|

[1]

|

Rajahram S S, Harvey T J, Wood R J K. Erosion-corrosion resistance of engineering materials in various test conditions[J]. Wear, 2009, 267(1-4):244-254 doi: 10.1016/j.wear.2009.01.052

|

|

[2]

|

Zu J B, Hutchings I M, Burstein G T. Design of a slurry erosion test rig[J]. Wear, 1990, 140(2):331-344 doi: 10.1016/0043-1648(90)90093-P

|

|

[3]

|

Saleh B, Abouel-Kasem A, Ahmed S M. Effect of surface properties modification on slurry erosion-corrosion resistance of AISI 5117 steel[J]. Journal of Tribology, 2015, 137(3):031105 doi: 10.1115/1.4029997

|

|

[4]

|

Malka R, Nešić S, Gulino D A. Erosion-corrosion and synergistic effects in disturbed liquid-particle flow[J]. Wear, 2007, 262(7-8):791-799 doi: 10.1016/j.wear.2006.08.029

|

|

[5]

|

Tian H H, Addie G R, Visintainer R J. Erosion-corrosion performance of high-Cr cast iron alloys in flowing liquid-solid slurries[J]. Wear, 2009, 267(11):2039-2047 doi: 10.1016/j.wear.2009.08.007

|

|

[6]

|

Wang L Q, Qiu N, Hellmann D H, et al. An experimental study on cavitation erosion-corrosion performance of ANSI 1020 and ANSI 4135 steel[J]. Journal of Mechanical Science and Technology, 2016, 30(2):533-539 doi: 10.1007/s12206-016-0106-9

|

|

[7]

|

Song Q N, Zheng Y G, Ni D R, et al. Corrosion and cavitation erosion behaviors of friction stir processed Ni-Al bronze:effect of processing parameters and position in the stirred zone[J]. Corrosion, 2014, 70(3):261-270 doi: 10.5006/1070

|

|

[8]

|

Aperador W, Delgado E, Duque J. Evaluation of the corrosion erosion by cavitation in[TiN/ZrN] multilayers coatings[J]. International Journal of Electrochemical Science, 2014, 9(7):3670-3679

|

|

[9]

|

Auret J G, Damm O F R A, Wright G J, et al. The pressure and velocity dependence of flow-type cavitation erosion[J]. Wear, 1993, 170(2):185-190 doi: 10.1016/0043-1648(93)90239-I

|

|

[10]

|

Hsu R W W, Yang C C, Huang C A, et al. Electrochemical corrosion properties of Ti-6Al-4V implant alloy in the biological environment[J]. Materials Science and Engineering:A, 2004, 380(1-2):100-109 doi: 10.1016/j.msea.2004.03.069

|

|

[11]

|

Pang Y, Liang L, Tang Y, et al. Numerical analysis and experimental investigation of combined erosion of cavitation and sandy water erosion[J]. Proceedings of the Institution of Mechanical Engineers, Part J:Journal of Engineering Tribology, 2016, 230(1):31-39 doi: 10.1177/1350650115587335

|

|

[12]

|

Wang Q Y, Bai S L, Liu Z D. Surface characterization and erosion-corrosion behavior of Q235 steel in dynamic flow[J]. Tribology Letters, 2014, 53(1):271-279 doi: 10.1007/s11249-013-0265-0

|

|

[13]

|

Barik R C, Wharton J A, Wood R J K, et al. Electro-mechanical interactions during erosion-corrosion[J]. Wear, 2009, 267(11):1900-1908 doi: 10.1016/j.wear.2009.03.011

|

|

[14]

|

Ryl J, Wysocka J, Slepski P, et al. Instantaneous impedance monitoring of synergistic effect between cavitation erosion and corrosion processes[J]. Electrochimica Acta, 2016, 203:388-395 doi: 10.1016/j.electacta.2016.01.216

|

|

[15]

|

Gou W J, Zhang H, Li H P, et al. Effects of silica sand on synergistic erosion caused by cavitation, abrasion, and corrosion[J]. Wear, 2018, 412-413:120-126 doi: 10.1016/j.wear.2018.07.023

|

|

[16]

|

Singh N, Banerjee S, Parkash O, et al. Tribological and corrosion behavior of (100-x)(Fe70Ni30)-(x)ZrO2 composites synthesized by powder metallurgy[J]. Materials Chemistry and Physics, 2018, 205:261-268 doi: 10.1016/j.matchemphys.2017.11.031

|

|

[17]

|

Zheng X Q, Liu Y. Slurry erosion-corrosion wear behavior in SiC-containing NaOH solutions of Mo2NiB2 cermets prepared by reactive sintering[J]. International Journal of Refractory Metals and Hard Materials, 2019, 78:193-200 doi: 10.1016/j.ijrmhm.2018.09.017

|

|

[18]

|

Hong S, Wu Y P, Gao W W, et al. Slurry erosion-corrosion resistance and microbial corrosion electrochemical characteristics of HVOF sprayed WC-10Co-4Cr coating for offshore hydraulic machinery[J]. International Journal of Refractory Metals and Hard Materials, 2018, 74:7-13 doi: 10.1016/j.ijrmhm.2018.02.019

|

|

[19]

|

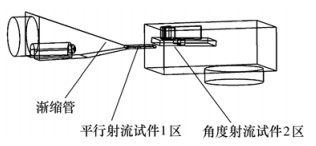

庞佑霞, 朱宗铭, 梁亮, 等.多种材料的冲蚀与空蚀交互磨损试验装置的研制及应用[J].机械科学与技术, 2012, 31(1):1-3 doi: 10.3969/j.issn.1672-1616.2012.01.001Pang Y X, Zhu Z M, Liang L, et al. Development and application on wearing experimental device of multi-material interactive erosion and cavitations[J]. Mechanical Science and Technology for Aerospace Engineering, 2012, 31(1):1-3(in Chinese) doi: 10.3969/j.issn.1672-1616.2012.01.001

|

下载:

下载: