Output Power Analysis and Dynamics Simulation of Three-cylinder Internal Combustion Air Compressor

-

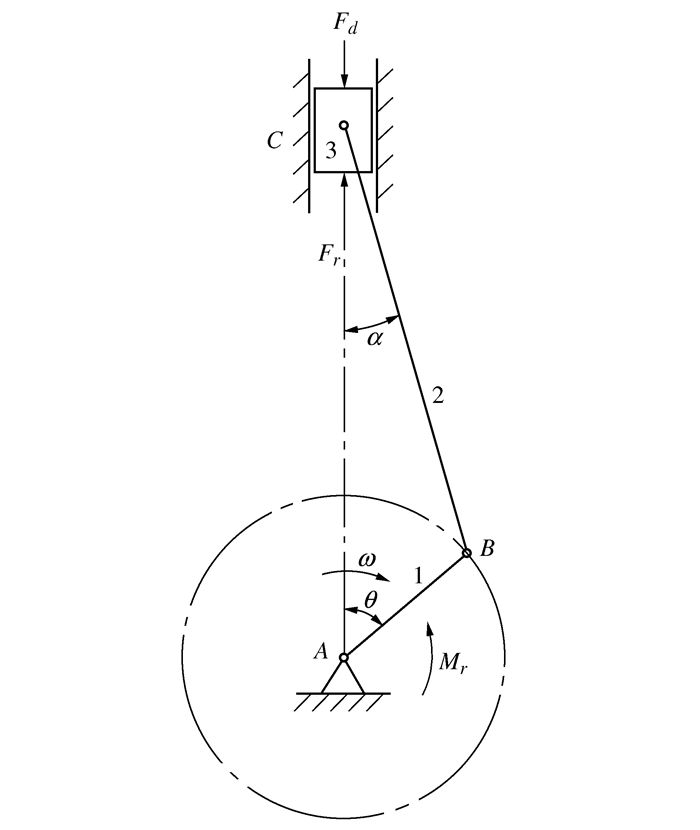

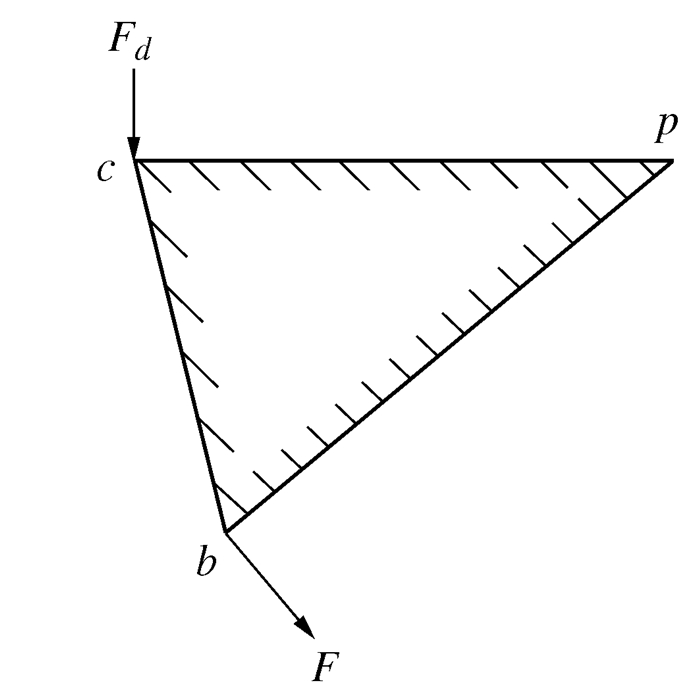

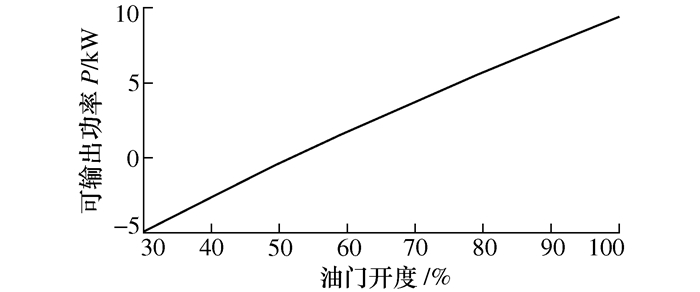

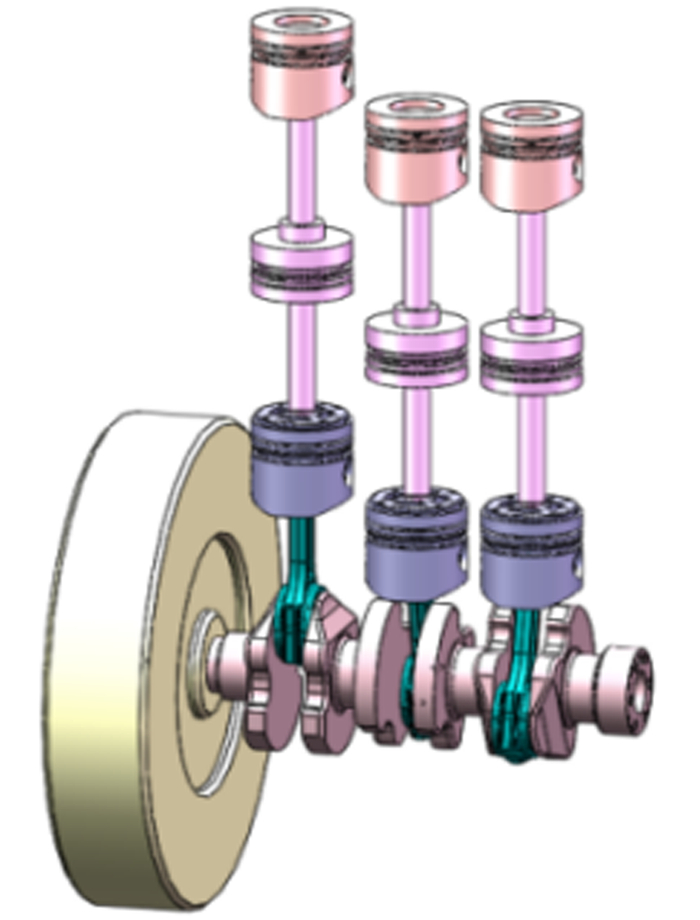

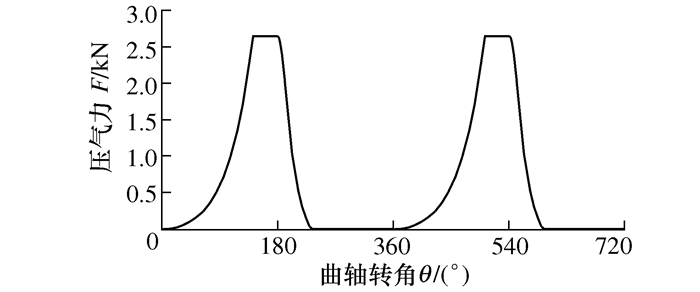

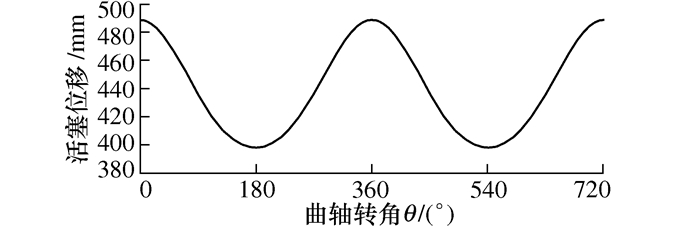

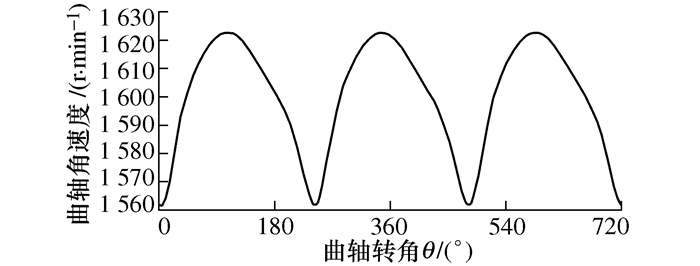

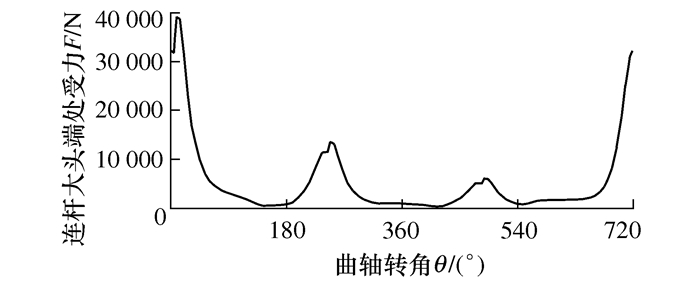

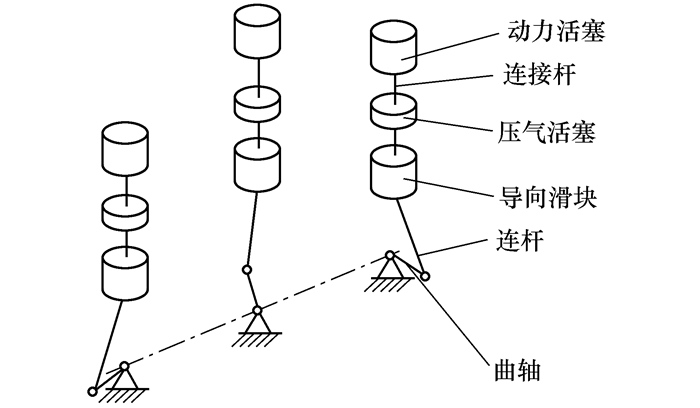

摘要: 针对传统内燃机驱动的活塞式空气压缩机工作过程中效率低的问题,设计了三缸内燃式空气压缩机原理方案,使其在输出气体压力能和驱动内燃机附属系统工作的基础上可额外提供一定的功率以带动机器外部的其他工作载荷。采用理论分析计算与仿真计算相结合的方法,研究得到了在不同油门开度和不同输出气压的工况下空气压缩机可输出功率的变化情况。基于虚拟样机技术建立了内燃式空气压缩机主体部分的动力学仿真模型,对其进行了动力学仿真分析,研究得到了特定工况下仿真模型运动特性和受力情况的数据,分析了计算结果和仿真结果的误差。Abstract: Aiming at the low efficiency in the working process of piston air compressor driven by internal combustion engine, a principle design scheme for three-cylinder internal combustion air compressor was proposed, which can output gas pressure energy and drive the auxiliary system of the internal combustion engine, but also can provide additional power to drive other working loads outside the machine. Based on the method of theoretical analysis and simulation calculation, the variation of the output power of air compressor under different throttle opening and different output air pressure was systematically studied. Based on the virtual prototype technique, the dynamic simulation model of the main part of the internal combustion air compressor was established, the dynamic simulation analysis was completed. The data of the motion characteristics and stress distribution of the simulation model under the specific working conditions were obtained, and the error of the simulation results and the calculation results was analyzed.

-

Key words:

- internal combustion engine /

- air compressor /

- dynamics simulation /

- output power

-

表 1 各工况下可输出功率PW

kW 油门开度/% 输出压力/MPa 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 30 -0.012 9 -2.418 7 -3.619 1 -4.300 0 -4.692 3 -4.913 75 -5.032 06 -5.049 33 35 1.152 4 -1.251 5 -2.453 8 -3.134 7 -3.527 0 -3.748 26 -3.866 57 -3.884 02 40 2.294 3 -0.111 5 -1.312 1 -1.992 8 -2.385 2 -2.606 51 -2.724 82 -2.742 09 45 3.412 0 1.006 3 -0.194 4 -0.875 1 -1.267 6 -1.488 83 -1.607 15 -1.624 42 50 4.496 3 2.090 5 0.890 1 0.209 2 -0.183 2 -0.404 67 -0.522 80 -0.540 08 55 5.556 8 3.151 3 1.950 6 1.269 8 0.877 6 0.656 12 0.537 81 0.520 53 60 6.598 5 4.192 9 2.992 3 2.311 4 1.919 2 1.697 71 1.579 57 1.562 12 65 7.624 4 5.218 8 4.018 2 3.337 3 2.945 0 2.723 60 2.605 46 2.588 01 70 8.630 4 6.224 8 5.024 4 4.343 5 3.951 2 3.729 76 3.778 97 3.594 18 75 9.615 8 7.210 2 6.009 4 5.328 7 4.936 4 4.714 99 4.596 85 4.579 58 80 10.589 0 8.182 5 6.981 9 6.301 2 5.908 7 5.687 30 5.569 17 5.551 89 85 11.537 1 9.132 1 7.931 4 7.250 7 6.858 4 6.636 93 6.518 80 6.501 35 90 12.465 2 10.059 6 8.858 8 8.178 1 7.785 7 7.564 23 7.446 09 7.428 64 95 13.379 8 10.972 6 9.772 9 9.092 0 8.699 7 8.478 43 8.360 12 8.342 67 100 15.947 9 11.865 5 10.666 0 9.984 9 9.592 6 9.371 17 9.252 86 9.235 59 -

[1] 徐少明, 金光熹.空气压缩机实用技术[M].北京:机械工业出版社, 1994Xu S M, Jin G X. Practical technology of air compressor[M]. Beijing: Machinery Industry Press, 1994(in Chinese) [2] 李玉辉.压缩机[M].北京:化工工业出版社, 1997:108-110Li Y H. Compressor[M]. Beijing: Chemical Industry Press, 1997:108-110(in Chinese) [3] 关利超, 郑欣, 王建宝.6kW柴油发电机组稳态与动态过程的仿真与分析[J].机械设计与制造, 2015(1):15-19 http://d.old.wanfangdata.com.cn/Periodical/jxsjyzz201501005Guan L C, Zheng X, Wang J B. Simulation and analysis of 6kW diesel generator set in steady-state and dynamic process[J]. Machinery Design & Manufacture, 2015(1):15-19(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/jxsjyzz201501005 [4] 薄少君, 牛胜涛.考虑运动副间隙的机构动态特性研究[J].现代电子技术, 2018, 41(19):155-160 http://d.old.wanfangdata.com.cn/Periodical/zdycj201111005Bo S J, Niu S T. Study on mechanism dynamic characteristic considering joint clearance[J]. Modern Electronics Technique, 2018, 41(19):155-160(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/zdycj201111005 [5] 任重, 谭秋林, 蔡婷, 等.基于MATLAB的内燃机曲柄连杆机构动力学GUI设计[J].机械传动, 2014, 38(8):92-95 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxcd201408024Ren Z, Tan Q L, Cai T, et al. Design of dynamics GUI of the internal combustion engine crank based on MATLAB[J]. Journal of Mechanical Transmission, 2014, 38(8):92-95(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jxcd201408024 [6] Zhao H Y, Xu M Q, Wang J D, et al. A parameters optimization method for planar joint clearance model and its application for dynamics simulation of reciprocating compressor[J]. Journal of Sound and Vibration, 2015, 344:416-433 doi: 10.1016/j.jsv.2015.01.044 [7] Ahn S, Choi S, Rhim Y C. Analysis of journal bearings in a scroll compressor considering deflections and dynamics of the crankshaft[J]. International Journal of Refrigeration, 2018, 93:205-212 doi: 10.1016/j.ijrefrig.2018.07.006 [8] 江志农, 马振涛, 周超, 等.含间隙的往复式压缩机变工况动力学分析研究[J].流体机械, 2018, 46(3):17-22 doi: 10.3969/j.issn.1005-0329.2018.03.004Jiang Z N, Ma Z T, Zhou C, et al. Dynamic analysis of reciprocating compressor transmission mechanism with joint clearance under variable working condition[J]. Fluid Machinery, 2018, 46(3):17-22(in Chinese) doi: 10.3969/j.issn.1005-0329.2018.03.004 [9] 孙志娟, 赵辛.往复式活塞压缩机曲轴系统运动学和动力学仿真研究[J].制造业自动化, 2014, 36(4):7-8, 19 http://d.old.wanfangdata.com.cn/Periodical/zzyzdh201407003Sun Z J, Zhao X. Research on crankshaft system kinematic and dynamic simulation of reciprocating piston compressor[J]. Manufacturing Automation, 2014, 36(4):7-8, 19(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/zzyzdh201407003 [10] 王彦伟, 朱贝, 郑英.十字滑块压缩机动力学仿真及平衡质量设计[J].机械设计与制造, 2018(S2):93-95, 99 http://d.old.wanfangdata.com.cn/Periodical/jxsjyzz2018z2025Wang Y W, Zhu B, Zheng Y. Dynamics simulation and balance mass design of quadro-flex compressors[J]. Machinery Design & Manufacture, 2018(S2):93-95, 99(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/jxsjyzz2018z2025 [11] 赵振峰, 郭顺宏, 张付军, 等.对置活塞折叠曲柄内燃机刚体动力学特性分析[J].内燃机工程, 2015, 36(6):91-97 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=nrjgc201506015Zhao Z F, Guo S H, Zhang F J, et al. Rigid-body dynamics characteristic analysis of a folded-cranktrain opposed-piston engine[J]. Chinese Internal Combustion Engine Engineering, 2015, 36(6):91-97(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=nrjgc201506015 [12] 田亚明, 张红光, 李高胜, 等.自由活塞直线发电机输出性能试验研究[J].西安交通大学学报, 2018, 52(3):119-125 http://d.old.wanfangdata.com.cn/Periodical/xajtdxxb201803016Tian Y M, Zhang H G, Li G S, et al. Experimental study on the power output performance of the free piston linear generator used for waste heat recovery[J]. Journal of Xi'an Jiaotong University, 2018, 52(3):119-125(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/xajtdxxb201803016 [13] 王庆前.内燃式水平对动空气压缩机平衡设计及多工况动力学仿真研究[D].山东青岛: 青岛大学, 2017 http://cdmd.cnki.com.cn/Article/CDMD-11065-1017723997.htmWang Q Q. Balance design and multi condition dynamics simulation study of internal combustion air compressor of horizontal moving[D]. Shandong Qingdao: Qingdao University, 2017(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-11065-1017723997.htm [14] 张圣彤, 张继忠, 赵梅, 等.内燃式水平对动空气压缩机的多工况动态特性分析[J].流体机械, 2015, 43(10):57-60, 87 http://d.old.wanfangdata.com.cn/Periodical/ltjx201510012Zhang S T, Zhang J Z, Zhao M, et al. Dynamic characteristic analysis of the internal combustion air compressor[J]. Fluid Machinery, 2015, 43(10):57-60, 87(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/ltjx201510012 [15] 商鹏飞, 张继忠, 张铁柱.内燃式压气机动力学仿真与运转平稳性分析内动仿与分[J].现代制造工程, 2007(8):55-56, 5 doi: 10.3969/j.issn.1671-3133.2007.08.018Shang P F, Zhang J Z, Zhang T Z. Dynamic simulating and working stationarity analysis of internal combustion compressor[J]. Modern Manufacturing Engineering, 2007(8):55-56, 5(in Chinese) doi: 10.3969/j.issn.1671-3133.2007.08.018 [16] 张继忠, 商鹏飞, 赵红, 等.内燃式压缩机动力学分析[J].中国机械工程, 2008, 19(20):2415-2418 doi: 10.3321/j.issn:1004-132X.2008.20.006Zhang J Z, Shang P F, Zhao H, et al. Dynamics analysis of internal combustion compressor[J]. China Mechanical Engineering, 2008, 19(20):2415-2418(in Chinese) doi: 10.3321/j.issn:1004-132X.2008.20.006 [17] 郑文纬, 吴克坚.机械原理[M].7版.北京:高等教育出版社, 1997:429-430Zheng W W, Wu K J. Mechanical principles[J]. 7th ed. Beijing: Higher Education Press, 1997:429-430(in Chinese) [18] 张小明, 魏德超, 郭晓杰.基于ADAMS的多缸内燃机曲柄连杆机构动力学仿真分析[J].机械传动, 2012, 36(12):95-97 http://www.cnki.com.cn/Article/CJFDTotal-JXCD201212025.htmZhang X M, Wei D C, Guo X J. Dynamics simulation analysis of crank connecting rod mechanism of multi-cylinder internal combustion[J]. Journal of Mechanical Transmission, 2012, 36(12):95-97(in Chinese) http://www.cnki.com.cn/Article/CJFDTotal-JXCD201212025.htm -

下载:

下载: