Survey on Current Research and Future Trends of Smart Manufacturing and its Key Technologies

-

摘要: 新一代信息技术、人工智能等迅猛发展及其在制造领域的融合不断促使各先进制造国家积极探索智能制造的发展战略,以实现全制造流程与全生命周期数据的互联互通、业务的协同联动及决策的动态优化,最终达到制造系统的智能化、协同化、透明化、绿色化。为更全面地理解智能制造的内涵、现状与趋势,本文详细介绍了智能制造的历史与起源、制造模式的发展与演化,分析了国内外典型智能制造战略的内涵与特点,并从中抽取了若干影响智能制造有效实施的关键使能技术。最后,结合团队在智能制造领域近年来的研究基础,分析和讨论了智能制造未来的发展趋势。Abstract: The rapid development of the latest information technology and artificial intelligence that are being integrated in the manufacturing field has prompted all advanced manufacturing countries to actively explore the development strategy of smart manufacturing. Through the plant-wide sharing of the production lifecycle data, the collaboration of business information, the dynamic optimization of decision-making processes, the manufacturing systems can eventually become smart, transparent, and green. In order to understand the connotation of smart manufacturing comprehensively, this paper presented the details about the history and origin of smart manufacturing, the development and evolution of manufacturing modes, as well as the connotation and characteristics of the typical smart manufacturing strategies. Besides, this paper extracted some key enabling technologies that have been implemented effectively, and reviewed the current research of them. Finally, by combining the research foundation on the smart manufacturing from our group, the future development trends of smart manufacturing were analyzed and discussed.

-

Key words:

- smart manufacturing /

- internet of things /

- cyber-physical system /

- big data /

- artificial intelligence

-

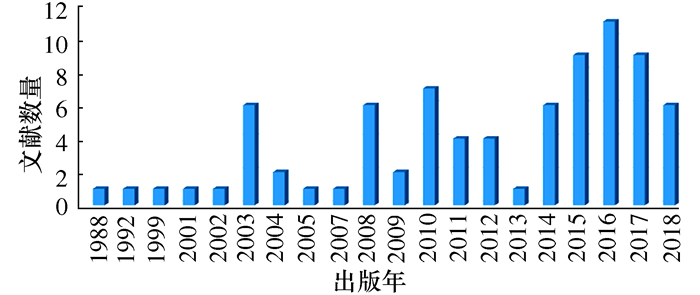

表 1 智能制造“关键词-文献源”统计数据

数据库 范围 智能制造 物联网+制造 信息物理系统+制造 大数据+制造 人工智能+制造 EI Subject/Title/Abstract 31 997 2 348 1 124 1 891 6 908 Web of Science Title 7 969 2 066 942 1 063 5 791 CNKI 主题 18 116 2 627 238 2 029 1 328 -

[1] Wright P K, Bourne D A. Manufacturing intelligence[M]. Boston:Addison-Wesley, 1988:100-102 [2] 赵东标, 朱剑英.智能制造技术与系统的发展与研究[J].中国机械工程, 1999, 10(8):927-931 doi: 10.3321/j.issn:1004-132X.1999.08.030Zhao D B, Zhu J Y. Intelligent manufacturing technology and system:a survey[J]. China Mechanical Engineering, 1999, 10(8):927-931(in Chinese) doi: 10.3321/j.issn:1004-132X.1999.08.030 [3] 杨叔子, 丁洪.智能制造技术与智能制造系统的发展与研究[J].中国机械工程, 1992, 3(2):15-18 doi: 10.3321/j.issn:1004-132X.1992.02.008Yang S Z, Ding H. Development and research of intelligent manufacturing technology and intelligent manufacturing system[J]. China Mechanical Engineering, 1992, 3(2):15-18(in Chinese) doi: 10.3321/j.issn:1004-132X.1992.02.008 [4] Evans P C, Annunziata M. Industrial internet: pushing the boundaries of minds and machines[R]. USA: General Electric Company, 2012: 1-23 [5] Kagermann H. Change through digitization-value creation in the age of industry 4.0[M]//Albach H, Meffert H, Pinkwart A, et al. Management of Permanent Change. Wiesbaden: Springer, 2015: 23-45 [6] 谭建荣.智能制造与机器人应用关键技术与发展趋势[J].机器人技术与应用, 2017(3):18-19 doi: 10.3969/j.issn.1004-6437.2017.03.007Tan J R. Key technologies and development trends in intelligent manufacturing and robotics applications[J]. Robot Technique and Application, 2017(3):18-19(in Chinese) doi: 10.3969/j.issn.1004-6437.2017.03.007 [7] Yu C Y, Xu X, Lu Y Q. Computer-integrated manufacturing, cyber-physical systems and cloud manufacturing-concepts and relationships[J]. Manufacturing Letters, 2015, 6:5-9 doi: 10.1016/j.mfglet.2015.11.005 [8] Offodile O F, Abdel-Malek L L. The virtual manufacturing paradigm:the impact of IT/IS outsourcing on manufacturing strategy[J]. International Journal of Production Economics, 2002, 75(1-2):147-159 doi: 10.1016/S0925-5273(01)00188-8 [9] Sanchez L M, Nagi R. A review of agile manufacturing systems[J]. International Journal of Production Research, 2001, 39(16):3561-3600 doi: 10.1080/00207540110068790 [10] 刘飞, 雷琦, 宋豫川.网络化制造的内涵及研究发展趋势[J].机械工程学报, 2003, 39(8):1-6 doi: 10.3321/j.issn:0577-6686.2003.08.001Liu F, Lei Q, Song Y C. Connotation, state-of-the-art and research tendency of networked manufacturing[J]. Chinese Journal of Mechanical Engineering, 2003, 39(8):1-6(in Chinese) doi: 10.3321/j.issn:0577-6686.2003.08.001 [11] Kara S, Manmek S, Herrmann C. Global manufacturing and the embodied energy of products[J]. CIRP Annals, 2010, 59(1):29-32 doi: 10.1016/j.cirp.2010.03.004 [12] 丁汉.机器人与智能制造技术的发展思考[J].机器人技术与应用, 2016(4):7-10 doi: 10.3969/j.issn.1004-6437.2016.04.001Ding H. Thoughts on the development of robots and intelligent manufacturing technology[J]. Robot Technique and Application, 2016(4):7-10(in Chinese) doi: 10.3969/j.issn.1004-6437.2016.04.001 [13] 张映锋, 赵曦滨, 孙树栋, 等.一种基于物联技术的制造执行系统实现方法与关键技术[J].计算机集成制造系统, 2012, 18(12):2634-2642 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201206136478Zhang Y F, Zhao X B, Sun S D, et al. Implementing method and key technologies for IoT-based manufacturing execution system[J]. Computer Integrated Manufacturing Systems, 2012, 18(12):2634-2642(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201206136478 [14] 侯瑞春, 丁香乾, 陶冶, 等.制造物联及相关技术架构研究[J].计算机集成制造系统, 2014, 20(1):11-20 http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201401002Hou R C, Ding X Q, Tao Y, et al. Internet of manufacturing things and relevant technical architecture[J]. Computer Integrated Manufacturing Systems, 2014, 20(1):11-20(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201401002 [15] Siderska J, Jadaan K S. Cloud manufacturing:a service-oriented manufacturing paradigm. A review paper[J]. Engineering Management in Production and Services, 2018, 10(1):22-31 http://cn.bing.com/academic/profile?id=9592add4eb0a6d7a8a6b9da466fd582b&encoded=0&v=paper_preview&mkt=zh-cn [16] 李伯虎, 张霖, 王时龙, 等.云制造——面向服务的网络化制造新模式[J].计算机集成制造系统, 2010, 16(1):1-7 http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201001001tLi B H, Zhang L, Wang S L, et al. Cloud manufacturing:a new service-oriented networked manufacturing model[J]. Computer Integrated Manufacturing Systems, 2010, 16(1):1-7(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201001001t [17] Gao N, Zhao S Z, Zhang X D. Research on the service-oriented manufacturing model[C]//Proceedings of 2009 IEEE International Conference on Industrial Engineering and Engineering Management. Hong Kong, China: IEEE, 2009 [18] Jie G, Yao Y L, Zhu V C Y, et al. Service-oriented manufacturing:a new product pattern and manufacturing paradigm[J]. Journal of Intelligent Manufacturing, 2011, 22(3):435-446 doi: 10.1007/s10845-009-0301-y [19] Fujimoto J, Umeda Y, Tamura T, et al. Development of service-oriented products based on the inverse manufacturing concept[J]. Environmental Science & Technology, 2003, 37(23):5398-5406 http://cn.bing.com/academic/profile?id=d160d7b94e28bd91b1f305fc21f06bf6&encoded=0&v=paper_preview&mkt=zh-cn [20] 陶飞, 戚庆林.面向服务的智能制造[J].机械工程学报, 2018, 54(16):11-23 http://d.old.wanfangdata.com.cn/Periodical/wxjyyy201709001Tao F, Qi Q L. Service-oriented smart manufacturing[J]. Journal of Mechanical Engineering, 2018, 54(16):11-23(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/wxjyyy201709001 [21] 孙家广.对我国制造业信息化的思考[J].中国制造业信息化, 2010, 39(10):10-12 doi: 10.3969/j.issn.1672-1616.2010.10.003Sun J G. Thoughts on the informatization of China's manufacturing industry[J]. Manufacturing Information Engineering of China, 2010, 39(10):10-12(in Chinese) doi: 10.3969/j.issn.1672-1616.2010.10.003 [22] Tao F, Cheng J F, Qi Q L. ⅡHub:an industrial internet-of-things hub toward smart manufacturing based on cyber-physical system[J]. IEEE Transactions on Industrial Informatics, 2018, 14(5):2271-2280 doi: 10.1109/TII.2017.2759178 [23] Tao F, Cheng Y, Zhang L, et al. Advanced manufacturing systems:socialization characteristics and trends[J]. Journal of Intelligent Manufacturing, 2017, 28(5):1079-1094 doi: 10.1007/s10845-015-1042-8 [24] Tao F, Zhang L, Nee A Y C. A review of the application of grid technology in manufacturing[J]. International Journal of Production Research, 2011, 49(13):4119-4155 doi: 10.1080/00207541003801234 [25] Tao F, Hu Y F, Zhao D M, et al. Study of failure detection and recovery in manufacturing grid resource service scheduling[J]. International Journal of Production Research, 2010, 48(1):69-94 doi: 10.1080/00207540802275871 [26] Fan Y S, Zhao D Z, Zhang L Q, et al. Manufacturing grid: needs, concept, and architecture[M]//Li M L, Sun X H, Deng Q N, et al. Grid and Cooperative Computing. Berlin, Heidelberg: Springer, 2004: 653-656 [27] 陈伟兴, 李少波, 黄海松.离散型制造物联过程数据主动感知及管理模型[J].计算机集成制造系统, 2016, 22(1):166-176 http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201601016Chen W X, Li S B, Huang H S. Active perception and management model for manufacturing data in discreteIoMT-based process[J]. Computer Integrated Manufacturing Systems, 2016, 22(1):166-176(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201601016 [28] Zhang Y F, Wang J Q, Sun S D. Real-time information capturing and integration framework of the internet of manufacturing things[J]. Applied Mechanics and Materials, 2012, 121-126:4059-4063 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.4028/www.scientific.net/AMM.121-126.4059 [29] 柴天佑, 丁进良, 徐泉, 等.基于物联网的选矿制造执行系统技术[J].物联网学报, 2018, 2(1):1-16 http://www.cnki.com.cn/Article/CJFDTOTAL-WLWX201801001.htmChai T Y, Ding J L, Xu Q, et al. Manufacturing execution system of mineral processing based on internet of things[J]. Chinese Journal on Internet of Things, 2018, 2(1):1-16(in Chinese) http://www.cnki.com.cn/Article/CJFDTOTAL-WLWX201801001.htm [30] Kiritsis D, Bufardi A, Xirouchakis P. Research issues on product lifecycle management and information tracking using smart embedded systems[J]. Advanced Engineering Informatics, 2003, 17(3-4):189-202 doi: 10.1016/S1474-0346(04)00018-7 [31] Makris S, Michalos G, Chryssolouris G. RFID driven robotic assembly for random mix manufacturing[J]. Robotics and Computer-Integrated Manufacturing, 2012, 28(3):359-365 doi: 10.1016/j.rcim.2011.10.007 [32] Ratava J, Lohtander M, Varis J. Tool condition monitoring in interrupted cutting with acceleration sensors[J]. Robotics and Computer-Integrated Manufacturing, 2017, 47:70-75 doi: 10.1016/j.rcim.2016.11.008 [33] Huang S H, Guo Y, Zha S S, et al. A real-time location system based on RFID and UWB for digital manufacturing workshop[J]. Procedia CIRP, 2017, 63:132-137 doi: 10.1016/j.procir.2017.03.085 [34] Lu K Y. A plug-and-play data gathering system using ZigBee-based sensor network sensor network[J]. Computers in Industry, 2011, 62(7):719-728 doi: 10.1016/j.compind.2011.05.002 [35] Lee E A. Cyber physical systems: design challenges[C]//Proceedings of the 200811th IEEE International Symposium on Object and Component-Oriented Real-Time Distributed Computing. Orlando, FL, USA: IEEE, 2008 [36] Lee J, Lapira E, Bagheri B, et al. Recent advances and trends in predictive manufacturing systems in big data environment[J]. Manufacturing Letters, 2013, 1(1):38-41 doi: 10.1016/j.mfglet.2013.09.005 [37] Leitao P, Barbosa J, Papadopoulou M E C, et al. Standardization in cyber-physical systems: the ARUM case[C]//Proceedings of 2015 IEEE International Conference on Industrial Technology. Seville, Spain: IEEE, 2015: 2988-2993 [38] Karnouskos S, Colombo A W, Bangemann T. Trends and challenges for cloud-based industrial cyber-physical systems[M]//Colombo A W, Bangemann T, Karnouskos S, et al. Industrial Cloud-Based Cyber-Physical Systems. Cham: Springer, 2014: 231-240 [39] Monostori L. Cyber-physical production systems:roots, expectations and R&D challenges[J]. Procedia CIRP, 2014, 17:9-13 doi: 10.1016/j.procir.2014.03.115 [40] Zhang Y F, Qian C, Lv J X, et al. Agent and cyber-physical system based self-organizing and self-adaptive intelligent shopfloor[J]. IEEE Transactions on Industrial Informatics, 2017, 13(2):737-747 doi: 10.1109/TII.2016.2618892 [41] Dai W B, Dubinin V N, Christensen J H, et al. Toward self-manageable and adaptive industrial cyber-physical systems with knowledge-driven autonomic service management[J]. IEEE Transactions on Industrial Informatics, 2017, 13(2):725-736 doi: 10.1109/TII.2016.2595401 [42] Kang W, Kapitanova K, Son S H. RDDS:a real-time data distribution service for cyber-physical systems[J]. IEEE Transactions on Industrial Informatics, 2012, 8(2):393-405 doi: 10.1109/TII.2012.2183878 [43] Bhuiyan M Z A, Wu J, Wang G J, et al. Sensing and decision making in cyber-physical systems:the case of structural event monitoring[J]. IEEE Transactions on Industrial Informatics, 2016, 12(6):2103-2114 doi: 10.1109/TII.2016.2518642 [44] Tao F, Cheng J F, Qi Q L, et al. Digital twin-driven product design, manufacturing and service with big data[J]. The International Journal of Advanced Manufacturing Technology, 2018, 94(9-12):3563-3576 doi: 10.1007/s00170-017-0233-1 [45] Liu W N, Su J M. A solution of dynamic manufacturing resource aggregation in CPS[C]//Proceedings of the 20116th IEEE Joint International Information Technology and Artificial Intelligence Conference. Chongqing, China: IEEE, 2011 [46] 孙家广.工业大数据[J].软件和集成电路, 2016(8):22-23 http://d.old.wanfangdata.com.cn/Periodical/xxydn201720053Sun J G. Industrial big data[J]. Software and Integrated Circuit, 2016(8):22-23(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/xxydn201720053 [47] 王建民.工业大数据技术[J].电信网技术, 2016(8):1-5 http://d.old.wanfangdata.com.cn/Periodical/ahnykx201634077Wang J M. Industrial big data technologies[J]. Telecommunications Network Technology, 2016(8):1-5(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/ahnykx201634077 [48] Li J R, Tao F, Cheng Y, et al. Big data in product lifecycle management[J]. The International Journal of Advanced Manufacturing Technology, 2015, 81(1-4):667-684 doi: 10.1007/s00170-015-7151-x [49] Zhang Z F, Cheng H, Chu X N. Aided analysis for quality function deployment with an Apriori-based data mining approach[J]. International Journal of Computer Integrated Manufacturing, 2010, 23(7):673-686 doi: 10.1080/0951192X.2010.492840 [50] Geng X L, Chu X N, Zhang Z F. A new integrated design concept evaluation approach based on vague sets[J]. Expert Systems with Applications, 2010, 37(9):6629-6638 doi: 10.1016/j.eswa.2010.03.058 [51] Ma J, Kwak M, Kim H M. Demand trend mining for predictive life cycle design[J]. Journal of Cleaner Production, 2014, 68:189-199 doi: 10.1016/j.jclepro.2014.01.026 [52] 谭建荣, 齐峰, 张树有, 等.基于模糊客户需求信息的设计检索技术的研究[J].机械工程学报, 2005, 41(4):79-84 doi: 10.3321/j.issn:0577-6686.2005.04.016Tan J R, Qi F, Zhang S Y, et al. Research on technology of de-sign retrieval based on fuzzy customer requirement[J]. Chinese Journal of Mechanical Engineering, 2005, 41(4):79-84(in Chinese) doi: 10.3321/j.issn:0577-6686.2005.04.016 [53] Magro M C, Pinceti P. A confirmation technique for predictive maintenance using the Rough Set Theory[J]. Computers & Industrial Engineering, 2009, 56(4):1319-1327 doi: 10.1016-j.cie.2008.07.024/ [54] 查海平, 王建民, 孙家广.一种基于滑窗的增量式过程挖掘算法[J].计算机集成制造系统, 2008, 14(1):203-208 http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt200801033Zha H P, Wang J M, Sun J G. Incremental algorithm for process mining based on sliding window[J]. Computer Integrated Manufacturing Systems, 2008, 14(1):203-208(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt200801033 [55] Purarjomandlangrudi A, Ghapanchi A H, Esmalifalak M. A data mining approach for fault diagnosis:an application of anomaly detection algorithm[J]. Measurement, 2014, 55:343-352 doi: 10.1016/j.measurement.2014.05.029 [56] Opresnik D, Taisch M. The value of big data in servitization[J]. International Journal of Production Economics, 2015, 165:174-184 doi: 10.1016/j.ijpe.2014.12.036 [57] Zhang Y F, Ren S, Liu Y, et al. A big data analytics architecture for cleaner manufacturing and maintenance processes of complex products[J]. Journal of Cleaner Production, 2017, 142:626-641 doi: 10.1016/j.jclepro.2016.07.123 [58] 柴天佑, 丁进良, 王宏, 等.复杂工业过程运行的混合智能优化控制方法[J].自动化学报, 2008, 34(5):505-515 http://d.old.wanfangdata.com.cn/Periodical/zdhxb200805001Chai T Y, Ding J L, Wang H, et al. Hybrid intelligent optimal control method for operation of complex industrial processes[J]. Acta Automatica Sinica, 2008, 34(5):505-515(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/zdhxb200805001 [59] Zhao R, Liu Y Y, Zhang N, et al. An optimization model for green supply chain management by using a big data analytic approach[J]. Journal of Cleaner Production, 2017, 142:1085-1097 doi: 10.1016/j.jclepro.2016.03.006 [60] 李雪飞, 周恩德, 杜小艳.基于大数据的我国再生资源回收体系优化研究[J].再生资源与循环经济, 2016, 9(6):11-14 doi: 10.3969/j.issn.1674-0912.2016.06.005Li X F, Zhou E D, Du X Y. Research on the optimization of renewable resources recovery system based on big data[J]. Recycling Research, 2016, 9(6):11-14(in Chinese) doi: 10.3969/j.issn.1674-0912.2016.06.005 [61] Vieira G E, Herrmann J W, Lin E. Rescheduling manufacturing systems:a framework of strategies, policies, and methods[J]. Journal of Scheduling, 2003, 6(1):39-62 doi: 10.1023/A:1022235519958 [62] Shen X N, Yao X. Mathematical modeling and multi-objective evolutionary algorithms applied to dynamic flexible job shop scheduling problems[J]. Information Sciences, 2015, 298:198-224 doi: 10.1016/j.ins.2014.11.036 [63] Yao S Q, Jiang Z B, Li N, et al. A multi-objective dynamic scheduling approach using multiple attribute decision making in semiconductor manufacturing[J]. International Journal of Production Economics, 2011, 130(1):125-133 doi: 10.1016/j.ijpe.2010.12.014 [64] 朱宝琳, 于海斌.炼钢-连铸-热轧生产调度模型及算法研究[J].计算机集成制造系统, 2003, 9(1):33-36 doi: 10.3969/j.issn.1006-5911.2003.01.007Zhu B L, Yu H B. Production scheduling model and algorithm for steelmaking-continuous casting-hot rolling processes[J]. Computer Integrated Manufacturing Systems, 2003, 9(1):33-36(in Chinese) doi: 10.3969/j.issn.1006-5911.2003.01.007 [65] Valckenaers P, van Brussel H, Holvoet T. Fundamentals of holonic systems and their implications for self-adaptive and self-organizing systems[C]//Proceedings of the 20082nd IEEE International Conference on Self-Adaptive and Self-Organizing Systems Workshops. Venice, Italy: IEEE, 2008 [66] Monostori L, Valckenaers P, Dolgui A, et al. Cooperative control in production and logistics[J]. Annual Reviews in Control, 2015, 39:12-29 doi: 10.1016/j.arcontrol.2015.03.001 [67] 李伯虎, 柴旭东, 朱文海, 等.复杂产品协同制造支撑环境技术的研究[J].计算机集成制造系统, 2003, 9(8):691-697 doi: 10.3969/j.issn.1006-5911.2003.08.016Li B H, Chai X D, Zhu W H, et al. Supporting environment technology for collaborative manufacturing of complex product[J]. Computer Integrated Manufacturing Systems, 2003, 9(8):691-697(in Chinese) doi: 10.3969/j.issn.1006-5911.2003.08.016 [68] 张翠华, 范岩, 于海斌, 等.分散决策供应链生产计划协同研究[J].计算机集成制造系统, 2008, 14(8):1622-1629 http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt200808024Zhang C H, Fan Y, Yu H B, et al. Collaborative production planning in distributed decision-making supply chain[J]. Computer Integrated Manufacturing Systems, 2008, 14(8):1622-1629(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt200808024 [69] Ren R X, Hung T, Tan K C. A generic deep-learning-based approach for automated surface inspection[J]. IEEE Transactions on Cybernetics, 2018, 48(3):929-940 doi: 10.1109/TCYB.2017.2668395 [70] Park J K, Kwon B K, Park J H, et al. Machine learning-based imaging system for surface defect inspection[J]. International Journal of Precision Engineering and Manufacturing-Green Technology, 2016, 3(3):303-310 doi: 10.1007/s40684-016-0039-x [71] Yang Z X, Wang X B, Zhong J H. Representational learning for fault diagnosis of wind turbine equipment:a multi-layered extreme learning machines approach[J]. Energies, 2016, 9(6):379 doi: 10.3390/en9060379 [72] 周佳军, 姚锡凡, 刘敏, 等.几种新兴智能制造模式研究评述[J].计算机集成制造系统, 2017, 23(3):624-639 http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201703020Zhou J J, Yao X F, Liu M, et al. State-of-Art review on new emerging intelligent manufacturing paradigms[J]. Computer Integrated Manufacturing Systems, 2017, 23(3):624-639(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201703020 [73] 姚锡凡, 练肇通, 杨屹, 等.智慧制造——面向未来互联网的人机物协同制造新模式[J].计算机集成制造系统, 2014, 20(6):1490-1498 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jsjjczzxt201406027Yao X F, Lian Z T, Yang Y, et al. Wisdom manufacturing:new humans-computers-things collaborative manufacturing model[J]. Computer Integrated Manufacturing Systems, 2014, 20(6):1490-1498(in Chinese) http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jsjjczzxt201406027 [74] Lee J, Bagheri B, Kao H A. A cyber-physical systems architecture for industry 4.0-based manufacturing systems[J]. Manufacturing Letters, 2015, 3:18-23 doi: 10.1016/j.mfglet.2014.12.001 [75] 庄存波, 刘检华, 熊辉, 等.产品数字孪生体的内涵、体系结构及其发展趋势[J].计算机集成制造系统, 2017, 23(4):753-768 http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201704010Zhuang C B, Liu J H, Xiong H, et al. Connotation, architecture and trends of product digital twin[J]. Computer Integrated Manufacturing Systems, 2017, 23(4):753-768(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/jsjjczzxt201704010 [76] 臧传真, 范玉顺.基于智能物件的实时企业复杂事件处理机制[J].机械工程学报, 2007, 43(2):22-32 doi: 10.3321/j.issn:0577-6686.2007.02.003Zang C Z, Fan Y S. Complex event processing of real time enterprises based on smart items[J]. Chinese Journal of Mechanical Engineering, 2007, 43(2):22-32(in Chinese) doi: 10.3321/j.issn:0577-6686.2007.02.003 [77] 江志斌.Petri网及其在制造系统建模与控制中的应用[M].北京:机械工业出版社, 2004:228Jiang Z B. Petri net and its application in modeling and control of manufacturing systems[M]. Beijing:China Machine Press, 2004:228(in Chinese) [78] Qi Q L, Tao F. Digital twin and big data towards smart manufacturing and industry 4.0:360 degree comparison[J]. IEEE Access, 2018, 6:3585-3593 doi: 10.1109/ACCESS.2018.2793265 [79] Zou X F, Tao F, Jiang P L, et al. A new approach for data processing in supply chain network based on FPGA[J]. The International Journal of Advanced Manufacturing Technology, 2016, 84(1-4):249-260 doi: 10.1007/s00170-015-7803-x -

下载:

下载: