Dynamic Feature Learning and Assembly Tightness Intelligent Monitoring of Bolted Joint Structure

-

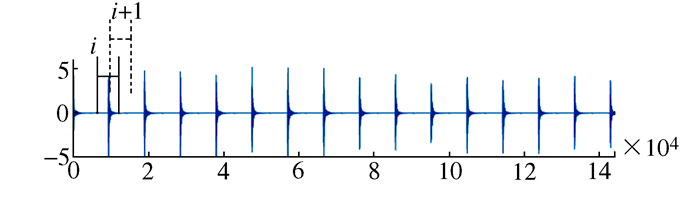

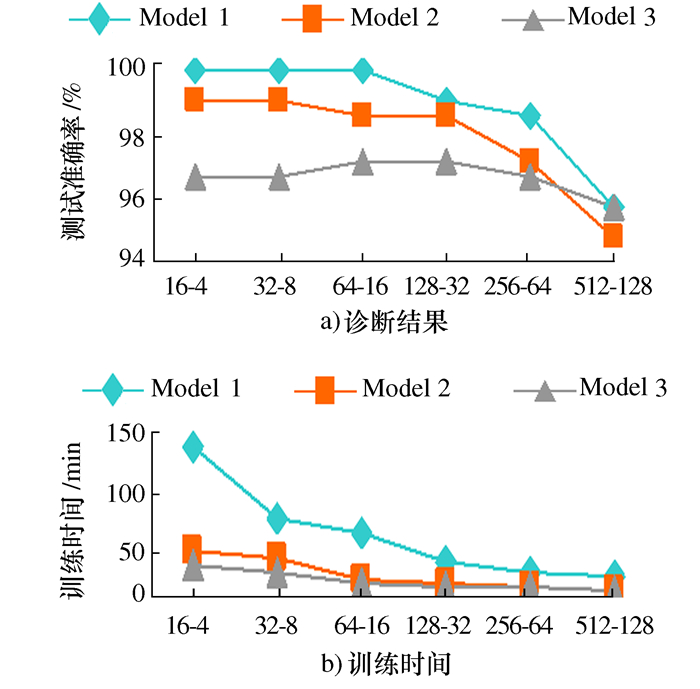

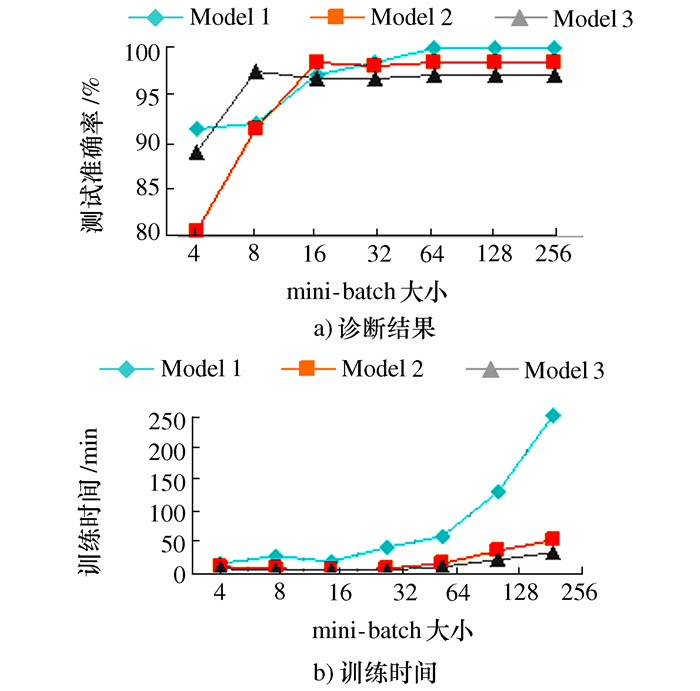

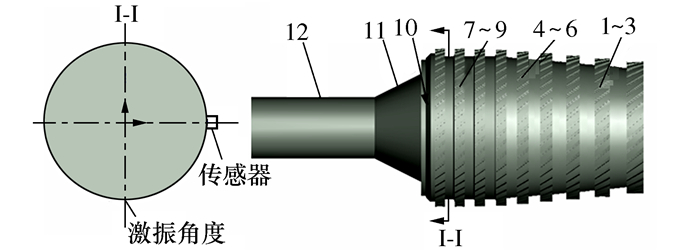

摘要: 自动特征提取在机械系统智能状态监测中起着至关重要的作用,可以自适应地从原始数据中学习特征并发现新的状态敏感特征。本文重点研究了不同深度的卷积神经网络(CNN)模型在没有先验知识的情况下从激励响应信号中挖掘代表信息和敏感特征的能力,并将螺栓连接结构的特征提取和装配紧度分类过程融合在一起。通过车架试验台螺栓连接转子激振实验数据验证该方法的有效性。结果表明,CNN方法自适应学习的特征可以表示信号与装配状态之间的复杂映射关系,并且比其他方法具有更高的准确率。Abstract: Automatic feature extraction plays a crucial role in the intelligent state monitoring of mechanical systems, which can adaptively learn features from raw data and discover new state-sensitive features. This research focuses on the ability of different depth convolution neural network (CNN) models to mine representative information and sensitive features from the excitation response signal without prior knowledge, and combine the feature extraction with assembly tightness classification process of the bolted structure. The effectiveness of the method is verified by excitation test data of car frame test bench bolt connection rotor. The results show that the feature learned adaptively by CNN can represent the complex mapping relationship between response signal and assembly state, and has higher accuracy than other methods.

-

Key words:

- bolt /

- monitoring /

- convolution neural network /

- features extraction

-

表 1 模型结构示意表

网络层 卷积核 输出大小

(宽度×深度)大小/步长 数目 卷积1 64×1/16×1 16 256×16 最大池化1 2×1/2×1 16 128×16 卷积2 3×1/1×1 32 128×32 最大池化2 2×1/2×1 32 64×32 卷积3 3×1/1×1 64 64×64 卷积4 3×1/1×1 64 64×64 最大池化3 2×1/2×1 64 32×64 卷积5 3×1/1×1 128 32×128 卷积6 3×1/1×1 128 32×128 最大池化4 2×1/2×1 128 16×128 卷积7 3×1/1×1 256 16×256 卷积8 3×1/1×1 256 16×256 最大池化5 2×1/2×1 256 8×256 全连接层1 2 048 1 2 048×1 全连接层2 1 024 1 1 024×1 Softmax 6 1 6 表 2 螺栓连接状态分类

螺栓连接状态 拧紧力矩 训练集/测试集数量 状态标签 正常装配 M1 6 600/35 1 个别螺栓松动 M2 6 600/35 2 局部螺栓松动 M3 6 600/35 3 整体轻微松动 M4 6 600/35 4 整体中度松动 M5 6 600/35 5 整体严重松动 M6 6 600/35 6 表 3 不同规模CNN模型参数

模型名称 模型参数 Model 1 16, 32, 64, 64, 128, 128, 256, 256-2048-1024 Model 2 16, 32, 64, 64, 64-100 Model 3 16, 32-100 表 4 不同方法的螺栓装配紧度评估准确率

方法 样本类型 样本数

(训练/测试)诊断

准确率SVM+随机特征量 时域特征 396/60 85% SVM+精选特征量 时频特征 396/60 90% 深层去噪自编码器方法 时域信号 39 600/210 94.285 7% CNN方法 时域信号 39 600/210 100% -

[1] 徐超, 周帮友, 刘信恩, 等.机械螺栓连接状态监测和辨识方法研究进展[J].强度与环境, 2009, 36(2):28-36 doi: 10.3969/j.issn.1006-3919.2009.02.004Xu C, Zhou B Y, Liu X E, et al. A review of vibration-based condition monitoring and indentification for mechanical bolted joints[J]. Structure & Environment Engineering, 2009, 36(2):28-36(in Chinese) doi: 10.3969/j.issn.1006-3919.2009.02.004 [2] 叶亮, 张有忱, 丁克勤, 等.基于压电阻抗法的机械螺栓组松动监测及识别[J].科学技术与工程, 2013, 13(18):5172-5176 doi: 10.3969/j.issn.1671-1815.2013.18.017Ye L, Zhang Y C, Ding K Q, et al. Monitoring and localization of loosened bolts based on e/m impedance method[J]. Science Technology and Engineering, 2013, 13(18):5172-5176(in Chinese) doi: 10.3969/j.issn.1671-1815.2013.18.017 [3] 杨志武.基于压电阻抗技术的螺栓松动监测的研究[D].武汉: 武汉科技大学, 2015 http://cdmd.cnki.com.cn/Article/CDMD-10488-1015582426.htmYang Z W. Research for bolt looseness monitoring based on the piezoelectric impedance technology[D]. Wuhan: Wuhan University of Science and Technology, 2015(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10488-1015582426.htm [4] Jing L Y, Zhao M, Li P, et al. A convolutional neural network based feature learning and fault diagnosis method for the condition monitoring of gearbox[J]. Measurement, 2017, 111:1-10 doi: 10.1016/j.measurement.2017.07.017 [5] Lei Y G, Jia F, Lin J, et al. An intelligent fault diagnosis method using unsupervised feature learning towards mechanical big data[J]. IEEE Transactions on Industrial Electronics, 2016, 63(5):3137-3147 doi: 10.1109/TIE.2016.2519325 [6] 余坚, 谢寿生, 任立通, 等.拉杆转子装配振动检测分形研究[J].振动与冲击, 2014, 33(14):84-88 http://d.old.wanfangdata.com.cn/Periodical/zdycj201414016Yu J, Xie S S, Ren L T, et al. Fractal research on the assembly vibration detection of rod fastening rotor[J]. Journal of Vibration and Shock, 2014, 33(14):84-88(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/zdycj201414016 [7] 叶亮.基于压电阻抗方法的结构健康监测与损伤识别研究[D].北京: 北京化工大学, 2013Ye L. Structural health monitoring and damage localization based on EMI technology[D]. Beijing: Beijing University of Chemical Technology, 2013(in Chinese) [8] Shao H D, Jiang H K, Zhang H Z, et al. Electric locomotive bearing fault diagnosis using a novel convolutional deep belief network[J]. IEEE Transactions on Industrial Electronics, 2018, 65(3):2727-2736 doi: 10.1109/TIE.2017.2745473 [9] 黄文坚, 唐源.TensorFlow实战[M].北京:电子工业出版社, 2017:2Huang W J, Tang Y. TensorFlow combat[M]. Beijing:Electronic Industry Press, 2017:2(in Chinese) [10] Ince T, Kiranyaz S, Eren L, et al. Real-time motor fault detection by 1-D convolutional neural networks[J]. IEEE Transactions on Industrial Electronics, 2016, 63(11):7067-7075 doi: 10.1109/TIE.2016.2582729 [11] Guo X J, Chen L, Shen C Q. Hierarchical adaptive deep convolution neural network and its application to bearing fault diagnosis[J]. Measurement, 2016, 93:490-502 doi: 10.1016/j.measurement.2016.07.054 [12] Zhang W, Li C H, Peng G L, et al. A deep convolutional neural network with new training methods for bearing fault diagnosis under noisy environment and different working load[J]. Mechanical Systems and Signal Processing, 2018, 100:439-453 doi: 10.1016/j.ymssp.2017.06.022 [13] Pan J, Zi Y Y, Chen J L, et al. LiftingNet:a novel deep learning network with layerwise feature learning from noisy mechanical data for fault classification[J]. IEEE Transactions on Industrial Electronics, 2018, 65(6):4973-4982 doi: 10.1109/TIE.2017.2767540 [14] Chen Z Q, Li C, Sanchez R V. Gearbox fault identification and classification with convolutional neural networks[J]. Shock and Vibration, 2015(2):1-10 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=Doaj000004007466 [15] Liao Y X, Zeng X Q, Li W H. Wavelet transform based convolutional neural network for gearbox fault classification[C]//Proceedings of 2017 Prognostics and System Health Management Conference. Harbin, China: IEEE, 2017: 1-6 [16] 张伟.基于卷积神经网络的轴承故障诊断算法研究[D].哈尔滨: 哈尔滨工业大学, 2017 http://cdmd.cnki.com.cn/Article/CDMD-10213-1017864225.htmZhang W. Study on bearing fault diagnosis algorithm based on convolutional neural network[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese) http://cdmd.cnki.com.cn/Article/CDMD-10213-1017864225.htm [17] 张小丽, 王保建, 陈雪峰, 等.航空发动机可拆卸盘鼓型转子拉杆螺栓装配紧度辨识方法[J].航空动力学报, 2015, 30(8):1967-1974 http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201508021Zhang X L, Wang B J, Chen X F, et al. Stay bolt assembly tightness identification method for dismountable disk-and-drum rotor of aero-engine[J]. Journal of Aerospace Power, 2015, 30(8):1967-1974(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/hkdlxb201508021 [18] 张子阳.基于复杂接触面的航空发动机拉杆转子装配动力特性研究[D].西安: 空军工程大学, 2012Zhang Z Y. Research on dynamic characteristics of aero-engine rod rotor assembly based on complex contact surfaces[D]. Xi'an: Air Force Engineering University, 2012(in Chinese) [19] 王名月, 缪炳荣, 李旭娟, 等.基于局部均值分解的螺栓连接振动松动研究[J].工程机械, 2017, 48(5):34-40 http://d.old.wanfangdata.com.cn/Periodical/gcjx201705008Wang M Y, Miao B R, Li X J, et al. Study on vibration loosening of bolted joints based on local mean decomposition[J]. Construction Machinery and Equipment, 2017, 48(5):34-40(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/gcjx201705008 [20] Goodfellow I, Bengio Y, Courville A.深度学习[M].赵申剑, 译.北京: 人民邮电出版社, 2017Goodfellow I, Bengio Y, Courville A. Deep learning[M]. Zhao S J, trans. Beijing: Posts and Telecommunications Press, 2017(in Chinese) [21] 王丽华, 谢阳阳, 周子贤, 等.基于卷积神经网络的异步电机故障诊断[J].振动、测试与诊断, 2017, 37(6):1208-1215 http://d.old.wanfangdata.com.cn/Periodical/zdcsyzd201706021Wang L H, Xie Y Y, Zhou Z X, et al. Motor fault diagnosis based on convolutional neural networks[J]. Journal of Vibration, Measurement & Diagnosis, 2017, 37(6):1208-1215(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/zdcsyzd201706021 [22] 王保建, 张小丽, 傅杨奥骁, 等.优化支持向量机及其在智能故障诊断中的应用[J].振动、测试与诊断, 2017, 37(3):547-552 http://d.old.wanfangdata.com.cn/Periodical/zdcsyzd201703020Wang B J, Zhang X L, Fuyang A X, et al. Optimization of support vector machine and its application in intelligent fault diagnosis[J]. Journal of Vibration, Measurement & Diagnosis, 2017, 37(3):547-552(in Chinese) http://d.old.wanfangdata.com.cn/Periodical/zdcsyzd201703020 -

下载:

下载: