Finite Element Analysis of Internal Crack Propagation Induced by Contact Fatigue of Rolling Bearing

-

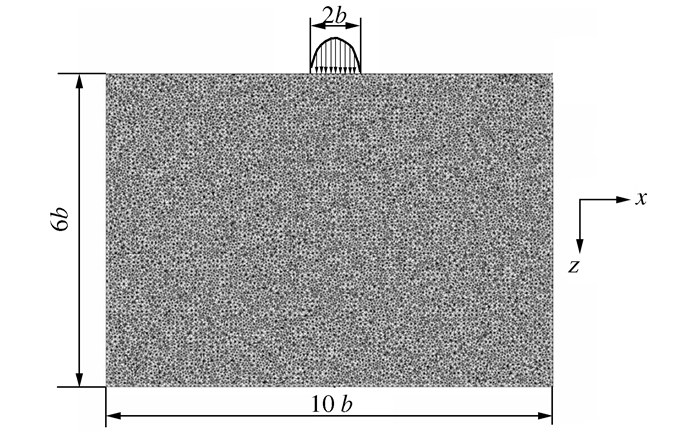

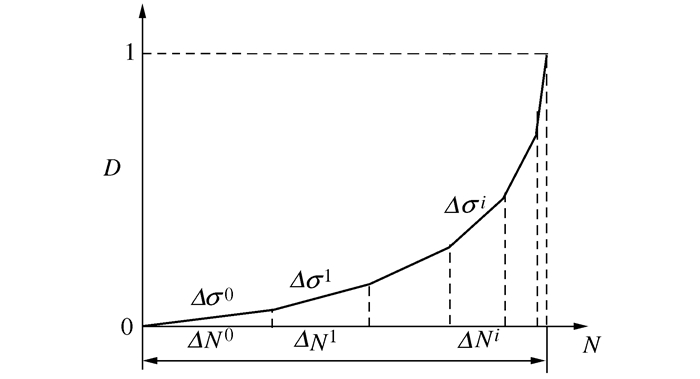

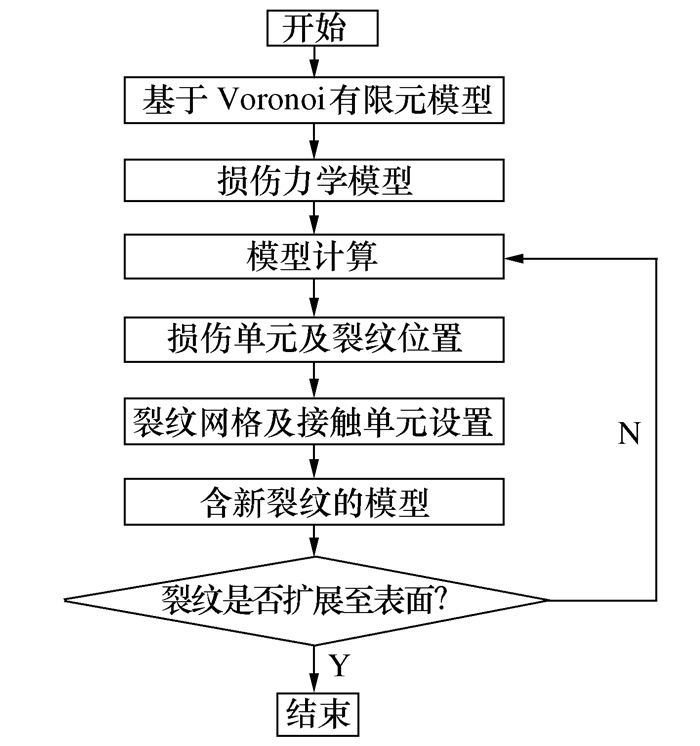

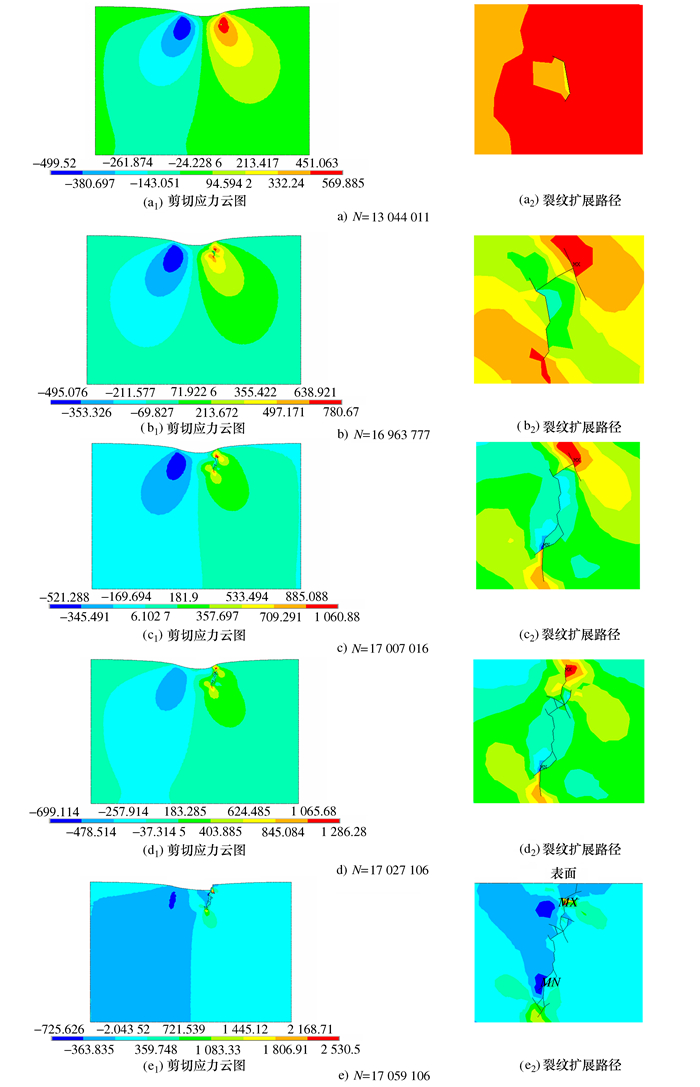

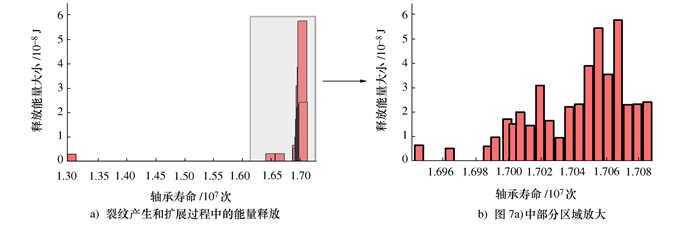

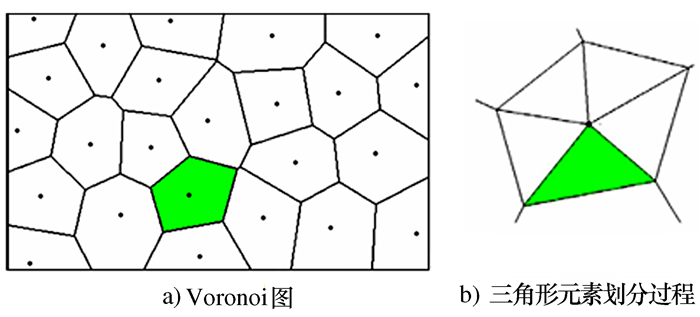

摘要: 滚动轴承滚道在工作过程中承受较大的接触应力,接触疲劳是滚动轴承失效的主要形式。为了探究轴承的接触疲劳以及接触疲劳引起的内部裂纹,将损伤力学带入Voronoi有限元方法中,仿真轴承材料拓扑随机性和材料的劣化过程。建立轴承接触疲劳裂纹扩展模型,有效仿真出轴承内部裂纹的萌生、生长、相交、扩展至表面的过程,得到轴承表面裂纹出现的寿命和内部裂纹扩展路径。计算了裂纹扩展过程中所释放的能量,研究内容能够为轴承接触疲劳损伤研究提供新的思路和工具。Abstract: The raceway of rolling bearing is subject to the large contact stress in working process, and contact fatigue is the main kind of bearing failure. In order to investigate the contact fatigue of the bearing and the internal crack induced by the contact fatigue, the present method can accurately simulate the topological randomness of bearing materials and the material fatigue damage process by combining the damage mechanics with the Voronoi finite element method. The contact fatigue crack propagation model for bearing is established, and the process of crack initiation, growth, intersection and propagation to the surface of the raceway is simulated effectively, the life of crack on bearing and the path of crack propagation are obtained. The energy released during crack propagation is calculated. The results can provide new ideas and tools for the study of contact fatigue damage of bearings.

-

Key words:

- rolling bearing /

- contact fatigue /

- crack propagation /

- damage mechanics /

- finite element method

-

表 1 轴承线接触弹性半空间模型参数

参数 数值 模型宽度 1 000 μm 模型深度 600 μm 单元平均尺寸 10 μm 赫兹接触半径b 100 μm 材料初始弹性模量E 200 GPa 泊松比μ 0.3 -

[1] Vijay A, Paulson N, Sadeghi F. A 3D finite element modelling of crystalline anisotropy in rolling contact fatigue[J]. International Journal of Fatigue, 2018, 106:92-102 doi: 10.1016/j.ijfatigue.2017.09.016 [2] Nazir M H, Khan Z A, Saeed A. Experimental analysis and modelling of c-crack propagation in silicon nitride ball bearing element under rolling contact fatigue[J]. Tribology International, 2018, 126:386-401 doi: 10.1016/j.triboint.2018.04.030 [3] Olver A V. The mechanism of rolling contact fatigue: an update[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2005, 219(5):313-330 doi: 10.1243/135065005X9808 [4] Sadeghi F, Jalalahmadi B, Slack T S, et al. A review of rolling contact fatigue[J]. Journal of Tribology, 2009, 131(4):041403 doi: 10.1115/1.3209132 [5] Konrad A, Nierlich W, Gegner J. Finite element analysis of the rolling-sliding contact of vibrationally loaded bearings based on a micro friction model[J]. Materials Science Forum, 2014, 768-769:714-722 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.4028/www.scientific.net/MSF.768-769.714 [6] 陈玉莲, 肖曙红, 陈署泉, 等.高速角接触球轴承接触疲劳寿命的有限元分析[J].机械设计与制造, 2009(9):9-11 doi: 10.3969/j.issn.1001-3997.2009.09.004Chen Y L, Xiao S H, Chen S Q, et al. Finite element analysis on the contact fatigue life of high speed angular contact ball bearings[J]. Machinery Design & Manufacture, 2009(9):9-11(in Chinese) doi: 10.3969/j.issn.1001-3997.2009.09.004 [7] Raje N, Sadeghi F, Rateick R G Jr, et al. A numerical model for life scatter in rolling element bearings[J]. Journal of Tribology, 2008, 130(1):011011 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=58e54ddf2c8e88db37818f2fb01f7c69 [8] Paulson N R, Bomidi J A R, Sadeghi F, et al. Effects of crystal elasticity on rolling contact fatigue[J]. International Journal of Fatigue, 2014, 61:67-75 doi: 10.1016/j.ijfatigue.2013.12.005 [9] Jalalahmadi B, Sadeghi F. A Voronoi finite element study of fatigue life scatter in rolling contacts[J]. Journal of Tribology, 2009, 131(2):022203 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=5c28b2f1a252f6709fc4dd6a0ec5efa0 [10] Londhe N D, Arakere N K, Subhash G. Effect of plasticity on the dynamic capacity of modern bearing steels[J]. Tribology International, 2019, 133:160-171 doi: 10.1016/j.triboint.2018.12.034 [11] Li F K, Hu W P, Meng Q C, et al. A new damage-mechanics-based model for rolling contact fatigue analysis of cylindrical roller bearing[J]. Tribology International, 2018, 120:105-114 doi: 10.1016/j.triboint.2017.12.001 [12] Jalalahmadi B, Sadeghi F, Peroulis D. A numerical fatigue damage model for life scatter of MEMS devices[J]. Journal of Microelectromechanical Systems, 2009, 18(5):1016-1031 doi: 10.1109/JMEMS.2009.2024800 [13] Sadeghi F, Jalalahmadi B, Slack T S, et al. A review of rolling contact fatigue[J]. Journal of Tribology, 2009, 131(4):041403 doi: 10.1115/1.3209132 [14] Ruellan A, Ville F, Kleber X, et al. Understanding white etching cracks in rolling element bearings: the effect of hydrogen charging on the formation mechanisms[J]. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 2014, 228(11):1252-1265 doi: 10.1177/1350650114522452 [15] Walvekar A A, Paulson N, Sadeghi F, et al. A new approach for fatigue damage modeling of subsurface-initiated spalling in large rolling contacts[J]. Journal of Tribology, 2017, 139(1):011101 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=5c28b2f1a252f6709fc4dd6a0ec5efa0 [16] Han N, Guo R. Two new Voronoi cell finite element models for fracture simulation in porous material under inner pressure[J]. Engineering Fracture Mechanics, 2019, 211:478-494 doi: 10.1016/j.engfracmech.2019.01.012 [17] Raje N, Sadeghi F, Rateick R G Jr. A statistical damage mechanics model for subsurface initiated spalling in rolling contacts[J]. Journal of Tribology, 2008, 130(4):042201 http://cn.bing.com/academic/profile?id=f767111c28474676cbcefd0eb7281a0a&encoded=0&v=paper_preview&mkt=zh-cn [18] Xiao S, Wang H L, Liu B, et al. The surface-forming energy release rate versus the local energy release rate[J]. Engineering Fracture Mechanics, 2017, 175:86-100 doi: 10.1016/j.engfracmech.2017.02.006 -

下载:

下载: