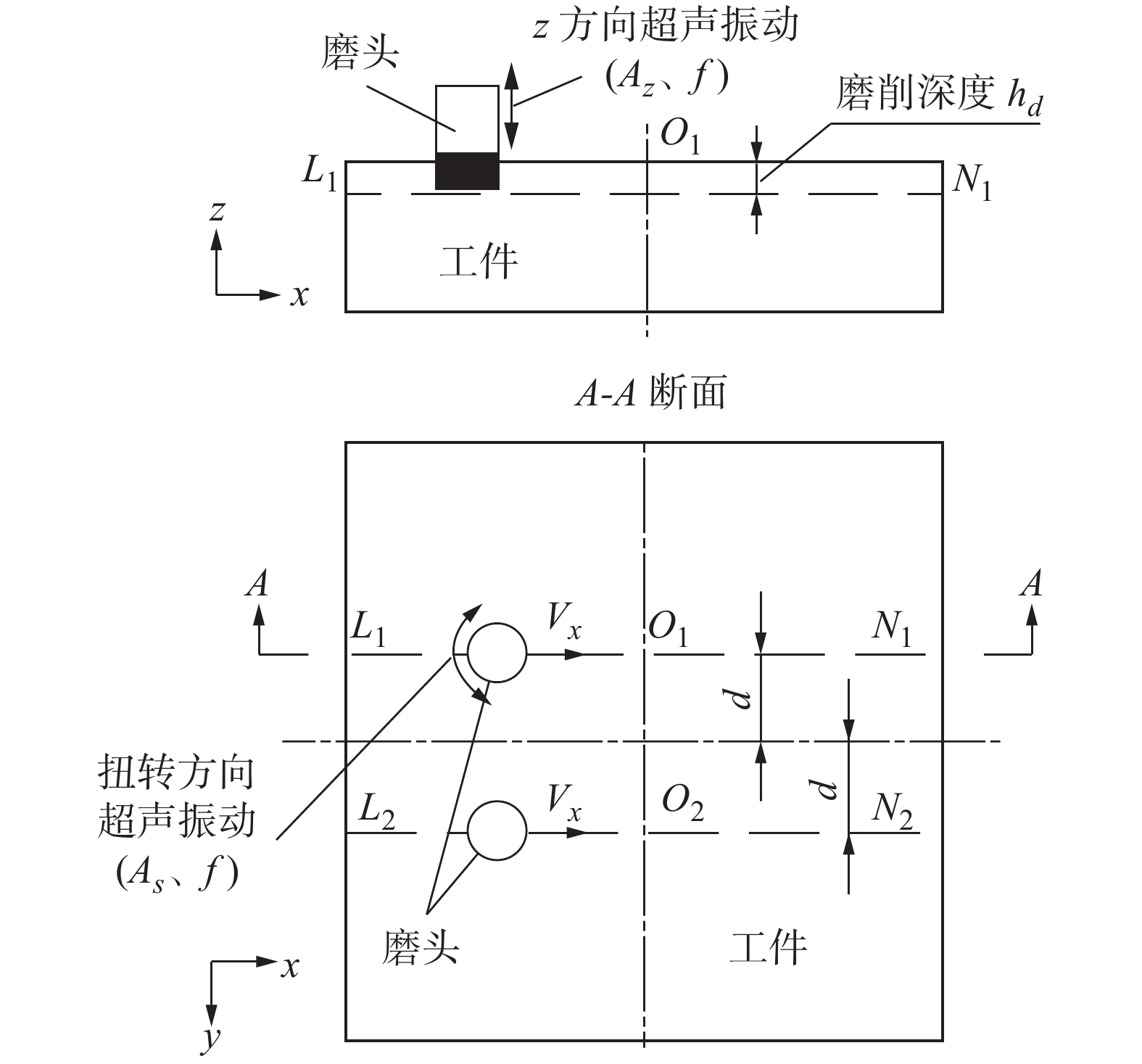

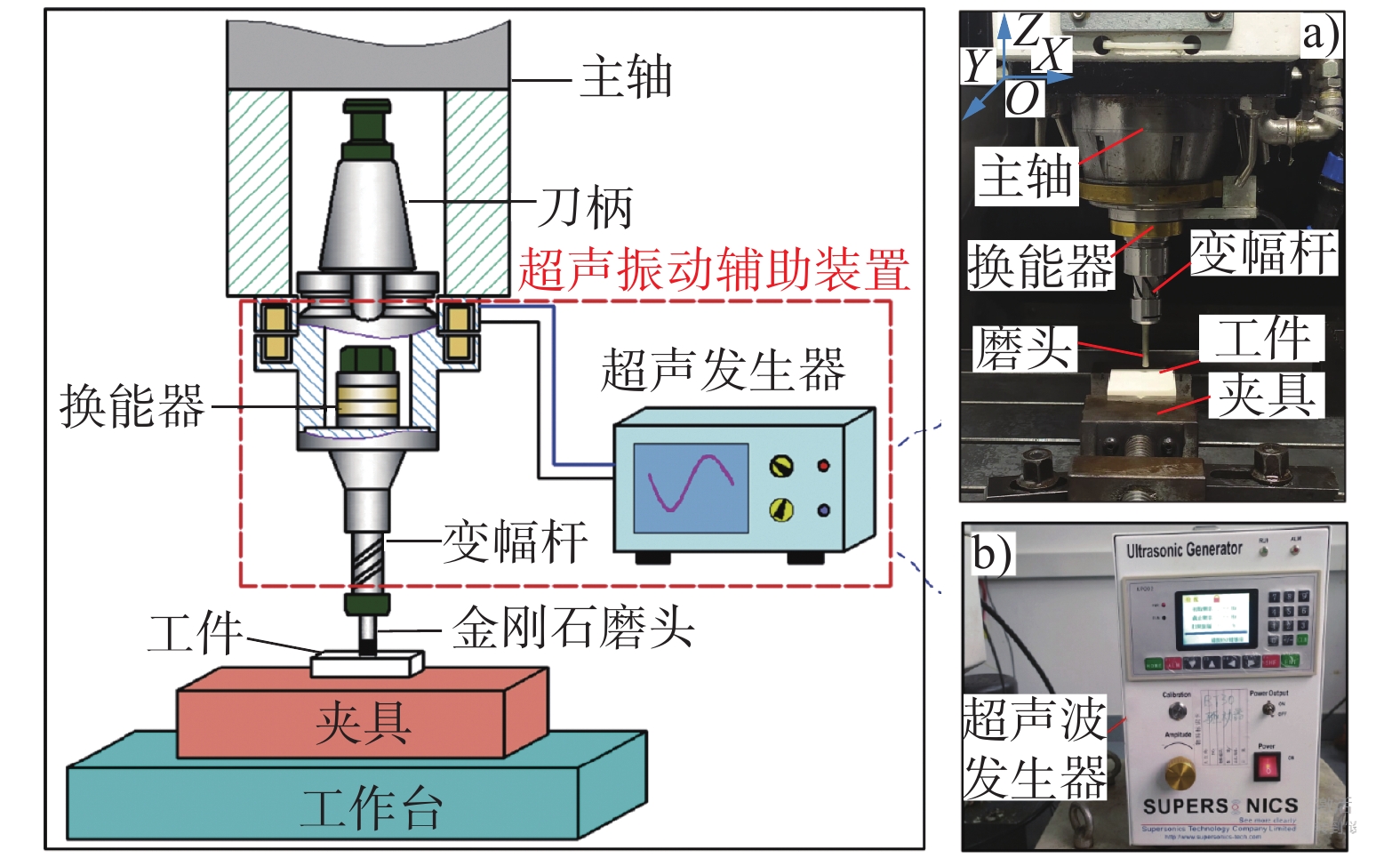

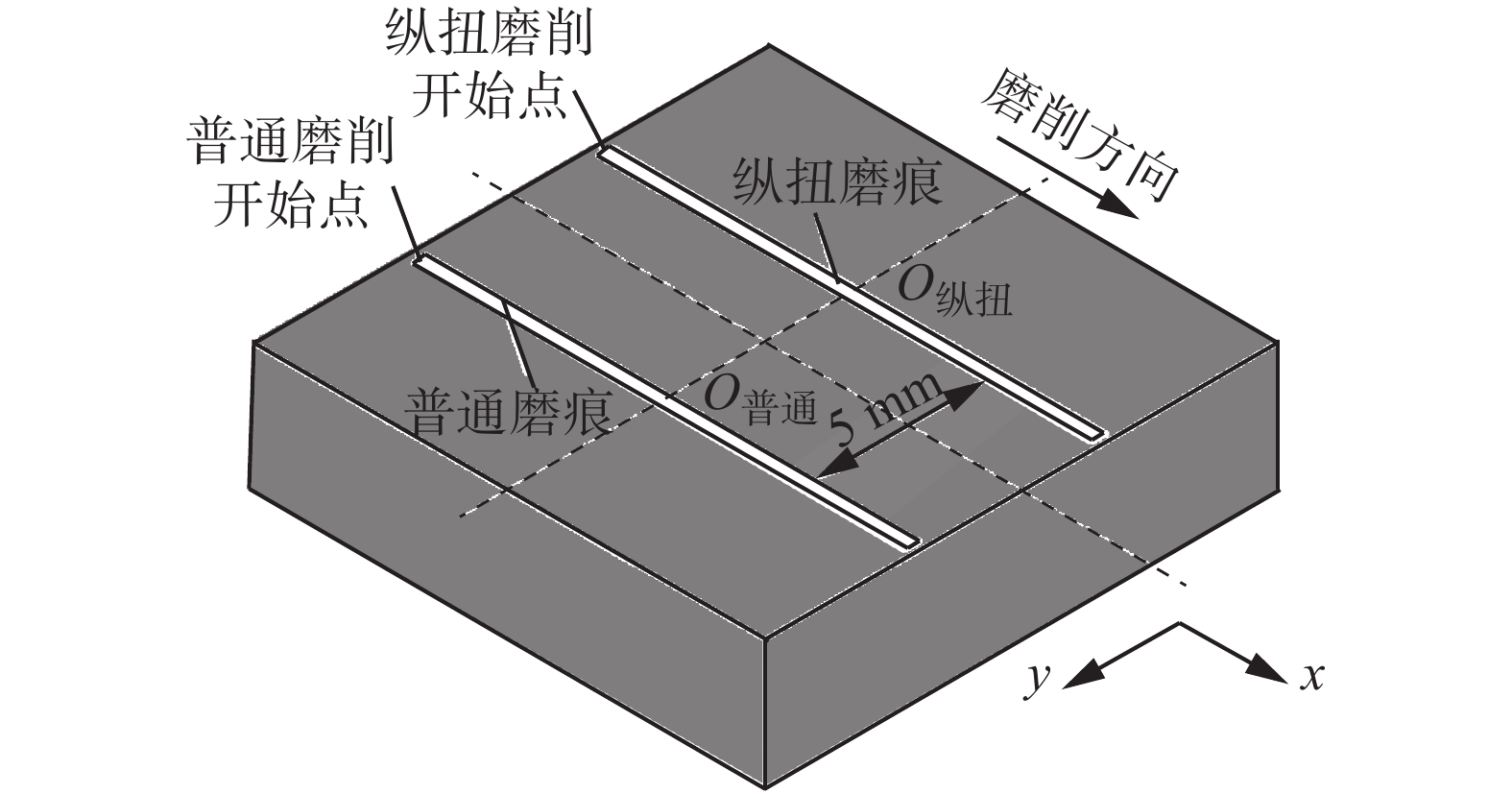

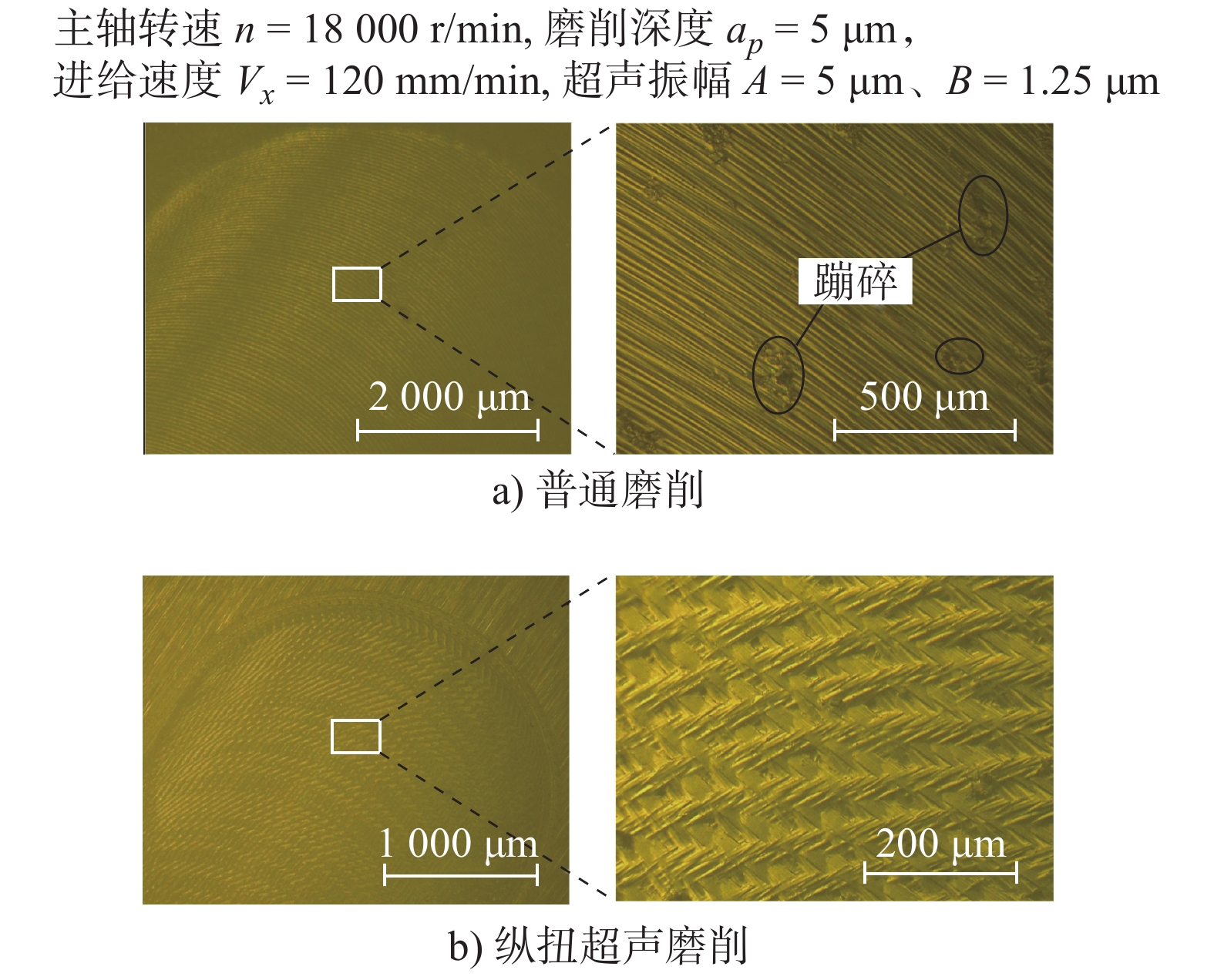

摘要: 以氧化锆陶瓷为研究对象,基于纵扭超声矢量分解原理,建立了单颗磨粒运动轨迹数学模型。借助MATLAB仿真软件,对比分析了普通磨削与纵扭超声磨削的运动轨迹,探讨了工艺参数对纵扭超声磨削运动轨迹的影响规律;同时通过普通磨削和纵扭超声磨削试验,研究了工艺参数对氧化锆陶瓷表面形貌的影响。结果表明:普通磨削与纵扭超声磨削运动轨迹仿真结果均与试验结果相吻合,验证了该运动轨迹数学模型的正确性;与普通磨削相比,纵扭超声磨削磨痕均匀、沟槽光滑,工件加工表面形貌得到明显改善。Abstract: Taking Zirconia ceramics as the research object, a mathematical models of single abrasive particle trajectory is established based on the principle of longitudinal torsion ultrasonic vector decomposition. With the MATLAB simulation software, the conventional grinding and longitudinal torsional ultrasonic grinding are analyzed and the influence of process parameters on the trajectory of longitudinal torsional ultrasonic grinding is discussed. Experiments of conventional grinding and longitudinal torsional ultrasonic grinding on zirconia ceramics are performed to analyze the trajectories of conventional and longitudinal torsional ultrasonic grinding, and the effect of processing parameters on the surface morphology are disclosed. The simulation results of motion trajectory of conventional grinding and longitudinal torsional ultrasonic grinding are consistent with the experimental results, which verifies the correctness of the mathematical model of the trajectory. Moreover, the machined surface morphology with uniform wear marks and slight grooves produced by longitudinal torsional ultrasonic grinding is obviously improved compared with the conventional grinding.

-

表 1 加工工艺条件

磨削方式 平面直线磨削 超声振动方向 纵扭复合振动 超声振动条件 超声频率自动扫频范围20 ~30 kHz,

振幅0 ~10 μm可调纵扭转换比 约为25% 表 2 单因素磨削试验参数

参数 数值 主轴转速n/(r·min−1) 16000/18000/20000/22000 单次磨削深度ap/μm 5 进给速度Vx/(mm·min−1) 80/100/120/140 超声输出振幅/μm A=5,B=1.25 动态谐振频率/Hz 20817~21135 -

[1] 冯平法, 王健健, 张建富, 等. 硬脆材料旋转超声加工技术的研究现状及展望[J]. 机械工程学报, 2017, 53(19): 3-21 doi: 10.3901/JME.2017.19.003Feng P F, Wang J J, Zhang J F, et al. Research status and future prospects of rotary ultrasonic machining of hard and brittle materials[J]. Journal of Mechanical Engineering, 2017, 53(19): 3-21 (in Chinese doi: 10.3901/JME.2017.19.003 [2] Thoe T B, Aspinwall D K, Wise M L H. Review on ultrasonic machining[J]. International Journal of Machine Tools and Manufacture, 1998, 38(4): 239-255 doi: 10.1016/S0890-6955(97)00036-9 [3] Zhang C L, Zhang J F, Feng P F. Mathematical model for cutting force in rotary ultrasonic face milling of brittle materials[J]. The International Journal of Advanced Manufacturing Technology, 2013, 69(1-4): 161-170 doi: 10.1007/s00170-013-5004-z [4] 李勋, 张德远. 不分离型超声椭圆振动切削试验研究[J]. 机械工程学报, 2010, 46(19): 177-182 doi: 10.3901/JME.2010.19.177Li X, Zhang D Y. Experimental study on the unseparated ultrasonic elliptical vibration cutting[J]. Journal of Mechanical Engineering, 2010, 46(19): 177-182 (in Chinese doi: 10.3901/JME.2010.19.177 [5] Xiao X Z, Zheng K, Liao W H, et al. Study on cutting force model in ultrasonic vibration assisted side grinding of zirconia ceramics[J]. International Journal of Machine Tools and Manufacture, 2016, 104: 58-67 doi: 10.1016/j.ijmachtools.2016.01.004 [6] Meng H, Zheng K, Xiao X Z, et al. Investigation on feed direction cutting force in ultrasonic vibration-assisted grinding of dental ceramics[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2017, 231(19): 3493-3503 doi: 10.1177/0954406216650915 [7] Zheng K, Liao W H, Sun L J, et al. Investigation on grinding temperature in ultrasonic vibration-assisted grinding of zirconia ceramics[J]. Machining Science and Technology, 2019, 23(4): 612-628 doi: 10.1080/10910344.2019.1575405 [8] Yang Z C, Zhu L D, Lin B, et al. The grinding force modeling and experimental study of ZrO2 ceramic materials in ultrasonic vibration assisted grinding[J]. Ceramics International, 2019, 45(7): 8873-8889 doi: 10.1016/j.ceramint.2019.01.216 [9] Yang Z C, Zhu L D, Ni C B, et al. Investigation of surface topography formation mechanism based on abrasive-workpiece contact rate model in tangential ultrasonic vibration-assisted CBN grinding of ZrO2 ceramics[J]. International Journal of Mechanical Sciences, 2019, 155: 66-82 doi: 10.1016/j.ijmecsci.2019.02.031 [10] Zhu L D, Ni C B, Yang Z C, et al. Investigations of micro-textured surface generation mechanism and tribological properties in ultrasonic vibration-assisted milling of Ti-6Al-4V[J]. Precision Engineering, 2019, 57: 229-243 doi: 10.1016/j.precisioneng.2019.04.010 [11] Li Z H, Zheng K, Liao W H, et al. Surface characterization of zirconia ceramics in ultrasonic vibration-assisted grinding[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2018, 40(8): 379 doi: 10.1007/s40430-018-1296-0 [12] Zahedi A, Tawakoli T, Akbari J. Energy aspects and workpiece surface characteristics in ultrasonic-assisted cylindrical grinding of alumina–zirconia ceramics[J]. International Journal of Machine Tools and Manufacture, 2015, 90: 16-28 doi: 10.1016/j.ijmachtools.2014.12.002 [13] Tawakoli T, Akbari J, Zahedi A. Ultrasonic-assisted cylindrical grinding of alumina-zirconia ceramics[C]//Proceedings of ASME 2013 International Mechanical Engineering Congress and Exposition. California, USA: ASME, 2013: 206-213. [14] Zahedi A, Tawakoli T, Azarhoushang B, et al. Picosecond laser treatment of metal-bonded CBN and diamond superabrasive surfaces[J]. The International Journal of Advanced Manufacturing Technology, 2015, 76(5-8): 1479-1491 doi: 10.1007/s00170-014-6383-5 [15] Alkawaz M H, Hafiz M S A, Kasim M S, et al. Study of dental zirconia milling using rotary ultrasonic Ma-Chining[J]. International Journal of Engineering & Technology, 2018, 7(4-16): 181-183 [16] Das S, Doloi B, Bhattacharyya B. Fabrication of stepped hole on zirconia bioceramics by ultrasonic machining[J]. Machining Science and Technology, 2016, 20(4): 681-700 doi: 10.1080/10910344.2016.1224016 [17] Bhosale S B, Pawade R S, Brahmankar P K. Effect of process parameters on MRR, TWR and surface topography in ultrasonic machining of alumina-zirconia ceramic composite[J]. Ceramics International, 2014, 40(8): 12831-12836 doi: 10.1016/j.ceramint.2014.04.137 [18] 皮钧. 圆环斜槽传振杆的纵扭振动转换[J]. 机械工程学报, 2008, 44(5): 242-248 doi: 10.3321/j.issn:0577-6686.2008.05.041Pi J. Longitudinal-torsional vibration converter of cylinder with multiple diagonal slits[J]. Chinese Journal of Mechanical Engineering, 2008, 44(5): 242-248 (in Chinese doi: 10.3321/j.issn:0577-6686.2008.05.041 [19] 沈学会. 超声振动辅助铣削加工技术及机理研究[D]. 济南: 山东大学, 2011: 16-18.Shen X H. Study on the technology and mechanism of ultrasonic vibration assisted milling[D]. Ji'nan: Shandong University, 2011: 16-18 (in Chinese). -

下载:

下载: